ESAB A6 Mastertrac Instruction Manual

Hide thumbs

Also See for A6 Mastertrac:

- Instruction manual (78 pages) ,

- Manual (50 pages) ,

- Instruction manual (22 pages)

Summary of Contents for ESAB A6 Mastertrac

- Page 1 A6 Mastertrac A6 TF/ A6 TF (Twin) Instruction manual 0449 265 201 GB 2007- -07- -12 Valid for serial no. 709- -xxx- -xxxx...

- Page 2 ESAB AB, Welding Equipment, 695 81 Laxå, Sweden, declares under sole responsibility that the au- tomatic welding machine A6 Mastertrac (A6 TF/A6 TF Twin) from serial number 709 xxx xxxx (2007 week 09) is designed and tested in conformity with the published standards in accordance with the conditions in the directives (98/37/EC) and (2004/108/EC).

-

Page 3: Table Of Contents

1 SAFETY ............2 INTRODUCTION . -

Page 4: Safety

SAFETY Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of welding equipment. The following recommen- dations should be observed in addition to the standard regulations that apply to the workplace. - Page 5 WARNING ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU- TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE BASED ON MANUFACTURERS’ HAZARD DATA. ELECTRIC SHOCK - - Can kill Install and earth the welding unit in accordance with applicable standards. Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

-

Page 6: Introduction

The A6 TF automatic welding machines are designed for Submerged--arc welding (SAW) of butt and fillet joints. All other applications are prohibited. They are intended for use in combination with A2--A6 Process Controller (PEH) and ESAB’s welding power sources LAF or TAF. Welding Method 2.2.1 Submerged Arc Welding (SAW) Submerged- - arc Heavy duty Submerged--arc heavy duty, with a ∅... -

Page 7: Technical Data

Technical data A6 TF Supply voltage 42 V AC Permissible load at 100 %: 1500 A DC Wire dimensions: 3.0--6.0 mm 3.0--6.0 mm solid single wire solid single wire 3.0--4.0 mm hollow wire 2x2.0--3.0 mm twin wire Wire feed speed, max 4 m/min Brake hub braking torque 1.5 Nm... -

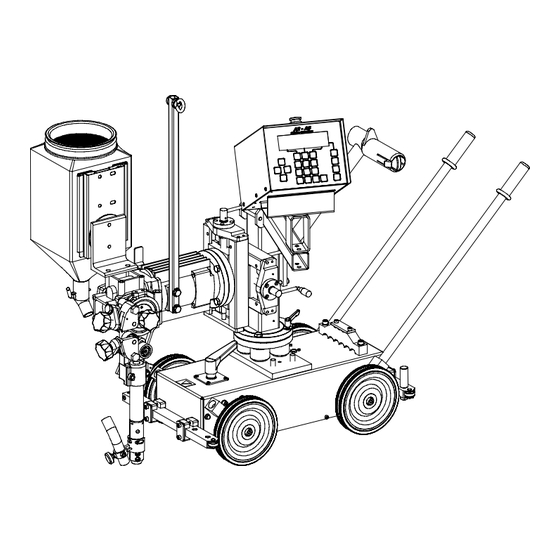

Page 8: Main Components A6 Tf (Saw), A6 Tf Twin (Saw)

Main components A6 TF (SAW), A6 TF Twin (SAW) Carriage Slide kit, manual Flux hopper Carrier Connector Flux tube Wire feed unit Motor with gear (A6 VEC) Flux nozzle See on page 9 for a description of the main components. - - 8 - - fhb3d1ea... -

Page 9: Description Of Main Components

Description of Main Components 2.7.1 Carriage The carriage is provided with 4--wheel drive. The carriage can be secured by way of the locking lever (1). 2.7.2 Carrier The control box, wire feed unit and flux hopper, among other things, are to be fitted on the carrier. -

Page 10: Installation

INSTALLATION General The installation must be executed by a professional. WARNING Rotating parts can cause injury, take great care. Mounting 3.2.1 Wire drum (Accessories) Wire drum (1) is mounted on the brake hub (2). Check that the carrier (3) is pointing upwards. NOTE! The maximum angle for the wire bobbin is 25°. -

Page 11: Connections

Connections 3.4.1 General The A2--A6 Process Controller (PEH) is to be connected by a qualified person. For the connection of A6 GMD, see instruction manual 0443 403 xxx. For the connection of A6 PAK, see instruction manual 0443 405 xxx. 3.4.2 Automatic welding machine A6 TF (Submerged arc welding, SAW) 1. -

Page 12: Operation

OPERATION General Caution: Have you read and understood the safety information ? You must not operate the machine before then ! General safety regulations for the handling of the equipment can be found on page 4. Read through before you start using the equipment! Select electrode type and flux powder or shielding gas so that the weld material is as close as possible to the analysis of the base metal. -

Page 13: Loading The Welding Wire (A6 Tf)

Loading the welding wire (A6 TF) 1. Mount the wire drum according to the instructions on page 10. 2. Check that feed roller (1) and contact jaw or contact tip (3) are of the correct dimension for the selected wire size. 3. -

Page 14: Changing The Feed Roller (A6 Tf)

Changing the feed roller (A6 TF) Single wire Release the knobs (3) and (4). Release the hand wheel (2). Change the feed roller (1). They are marked with their respective wire sizes. Twin wire (Twin- -arc) Change the feed roller (1) with twin grooves in the same way as for single wire. NOTE! The pressure roller (5) must also be changed. -

Page 15: Contact Equipment For Submerged Arc Welding

Contact equipment for Submerged arc welding 4.4.1 For single wire 3,0 - - 6,0 mm Use automatic welding machine A6 TF (UP) where the following are included: Wire feed unit (1), Connector D35 (2) Contact jaw (3) Ensure that good contact is achieved between the contact jaws and the wire. -

Page 16: Refilling With Flux Powder (Submerged Arc Welding)

Refilling with flux powder (Submerged arc welding) 1. Close the flux valve (1) on the flux hopper. 2. Remove the cyclone on the flux recovery unit, if fitted. 3. Fill with flux powder. NOTE! The flux powder must be dry. Where possible avoid using agglomerating flux powder outdoors and in damp environments. -

Page 17: Maintenance

MAINTENANCE General Note: All warranty undertakings given by the supplier cease to apply if the customer attempts to rectify any faults on the machine during the warranty period. NB! Before doing any kind of maintenance work, make sure the mains is disconnected. -

Page 18: Troubleshooting

Use cables with a larger cross--section or use parallel cables. ORDERING OF SPARE PARTS Spare parts are ordered through your nearest ESAB representative, see back cover. When ordering spare parts, please state machine type and number as well as desig- nation and spare part number as shown in the spare parts list on page 23. -

Page 19: Wear Components

Wear components Feed rollers SAW and MIG/MAG Part no D (mm) 0218 510 281 0218 510 282 0218 510 283 0218 510 286 0218 510 287 0218 510 288 0218 510 298 3,0--3,2 SAW Twin (D35) Part no D (mm) 0218 522 480 0218 522 481 3--3,2... - Page 20 Pressure rollers SAW and MIG/MAG tubular wire Part no D (mm) 0146 025 880 0,8--1,6 0146 025 881 2,0--4,0 0146 025 882 5,0--7,0 SAW Twin Part no 0218 524 580 0146 253 001 Stub shaft 0144 953 001 Sperical ball bearing 0190 452 178 Washer Stub shaft for pressure roller...

- Page 21 Contact tip MIG/MAG and SAW Twin LD (D35) Part no D (mm) 0153 501 002 0153 501 004 0153 501 005 0153 501 007 0153 501 009 0153 501 010 2,4--2,5 MIG/MAG (D35) Part no D (mm) 0258 000 908 0258 000 909 0258 000 910 0258 000 911...

-

Page 22: Dimension Drawing

Dimension drawing - - 22 - - dimdoc... -

Page 23: Spare Parts List

Spare parts list Edition 2007- -02- - 26 Ordering no. Denomination Notes 0449 260 880 Automatic welding machine A6 TF SAW 0449 260 881 Automatic welding machine A6 TF SAW, Twin 0449 260 890 Automatic welding machine A6 TF SAW 0449 260 891 Automatic welding machine A6 TF SAW, Twin... - Page 24 Item Ordering no. Denomination Notes 0449260880 Automatic welding machine A6TF (156:1), SAW 0334183881 Carriage 0449254880 Carrier 0449252880 Slide travel kit, manual 90 mm 0449250880 Wire feed unit, right 156:1 0443741880 Control box 0449253880 Cable set L = 1,6 m 0456490880 Motor cable 1,5 m 0456504881...

- Page 25 Item Ordering no. Denomination Notes 0449260881 Automatic welding machine A6TF (156:1), SAW Twin 0334183881 Carriage 0449254880 Carrier 0449252880 Slide travel kit, manual 90 mm 0449250881 Wire feed unit, Twin 156:1 0443741880 Control box 0449253880 Cable set L=1,6m 0456490880 Motor cable 1,5 m 0456504881 Arc welding cable...

- Page 26 Item no. Ordering no. Denomination Notes 0334183881 Carriage 0334295880 Handle 0449205880 Guide arm 0229202280 Wheel 0219501013 Spring washer d18,1/10,2 0334198880 Front shaft with sprocket 0334264001 Flange bearing unit 0218201502 Chain 1/2”x4,88 0218201602 Chain lock simple 1/2”x4,88 0334160001 Stub shaft 0334163880 Sprocket 0334162880 Sprocket...

- Page 27 Item Ordering no. Denomination Notes 0449254880 Carrier 0334168880 Column 0334170001 Clamping ring 0219504307 Cup spring d20/10.2 0193571106 Locking plate steel 26/10,5x22 0193570129 Locking arm m10x32 0334176880 Reel holder 0146967880 Brake hub 0334297880 Box holder 0334185886 Box girder beam 0334707883 Thread steerer - - 27 - - f449254s...

- Page 28 Item Ordering no. Denomination Notes 0449252880 Slide travel kit, manual 90mm 0154465880 Slide manual L=90 0334171001 Plate 0334170001 Clamping ring 0334172001 Gear bracket - - 28 - - f449252s...

- Page 29 Item Orderingno. Denomination Remarks 0154465880 Slide, manually operated L=90 0154464001 Slide frame 0154463880 Carriage with slide rails 0190509485 Stop screw M10x10 0154458001 End piece 0211102957 Roll pin D5x20 0154461001 Lead screw 0190531201 Ball bearing SKF 3201 0154456001 Lock nut 0154457001 Ball bearing cap 0334537001 Handle crank...

- Page 30 Item Ordering no. Denomination Notes 0449250880 Wire feed unit complete (Right mounted) SAW (156:1), Single 0145063906 Motor with gear A6 VEC (156:1), see separate manual 0147639880 Wire straightener, right mounted 0218810183 Insulated hand wheel 0334290882 Contact equipment D35/ L275 0148487880 Bracket for flux hopper 0147649881 Flux hopper...

- Page 31 Item Ordering no. Denomination Notes 0449250881 Wire feed unit complete (Right mounted) SAW (156:1), Twin 0145063906 Motor with gear A6 VEC (156:1), see separate manual 0147639887 Wire straightener, right mounted D35, Twin 0218810183 Insulated hand wheel 0334290882 Contact equipment D35/ L275 0148487880 Bracket for flux hopper 0147649881...

- Page 32 Item Ordering no. Denomination Notes 0449250890 Wire feed unit complete (Right mounted) SAW (74:1), Singel 0145063907 Motor with gear A6 VEC (74:1), see separate manual 0147639880 Wire straightener, right mounted 0218810183 Insulated hand wheel 0334290882 Contact equipment D35/ L275 0148487880 Bracket for flux hopper 0147649881 Flux hopper...

- Page 33 Item Ordering no. Denomination Notes 0449250891 Wire feed unit complete (Right mounted) SAW (74:1), Twin 0145063907 Motor with gear A6 VEC (74:1), see separate manual 0147639891 Wire straightener, right mounted D35, Twin 0218810183 Insulated hand wheel 0334290882 Contact equipment D35/ L275 0148487880 Bracket for flux hopper 0147649881...

- Page 34 Item Ordering no. Denomination Notes 0147639880 Straightener (right mounted) 0156449001 Clamp 0215503601 Insulating sleeve 0156530001 Clamp half 0212900001 Spacer screw 0215201209 Sealing, O- -ring D11.3x2.4 0218400801 Pressure roller arm 0218810181 Handwheel, insulated 0218810182 Handwheel, insulated 0332408001 Stub shaft 0153148880 Pressure roller 0415498001 Pressure roller, upper 0212902601...

- Page 35 Item Ordering no. Denomination Notes 0147639887 Straightener (right mounted) A6 D35 TWIN 0156449001 Clamp 0215503601 Insulating sleeve 0156530001 Clamp half 0212900001 Spacer screw 0215201209 Sealing, O- -ring 11,3x2,4 0218400801 Pressure roller arm 0218810181 Handwheel, insulated 0218810182 Handwheel, insulated 0332408001 Stub shaft 0218524580 Pressure roller twin 0153148880...

- Page 36 Item Ordering no. Denomination Notes 0147639891 Straightener (right mounted) 0156449001 Clamp 0215503601 Insulating sleeve 0156530001 Clamp half 0212900001 Spacer screw 0215201209 Sealing, O- -ring D11.3x2.4 0218400801 Pressure roller arm 0218810181 Handwheel, insulated 0218524580 Pressure roller twin 0415498001 Pressure roller, upper 0212902601 Spacer screw 0219501013...

- Page 37 Item Orderingno. Denomination Remarks 0334290882 Contact equipment single wire 0417959881 Contact jaw tube L=275 0153299880 Flux nozzle complete - - 37 - - f334290s...

- Page 38 Item Ordering no. Denomination Notes 0417959881 Contact jaw tube L = 275 mm 0443372001 Fitting bolt 0219504307 Cup spring d20/10.2, T=1.1 0417979001 Ring 0443344881 Contact tube L = 275 mm - - 38 - - f417959s...

- Page 39 Item Ordering no. Denomination Notes 0153299880 Flux nozzle complete 0153290002 Holder for flux pipe 0153296001 Flux pipe, bent 0153425001 Wheel - - 39 - - f153299s...

- Page 40 Item Ordering no. Denomination Notes 0147649881 Flux Hopper 0154007001 Flux hopper 0148837001 Window (a6 flux hopper) 0147645001 Mounting 0153347880 Flux valve 0215201232 Sealing, O- -ring 69,2x5,7 0020301780 Flux strainer 0443383002 Flux hose L=500 - - 40 - - f147649s...

- Page 41 Item Ordering no. Denomination Notes 0145787880 Fine wire straightener for twin wire 0145788001 Case 0145789001 Roller 0145790001 Roller 0145791001 Searing bushing 0190240103 Bearing bushing D12/10 0145793001 Runner 0145794001 Knob 0145795001 Link 0151287001 Hose - - 41 - - f145787s...

- Page 42 ESAB subsidiaries and representative offices Europe Asia/Pacific Representative offices NORWAY AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna- -Liesing Sofia Shanghai Fax: +47 33 11 52 03...

Need help?

Do you have a question about the A6 Mastertrac and is the answer not in the manual?

Questions and answers