Table of Contents

Advertisement

Quick Links

DO NOT OPERATE THE GENERATOR BEFORE READING THIS MANUAL AND ENGINE

MANUFACTURER'S OWNER'S MANUAL AND WARNINGS.

THIS STEPHILL GENERATOR HAS BEEN DESIGNED TO PROVIDE SAFE AND EFFICIENT SERVICE IF

MANY ACCIDENTS OCCUR THROUGH FAILURE TO ADHERE TO FUNDAMENTAL SAFETY

Stephill Generators Ltd

Wallis close

Park Farm South

Wellingborough

Northants

NN8 6AG

Issue 1

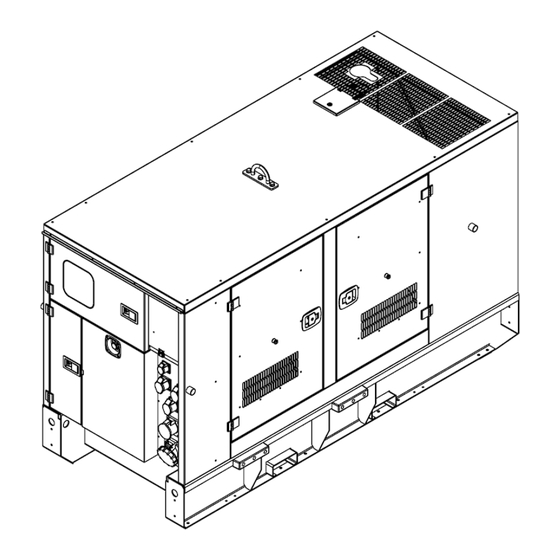

SSDP120 Handbook

Deep Sea Electronics 7310

OPERATED AND MAINTAINED CORRECTLY.

PROCEDURES.

Tel : +44 (0)1933 677911

Fax : +44 (0)1933 677916

E-mail :

info@stephill-generators.co.uk

Web

: Web

:

www.stephill-generators.co.uk

Advertisement

Table of Contents

Summary of Contents for Stephill SSDP120

- Page 1 DO NOT OPERATE THE GENERATOR BEFORE READING THIS MANUAL AND ENGINE MANUFACTURER’S OWNER’S MANUAL AND WARNINGS. THIS STEPHILL GENERATOR HAS BEEN DESIGNED TO PROVIDE SAFE AND EFFICIENT SERVICE IF OPERATED AND MAINTAINED CORRECTLY. MANY ACCIDENTS OCCUR THROUGH FAILURE TO ADHERE TO FUNDAMENTAL SAFETY PROCEDURES.

-

Page 2: Table Of Contents

11.0 Service and maintenance 11.1 Engine service 19-20 11.2 Light load operation 20-21 11.3 Alternator service 12.0 Warranty SSDP120 400V Wiring DSE 7310 Perkins 1100 Series Wiring ECU Deep Sea 7310 SSDP120 Exploded view SSDP120 Canopy parts list Issue 1... -

Page 3: Specification

1 SPECIFICATION GENERATOR SPECIFICATION SSDP120 Frequency 50Hz Phase Voltage 400/230 Standby Power (ESP) 117.1 kVA 93.7 kW Prime Power (PRP) 106.1 kVA 84.9 kW Engine Perkins 1104D-E44TAG2 Engine Emissions certified EU (EU 97/68/EC Stage IIIa) Displacement 4.4 Litres Aspiration Turbo charged... -

Page 4: Reference Relative Humidity

Engine/Alternator only. 4.6 Earth connection All Stephill products are fitted with an earth stud on the control panel this must be connected to an earthing system or spike. Any earth spike required is dependant on the local conditions of use. The size is determined by reference to current IEE regulations or to a competent electrician. -

Page 5: Noise

be facing an open area to prevent fumes being recirculated. There is the danger of asphyxiation due to exhaust gases. Inhalation of poisonous exhaust fumes can lead to serious injury or death. The generator must not be used in a poorly ventilated or enclosed area. 4.8 Noise Ear protection may be required depending on the combined noise level of the Generator, auxiliary load and the operator’s distance from it and the length of exposure. -

Page 6: Variable Rcd Elr-3C

The generator is equipped with a pair of normally open contacts which will start the generator when closed. 5.9 Long term storage For storage or long periods of inactivity, Stephill Generators recommend the following: Generators should be stored with oil filled to the correct capacity; Storage periods of 18 months and over may require special lubricants and treatments. -

Page 7: Deep Sea 7310 Operating Instructions

6 DEEP SEA 7310 Operating instructions 6.1 Controls Control of the module is via push buttons mounted on the front of the module with Stop/Reset Mode and Start functions. For normal operation, these are the only controls Manual Mode , Auto Mode which need to be operated. -

Page 8: Manual Mode

Auto This button places the module into its ‘Automatic’ mode. This mode allows the module to control the function of the generator automatically. The module will monitor the remote start input and mains supply status and once a start request is made, the set will be automatically started and placed on load. -

Page 9: Stopping Sequence

6.2.3 STOPPING SEQUENCE In Manual Mode the set does not continue to run until either: The Stop/Reset Mode button is pressed – The delayed load outputs are de-activated immediately and the set immediately stops. The Auto Mode button is pressed. The set observes all Auto Mode start requests and stopping timers before beginning the Auto Mode Stopping Sequence. -

Page 10: Viewing The Instrument Pages

6.5 VIEWING THE INSTRUMENT PAGES It is possible to scroll to display the different pages of information by repeatedly operating the next / previous page buttons. If you want to view one of the instrument pages towards the end of the list, it may be quicker to scroll left through the pages rather than right! Example... -

Page 11: Engine

6.5.2 ENGINE Contains instrumentation gathered about the engine itself, some of which may be obtained using the CAN or other electronic engine link. • Engine Speed • Oil Pressure • Coolant Temperature • Engine Battery Volts • Run Time • Fuel Level •... -

Page 12: Ecu Overide

Example showing the configuration of the DSE7310 event log (DSE Configuration Suite Software) (Only shutdown alarms and the mains status are logged). Once the log is full, any subsequent shutdown alarms will overwrite the oldest entry in the log. Hence, the log will always contain the most recent shutdown alarms. The module logs the alarm, along with the date and time of the event. -

Page 13: Engine

This is also useful if the engine manufacturer’s tools need to be connected to the engine, for instance to configure the engine as the ECU needs to be powered up to perform this operation. 6.7 ENGINE These pages contain instrumentation gathered about the engine measured or derived from the module’s inputs. -

Page 14: Shutdown / Electrical Trip Alarms

In the event of a warning alarm, the LCD will display the appropriate text. If a shutdown then occurs, the module will again display the appropriate text. Example:- 7.1.1 SHUTDOWN / ELECTRICAL TRIP ALARMS Under Shutdown or Electrical Trip alarm conditions (excluding Emergency Stop) : The alarm is displayed on the screen as detailed in the section entitled Shutdown alarms elsewhere in this document. -

Page 15: High Current Warning Alarm

By default, warning alarms are self-resetting when the fault condition is removed. However enabling ‘all warnings are latched’ will cause warning alarms to latch until reset manually. This is enabled using the 7000 series configuration suite in conjunction with a compatible PC. 7.2.1 HIGH CURRENT WARNING ALARM GENERATOR HIGH CURRENT, if the module detects a generator output current in excess of the pre-set trip a warning alarm initiates. -

Page 16: Idmt Alarm

Display Reason The module is configured for CAN operation and does not detect data on ECU DATA FAIL the engine Can datalink, the engine shuts down. The engine ECU has detected a shutdown alarm and has informed the ECU SHUTDOWN DSE module of this situation. -

Page 17: Maintenance Alarm

These settings provide for normal running of the generator up to 100% full load. If full load is surpassed, the Immediate Warning alarm is triggered, the set continues to run. The effect of an overload on the generator is that the alternator windings begin to overheat; the aim of the IDMT alarm is to prevent the windings being overload (heated) too much. -

Page 18: Fault Finding 7310

NOTE: The PIN number is not set by DSE when the module leaves the factory. The module has a PIN code set, this has been set by Stephill If the code has been changed then ‘lost’ or ‘forgotten’, the module must be returned to the DSE factory to have the module’s code removed. A charge will be made for this procedure. -

Page 19: Fault Finding General

9 Fault finding general Fault Action High engine Check Water/Antifreeze level in the radiator. temperature Check for loose wires on the temperature switch & DC loom connector block. Check the continuity of the earth wire. (Refer to wiring diagram) Check radiator surface (both sides) and fins are not obstructed. Check operation of the Temperature switch. -

Page 20: Spares

Usually the part numbers are on the filters or in the case of air filters on the air cleaner cover. We have implemented writing the part numbers to the test sheet should the numbers become illegible in which case quote the Stephill Generators serial number. 10.2... -

Page 21: Service And Maintenance

Part Number Description 045-0020 ISOLATOR SWITCH BATTERY 0/605/00 045-0024 PUSH BUTTON RCAS-PBF6 BLUE 045-0025 CONTACT BLOCK RAS-CB NO N/O 045-1031 CA741/4 4 WAY INSULATED PRE ASSEMBLED 045-2008 DEEP SEA CONTROLLER 7310 AUTOSTART 046-0063 BELDEN 9841 - LSF ALTERNATIVE CABLE 047-0012 WELDING / BAT CABLE 50mm 054-0010 BATTERY 663 (778CCA - 105AH) SSDP33/50/70... -

Page 22: Light Load Operation

Daily Alternator and Fan Belts - Inspect/Adjust/ Replace Cooling System Coolant Level - Check Every 2000 Service Hours Driven Equipment - Check Aftercooler Core - Inspect Engine Air Cleaner Service Indicator - Inspect Alternator - Inspect Engine Oil Level - Check Engine Mounts - Inspect Fuel System Primary Filter/Water Separator - Starting Motor - Inspect... -

Page 23: Alternator Service

No warranty claim will be considered by STEPHILL GENERATORS LTD unless any defective parts are available for inspection by us, or our nominees, to determine the reason or cause of failure, and STEPHILL GENERATORS LTD is given the option of repair or replacement. -

Page 26: Ssdp120 Exploded View

16-254 SSD30 MK2 Control panel door catch 16-513 SSDP120 Socket panel housing 16-536 SSDP120 Socket panel 1 x 125 1 x 63 3 x 32 1 x 16 16-523 SSDP120 Hard wire box 16-535 SSDP120 Hard wire 250A MCCB plate...

Need help?

Do you have a question about the SSDP120 and is the answer not in the manual?

Questions and answers