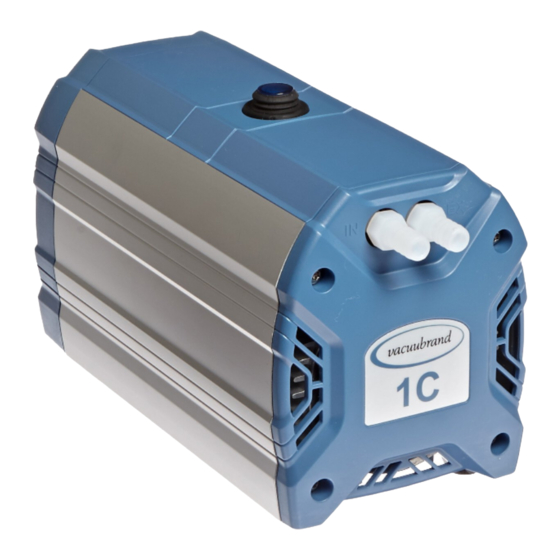

vacuubrand ME 1 Instructions For Use Manual

Diaphragm pumps

Hide thumbs

Also See for ME 1:

- Instructions for use manual (96 pages) ,

- Instructions for use manual (100 pages)

Summary of Contents for vacuubrand ME 1

- Page 1 1 of 57 Technology for Vacuum Systems Instructions for use ME 1 ME 1C MZ 1C Diaphragm pumps...

- Page 2 2 of 57 Dear customer, Your VACUUBRAND diaphragm pumps are designed to provide you with many years of trouble-free service with optimal performance. Our many years of practical experience allow us to provide a wealth of application and safety information. Please read these instructions for use before the initial operation of your pump.

- Page 3 page 3 of 57 Achtung: Die vorliegende Betriebsanleitung ist nicht in allen EU-Sprachen verfügbar. Der Anwender darf die beschriebenen Geräte nur dann in Betrieb nehmen, wenn er die vorliegende Anleitung versteht oder eine fachlich korrekte Übersetzung der voll- ständigen Anleitung vorliegen hat. Die Betriebsanleitung muss vor Inbetriebnahme der Geräte vollständig gelesen und verstanden werden, und alle geforderten Maß- nahmen müssen eingehalten werden.

- Page 4 page 4 of 57 Bemærk: Denne manual foreligger ikke på alle EU sprog. Brugeren må ikke be- tjene apparatet hvis manualen ikke er forstået. I det tilfælde skal en teknisk korrekt oversættelse af hele manual stilles til rådighed. Manual skal være gennemlæst og forstået før apparatet betjenes og alle nødvendige forholdsregler skal tages.

- Page 5 page 5 of 57 Figyelem! Ez a kezelési utasítás nem áll rendelkezésre az EU összes nyelvén. Ha a felhasználó nem érti jelen használati utasítás szövegét, nem üzemeltetheti a készüléket. Ez esetben a teljes gépkönyv fordításáról gondoskodni kell. Üzembe helyezés előtt a kezelőnek végig kell olvasnia, meg kell értenie azt, továbbá az üzemeltetéshez szükséges összes mérést el kell végeznie.

- Page 6 page 6 of 57 Attentie: Deze gebruiksaanwijzing is niet in alle talen van de EU verkrijgbaar. De gebruiker moet niet met dit apparaat gaan werken als voor hem/haar de gebruiks- aanwijzing niet voldoende duidelijk is. Bij gebruik van deze apparatuur is het nood- zakelijk een technisch correcte vertaling van de complete gebruiksaanwijzing te hebben.

- Page 7 page 7 of 57 Varning: Denna instruktion är inte tillgänglig på alla språk inom EU. Användaren får inte starta utrustningen om hon/han inte förstår denna instruktion. Om så är fallet måste en tekniskt korrekt instruktion göras tillgänglig. Instruktionen måste läsas och förstås helt före utrustningen tas i drift och nödvändiga åtgärder göres.

-

Page 8: Table Of Contents

page 8 of 57 Contents Safety information! ............. 9 Important information! ................. 9 General information ................11 Intended use..................11 Setting up and installing the equipment ..........12 Ambient conditions ................14 Operating conditions ................. 15 Safety during operation ..............17 Maintenance and repair..............19 Important information: Equipment marking (ATEX) ..... -

Page 9: Safety Information

Make operating personnel aware of dangers arising from the pump and the pumped substances. VACUUBRAND disclaims any liability for inappropri- ate use of these pumps and for damage from failure to follow instructions contained in this manual. - Page 10 page 10 of 57 ➨ DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. + WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. • CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

-

Page 11: General Information

page 11 of 57 General information Remove all packing material from the packing box. Re- NOTICE move the product from its packing-box and retain all pack- aging until the equipment is inspected and tested. Re- move the protective caps from the inlet and outlet ports and retain for future use. -

Page 12: Setting Up And Installing The Equipment

page 12 of 57 sure ventilation is adequate to maintain recommended operating temperature. Install an external automatic ventilation system if necessary. If pumping hot process gases, make sure that the maximum permitted gas in- let temperature is not exceeded. The maximum permit- ted gas inlet temperature depends on several parame- ters like inlet pressure and ambient temperature (see ”Technical data”, pg. - Page 13 page 13 of 57 there is an exhaust isolation valve, make sure that you cannot operate the equipment with the valve closed to avoid a risk of bursting! + Always provide a free and pressureless exhaust outlet to avoid damage to pump valves and risk of bursting. + Keep the electrical power cord away from heated sur- faces.

-

Page 14: Ambient Conditions

page 14 of 57 the setting of the voltage selection switch while the pump is connected to AC power. Unplug the pump be- fore setting the voltage selection switch. Note: If the pump is switched on with wrong voltage selection, the motor may be damaged! Keep a minimum distance of 8 in (20 cm) between the NOTICE... -

Page 15: Operating Conditions

page 15 of 57 • Adopt suitable measures in case of differences from recommended conditions, e.g., using the equipment outdoors, installation in altitudes of more than 3300 ft (1000 m) above mean sea level, conductive pollution or external condensation on the pump. •... - Page 16 page 16 of 57 - substances which react explosively when being ex- posed to elevated temperatures without air, - substances subject to auto-ignition, - substances which are inflammable without air - explosive substances. ➨ The pumps are not approved for operation below ground.

-

Page 17: Safety During Operation

page 17 of 57 Safety during operation ➨ Adopt suitable measures to prevent the release of dan- gerous, toxic, explosive, corrosive, noxious or polluting fluids, vapors and gases. To prevent any emission of such substances from the pump outlet, install an ap- propriate collecting and disposal system and take pro- tective action for pump and environment. - Page 18 page 18 of 57 + Use only original manufacturer’s spare parts and accessories. Otherwise the safety and performance of the equipment, as well as the electromagnetic compat- ibility of the equipment might be reduced. The CE mark may be voided if not using original manu- facturer’s spare parts.

-

Page 19: Maintenance And Repair

For details and for the online ”Instructions for repair” man- ual see www.vacuubrand.com. In case of normal wear, the lifetime of the diaphragms and valves is > 10000 operating hours. Bearings have a... - Page 20 page 20 of 57 typical durability of 40000 h. Motor capacitors have a typi- cal durability in the range of 10000 to 40000 h depending strongly on operation conditions including ambient tem- perature, humidity or load. ➨ Ensure that the pump cannot be operated acciden- tally.

- Page 21 page 21 of 57 Ensure that maintenance is done only by suitably trained NOTICE and supervised technicians. Ensure that the maintenance technician is familiar with the safety procedures, which re- late to the products processed by the pumping system. Only dismantle the pump as far as necessary.

-

Page 22: Important Information: Equipment Marking (Atex)

The overall category of the equipment depends on the connected compo- nents. If the connected components do not comply with the classification of the VACUUBRAND equipment, the specified category of the VACU- UBRAND equipment is no longer valid. Vacuum pumps and vacuum gauges in category 3 are intended for con- nection at equipment in which during normal operation explosive atmo- spheres caused by gases, vapors or mists normally don’t occur or, if they... - Page 23 page 23 of 57 The pumps are marked with ”X” (according to EN 13463-1), i. e. restric- tions of the operation conditions: • The equipment is designated for a low degree of mechanical stress and have to be installed in a way so that they cannot be damaged from outside.

-

Page 24: Technical Data

In case of supply voltage below 100V, the lock of the cutout might be impaired. ** Measurement according to EN ISO 2151:2004 and EN ISO 3744:1995 at 230V/50Hz and at ultimate vacuum with exhaust tube (ME 1C / MZ 1C) or with silencer (ME 1) at outlet. Gas inlet temperatures... - Page 25 25 of 57 Type ME 1 ME 1C Maximum pumping speed 0.4/ 0.5 50/60 Hz (ISO 21360) (0.7 / 0.85) Torr Ultimate vacuum (absolute) (mbar) (100) Rated motor power hp (kW) 0.054 (0.04) Maximum permissible range 100-120 V~ 50/60 Hz of supply voltage ( ±10% )

- Page 26 page 26 of 57 Type MZ 1C Maximum pumping speed 0.44 / 0.53 50/60 Hz (ISO 21360) (0.75 / 0.9) Ultimate vacuum (absolute) Torr without gas ballast (mbar) (12) Ultimate vacuum (absolute) Torr with gas ballast (mbar) (20) Maximum permissible pressure 17.5 (absolute) at gas ballast valve (bar)

-

Page 27: Wetted Parts

27 of 57 Wetted parts Components Wetted materials ME 1 ME 1C MZ 1C Housing cover Aluminum alloy (AlMgSi) Housing cover PTFE carbon PTFE carbon insert reinforced reinforced Head cover Aluminum alloy (AlMgSi) ETFE ETFE Diaphragm ETFE carbon ETFE carbon... - Page 28 28 of 57 ME 1 ME 1C...

- Page 29 page 29 of 57 MZ 1C ON/OFF switch pump switched off pump switched on...

-

Page 30: Use And Operation

page 30 of 57 Use and operation Installing a pump in a vacuum system ➨ If dangerous or polluting fluids could be released at the outlet, install an appropriate system to catch and dis- pose of those fluids. + Connect a gas-tight exhaust line at the pump outlet if necessary. - Page 31 page 31 of 57 • Check the power source and the pump’s rating plate to be sure that the power source and the equipment match in voltage, phase, and frequency. • Pump with dual-voltage motor: Check that the volt- age selection switch is positioned correctly. Check ev- ery time before starting the pump.

-

Page 32: During Operation

page 32 of 57 During operation ➨ Vent and dispose of potentially dangerous gases or vapors at the outlet of the pump appropriately. + Due to the high compression ratio, the pump might gen- erate overpressure at the outlet. Check pressure com- patibility with system components (e.g., exhaust tubing or exhaust valve) at the outlet. -

Page 33: Important Notes Regarding The Use Of Gas Ballast

page 33 of 57 The diaphragms and valves will be damaged, if liquids are pumped in significant amounts. Check the pump regularly for external soiling and depos- its. Clean the pump if necessary to avoid an increase of the pump’s operating temperature. In case of overload, the motor is shut down by a self-hold thermal circuit breaker in the winding. -

Page 34: Shutdown & Storage

page 34 of 57 To reduce condensation in the pump, do not pump vapor NOTICE before the pump has reached its operating temperature. Open the gas ballast valve when pumping condensable vapors. Turn gas ballast cap to open valve. For condensable vapors (water vapor, sol- gas ballast (open) vents, etc.):... -

Page 35: Accessories

Kit ”Vacuum adjustment device” ...............696842 with manometer for ME 1 Kit ”Vacuum adjustment device” ...............696843 with manometer for ME 1C / MZ 1C For additional accessories such as vacuum valves, small-flange components, vac- uum gauges or vacuum controllers refer to www.vacuubrand.com... -

Page 36: Troubleshooting

page 36 of 57 Troubleshooting Fault Possible cause Remedy ❑ Pump does not ➨ Electrical power cord ✔ Plug in power cord. start or stops im- not plugged in, electri- Check fuse. Check supply mediately. cal supply failure? voltage. ➨ Device fuse blown? ✔... - Page 37 page 37 of 57 Fault Possible cause Remedy ❑ Pump too noisy. ➨ Atmospheric or high ✔ Connect hose or silencer pressure at the pump to pump outlet. Be careful inlet? not to cause outlet over- pressure, especially with condensable vapors. ➨...

-

Page 38: Replacing Diaphragms And Valves

page 38 of 57 Replacing diaphragms and valves + Please read section ”Replacing diaphragms and valves” com- pletely before starting maintenance. The pictures may show other versions of pumps. This does not change the method of replacing diaphragms and valves. ➨... - Page 39 - Regular maintenance will improve the lifetime of the pump and also protect both users and the environ- ment. Service kit for ME 1 / ME 1C ..............696874 (diaphragm, valves, diaphragm key) Service kit for MZ 1C ..................696876 (diaphragms, valves, diaphragm key)

-

Page 40: Cleaning And Inspecting The Pump Heads

MZ 1C ➨ Disassemble housing cover (C) to check the diaphragm and valves. ME 1 / ME 1C: ➨ Unscrew four screws with a Torx driver T20. Remove the housing cov- er (C) (ME 1C: housing cover (C) with housing cover insert (C1)). Pay attention to the washers. - Page 41 41 of 57 View of the disassembled pump head parts ME 1 A: Front cover G: Diaphragm B: Cover H: Diaphragm support disc C: Housing cover I : Washers D: Valve J: Rod E: Head cover K: Housing F: Diaphragm clamping disc with square head screw This labeling is used throughout this chapter.

- Page 42 page 42 of 57 View of the disassembled pump head parts ME 1C Front cover Diaphragm clamping disc Cover with square head screw Housing cover Diaphragm C1: Housing cover insert Diaphragm support disc Valve Washers Head cover E1: Guidance pin Housing This labeling is used throughout this chapter.

- Page 43 page 43 of 57 View of the disassembled pump head parts MZ 1C Front cover Diaphragm Cover Diaphragm support disc Housing cover Washers C1: Housing cover insert Valve Housing Head cover Gas ballast tube Diaphragm clamping disc Gas ballast cap with square head screw This labeling is used throughout this chapter.

-

Page 44: Replacing The Diaphragm

44 of 57 ME 1 ME 1C MZ 1C ➨ Note position and alignment of valves (D). Remove the valves. + Replace valves if necessary. + Use petroleum ether or other industrial solvent to remove deposits. Do not inhale vapors. -

Page 45: Assembling The Pump Head

page 45 of 57 ➨ Position new diaphragm (G) between dia- phragm clamping disc with square head screw (F) and diaphragm support disc (H). + Note: Position diaphragm with pale side to- wards diaphragm clamping disc (facing pump chamber). + Make sure that the square head screw of the diaphragm clamping disc is correctly seated in the guide hole of the diaphragm support disc. - Page 46 ME 1 ME 1C MZ 1C ➨ Put on housing cover (C) (ME 1) or housing cover (C) and housing cover insert (C1) (ME 1C / MZ 1C). + Move housing cover or housing cover insert slightly to ensure that the...

- Page 47 47 of 57 ME 1 / ME 1C: ➨ Screw in 4 screws with washers at the housing cover diagonally at first slightly with a Torx driver T20, then tighten. + Do not tighten until head cover is in contact with housing, maximum torque: 2.2 ft...

-

Page 48: Replacing The Fuse

page 48 of 57 Checking the ultimate vacuum ➨ After any intervention at the equipment (e.g., repair / maintenance) the ultimate vacuum of the pump has to be checked. Only if the pump achieves its specified ultimate vacuum, the pump’s leak rate is low enough to ensure that no explosive atmospheres will occur in the inte- rior of the equipment. - Page 49 page 49 of 57 ➨ Slide the cover containing the electrical system carefully aside. Remove the cover completely from the pump. Attention: The electrical system (wires and capacitors) is integrated inside the cover! + The pigtail fuses are integrated into wires ((1), black and blue) between the power con- nection and the ON/Off switch.

-

Page 50: Notes On Return To The Factory

page 50 of 57 Notes on return to the factory Repair - return - DAkkS calibration Safety and health of our staff, laws and regulations re- NOTICE garding the handling of dangerous goods, occupational health and safety regulations and regulations regarding safe disposal of waste require that for all pumps and oth- er products, the “Health and safety clearance form“, see pg. - Page 51 page 51 of 57 We submit repair quotations only on request and always at the customer’s expense. If an order is placed, the costs incurred for problem diagnosis are offset from the costs for repair or from the purchase price, if the customer pre- fers to buy a new product instead of repairing the defec- tive one.

- Page 52 page 52 of 57 Scrapping and waste disposal: Dispose of the equipment and any components removed from it safely in accordance with all local and national safety and environmental requirements. Particular care must be taken with components and waste oil which have been contaminated with dangerous substances from your processes.

-

Page 53: Warranty

53 of 57 Warranty VACUUBRAND shall be liable for insuring that this prod- uct, including any agreed installation, has been free of de- fects at the time of the transfer of risk. VACUUBRAND shall not be liable for the consequences... -

Page 54: Health And Safety Clearance Form

By our signature below, we acknowledge that we accept liability for any damage caused by providing in- complete or incorrect information and that we shall indemnify VACUUBRAND from any claims as regards damages from third parties. We are aware that as expressed in § 823 BGB (Public Law Code of Ger- many) we are directly liable for injuries or damages suffered by third parties, particularly VACUUBRAND employees occupied with handling/repairing the product. -

Page 55: Ec Declaration Of Conformity Of The Machinery

Bevollmächtigter für die Zusammenstellung der technischen Unterlagen / Person authorised to compile the technical file / Personne autorisée à constituer le dossier technique: Dr. J. Dirscherl · VACUUBRAND GMBH + CO KG · Alfred-Zippe-Str. 4 · 97877 Wertheim · Ger- many Wertheim, 12.01.2012... - Page 56 page 56 of 57 This certificate is only valid for pumps with the respec- tive mark (Licensed Test mark) on the pump rating plate.

- Page 57 Alfred-Zippe-Str. 4 · 97877 Wertheim / Germany T +49 9342 808-0 · F +49 9342 808-5555 info@vacuubrand.com · www.vacuubrand.com VACUUBRAND GMBH + CO KG - Technology for Vacuum Systems - © 2012 VACUUBRAND GMBH + CO KG Printed in Germany Manual-no.: 999241 / 01/12/2012...

Need help?

Do you have a question about the ME 1 and is the answer not in the manual?

Questions and answers