HWH 2000 SERIES Operator's Manual

Computer-controlled

leveling system.

touch panel leveling control

air leveling

one or two room extensions

(with air seals)

Hide thumbs

Also See for 2000 SERIES:

- Operator's manual (52 pages) ,

- Operator's manual (42 pages) ,

- Operator's manual (35 pages)

Advertisement

Quick Links

Download this manual

See also:

Operator's Manual

OPERATOR'S MANUAL

HWH COMPUTER-CONTROLLED

Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408

AP27238

H

W

CORPORATION

LEVELING SYSTEM

2000 SERIES

FEATURING:

Touch Panel Leveling Control

Air Leveling

One or Two Room Extensions

(With Air Seals)

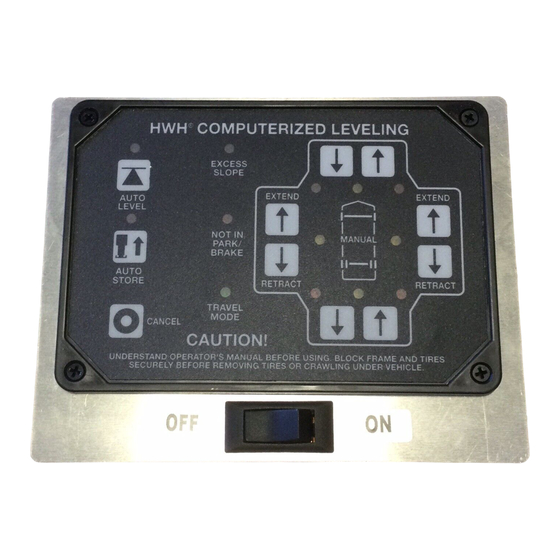

HWH COMPUTERIZED LEVELING

EXCESS

SLOPE

AIR

NOT IN

PARK/

TRAVEL

BRAKE

MODE

DUMP

EMERGENCY

STOP

TRAVEL

MODE

CAUTION!

RAISE

UNDERSTAND OPERATOR'S MANUAL BEFORE USING. BLOCK FRAME AND TIRES

SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

HWH CORPORATION

(On I-80, Exit 267 South)

2096 Moscow Road | Moscow, Iowa 52760

www.hwh.com

H

R

ML27239/MP05.998T

18SEP02

Advertisement

Summary of Contents for HWH 2000 SERIES

- Page 1 CORPORATION OPERATOR’S MANUAL HWH COMPUTER-CONTROLLED LEVELING SYSTEM 2000 SERIES FEATURING: Touch Panel Leveling Control Air Leveling One or Two Room Extensions (With Air Seals) HWH COMPUTERIZED LEVELING EXCESS SLOPE NOT IN PARK/ TRAVEL BRAKE MODE DUMP EMERGENCY STOP TRAVEL MODE...

-

Page 2: How To Obtain Warranty Service

HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION. -

Page 3: Control Identification

CONTROL IDENTIFICATION "EXCESS SLOPE" HARD RESET SWITCH LIGHT (SEE HWH LIGHTED RESET SWITCH) "NOT IN PARK" LIGHT MASTER WARNING LIGHT LEVELING SYSTEM ACTIVE LIGHT LOWER FRONT BUTTON "AIR" (ON) BUTTON RAISE FRONT BUTTON HWH COMPUTERIZED LEVELING DUMP LIGHT WARNING LIGHTS... - Page 4 MASTER WARNING LIGHT This light is on the dash, separate from the control panels. The light will be on if a HWH low air pressure switch is on, It can be on only if the ignition key is in the "ON" position.

- Page 5 The HWH lighted reset switch is located on the shifter panel. A network problem with one room will not inhibit the use of If there is a failure at any time in the HWH CAN network, the the other rooms or leveling system after the reset switch is network will shut down.

- Page 6 Refer to "DUMP" and "RAISE" FUNCTIONS operating procedures when moving the vehicle with the suspension A lit "TRAVEL MODE" light indicates that the HWH Leveling NOT at the proper ride height. System is in the TRAVEL MODE. It does not indicate that the suspension is at ride height or that the coach is ready to travel.

- Page 7 OPERATING PROCEDURES AUTOMATIC AIR OPERATION (Continued) NOTE: The CAN Network will stay active for 10 minutes NOTE: Room extensions can not be extended if the "EXCESS SLOPE" light is on but they can be retracted. after releveling the vehicle and then shut down, turning the touch panel lights OFF.

- Page 8 OPERATING PROCEDURES MANUAL AIR OPERATION NOTE: The ignition must be in the "ON" or "ACC" panel in conjunction with the yellow LEVEL indicator lights. position to use the "AIR" button. Once the operation Any side to side leveling should be done, if needed, is started, the ignition can be moved to the "OFF"...

- Page 9 DO NOT FORCE THE ROOM. DO NOT REVERSE DIRECTION OF THE ROOM. BINDING OF ROOM CAN NOTE: Make sure there is adequate clearance to fully CAUSE ROOM DAMAGE. CONTACT HWH CORPORATION extend the room. CUSTOMER SERVICE FOR ASSISTANCE. 2. Insert the KEY into the KEY SWITCH on the room NOTE: The READY TO OPERATE light will flash when extension operator’s panel and turn it to the "ON"...

- Page 10 "READY TO OPERATE" light will flash while the DIRECTION OF THE ROOM. BINDING OF ROOM CAN Leveling System is being operated. CAUSE ROOM DAMAGE. CONTACT HWH CORPORATION CUSTOMER SERVICE FOR ASSISTANCE. 3. To retract the room, push and hold the ROOM CONTROL SWITCH in the retract position.

- Page 11 Follow steps 2 and 3 and try pushing the room in. it to the room according to the vehicle manufacturer’s Contact the vehicle manufacturer or HWH Customer instructions. To extend the WINCH STRAP firmly grasp Service at 1-800-321-3494 or 563-724-3396 for assistance.

-

Page 12: Maintenance

OIL LEVEL It is important that all front rooms are fully retracted before FLUID: HWH Specialty Hydraulic Oil is recommended. In an checking the hydraulic oil level. If the coach has a bed slide, emergency Dexron automatic transmission fluid can be used. - Page 13 HYDRAULIC LINE CONNECTION DIAGRAM FRONT ROOM - LATERAL ARM ROOM EXTENSION (WITH SYNCHRONIZING CYLINDER) THE LINES (A) BETWEEN THE CAP END OF THE HYDRAULIC ROOM SYNCHRONIZING CYLINDER CYLINDERS AND THE TEE MUST BE THE SAME LENGTH AND DIAMETER. PRESSURE THE LINES (B) BETWEEN SWITCH THE ROD END OF THE 3000 PSI...

- Page 14 HYDRAULIC LINE CONNECTION DIAGRAM WARDROBE - LATERAL ARM ROOM EXTENSION (WITH SYNCHRONIZING CYLINDER) THE LINES (A) BETWEEN THE CAP END OF THE HYDRAULIC ROOM CYLINDERS AND THE TEE MUST BE THE SAME LENGTH AND DIAMETER. THE LINES (B) BETWEEN THE ROD END OF THE HYDRAULIC ROOM CYLINDER AND THE SYNCHRONIZING CYLINDER MUST BE THE SAME LENGTH AND DIAMETER.

- Page 15 HYDRAULIC FLOW DIAGRAM VERTICAL ARM OR DUAL CYLINDER ROOM EXTENSION WITH SYNCHRONIZING CYLINDER STATIONARY POSITION FRONT CYLINDER FIXED TO VEHICLE SYNCHRONIZING VALVE SYNCHRONIZING VALVE SYNCHRONIZING CYLINDER FIXED TO VEHICLE REAR CYLINDER CYLINDER CYLINDER EXTEND RETRACT VALVE VALVE RETURN PRESSURE MP65.9455 10NOV03...

- Page 16 AIR LINE CONNECTION DIAGRAM FRONT AND DRIVE AXLE LINE FROM HEIGHT LINE FROM HEIGHT FRONT AIR CONTROL VALVE CONTROL VALVE MANIFOLD LINE TO AIR BAG AIR BAG FRONT LF AIR BAG RF AIR BAG AXLE PRESS SW 10 PSI PRESS SW 10 PSI LINE TO LINE TO AIR BAG...

- Page 17 AIR LEVEL SCHEMATIC - FORETRAVEL 4 - POINT LEVELING WITH TAG AXLE PRESSURE SWITCHES FRONT AND DRIVE AXLE PROTECTION SEE AIR VALVE COMPRESSOR FRONT HEIGHT CONTROL VALVE DIAGRAM (HCV) FRONT MANIFOLD ASSEMBLY FRONT BRAKE PRESSURE LEFT TANK SWITCH (2) 10 P.S.I. TANK TRAV.

- Page 18 FRONT AIR SOLENOID MANIFOLD CONNECTIONS 6 VALVE WITH TWO PRESSURE SWITCHES LINES FROM HEIGHT CONTROL VALVES - TWO MAY BE TEE’D 3.400" TOGETHER IF ONE HCV IS USED. REAR VIEW *COACHES WITH INDEPENDANT FRONT SUSPENSION MAY HAVE 20 PSI SWITCHES. EXHAUST EXHAUST PORT...

- Page 19 REAR AIR SOLENOID MANIFOLD CONNECTIONS 6 VALVE WITH THREE PRESSURE SWITCHES LINES FROM HEIGHT NOTE: SOLENOID VALVES AND CONTROL VALVES - AIR LINE CONNECTIONS TWO MAY BE TEE’D 3.400" ARE LABELED. TOGETHER IF ONE HCV IS USED. REAR VIEW EXHAUST EXHAUST PORT PORT...

- Page 20 DIAGRAM - AUXILIARY COMPRESSOR CONNECTIONS REMOTE WATER TRAP PORT C AND FILTER ASSEMBLY PORT (A) IS CONNECTED TO THE HWH AIR LEVELING SYSTEM. 5 MICRON FILTER PORT (B) IS CONNECTED TO PRESSURE SWITCH - SET BY FORETRAVEL THE COACH AIR SUPPLY SYSTEM.

- Page 21 AIR LINE CONNECTION DIAGRAM HWH WATER TRAP ASSEMBLY THE WATER TRAP ASSEMBLY IS MOUNTED REMOTE FROM THE AUXILIARY COMPRESSOR ASSEMBLY AIR SUPPLY FROM AUXILIARY COMPRESSOR TOP VIEW CHECK VALVE AIR SUPPLY TO AUXILIARY COMPRESSOR ASSEMBLY FLOW SIDE VIEW DESICCANT FILTER...

- Page 22 NORMALLY COACH OPEN TANK TANK EXHAUST SOLENOID (1) DUMPS WATER OUT OF FILTER WHEN COMPRESSOR IS OFF. BRAKES/ HWH ROOM SUSPENSION AIR SEAL SOLENOID (2) ALLOWS COACH AIR TO OR OTHER BE PUMPED UP FROM AUX. COMPRESSOR. ACCESSORIES MP75.625C 15DEC03...

- Page 23 AIR SEAL CONNECTION DIAGRAM AIR SEAL AND RAIL ASSEMBLY *NOTE: O.E.M. MAY DETAIL A TEE BOTH CONNECTORS TOGETHER ELECTRICALLY. +12 VOLT CONNECTING 3-WAY AIR VALVE 3-WAY HOSE VACUUM WHEN THERE IS NO +12 POWER TO THE AIR VALVES CONSTANT +12 VOLT NORMALLY AIR PRESSURE IS SUPPLIED TO CLOSED AIR VALVE THE AIR SEAL FROM THE AIR...

- Page 24 AUXILLIARY AIR TANK NORMALLY CLOSED COMPRESSOR MOTOR NOTE: SEE AIR CONNECTION DIAGRAM - AUXILIARY COMPRESSOR OR HWH WATER TRAP ASSEMBLY FOR THE CORRECT FUNCTION AND LOCATION OF THE 2 SOLENOID VALVES. SOLENOID (1) - WATER TRAP - NORMALLY OPEN (MOUNTED WITH THE WATER TRAP REMOTE FROM THE AUXILIARY COMPRESSOR) MP85.515C...

- Page 25 BREATHER CAP - DIPSTICK - 1/4" NUT DRIVER 1 1/2" DIAMETER VALVE RELEASE SOLENOID VALVE NOTE: DO NOT turn the valve release nut more than 4 and 1/2 (four and one half) turns counter clockwise. Damage to the valve may result. VALVE RELEASE PLASTIC PLUG 2 1/4"...