HWH 200 Series Installation Manual

Hwh joy stick-controlled leveling system for motorhomes

Hide thumbs

Also See for 200 Series:

- Operator's manual (13 pages) ,

- Operator's manual (24 pages) ,

- Operator's manual (25 pages)

Advertisement

Quick Links

INSTALLATION MANUAL

HWH JOY STICK-CONTROLLED

HWH HYDRAULIC LEVELING

OPERATE

EXTEND

FRONT

EXTEND

EXTEND

LEFT

RIGHT

EXTEND

REAR

OPERATE

"CAUTION"

UNDERSTAND OPERATOR'S MANUAL BEFORE USING.

BLOCK FRAME AND TIRES SECURELY BEFORE

REMOVING TIRES OR CRAWLING UNDER VEHICLE.

INTERNET: http: //www.hwhcorp.com

H

W

CORPORATION

LEVELING SYSTEM

200 SERIES

FOR MOTORHOMES

STORE

FRONT

STORE

REAR

HWH CORPORATION

(ON I-80, EXIT 267 SOUTH)

2096 MOSCOW ROAD

MOSCOW, IOWA 52760

(800) 321-3494 / (563) 724-3396

H

R

HWH HYDRAULIC LEVELING

ON

NOT IN

PARK/

BRAKE

OFF

CAUTION!

UNDERSTAND OPERATOR'S MANUAL BEFORE USING. BLOCK FRAME AND TIRES

SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

5 AMP

FUSE

ML10897/MI35.0006

19MAR01

Advertisement

Summary of Contents for HWH 200 Series

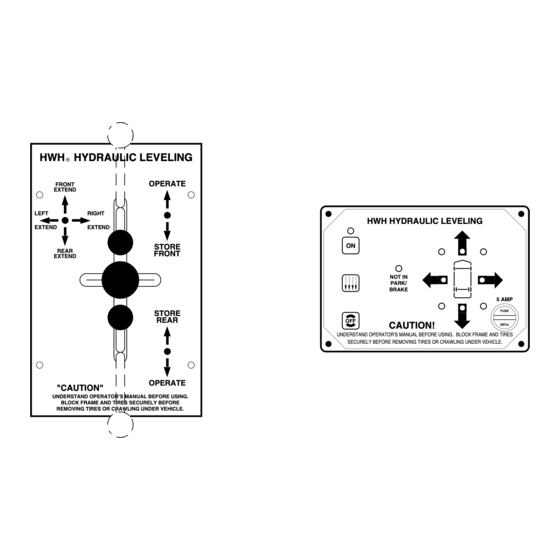

- Page 1 CORPORATION INSTALLATION MANUAL HWH JOY STICK-CONTROLLED LEVELING SYSTEM 200 SERIES FOR MOTORHOMES HWH HYDRAULIC LEVELING OPERATE EXTEND FRONT HWH HYDRAULIC LEVELING EXTEND EXTEND LEFT RIGHT STORE NOT IN EXTEND FRONT PARK/ REAR BRAKE 5 AMP FUSE CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. BLOCK FRAME AND TIRES STORE SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

- Page 2 DESIGN, CHASSIS, SUSPENSIONS,TIRES AND COACH WEIGHTS MAKE IT IMPOSSIBLE TO ANTICIPATE AND ADDRESS ALL INSTALLATION PROBLEMS AND POSSIBILITIES. SOME VEHICLE BUILDERS OR CHASSIS BUILDERS MAY USE PRACTICES DIFFERENT FROM THOSE IN THIS MANUAL. CONSULT HWH CORPORATION OR THE VEHICLE BUILDER FOR INFORMATION CONCERNING CORRECT SYSTEM CAPACITY AND TYPE FOR THE VEHICLE, INSTALLATION QUESTIONS, AND INSTALLATION OF OTHER HWH EQUIPMENT.

-

Page 3: Pre-Installation Checks

Does the vehicle have a good set of batteries that are fully charged? NOTE: Do not use kickdown style jacks and straight acting jacks on the same vehicle. IF THERE ARE ANY PROBLEMS WITH ANY OF THE ABOVE ITEMS, CONTACT HWH CORPORATION BEFORE STARTING THE INSTALLATION MI35.1005... -

Page 4: Jack Installation

Mounting the front jacks in front of the control valve and the air bag. Usually the fitting at the height axle is not suggested. (See FIGURE 2) Contact HWH Corpor- control valve is easiest to get to. (See the SUSPENSION AIR... - Page 5 Heat shields tracted or extended. supplied with HWH brackets should be applied to both sides. After-market exhaust systems may be added at a later date 7.) Front jacks and mounting brackets must be mounted so exposing jacks to high temperatures.

- Page 6 PART II CLEARANCE AND MOUNTING DIMENSION CHART KICK - DOWN JACKS SIDE VIEW TOP VIEW GROUND LINE DIMENSION "I" INCLUDES SPRINGS. RETRACTED JACK EXTENDED STROKE MOUNTING MOUNTING BOLT DIMENSIONS DIMENSIONS WIDTH PATTERN 6000# SHORT 12.5" 19.5" 4.5" 12.0" 14.0" 19.0" 2.0"...

- Page 7 SIDE VIEW GROUND LINE JACK MOUNTING GROUND STROKE RETRACTED BRACKET WIDTH CLEARANCE HEIGHT CLEARANCE HEIGHT AP2025 AP2026 CALL HWH CORPORATION CHEVY P-30 FRONT AP0468** 8.0" MIN FORD OSKOSH-X 13.0" 19.5" 14.5" 0.5" 8.0" 4.9" 10.0" MAX FRONT 8.0" MIN A-P1197** 13.0"...

- Page 8 JACK INSTALLATION WELDING HWH Corporation does not suggest welding brackets to the frame rails. However, if any welding is done such as modifying a jack bracket already mounted, the following precautions should be observed: Connect welding ground to part being welded. NEVER weld to suspension parts such as spring shackles. NEVER weld across the bottom flange of the frame rail.

-

Page 9: Component Installation

Do not run hoses across the transmission crossmembers on front control coaches. The joystick (200 Series) light panel may be flush mounted in CAUTION: a flat surface such as the dash or may be surface mounted A LEAKING HOSE CAN POSE A FIRE HAZARD. - Page 10 PART III COMPONENT INSTALLATION KICK DOWN JACKS: 6000# KICK DOWN JACK- A short hose is attached to the 16000# KICK DOWN JACK- Route the hose around the left jack at the factory. The hose is clamped to the pivot bracket. pivot, then across the back side of the cylinder and connect It can be moved to the opposite side of the jack if necessary to the actuator fitting.

- Page 11 If power is taken directly SWITCH from the battery, the fuse should be at least 18" from the bat- tery. A fuse kit is available from HWH Corporation. FIGURE 8 Wiring harnesses supplied are usually adequate for most installations.

- Page 12 SPRINGS (3) STICKERS SCREWS (3) On the 200 Series, the air dump signal is on the yellow wires ON TOP coming from the control panel. There is one connection at the front of the vehicle and one at the rear. A Tee adaptor is sup- FIGURE 10 plied with the control system.

- Page 13 PART III COMPONENT INSTALLATION Check list 1. Check all bolts and brackets for tightness. 2. Check that all hoses are securely clamped or tie wrapped. 3. Check that all wires are securely clamped or tie wrapped. 4. Check oil level before operating the system. 5.

- Page 14 4.6240 3.1240 3.610 3.250 0.4883 4.750 DASH LINE INDICATES OUTER BEZEL * USE ACTUAL BEZEL FOR POSITIONING MOUNTING HOLES...

-

Page 15: Start-Up & Adjustments

PART IV START-UP & ADJUSTMENTS FRONT STORE FRONT STORE LEVER (OPERATE LEVER (STORE/TRAVEL HWH HYDRAULIC LEVELING POSITION) POSITION) OPERATE EXTEND FRONT EXTEND EXTEND LEFT RIGHT STORE EXTEND FRONT REAR JACK CONTROL LEVER STORE REAR REAR STORE REAR STORE LEVER (STORE/TRAVEL OPERATE "CAUTION"... - Page 16 PART IV START-UP & ADJUSTMENTS 9000# JACK 16000# JACK 6000# JACK UPPER LOWER ADJUSTING ADJUSTING SET SCREW ADJUSTING STOP STANDARD & HEAVY DUTY SET SCREWS LOW PROFILE LEVELING ADJUSTING NUTS UNITS UNITS FIGURE 11 FIGURE 12 FIGURE 13 A. HYDRAULIC START-UP 1.

- Page 17 1. Extend one jack at a time and check the corresponding lights The "NOT IN PARK/BRAKE" circuit must be tested on the to be sure that the wiring is correct and that all lights are func- 200 Series Systems. tioning properly. CAUTION: BEFORE RELEASING THE PARK BRAKE, 2.

- Page 18 HYDRAULIC LINE CONNECTION DIAGRAM 200/210/225 SERIES BI-AXIS VALVE NOTE: Hose fittings at the pump will come directly out of the pump or if equipped with a room manifold, out of the top of the room manifold. BREATHER/ FILLER CAP PRESSURE RETURN PRESSURE RIGHT FRONT...

- Page 19 AIR LINE CONNECTION DIAGRAM SUSPENSION AIR BAGS FROM WIRE HARNESS SEE ELECTRICAL AIR DUMP SOLENOID VALVES DIAGRAM FOR ARE ACTIVATED (OPENED) BY CONNECTION A +12 SIGNAL. 4 AIR DUMP SOLENOID VALVES AND 4 HEIGHT CONTROL VALVES ARE SHOWN. THE AIR DUMP VALVE IS TO TEE INTO THE LINE BETWEEN THE AIR BAG AND THE HEIGHT CONTROL VALVE.

- Page 20 ELECTRICAL CONNECTION DIAGRAM 200 SERIES LEVELING SYSTEM 8600 6230 HWH HYDRAULIC LEVELING FRONT OPERATE SEE PUMP RELAY RAISE LEFT RIGHT RAISE RAISE CONNECTION DIAGRAM STORE REAR FRONT RAISE (BLUE) 9000 SEE PANEL STORE REAR CONNECTION HWH HYDRAULIC LEVELING OPERATE TO BRAKE "CAUTION"...

- Page 21 ELECTRICAL CONNECTION DIAGRAM 200 SERIES LEVELING SYSTEM PUMP RELAY CONNECTION DIAGRAM PUMP MUST BE MOUNTED SOLIDLY TO FRAME. SOME PUMPS HAVE A GROUND CABLE THAT IS TO BE ATTACHED TO THE GROUND STUD. WIRE FROM NOTE: THE (4) DIGIT WIRE NUMBER SUPERSEDES ANY AND ALL WIRE COLORS.

- Page 22 ELECTRICAL CONNECTION DIAGRAM 200 SERIES BI-AXIS VALVE WITH SUSPENSION AIR DUMP PUMP RELAY HARNESS HWH HYDRAULIC LEVELING 6230 OPERATE FRONT RAISE SEE PUMP RELAY LEFT RIGHT RAISE RAISE CONNECTION DIAGRAM STORE REAR FRONT RAISE 8600 (BLUE) 9000 STORE REAR HWH HYDRAULIC LEVELING...

- Page 23 ELECTRICAL CONNECTION DIAGRAM 200 LEVELING SYSTEM BI-AXIS VALVE WITH SUSPENSION AIR DUMP PUMP RELAY CONNECTION DIAGRAM PUMP MUST BE MOUNTED SOLIDLY TO FRAME. SOME PUMPS HAVE A GROUND CABLE THAT IS TO BE ATTACHED TO THE GROUND STUD. WIRE FROM HARNESS - (BLUE) 6820 BATTERY 8600...

- Page 24 NOTE: DO NOT USE (PURPLE) WIRE - 6121 REMOVE (PURPLE) WIRE - 6121 6111 FROM HARNESS. NOTE: SPLICE (BROWN) WIRE - 7699 FROM HWH LIGHT PLATE TO (BROWN) - 7699 PIGTAIL WITH BUTT CONNECTOR. PIGTAIL JACKS DOWN LIGHT PROVIDED - (BROWN) 7699 INCLUDED IN HARDWARE KIT.

Need help?

Do you have a question about the 200 Series and is the answer not in the manual?

Questions and answers