HWH 2000 Series Operator's Manual

Hwh computer-controlled leveling system

Hide thumbs

Also See for 2000 Series:

- Operator's manual (52 pages) ,

- Operator's manual (15 pages) ,

- Operator's manual (19 pages)

Advertisement

Quick Links

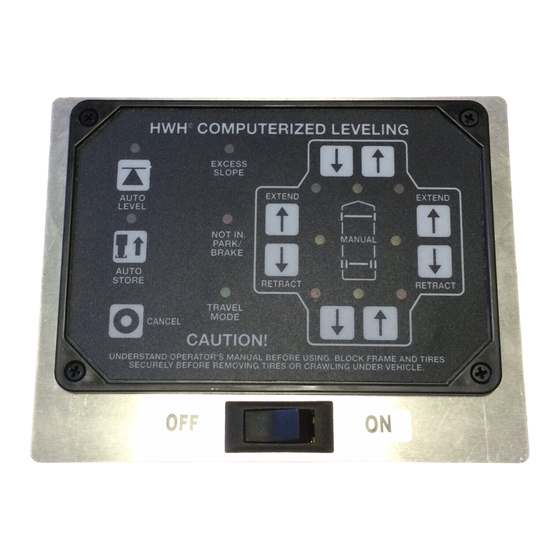

OPERATOR'S MANUAL

HWH COMPUTER-CONTROLLED

Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408

AP44981

H H

W

CORPORATION

LEVELING SYSTEM

2000 SERIES

FEATURING:

BI-AXIS Hydraulic Leveling

R

Straight-Acting Jacks

Multiple Room Extensions

Hydraulic Joey Beds

HWH CORPORATION

(On I-80, Exit 267 South)

2096 Moscow Road | Moscow, Iowa 52760

www.hwh.com

R

ML44982/MP04.3945

18JUN09

Advertisement

Summary of Contents for HWH 2000 Series

- Page 1 CORPORATION OPERATOR’S MANUAL HWH COMPUTER-CONTROLLED LEVELING SYSTEM 2000 SERIES FEATURING: BI-AXIS Hydraulic Leveling Straight-Acting Jacks Multiple Room Extensions Hydraulic Joey Beds HWH CORPORATION (On I-80, Exit 267 South) 2096 Moscow Road | Moscow, Iowa 52760 Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408 www.hwh.com...

-

Page 2: How To Obtain Warranty Service

HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION. -

Page 3: Cold Weather Operations

For cold weather information see "COLD WEATHER OPERATIONS" below. The HWH systems with a computer processor monitor the pump run time and will turn the pump off if the run time exceeds a specified time. This time can vary with different systems. Due to available electronics or system design, the pump run time programs will also vary. -

Page 4: General Instructions

If there is a the other rooms or leveling system after the reset switch is failure at any time in the HWH CAN network, the network will pushed. shut down. The leveling system and all room extensions will not operate. -

Page 5: Operating Procedures

APEX SYSTEM OPERATING PROCEDURES AUTOMATIC HYDRAULIC LEVELING Place transmission in the recommended position for AUTO LEVEL SEQUENCE: During the automatic leveling parking the vehicle and set parking brake. Turn the coach sequence, after the system has extended the appropriate engine off. Turn the ignition to the "ACCESSORY" position. jacks to level the vehicle, the system will then stabilize the vehicle. - Page 6 APEX SYSTEM OPERATING PROCEDURES JACK RETRACTION WARNING: THE OPERATOR MUST BE SURE THAT IMPORTANT: If power to the system is interrupted THERE ARE NO OBJECTS UNDER THE VEHICLE AND THAT after starting a store procedure, the store procedure ALL PEOPLE ARE CLEAR OF THE VEHICLE. should be reinitiated and the jacks should be completely retracted.

- Page 7 APEX SYSTEM OPERATING PROCEDURES MANUAL JACK RETRACTION The solenoid valves on the power unit valve assembly are 3. Retract the front jacks by opening the two center valves. equipped with a manual valve release. The large valves Slowly turn the manual valve releases counter clockwise have a valve release T-Handle.

- Page 8 NOTE: If the MANUAL RETRACT WINCH is attached to stops moving, release the room control immediately. DO the room remove it before extending the room. NOT force the room. DO NOT reverse direction of the room, contact HWH Customer Service WARNING: KEEP PEOPLE AND OBSTRUCTIONS for assistance 1-800-321-3494.

- Page 9 APEX SYSTEM OPERATING PROCEDURES AUXILIARY ROOM CONTROL SWITCHES The vehicle is equipped with auxiliary room control switches. The park brake must be set to use the auxiliary room The auxiliary switch panel is in the passenger side front control switches. compartment with the hydraulic pump assembly.

- Page 10 A MANUAL RETRACT WINCH PROVIDED place the RATCHET LEVER in its ON position and slowly BY HWH IS EQUIPPED FOR MANUALLY RETRACTING THE rotate the WINCH HANDLE clockwise until the ROOM ONLY. IT IS NOT TO BE USED FOR LIFTING OR ANY RATCHET LEVER locks.

- Page 11 IMPORTANT: If at any stage something is not VALVE understood or if the room begins to bind DO NOT force RELEASE the room, contact HWH Customer Service for assistance OPEN 1-800-321-3494. NOTE: Leave the solenoid valves open and the BREATHER...

- Page 12 CAP-DIP IMPORTANT: If at any stage something is not STICK understood or if the room begins to bind DO NOT force the room, contact HWH Customer Service for assistance HYDRAULIC PUMP/MANIFOLD 1-800-321-3494. LEVELING SYSTEM MANIFOLD NOT SHOWN If this manifold is equipped with an auxiliary hand pump, you...

-

Page 13: Maintenance

ROOM EXTENSIONS The HWH room mechanisms need no maintenance. Any visible mechanism can be kept clean by washing DO NOT grease or lubricate any parts of the HWH with water. Refer to the vehicle manufacturer for mechanism. correct maintenance of the room seals. - Page 14 To help reduce the corrosion of jacks after exposure to anti- continue to absorb moisture from the air even after they icing / deicing agents, thoroughly wash jacks with warm have dried. This can facilitate corrosion of metallic soapy water. components, such as HWH jacks. MP44.0509 21NOV16...

- Page 15 Move the adjustment for that light very, very, slightly in qualified RV repair center, your vehicle or coach the OPPOSITE direction that is given in the above manufacturer, or HWH CORPORATION for service or repair. instructions for LED’s A, B, C, and D. This will allow MP44.1501 20APR09 MP45.3259...

-

Page 16: Hydraulic Connection Diagram

APEX SYSTEM HYDRAULIC CONNECTION DIAGRAM MP64.9910 17JUN09... - Page 17 APEX SYSTEM HYDRAULIC CONNECTION DIAGRAM MP64.9911 17JUN09...

- Page 18 APEX SYSTEM HYDRAULIC CONNECTION DIAGRAM MP64.9912 17JUN09...

- Page 19 APEX SYSTEM HYDRAULIC CONNECTION DIAGRAM MP64.9913 17JUN09...

- Page 20 APEX SYSTEM HYDRAULIC CONNECTION DIAGRAM MP64.9914 17JUN09...

- Page 21 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9460 17JUN09...

- Page 22 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9461 17JUN09...

- Page 23 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9462 17JUN09...

- Page 24 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9463 17JUN09...

- Page 25 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9464 17JUN09...

- Page 26 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9465 17JUN09...

- Page 27 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9466 17JUN09...

- Page 28 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9467 17JUN09...

- Page 29 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9468 17JUN09...

- Page 30 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9469 17JUN09...

- Page 31 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9470 17JUN09...

- Page 32 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9471 17JUN09...

- Page 33 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9472 17JUN09...

- Page 34 APEX SYSTEM SYSTEM SCHEMATIC ELECTRICAL MP84.9473 17JUN09...

- Page 35 INFORMATION/INSTRUCTION SHEET HYDRAULIC SOLENOID VALVE INDENTIFICATION - MANUAL OPERATIONS - REPLACEMENT REPLACEMENT VALVES WILL HAVE A VALVE RELEASE CAM SOLENOID VALVES WITH CAM RELEASE BREATHER CAP W/NUT DRIVER 1 1/2" DIAMETER SOLENOID VALVE CAM RELEASE VALVE CLOSED Default position THE BREATHER CAP IS NOTE: The cam release may be LOCATED ON THE TOP rotated in any direction on the...

Need help?

Do you have a question about the 2000 Series and is the answer not in the manual?

Questions and answers