HWH 2000 Series Operator's Manual

Computer-controlled leveling system

Hide thumbs

Also See for 2000 Series:

- Operator's manual (52 pages) ,

- Operator's manual (15 pages) ,

- Operator's manual (22 pages)

Advertisement

Quick Links

OPERATOR'S MANUAL

HWH COMPUTER - CONTROLLED

2000 SERIES LEVELING SYSTEM

Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408

AP46142

H

W

CORPORATION

R

FEATURING:

Touch Panel Leveling Control

BI-AXIS Hydraulic Leveling

R

Air Leveling

Straight-Acting Jacks

COMPUTERIZED LEVELING

EXCESS

SLOPE

HYD

AIR

LEVEL

NOT IN

PARK/

BRAKE

STORE

DUMP

TRAVEL

MODE

OFF

RAISE

CAUTION!

UNDERSTAND OPERATOR'S MANUAL BEFORE USING. BLOCK FRAME AND TIRES

SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

HWH CORPORATION

(On I-80, Exit 267 South)

2096 Moscow Road | Moscow, Iowa 52760

www.hwh.com

H

R

ML46143/MP04.3948

01MAR10

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for HWH 2000 Series

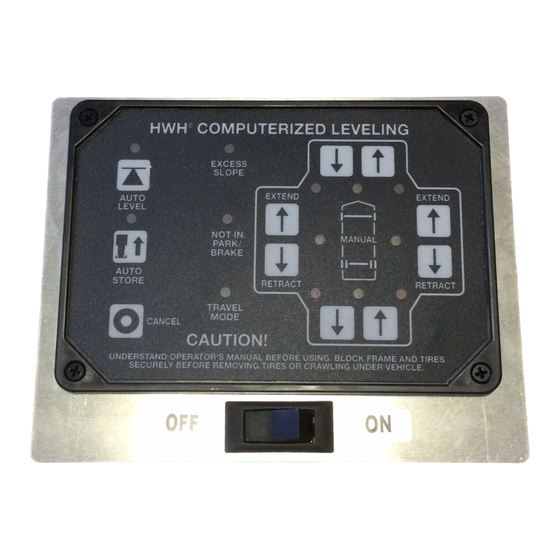

- Page 1 CORPORATION OPERATOR’S MANUAL HWH COMPUTER - CONTROLLED 2000 SERIES LEVELING SYSTEM FEATURING: Touch Panel Leveling Control BI-AXIS Hydraulic Leveling Air Leveling Straight-Acting Jacks COMPUTERIZED LEVELING EXCESS SLOPE LEVEL NOT IN PARK/ BRAKE STORE DUMP TRAVEL MODE RAISE CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. BLOCK FRAME AND TIRES SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

- Page 2 HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION.

- Page 3 CONTROL IDENTIFICATION "EXCESS SLOPE" DUMP "NOT IN PARK" LIGHT AIR OPERATION LIGHT LIGHT LIGHT LOWER FRONT BUTTON "LEVEL AIR" BUTTON RAISE FRONT BUTTON HYDRAULIC OPERATION LIGHT COMPUTERIZED LEVELING WARNING LIGHTS "LEVEL HYD" BUTTON (4-Red) EXCESS SLOPE LEVEL STORE LIGHT RAISE RIGHT SIDE BUTTON NOT IN PARK/ BRAKE...

- Page 4 MASTER WARNING INDICATORS The HWH Master Warning light and Buzzer are used to If the HWH buzzer and light come on and stay on, the indicate a jack has not been retracted or has extended vehicle should be pulled over as soon as it is safe to do so.

- Page 5 For cold weather information see "COLD WEATHER OPERATIONS" below. The HWH systems with a computer processor monitor the pump run time and will turn the pump off if the run time exceeds a specified time. This time can vary with different systems. Due to available electronics or system design, the pump run time programs will also vary.

- Page 6 OPERATING PROCEDURES AIR LEVELING LOCK OUT Computerized or manual air leveling functions cannot be The "AIR" button will not function until all jacks are fully used if hydraulic functions have been used and any jacks retracted with the warning lights off. The "STORE" button or are extended.

- Page 7 OPERATING PROCEDURES AUTOMATIC HYDRAULIC LEVELING 1. Place transmission in the recommended position for The system will automatically extend the jacks to level the parking vehicle and set parking brake. Turn the coach vehicle and then extend any remaining jacks for stabilizing. engine off.

- Page 8 OPERATING PROCEDURES MANUAL HYDRAULIC OPERATION 1. Place transmission in the recommended position for parking Jacks will extend (or retract) in pairs to raise (or lower) a side the vehicle, and set the parking brake. Turn the ignition to the or end of the vehicle. Any jack not used for leveling can be "ACCESSORY"...

- Page 9 Use the manual valve release for retracting the jacks only removed to gain access. Open valve 1-1/2 to 2 full turns. if the STORE feature on the HWH control panel will not DO NOT turn the 1/4" valve release nut more than retract the jacks.

- Page 10 OPERATING PROCEDURES AUTOMATIC AIR OPERATION If no yellow level lights are on when the air button is pushed NOTE: The ignition must be in the "ON" or "ACC" position to use the "AIR" button. Once the operation is the second time, the system will still exhaust all air from all the air bags.

- Page 11 OPERATING PROCEDURES MANUAL AIR OPERATION NOTE: The ignition must be in the "ON" or "ACC" panel in conjunction with the yellow LEVEL indicator lights. position to use the "AIR" button. Once the operation Any side to side leveling should be done, if needed, is started, the ignition can be moved to the "OFF"...

- Page 12 INSTRUCTION SHEET SENSING UNIT MAINTENANCE/SERVICE SENSING UNIT ACCURACY TOLERANCE The sensing unit has an accuracy tolerance of ± 5.4 inches front to rear and ± 1 inch side to side on a 36 foot vehicle. Typical leveling results will be better. SENSING UNIT ADJUSTMENT / WITHOUT ADJUSTING ENHANCEMENT SWITCH To adjust the sensing unit, first the vehicle must be level.

- Page 13 Sensing Unit. If lit LEDs on the sensing unit plate do 1/2", or 1/4" sizes will be needed. not match the yellow level lights on the touch panel, the control box is not properly oriented. Contact HWH The Sensing Unit is mounted inside the Control Box. The Corporation for assistance.

- Page 14 HYDRAULIC LINE CONNECTION DIAGRAM 2000 SERIES LEVELING SYSTEM (WITH 4 STRAIGHT-ACTING JACKS) BREATHER LARGE VALVE LEFT RIGHT WITH RELEASE FRONT FRONT NUT LOCATED UNDER PLASTIC PLUG SHUTTLE VALVE 3000PSI PRESSURE SWITCH NOTE: SOME MANIFOLDS 50PSI ARE EQUIPPED PRESSURE WITH VELOCITY...

- Page 15 HYDRAULIC SCHEMATIC DIAGRAM BI-AXIS LEVELING WITH STRAIGHT-ACTING JACKS 625 - 625S OR 2000 SERIES NOTE: 50 PSI PRESSURE SWITCH RELIEF VALVE MAY NOT BE USED ON ALL 625 MANIFOLDS. 3500 P.S.I. HYDRAULIC ROOM EXTENSION POWER UNIT MANIFOLD LOCATED HERE WHEN APPLICABLE...

- Page 16 PRESS SW 20 PSI PRESS SW 20 PSI FRONT AXLE AIR SUPPLY NOTE: HWH ONLY SUPPLIES THE FRONT AND DRIVE AXLE AIR MANIFOLDS ALONG WITH AN AUXILIARY AIR COMPRESSOR. ALL OTHER EQUIPMENT IS BY THE SEE SPECIFIC MANIFOLD VEHICLE OR CHASSIS MANUFACTURER.

- Page 17 AIR LINE CONNECTION DIAGRAM 4-POINT LEVELING SYSTEM SCHEMATIC PRESSURE SWITCHES FRONT AND REAR NOTE: HWH ONLY SUPPLIES THE FRONT AND DRIVE AXLE AIR HWH AUXILIARY AIR COMPRESSOR MANIFOLD ASSEMBLIES ALONG WITH THE HWH AUXILIARY AIR COMPRESSOR. ALL OTHER EQUIPMENT AND PLUMBING IS SEE AIR LINE CONNECTION DIAGRAM SUPPLIED BY THE VEHICLE OR CHASSIS MANUFACTURER.

- Page 18 FRONT AIR SOLENOID MANIFOLD CONNECTIONS 6 VALVE WITH TWO PRESSURE SWITCHES LINES FROM HEIGHT NOTE: SOLENOID VALVES AND CONTROL VALVES - AIR LINE CONNECTIONS ARE TWO MAY BE TEE’D 3.400" LABELED. TOGETHER IF ONE HCV IS USED. REAR VIEW LINE TO LR LINE TO RR AIR BAG AIR BAG...

- Page 19 REAR AIR SOLENOID MANIFOLD CONNECTIONS 6 VALVE WITH THREE PRESSURE SWITCHES LINES FROM HEIGHT NOTE: SOLENOID VALVES AND CONTROL VALVES - AIR LINE CONNECTIONS ARE TWO MAY BE TEE’D 3.400" LABELED. TOGETHER IF ONE HCV IS USED. REAR VIEW LINE TO LR LINE TO RR AIR BAG AIR BAG...

- Page 20 AIR LINE CONNECTION DIAGRAM HWH AIR COMPRESSOR FUSE 15 AMP FROM +12 BATTERY 12 VOLT RELAY AIR FILTER GROUND CHECK VALVE FLOW TO HWH AIR LEVELING MANIFOLDS RELIEF VALVE (110 PSI) +12 CONTROL AIR SOLENOID FROM HWH AIR NORMALLY OPEN...

- Page 21 AIR LINE CONNECTION DIAGRAM HWH AIR COMPRESSOR SCHEMATIC AUX. 12V COMPRESSOR PORT TO LEVELING SYSTEM COMP- MANIFOLDS PRESSOR MOTOR EXHAUST RELIEF VALVE 110 P.S.I. WATER TRAP SOLENOID (1) SOLENOID (1) DUMPS WATER OUT OF NORMALLY FILTER WHEN COMPRESSOR IS OFF.

- Page 22 ELECTRICAL CONNECTION DIAGRAM CENTRAL CONTROL / FRONT AIR / HYDRAULIC LEVELING MODULE HARNESS ROUTING PAGE 1 OF 2 SEE ELECTRICAL CONNECTION DIAGRAM 2000 SERIES LEVELING SYSTEM PUMP AND MASTER RELAYS LEVELING SYSTEM SEE ELECTRICAL CONNECTION DIAGRAM TOUCH PANEL CENTRAL CONTROL / FRONT AIR /...

- Page 23 6230 2000 1000 6230 1200 2200 9700 - TO SEE ELECTRICAL CONNECTION COMPRESSOR DIAGRAM - 2000 SERIES LEVELING PUMP AND MASTER RELAYS SEE ELECTRICAL CONNECTION 9900 DIAGRAM - 2000 SERIES LEVELING SYSTEM - LEVELING SYSTEM HYDRAULIC MANIFOLD BLACK GRAY GRAY...

- Page 24 ELECTRICAL CONNECTION DIAGRAM REAR AIR / HYDRAULIC MODULE HARNESS ROUTING TO CENTRAL CONTROL MODULE AND TOUCH PANEL 12 PIN BROWN SEE ELECTRICAL CONNECTION DIAGRAM 120 OHM REAR AIR - HYDRAULIC MODULE TERMINATION WIRE AND CONNECTION INFORMATION RESISTOR 8 PIN 8 PIN BLACK BLACK GREEN...

- Page 25 ELECTRICAL CONNECTION DIAGRAM CENTRAL CONTROL / FRONT AIR / HYDRAULIC MODULE WIRE AND CONNECTION INFORMATION - PAGE 1 OF 5 BOTTOM VIEW PIN 8 PIN 1 PIN 12 PIN 8 PIN 1 PIN 6 PIN 1 PIN 1 CN10 CN11 WIRE WIRE PIN #...

- Page 26 ELECTRICAL CONNECTION DIAGRAM CENTRAL CONTROL / FRONT AIR / HYDRAULIC MODULE WIRE AND CONNECTION INFORMATION - PAGE 2 OF 5 RIGHT SIDE VIEW PIN 1 PIN 4 PIN 1 GRAY BROWN BLACK NEUTRAL HOLD LEVELING SENSING UNIT PIN 1 PIN 12 PIN 12 OVERRIDE ADJUSTMENT MECHANISM -...

- Page 27 ELECTRICAL CONNECTION DIAGRAM CENTRAL CONTROL / FRONT AIR / HYDRAULIC MODULE LED - FUSE LOCATION AND DESCRIPTION - PAGE 3 OF 5 CENTRAL CONTROL MOTHER BOARD 15AMP SWITCHED BATTERY TO CAN MODULES 11-RED SENSING UNIT PARK BRAKE +12V 8-RED 9 (NOT USED) REAR NEUTRAL 7-RED...

- Page 28 ELECTRICAL CONNECTION DIAGRAM CENTRAL CONTROL / FRONT AIR / HYDRAULIC MODULE LED - FUSE LOCATION AND DESCRIPTION - PAGE 4 OF 5 HYDRAULIC OUTPUT BOARD FUSE CN4 BLACK NOTE: FOR DETAILED INPUT / OUTPUT INFORMATION ABOUT PIN CONNECTIONS RELAY DESCRIPTION FUSE BLACK SEE ELECTRICAL CONNECTION DIAGRAM -...

- Page 29 ELECTRICAL CONNECTION DIAGRAM CENTRAL CONTROL / FRONT AIR / HYDRAULIC MODULE LED - FUSE LOCATION AND DESCRIPTION - PAGE 5 OF 5 AIR LEVEL OUTPUT BOARD FUSE CN2 BROWN NOTE: FOR DETAILED INPUT / OUTPUT INFORMATION ABOUT PIN CONNECTIONS RELAY DESCRIPTION FUSE BROWN SEE ELECTRICAL CONNECTION DIAGRAM -...

- Page 30 ELECTRICAL CONNECTION DIAGRAM REAR AIR / HYDRAULIC MODULE WIRE AND CONNECTION INFORMATION - PAGE 1 OF 4 FRONT RIGHT SIDE PIN 1 PIN 1 BLACK PIN 1 PIN 12 PIN 12 PIN 8 WIRE WIRE PIN # WIRE DESCRIPTION AND FUNCTION COLOR NUMBER FRONT...

- Page 31 ELECTRICAL CONNECTION DIAGRAM REAR AIR / HYDRAULIC MODULE WIRE AND CONNECTION INFORMATION - PAGE 2 OF 4 LEFT SIDE PIN 4 PIN 1 PIN 1 GRAY BLACK PIN 8 BROWN PIN 12 PIN 1 WIRE WIRE PIN # WIRE DESCRIPTION AND FUNCTION COLOR NUMBER CN1 - 12 PIN BROWN CONNECTOR...

- Page 32 ELECTRICAL CONNECTION DIAGRAM REAR AIR / HYDRAULIC MODULE LED LOCATION AND DESCRIPTION - PAGE 3 OF 4 GREEN GRAY LED 18 - RED POWER ON FOR MODULE LED 17 - RED LINK LIGHT LED 16 - RED - NOT USED LED 1 - RED - L.R.

- Page 33 ELECTRICAL CONNECTION DIAGRAM REAR AIR / HYDRAULIC MODULE LED LOCATION AND DESCRIPTION - PAGE 4 OF 4 REAR AND TAG AIR LEVEL OUTPUT BOARD FUSE - NOT USED LED - NOT USED TOP RING BLACK NOTE: FOR DETAILED INPUT / OUTPUT RELAY DESCRIPTION FUSE BLACK...

- Page 34 ELECTRICAL CONNECTION DIAGRAM 2000 SERIES LEVELING SYSTEM LEVELING SYSTEM HYDRAULIC MANIFOLD 6231 4400 6231 LEVELING MANIFOLD 1400 7600 50 PSI 2400 PRESS 7601 SWITCH 3400 3000 PSI TO HWH GROUND STUD PRESS SWITCH LOCATED AT THE 8100 POWER UNIT 3000 LB...

- Page 35 ELECTRICAL CONNECTION DIAGRAM FRONT AIR MANIFOLD PIGTAIL AND VALVE CONNECTIONS TO 12 PIN (CN100) GRAY CONNECTOR CENTRAL CONTROL MODULE TO 12 PIN BROWN CONNECTOR FRONT AIR MODULE AIR MANIFOLD PIGTAIL SYSTEM PRESSURE SWITCH NOTE: HARNESS AND VALVE NOT USED CONNECTIONS ARE LABELED LEFT AND RIGHT CONNECTIONS MUST BE MAINTAINED AS SHOWN 1700...

- Page 36 ELECTRICAL CONNECTION DIAGRAM REAR AIR MANIFOLD PIGTAIL AND VALVE CONNECTIONS TO 12 PIN BROWN CONNECTOR AT REAR AIR MODULE TO 12 PIN (CN3) GRAY CONNECTOR AT REAR AIR MODULE TO 12 PIN (CN2) GREEN CONNECTOR AT REAR AIR MODULE AIR MANIFOLD PIGTAIL NOTE: HARNESS AND VALVE CONNECTIONS ARE LABELED...

- Page 37 COMPRESSOR DIAGRAM GRAY FROM FUSE AIR SOLENOID 15 AMP 12 VOLT RELAY (2) TO +12 BATTERY POWER - 6100 GROUND CHECK VALVE (3) AIR LINE TO SUSPENSION FLOW AIR FILTER NORMALLY OPEN AIR SOLENOID (1) GROUND TO RELAY MOUNTING BOLT COMPRESSOR HARNESS FROM CONTROL BOX - (BLACK) 9700 The control box sends a +12 signal to the normally open The normally open air solenoid (1) will open any time the...

- Page 38 ELECTRICAL CONNECTION DIAGRAM AIR COMPRESSOR COMPRESSOR HARNESS FROM +12 SIGNAL - 9700 CONTROL BOX WHITE GROUND 12 VOLT ESSEX BLACK ( GROUND ) RELAY RELAY MTG. BOLT RED +12 COMPRESSOR MOTOR FUSE 15 AMP (GROUND) (+12 SIGNAL) 6100 NORMALLY OPEN 12 VOLT AIR SOLENOID +12 VOLT BATTERY POWER...

- Page 39 ELECTRICAL CONNECTION DIAGRAM 2000 SERIES LEVELING SYSTEM PUMP AND MASTER RELAYS TO REAR AIR / HYDRAULIC MODULE MAIN CAN TRUNK HARNESS FROM +12 BATTERY SWITCHED BATT FROM PUMP MASTER RELAY RELAY 9901 8500 FUSE 8600 MASTER PUMP 40 AMP RELAY...

- Page 40 ELECTRICAL CONNECTION DIAGRAM 2000 SERIES AIR / HYDRAULIC LEVELING SYSTEM TOUCH PANEL CONNECTIONS COMPUTERIZED LEVELING EXCESS SLOPE LEVEL NOT IN PARK/ BRAKE STORE DUMP TRAVEL MODE CAUTION! RAISE UNDERSTAND OPERATOR’S MANUAL BEFORE USING. BLOCK FRAME AND TIRES SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

- Page 41 MASTER WARNING LIGHT/BUZZER CONNECTION DIAGRAM 2000 SERIES LEVELING SYSTEM A MASTER WARNING INDICATOR SHOULD ALWAYS BE USED. WHEN THE LEVELING SYSTEM HAS STRAIGHT-ACTING JACKS A WARNING BUZZER MUST BE USED. NOTE: BY SUPPLYING IGNITION POWER TO THE WARNING BUZZER, AND "ACC" POWER TO THE WARNING LIGHT, THE SYSTEM MAY BE OPERATED IN ACCESSORY WITHOUT THE BUZZER SOUNDING.

- Page 42 INFORMATION/INSTRUCTION SHEET HYDRAULIC SOLENOID VALVE INDENTIFICATION - MANUAL OPERATIONS - REPLACEMENT REPLACEMENT VALVES WILL HAVE A VALVE RELEASE CAM SOLENOID VALVES WITH CAM RELEASE BREATHER CAP W/NUT DRIVER 1 1/2" DIAMETER SOLENOID VALVE CAM RELEASE VALVE CLOSED Default position THE BREATHER CAP IS NOTE: The cam release may be LOCATED ON THE TOP rotated in any direction on the...

Need help?

Do you have a question about the 2000 Series and is the answer not in the manual?

Questions and answers