Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Jungheinrich EKE 30-2 ac

- Page 1 EKE 30-2 ac 08.02- Operating instructions 50272276 09.03...

- Page 2 Used to indicate standard equipment. Used to indicate optional equipment. Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the truck. No guarantee of particular features of the truck should therefore be inferred from the present operating instructions.

-

Page 4: Table Of Contents

Table of contents Correct use and application of the truck Truck description Application description ................ B 1 Description of assembly groups and functions ........B 2 Truck ....................B 3 Technical data - standard version ............B 4 Performance data ................B 4 Dimensions .................. - Page 5 Operational safety and environmental protection ........ F 1 Safety regulations applicable to truck maintenance ......F 1 Servicing and inspection ..............F 3 EKE 30-2 ac maintenance checklist ........... F 4 EKE 30-2 ac lubrication schedule ............F 6 Fuels, coolants and lubricants ............. F 7 Notes on maintenance ................

-

Page 6: A Correct Use And Application Of The Truck

A Correct use and application of the truck The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are included in the scope of delivery for this truck. The guidelines are part of these ope- rating instructions and must always be heeded. National regulations are fully applica- ble. -

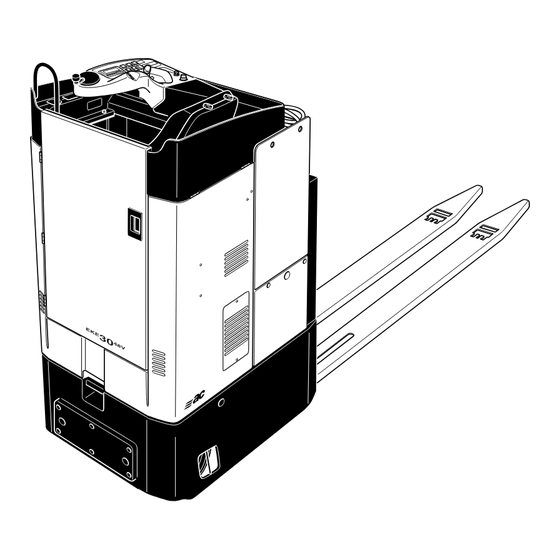

Page 8: B Truck Description

Great emphasis has been placed on the ergonomic driver position and on-the-job safety. The controls are evidently and clearly arranged and have been matched to the transport task. Truck types and capacity: Type Capacity EKE 30-2 ac 3000kg... -

Page 9: Description Of Assembly Groups And Functions

Description of assembly groups and functions Item Designation Item Designation t Information and t Accelerator pedal service display (LISA) t Hydraulics control t Driver seat knob t Parking brake t Lifting device t Key switch t Drive wheels t Main switch t Emergency steering switch (EMERGENCY STOP) t Driver door... -

Page 10: Truck

Truck Safety devices Closed, smooth truck contour. The drive wheels (11) are protected by a sturdy collision guard. It protects the load against collisions. All electric functions can be disabled in case of danger using the key switch (4) or the main switch (EMERGENCY STOP) (5). -

Page 11: Technical Data - Standard Version

Technical data - standard version Indication of technical data according to VDI 2198. Subject to modification and supplementing. Performance data Designation EKE 30-2ac Q Rated load capacity 3000 Load centre distance at 1800 standard fork length * Travel speed 18.1 / 18.3 km/h with/without rated load Lifting speed... -

Page 12: Dimensions

Dimensions (all dimensions in mm) Designation Standard Lifting height Seating height 1450 Lowered height of fork 90 +5 Overall length 4855 Front section length 1255 Truck width 1000 Distance between forks, outside Track width, drive Track width, load section Turning radius 3900 Aisle width with pallet 1000 x 1200 in 5055... -

Page 13: En Standards

EN standards Continuous sound level: 68 dB(A) according to EN 12053 as stipulated in ISO 4871 The continuous sound level is a value averaged according to standard regulations, taking the sound pressure level into account when driving, lifting and idling. The sound pressure level is measured at the ear. -

Page 14: Technical Description - Load Lifting Devicet

Technical description – load lifting devicet Lifting device: The lifting cylinder and the lifting linkage connect the lifting device (10) with the fork and the chassis. The fork is raised by extending the lifting cylinder while the lifting linkage simultaneously swivels the load bearing wheel holders. Label positions and identification plates Xxxx Xxxxxxx... -

Page 15: Truck Identification Plate

Truck identification plate Xxxx Xxxxxxx Xxxxxx Xxxxxxxxx Xxxxxx Xxxxxxxxx Xxxxxxxxxxxxxxxxxxx Xxxxxxxxxxxxxxxxxx Xxxxxxxxxx Xxxxxxxxxxxxxxxxx Xxxxxxxxxxxxxxxxxxx Xxxxxxxxx Xxxxxxxxxxxxxxxxxxx xxxxxxxxxx Xxxxxxxxxx Xxxxxxxxxxxxxxxxx xxxxxxxx Xxxxxxx Xxxxxx Xxxxx Xxxxxxxxxxxxxxxx Xxxx Xxxxxxxxxxxxxxxxxx Item Designation Item Designation Type Driving power in kW Serial no. Customer No. Rated carrying capacity in kg Min./max. -

Page 16: C Transportation And Commissioning

C Transportation and commissioning Transportation by crane Use hoisting equipment with appropriate carrying capacity (refer to the truck ID plate for the truck weight) only. – Remove the blind plugs on the load section and screw in two eye bolts (1). –... -

Page 17: Commissioning

Commissioning Operate the truck on battery power only! Rectified alternate current will damage the electronic components. Cables connected to the battery (trailing cables) must be less than 6 meters in length. To make the truck operational after delivery or transport, perform the following steps: –... -

Page 18: D Battery - Servicing, Recharging, Replacement

D Battery Servicing, recharging, replacement Safety regulations governing the handling of lead-acid batteries The truck must be parked and rendered safe before any operations on batteries are undertaken (refer to chapter E). Servicing staff: Recharging, servicing and replacing of batteries must only be per- formed by qualified personnel. -

Page 19: Battery Types

Battery types Depending on the truck version, the truck is supplied with different battery types. The following table shows the standard combinations, indicating the capacity: 48V - PzS battery, low-maintenance 2 x 500 Ah 48V - PzS battery, maintenance-free 1000 Ah The battery weights can be seen on the battery identification plate. -

Page 20: Charging The Battery

Charging the battery – Park and lock the truck (refer to chapter E). To ensure sufficient ventilation, the surface of low-maintenance battery cells must be exposed during charging. This is not required for maintenance-free types. No metal objects must be placed on the battery. Prior to starting the recharging operation, check all cable connections and plugged connections for visible damage. -

Page 21: Removing And Installing The Battery

Removing and installing the battery – Expose the battery (see section 3). To avoid short circuits, cover batteries with open poles or connectors with a rubber mat. When changing batteries with the aid of a crane, ensure that the crane is of adequate capacity (the battery weight is indicated on the battery identification plate at the battery trough). -

Page 22: Information And Service Display (Lisa)

Information and service display (LISA) Battery discharge indicator: The LISA display indicates the battery discharge state (6) in 10% steps. default, battery discharge indicator / discharge monitor is adjusted to standard batteries. When maintenance-free batteries are used, the indicator must be adjusted such that the T symbol (7) appears after the percentage display. -

Page 24: Safety Regulations Governing The Operation Of The Fork Lift Truck

E Operation Safety regulations governing the operation of the fork lift truck Driving permission: The fork lift truck must only be operated by persons who have been trained in the operation of trucks, who have demonstrated to the user or his rep- resentative their capability of moving and handling loads, and who have expressly been charged by the user or his representative with the operation of the truck. -

Page 25: Description Of Operating And Display Elements

Description of operating and display elements Item Operating and Function display element t Steers truck in desired direction Steering wheel t Indicates important drive and lift parameters; Information and service display (LISA) warnings, notes on incorrect operation and service messages (see section 5) o Switches driver seat heating on and off Switch –... - Page 26 10 11 17 18...

-

Page 27: Starting Up The Truck

Starting up the truck Before starting or operating the truck, or before lifting any loads, the driver has to make sure that nobody is within the danger area. Checks and operations to be performed before starting daily work – Check the entire truck (in particular the wheels and the load lifting device) for obvious damages. - Page 28 Fastening the safety seat belt Fasten the safety seat belt (21) each time you ride on the truck! The seat belt buckle must audibly engage when being closed. Make sure the seat belt (21) runs tightly across your pelvis and is not distorted (do not run it over hard or fragile objects in your pockets).

-

Page 29: Emergency Stop Facility

Emergency stop facility The truck features an emergency stop facility. The steering controller automatically performs a safety test when main switch (11) and key switch (10) have been switched Emergency stop The truck is automatically braked down until it stops if a steering system malfunction occurs during driving that might impair the driver’s safety. -

Page 30: Operation Of The Fork Lift Truck

Operation of the fork lift truck Safety regulations applicable when operating the truck Driving lanes and work areas: Only such lanes and routes that are specially allo- cated for truck traffic must be used. Unauthorized persons must stay away from work areas. -

Page 31: Driving, Steering, Braking

Driving, steering, braking EMERGENCY STOP – Push the main switch (11) down. All electrical functions are switched off. Door contact switch To operate any of the functions, the door contact switch must be actuated (door closed). All functions except that of the battery discharge indicator are disabled if the door contact switch is not actuated. - Page 32 Braking The braking behaviour of the truck is mainly dependent on the ground structure. The driver must take this into account. The truck may be braked in two ways: – Using the service brake – Using the counter-current brake Braking by means of service brake: –...

-

Page 33: Picking Up And Putting Down Load Units

Picking up and putting down load units Before picking up a load unit the driver must make sure that it has been correctly palletised and does not exceed the permissible capacity of the truck. – Insert the fork arms under the load as far as possible. Lifting –... -

Page 34: Troubleshooting

Troubleshooting This chapter allows the user to locate and eliminate simple malfunctions by himself. When trying to locate a fault, proceed in the order shown in the table. Fault Possible cause Remedial action Truck does not – Battery connector not –... -

Page 35: Emergency Steering

Emergency steering Mechanical auxiliary steering The mechanical auxiliary steering must be used to rescue the truck when the electric steering has failed. This may be done by an expert maintenance engineer who has been instructed accordingly only. – Switch off main switch and key switch –... -

Page 36: Electric Emergency Steering Mode

Electric emergency steering mode – Open the driver door and the steering controller (see chapter F). – Actuate the emergency steering switch (25) (brake is released). – Set both steering wheels straight by turning the star grips (24). – The straight position can be verified by inserting a 6-mm pin in the index bores (26). –... - Page 37 E 14...

-

Page 38: F Maintenance Of The Fork Lift Truck

F Maintenance of the fork lift truck Operational safety and environmental protection The checks and servicing operations contained in this chapter must be performed in accordance with the intervals as indicated in the servicing checklists. Modifications of fork lift truck assemblies, especially of the safety installations, are not permitted. - Page 39 Work on the electric system: Work on the electric system of the truck must only be performed by personnel specially trained for such operations. Before commencing any work on the electric system, all measures required to prevent electric shocks have to be taken. For battery-operated fork lift trucks, the truck must also be depow- ered by removing the battery plug.

-

Page 40: Servicing And Inspection

Servicing and inspection Thorough and expert servicing is one of the most important preconditions for safe op- eration of the fork lift truck. The neglect of regular servicing intervals can lead to fork lift truck failure and constitutes a potential hazard to personnel and equipment. The indicated servicing intervals are based on single-shift operation under normal op- erating conditions. -

Page 41: Eke 30-2 Ac Maintenance Checklist

EKE 30-2 ac maintenance checklist Maintenance intervals = t W M M M Standard = k 1 3 6 12 Cold store Chassis/ 1.1 Check all load bearing elements for damage super- 1.2 Check all bolted connections structure: Drive: 2.1 Check transmission for noise and leaks 2.2 Check the transmission oil level... - Page 42 Maintenance intervals = t W M M M Standard = k 1 3 6 12 Cold store Electric 7.1 Function check system: 7.2 Check cables for secure connection and damage 7.3 Check fuses for correct amperage 7.4 Check switches and switch cams for secure seat and proper function 7.5 Check the warning facilities and safety circuits for proper function...

-

Page 43: Eke 30-2 Ac Lubrication Schedule

EKE 30-2 ac lubrication schedule D 0,2 l A + C 0,7 l 3,9 l 140 Nm Glide surfaces Lubricating nipples Hydraulic oil filler neck Gear oil filler neck Gear oil drain plug Cold store application Brake fluid filler neck... -

Page 44: Fuels, Coolants And Lubricants

Fuels, coolants and lubricants Handling consumption type material: Consumption type material must always be handled properly. Manufacturer's instructions to be observed. Improper handling is injurious to health, life, and environment. Consumption type ma- terials must be stored in adequate containers. They might be inflammable and, there- fore, must not come into contact with hot components or open fire. -

Page 45: Notes On Maintenance

Notes on maintenance Preparing the truck for servicing and maintenance operations All required safety measures must be taken to prevent any accidents in the course of the servicing and maintenance operations. The following preparatory operations must be performed: – Park and lock the truck (refer to chapter E). –... -

Page 46: Opening The Steering Controller

Opening the steering controller – Loosen the screw (4) und remove it. – Carefully swing down the steering controller (5). – Loosen and remove the screws (6) of the ventilation plate (7). – Remove the ventilation plate. – Loosen and remove the screws (8) of the cover plate (9). –... -

Page 47: Checking Electric Fuses

Checking electric fuses – Preparing the truck for servicing and maintenance operations (see section 6.1). – Open the steering controller (see section 6.4). – Check all fuses for correct ratings as per the table and replace them if necessary. 20 19 18 17 16 15 Item Designation Protects:... -

Page 48: Recommissioning The Truck

Recommissioning the truck Recommissioning of the truck following the performance of cleaning or maintenance work is permitted only after the following operations have been performed: – Check the horn for proper functioning. – Check the master switch for correct functioning. –... -

Page 49: Recommissioning The Truck

Recommissioning the truck – Thoroughly clean the fork lift truck. – Lubricate the fork lift truck according to the lubrication chart (refer to chapter F). – Clean the battery. Grease the pole screws using pole grease and reconnect the battery. –...

Need help?

Do you have a question about the EKE 30-2 ac and is the answer not in the manual?

Questions and answers