Table of Contents

Advertisement

MODELS

S4L(X

), S4LRC/S4LVX

*

S4B(X

), S4K(X

*

S6L(X

), S6A(X

*

Used in Hazardous Locations Class I, Division 1

*

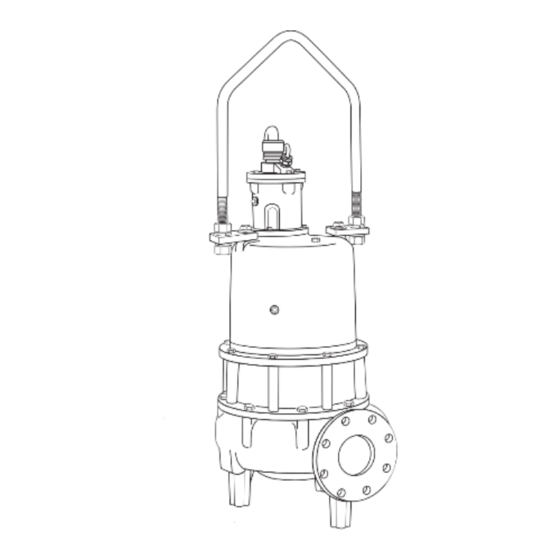

SUBMERSIBLE

SOLIDS HANDLING PUMPS

INSTALLATION AND SERVICE MANUAL

For use with product built with USEM motor.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-491 | Part # 5625-491-1 | © 2014 Pentair Ltd. | 08/25/14

), H4Q(X

*

) and S8F(X

*

,

*

),

*

)

*

Motor End)

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Pentair Hydromatic S4BX

- Page 1 NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Item # E-03-491 | Part # 5625-491-1 | © 2014 Pentair Ltd. | 08/25/14...

- Page 2 the sensing unit at ground surface sensors automatically reset when General causing a red light to flash. The motor cools to safe temperature. Information electrode probe is installed in The sensors are connected in all units, but the sensing unit is This manual contains important series with the motor starter coil supplied at extra cost and must...

- Page 3 Overload Heaters: pump. Extra floats with ap pro pri- prevent freezing. This can be done ate controls can be supplied for only with short discharge lines, If the Hydromatic electrical panel alarm functions. Triplex systems otherwise water will return to the is not used, starters with 3 leg use four controls: one set at sump and cause short cycling of...

- Page 4 IMPORTANT: If equipment The size wire to use from panel to pump starts. Allow pump to is not properly wired and sump depends on motor size and operate until the level drops distance in feet. protected as recommended, the to turn-off point. warranty is void.

- Page 5 If the leads to the connection the hazardous location rating of Pump box are burned, a complete the pump and com ply with our new con nec tion box with new Maintenance warranty re quire ments. wire must be used. The wires NOTE: Any unauthorized field Field Service on Motor: are potted in with sealing...

- Page 6 10. Replace stator housing onto 3. Remove bolts that hold seal 12. Examine all O-rings for nicks seal chamber and bolt in cham ber to pump housing. before using. place. Be sure seal failure Use back-off screws to break 13. Use Locktite on socket head ®...

-

Page 7: Troubleshooting

Pump does not deliver Pump proper capacity. Troubleshooting 1. Discharge gate valve may The following is a list of common be partially closed or problems and their probable causes. partially clogged. Pump will not start. 2. Check valve may be partially clogged. - Page 8 Wet End Components S4LVX S4L(X) S4LRC S4B(X) H4Q(X) S4K(X) S6L(X) S6A(X) S8F(X)

- Page 9 Wet End Parts List For use with product built with USEM motor. Item S4LRC S4LRC/ Description S4B(X) S4L(X) S6A(X) S6L(X) S8F(X) S4K(X) H4Q(X) 3450 RPM S4LVX SCREW – HHC 5/8-11 UNF x 1-1/4 005700181 005700181 005700181 005700181 005700181 005700181 005700181 005700181 005700181 019450001...

- Page 10 Standard Location S4L, S4LRC, S4B, S4K, H4Q, S6L, S6A and S8F Motor End Components...

- Page 11 Standard Location S4L, S4LRC, S4B, S4K, H4Q, S6L, S6A and S8F Motor End Parts List For use with product built with USEM motor. Ref. Part Part Ref. Part Part Ref. Part Part Description Qty. Description Qty. Description Qty. 05454A027 WASHER – LOCK 5/8 SST 029210011 SCREW –...

- Page 12 Hazardous Location S4LX, S4LVX, S4BX, S4KX, H4QX, S6LX, S6AX and S8FX Motor End Components...

- Page 13 Hazardous Location S4LX, S4LVX, S4BX, S4KX, H4QX, S6LX, S6AX and S8FX Motor End Parts List For use with product built with USEM motor. Ref. Part Part Ref. Part Part Ref. Part Part Description Qty. Description Qty. Description Qty. 001500191 0-RING 1/8 x 6.734 I.D. 109010001 TERMINAL –...

- Page 14 Hazardous Location S4LX, S4LVX, S4BX, S4KX, H4QX, S6LX, S6AX and S8FX Motor End Parts List (Continued) For use with product built with USEM motor. 4-Pole 1750 RPM 4Pole 1750 RPM 10 hp 10 hp 10 hp 15 hp 15 hp 15 hp Item Description...

-

Page 15: Wiring Diagrams

Wiring Diagrams PROBE TEST RESISTOR ON HAZARDOUS LOCATION ONLY – PROBE TEST RESISTOR PROBE TEST RESISTOR ON HAZARDOUS LOCATION ONLY ON HAZARDOUS LOCATION ONLY – –... - Page 16 Pentair Hydromatic will cover only the lower seal and labor thereof for all dual seal pumps. under no circumstance will Pentair Hydromatic be responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight expenses to and from the factory or an authorized Pentair Hydromatic service facility.

- Page 17 NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Item # E-03-314 | Part # 5625-314-1 | © 2013 Pentair Ltd. | 11/26/13...

-

Page 18: General Information

operate without damage, but the seal Three pumps operate together only if General Information should be checked immediately after sump level rises to the fourth control failure is indicated. (second override). This control also Attention: brings on the third pump in case of failure The sensing unit is recommended on all This manual... - Page 19 Installing Float Switch Controls: Making Electrical Connections: A check valve must be installed on each pump. A gate or plug valve in each pump The controls are supported by a mounting All electrical wiring must be in discharge line is also recommended. bracket that is attached to sump wall or accordance with the local codes, This valve should be installed on the...

- Page 20 6. Turn both H-O-A switches is not taken to an authorized Hydromatic 8. Check bearing. clean to Auto position and allow sump to service center. and does not turn rough, bearings fill to the override control level. can be reused and it is not necessary When field service is performed on to completely dismantle pump to 7.

-

Page 21: Pump Troubleshooting

Replacing Seals and Bearings: Pump runs but will not shut off. 12. Examine all O-rings for nicks before using. 1. Drain all oil from motor chamber and 1. Pump may be air locked. Turn pump seal chamber as described. off and let set for several minutes, 13. - Page 22 S4L Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 060000035 Wire & Terminal Assy. – (Prior to 5/1/78) 060000211 Wire & Terminal Assy. – (Present) 005570001 Wire Connector Rotor & Shaft 000640051 Bearing Spring Stator 025970022...

- Page 23 S4B Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 001500121 O-Ring 005570001 Con nec tor 060000211 Wire & Terminal Assy. 000640051 Bearing Spring Cord Cap Assy. – 35' 062370005 Conn Box Assy. – 230/460 062370015 Conn Box Assy.

- Page 24 S4K Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 001500121 O-Ring 005570001 Con nec tor Cord Cap Assy. – 35' 025970022 Motor Housing – 20 hp 048320012 Motor Housing – 25–40 hp 062370005 Conn Box Assy.

- Page 25 S4Q Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. Cord Cap Assy. – 30' 005570001 Con nec tor Stator 076650001 Spacer – 10–20 hp, 1750 RPM 062370005 Conn Box Assy. – 230/460 062370015 Conn Box Assy.

- Page 26 H4Q Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. Cord Cap Assy. – 35' 005570001 Con nec tor 062370005 Conn Box Assy. – 230/460 062370015 Conn Box Assy. – 200/575 076650001 Spacer – 10–20 hp, 1750 RPM 024980041 Wire Connector –...

- Page 27 S4LRC – 1750 RPM Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. Stator 000730011 Wire Connector 025970022 Motor Housing – 20 hp & below 048320012 Motor Housing – 25 hp & above, 15 hp, 1150 RPM 000640051 Bearing Spring –...

- Page 28 S4LRC – 3450 RPM Parts List For use with product built with GE motor. ® Part Part Part Part Part Part Description Qty. Description Qty. Description Qty. 19101A010 Screw – HHC 3/8-16 x 1" 009750061 Ring – Retaining Stator 021500121 O-Ring –...

- Page 29 S6A Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 001500121 O-Ring 005570001 Con nec tor Stator 076650011 Spacer – 3–15 hp, 1150 RPM 076650001 Spacer – 10–20 hp, 1750 RPM 076650061 Spacer – 3–5 hp, 870 RPM Cord Cap Assy.

- Page 30 S6L Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 060000035 Wire & Terminal Assy. – (Prior to 5/1/78) 060000211 Wire & Terminal Assy. – (Present) 000730011 Wire Connector Rotor & Shaft 000640051 Bearing Spring Stator 025970022...

- Page 31 S8F Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 060000211 Wire & Terminal Assy. – (Present) 000730011 Wire Connector Rotor & Shaft 000640051 Bearing Spring Stator 025970022 Motor Housing – (20 hp and Below) 048320012 Motor Housing –...

- Page 32 Pentair Hydromatic will cover only the lower seal and labor thereof for all dual seal pumps. under no circumstance will Pentair Hydromatic be responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight expenses to and from the factory or an authorized Pentair Hydromatic service facility.

Need help?

Do you have a question about the Hydromatic S4BX and is the answer not in the manual?

Questions and answers