Table of Contents

Advertisement

H36.0.12.6C-09

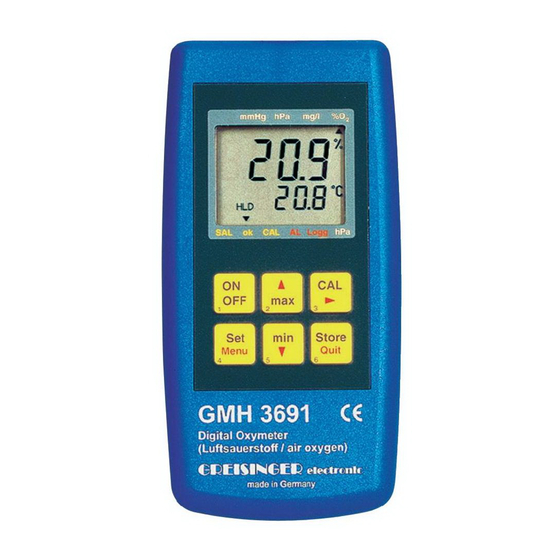

Hand-held measuring device with alarm function

for gaseous oxygen and temperature

GMH 3691

Operating Manual

as of version V1.6

WEEE-Reg.-Nr. DE93889386

GREISINGER

electronic GmbH

D - 93128 Regenstauf, Hans-Sachs-Straße 26

+49 (0) 9402 / 9383-0

+49 (0) 9402 / 9383-33

info@greisinger.de

Advertisement

Table of Contents

Summary of Contents for GREISINGER GMH 3691

- Page 1 H36.0.12.6C-09 Hand-held measuring device with alarm function for gaseous oxygen and temperature GMH 3691 Operating Manual as of version V1.6 WEEE-Reg.-Nr. DE93889386 GREISINGER electronic GmbH D - 93128 Regenstauf, Hans-Sachs-Straße 26 +49 (0) 9402 / 9383-0 +49 (0) 9402 / 9383-33...

-

Page 2: Table Of Contents

Designated Use The GMH 3691 measures the oxygen partial pressure and the oxygen concentration in gas mixtures and air. For the measurement a external sensor of the type GOO ... or GGO ... is required. The measurement takes place at the opening of the external sensor. -

Page 3: Operating And Maintenance Advice

H36.0.12.6C-09 Operating Manual GMH 3691 page 3 of 12 Operating and Maintenance Advice a) When to replace battery: and ´bAt´ are shown in the lower display the battery has been used up and needs to be replaced. The de- vice will, however, operate correctly for a certain time. -

Page 4: Display And Control Elements

H36.0.12.6C-09 Operating Manual GMH 3691 page 4 of 12 Display and control elements 5.1 Display elements Display with two sensors connected: Main display: possible views: mmHg mg/l Oxygen concentration in % (% O Oxygen partial pressure (hPa) Secondary display: °C Sensor temperature (°C or °F) -

Page 5: Pushbuttons

H36.0.12.6C-09 Operating Manual GMH 3691 page 5 of 12 5.2 Pushbuttons On/off key min/max when taking measurements: press shortly: min. or max. measuring value will be displayed press for 1 sec.: the min. or max. value will be deleted up/down for configuration:... - Page 6 H36.0.12.6C-09 Operating Manual GMH 3691 page 6 of 12 ’AL.’: Alarm Functions mmH g mg/l off: alarm function switched off No.So: alarm function active, alarm will be displayed by the 'AL'-arrow alarm function active, alarm will be displayed by the 'AL'-arrow,...

-

Page 7: Notes To Special Functions

H36.0.12.6C-09 Operating Manual GMH 3691 page 7 of 12 Notes to Special Functions 7.1 Input of absolute pressure ('P.Abs') To get most accurate measurings the absolute pressure should be inspected both before calibration and measuring. The determining pressure is the actual pressure at the sensor membrane. Keep in mind that gas flows may change the absolute pressure at the membrane and therefore may cause measuring errors! 7.2 Zero Displacement (’Offset’) temperature... -

Page 8: Calibration Of The Oxygen Sensor

H36.0.12.6C-09 Operating Manual GMH 3691 page 8 of 12 Calibration of The Oxygen Sensor In order to compensate for ageing of the sensor, the sensor has to be calibrated at regular intervals. The device is equipped with two easy to handle calibration functions. We recommend to calibrate at least once a week or, for optimum measuring results, directly before starting the measuring process. -

Page 9: Error And System Messages

H36.0.12.6C-09 Operating Manual GMH 3691 page 9 of 12 10 Error And System Messages Display Description / Reason Remedy No sensor Connect sensor or sensor defective sensor defective => return sensor to manufac- turer for repair Low battery voltage replace battery... -

Page 10: The Serial Interface

H36.0.12.6C-09 Operating Manual GMH 3691 page 10 of 12 check calibration environment (p.r.t. 'Calibration input signal (O2-partial pressure) to of the oxygen sensor'). If error are unremedied high ERR.6 replace sensor element. 11 The serial interface All measuring data and settings of the device can be read and changed by means of the serial interface and a suit- able electrically isolated interface adapter (GRS3100, GRS3105 or USB3100). -

Page 11: Specification

H36.0.12.6C-09 Operating Manual GMH 3691 page 11 of 12 12 Specification Measuring range: Oxygen concentration 0.0 ... 100.0 % O Oxygen partial pressure 0 ... 1100 hPa Sensor temperature -20.0 ... 50.0 °C Pressure range 500 ... 2000 hPa abs. - Page 12 H36.0.12.6C-09 Operating Manual GMH 3691 page 12 of 12...

- Page 13 -partial pressure Alarm detector with integrated horn Automatic temperature compensation Min./Max. value memory, Hold function Serial interface, device can be connected to bus system (up to 5 devices can be con- nected to one PC interface) Battery and d.c. operation GMH 3691 GOG Wide range of application Application: Most simple calibration in atmospheric air Essentially there, where delicate products are conserved by low-oxygen atmospheres (protec- tive gas), this instrument is suitable to check the GMH 3691 Sensor not included - please order separately! residual oxygen content. packaging industry ...

Need help?

Do you have a question about the GMH 3691 and is the answer not in the manual?

Questions and answers