Subscribe to Our Youtube Channel

Summary of Contents for Fromm P404

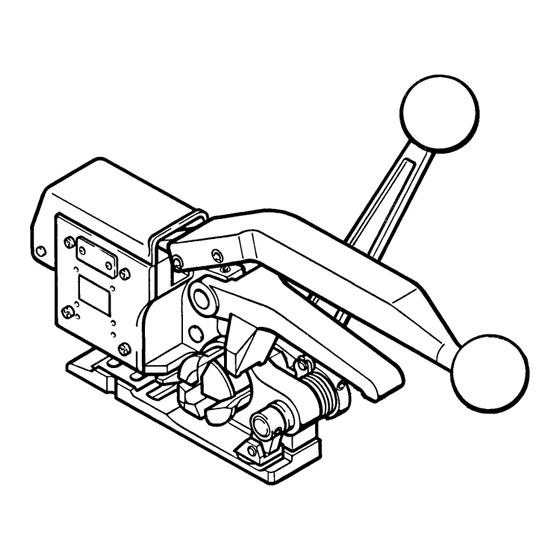

- Page 1 OPERATION MANUAL / SPARE PARTS LIST MANUAL PLASTIC STRAPPING TOOL MODEL P404 43.0404.02...

-

Page 2: Table Of Contents

INDEX PAGE SAFETY INSTRUCTIONS TECHNICAL DATA OPERATION ELEMENTS ADJUSTMENT OF THE STRAP THICKNESS OPERATION SPARE PARTS LIST 43.0404.02 EXCHANGE OF WEARING PARTS Exchange of the cutter ....12 Exchange of gripper and gripping jaw . -

Page 3: Technical Data

Joints You are fully responsible to review the joints made by your tool. Become familiar with the seal control and seal adjustment described in this operation manual. Misformed joints may not secure the load and could cause serious injury. Never handle or ship any load with improperly formed joints. -

Page 4: Operation Elements

Strap Qualities Polypropylene, plain or embossed Polyester, plain or embossed Seals P404 / 16 MM Item No.: 41.5082 Joint strength Depending on the strap quality the joint strength varies between 40 to 80 % of the breaking strength of the strap. -

Page 5: Adjustment Of The Strap Thickness

ATTENTION! Before starting using the tool it has to be adjusted to the strap thickness used! ADJUSTMENT OF THE STRAP THICKNESS In order to achieve the highest possible Pos. 2 P40.2511 seal efficiency the tool must be adjusted to the respective strap thickness through the Pos. - Page 6 Inserting the lower strap The lifting handle is raised with the right hand. The lower strap is inserted into the seal and the stop behind the gripper respectively. The strap end should slightly protrude the seal. By lowering the lifting handle the strap is clamped in its position.

- Page 7 Cutting off of the plastic strap By raising the lifting handle the gripper is released and the plastic strap is cut off. Removing the tool Remove the tool from the strap to the right with the lifting handle in a raised position. Straightening the plastic strap Remove the strap from the tensioning drum and straighten the strap bent by the winding of the...

- Page 8 N2.2441 N2.1128 P40.2018 P40.2017 P40.2513 ➂ N11.1154 N2.1122 ➀ A43.1207 N2.5211 N3.3150 N1.6226 P40.2517 N7.1207 ➀ N3.3148 P40.0101 ➀ P40.2504 P40.2501 N2.1609 ➀ N1.3511 P40.2516 P40.2511 ➀ N2.5234 P40.2515 ➀ N2.5820 N3.3171 P40.2523 N2.4902 N2.2185 N1.2104 P40.2503 N3.3167 P40.0102 ➀ ➀...

- Page 9 P40.2514 N4.1116 P40.0103 N1.3106 N1.5131 N1.3508 P40.2528 P40.2030 P40.2518 ➀ N3.3113 ➀ A33.3111 ➀ N2.5154 P40.2029 ➀ P40.2004 N3.3113 N2.2709 ➀ A43.1207 P40.2029 ➀ N3.2609 P40.2025 N2.2457 N2.2709 N2.5819 P40.2028 N3.3151 N2.2185 N2.2185 P40.2520 N4.5120 N2.2806 P40.2024 ➀ P40.2509 ➀ ➁...

-

Page 10: Spare Parts List 43.0404.02

SPARE PARTS LIST 43.0404.02 43.0404.02 P404/15-16/0.50-0.90 P404.0001.02 12.01.00 Item-No. in group Pcs. description Dimension Field A33.3111 2 CATCH PAWL A43.1207 2 DISK N11.1154 2 SCREW M10 X 97 N1.1125 3 SCREW M6 X 16 N1.1162 2 SCREW M3 X 12 N1.1909... - Page 11 43.0404.02 P404/15-16/0.50-0.90 P404.0001.02 12.01.00 Item-No. in group Pcs. description Dimension Field [P40.0104] 1 BASE PLATE P40.2004 1 TENSION SHAFT P40.2012 1 HOLDING-DOWN CLAMP P40.2017 1 ROD BAR P40.2018 1 BUSH P40.2024 1 SHAFT P40.2025 1 LEVER P40.2028 1 HINGE P40.2029 2 SPLIT-PIN BOLT P40.2030...

-

Page 12: Exchange Of Wearing Parts

EXCHANGE OF WEARING PARTS Exchange of the cutter Disassembly Remove screw with pivot P40.2045 including safety disk N1.6504. The lower cutter P40.2524 is lifted against the sealing lever by operating the lifting handle. Insert a screw driver into the boring of the lower side of the cutter. Lift out the cutters complete with bolt P40.2526 and the cup springs N2.5614 from the support. -

Page 13: Exchange Of Gripper And Gripping Jaw

Exchange of gripper and gripping jaw Drive out the spirally rolled pin N2.2806 using a split pin driver. Remove the clamping lever P40.2520 with the pin P40.2522 and the gripping jaw P40.2521. Screw off and exchange the gripper P40.2053. Reassemble in the opposite order. *Depending on the strap thickness 2, 1 or no shim P40.2052 must be assembled under the gripping jaw. -

Page 14: Warranty Conditions And Liability

WARRANTY CONDITIONS AND LIABILITY FROMM Holding AG warrants all its strapping tools and machine heads during a period of 90 days from the date of sale. The warranty includes all deficiencies clearly resulting from poor manufacturing or faulty materials. Damage claims as a result of production shutdowns and claims for damage to persons and to property resulting from warranty deficiencies cannot be asserted by the customer.

Need help?

Do you have a question about the P404 and is the answer not in the manual?

Questions and answers