Table of Contents

Advertisement

Quick Links

Waterstage 3 phase

Document 1394-1 ~ 29/01/2010

EN

FR NL

DE

IT

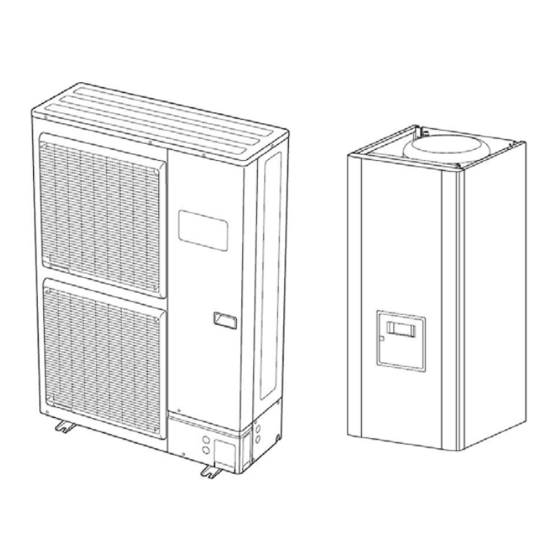

Air/Water Heat Pump

Split System, Single Service 3 phase

112, 140 and 160

Maintenance

Document

Intended for

professional use

Fujitsu General (Euro) GmbH

Werftstrasse 20

40549 Düsseldorf - Germany

Subject to change without notice

Non contractual document

29/01/2010

Advertisement

Table of Contents

Summary of Contents for Fujitsu WATERSTAGE 112

- Page 1 FR NL Air/Water Heat Pump Split System, Single Service 3 phase 112, 140 and 160 Maintenance Document Intended for professional use Fujitsu General (Euro) GmbH Werftstrasse 20 40549 Düsseldorf - Germany Subject to change without notice Non contractual document 29/01/2010...

-

Page 3: Table Of Contents

Contents Technical Characteristics ....................6 Specifications .........6 1.2.4 Performance Curves for Waterstage 140..............7 Performance Data ......6 1.2.5 Performance Curves for Waterstage 1.2.1 Rated Performance......6 160..............8 1.2.2 Maximum Stated Performance ..6 Hydraulic Characteristics ....8 1.2.3 Performance Curves for Waterstage Refrigeration Diagram....9 112..............7 Installation Rules ......................10 Heat Pump ........10 2.2.2... - Page 4 Heat Pump, Split System, Single Service, 3 phase Control Settings ......................63 General ........63 6.3.8 Heat Pump Functions ....92 6.3.9 DHW Tank Functions ....93 Function Table ......63 6.3.10 Configuration Functions....95 Adjustment Function Details ..69 6.3.11 Error Functions ......97 6.3.1 Date and Time Functions....

- Page 5 Heat Pump, Split System, Single Service, 3 phase 12 Related Documents ....................131 12.1 Quick-Start Procedure....131 12.3 Settings Sheet......134 12.2 Startup Checklist ......132 12.4 Startup Data Sheet ....135 Maintenance Document 1394-1...

-

Page 6: Technical Characteristics

Heat Pump, Split System, Single Service, 3 phase Technical Characteristics Specifications WATERSTAGE WATERSTAGE WATERSTAGE Heating system operating limits Exterior temp mini/maxi °C -20/+35 Initial max heating water temperature - Floor heating system °C - Low temperature radiator °C Flow min heating water temperature °C Performance Data 1.2.1 Rated Performance... -

Page 7: Performance Curves For Waterstage 140

Heat Pump, Split System, Single Service, 3 phase 1.2.3 Performance Curves for Waterstage 112 1.2.4 Performance Curves for Waterstage 140 Maintenance Document 1394-1... -

Page 8: Hydraulic Characteristics

Heat Pump, Split System, Single Service, 3 phase 1.2.5 Performance Curves for Waterstage 160 Hydraulic Characteristics WATERSTAGE WATERSTAGE WATERSTAGE HEAT PUMP Connection diameter 1’’ – 25.4 mm (male) Exchanger tank volume (L) Expansion vessel volume (L) Max pressure water circuit (Bar) Max flow rate (l/h) 2400 3000... -

Page 9: Refrigeration Diagram

Heat Pump, Split System, Single Service, 3 phase Refrigeration Diagram Outdoor Unit Hydraulic Unit Expansion vessel Circulation pump Pressure Strainer check valve Hot water 4- Way column sensor Pressure sensor valve Air bleeding valve Accumulator Heat Heating exchanger Auxiliary heater unit (Floor heating,... -

Page 10: Installation Rules

Heat Pump, Split System, Single Service, 3 phase 2 Installation Rules Heat Pump 2.1.1 Outdoor Units In snowy areas: raise the outdoor unit by a height equal to the maximum height of snow cover plus 20cm. Maintenance Document 1394-1... -

Page 11: Hydraulic Unit

Heat Pump, Split System, Single Service, 3 phase 2.1.2 Hydraulic Unit Minimum clearance dimensions must be provided > Warning! < around the appliance as shown on the drawing, to Maintain a distance of at least 20 cm between enable the machine to be serviced. the unit and the ceiling to allow replacement of heaters. -

Page 12: User Interface

Heat Pump, Split System, Single Service, 3 phase Control Terminal 2.2.1 Room Unit The room thermostat gives the user access to the In addition, the room thermostat shows the user the following basic functions: following information: • • Adjustment of the room temperature setting by the current temperature simply turning the knob •... - Page 13 Heat Pump, Split System, Single Service, 3 phase Select heating mode Adjust comfort setpoint temperature The comfort setpoint is adjusted directly by turning Auto mode the knob, the value must be confirmed with the OK The temperature is controlled automatically: key.

-

Page 14: Electrical Connections

Heat Pump, Split System, Single Service, 3 phase Electrical Connections 2.3.1 Installation Precautions All machines in the ATW Split System Inverter range Protections will be of the omnipolar, D curve circuit are designed to operate at 3x400V 50Hz. Power breaker type, with a contact opening distance of at supplies must be compliant with NFC 15-100. - Page 15 Heat Pump, Split System, Single Service, 3 phase Hydraulic Unit Connection Outdoor Unit Connection The wiring of all Waterstage outdoor units is as follows: Maintenance Document 1394-1...

- Page 16 Heat Pump, Split System, Single Service, 3 phase 2.3.3 Hydraulic Unit Connection Diagram * If the control device does not provide a potential-free contact, the contact must be relayed to create equivalent wiring. In all cases, please refer to the instruction manuals for the external components (load limiting device, power meters) to create the wiring.

-

Page 17: Getting Started

Heat Pump, Split System, Single Service, 3 phase 3 Getting Started Checks 3.1.1 Outdoor Unit 3.1.5 Refrigeration System • Unit is secured to a stable surface • Make sure connections are compliant (diameters, • Unit is raised in regions of regular snowfall minimum and maximum lengths) •... -

Page 18: Manual Adjustment

Heat Pump, Split System, Single Service, 3 phase Settings Depending on their associated functions, the control To adjust the various settings: • settings are not accessed at the same level. There From the main menu, after obtaining the desired are 4 levels of access: level U: end-user level •... - Page 19 Heat Pump, Split System, Single Service, 3 phase Heating Curves 1,75 1,25 0,75 0,25 20,0 15,0 10,0 -5,0 -10,0 -15,0 -20,0 Outdoor Temperature (°C) Graph 1: Heating Curves The heating curves shown above refer to a 20°C The heating curve offset (setting 721) changes the room temperature setpoint.

-

Page 20: Auto Adapt Adjustment

Heat Pump, Split System, Single Service, 3 phase 3.3.2 Auto Adapt Adjustment When this function has been activated (setting 726) • the room in which the room sensor is installed the heating curve is automatically adjusted, and must not contain any thermostatic valves. If it therefore, there is no need to change the slope or does, these valves must be fully opened. -

Page 21: Principle Of Operation

Heat Pump, Split System, Single Service, 3 phase 3.5.1 Principle of Operation DHW production starts when the temperature inside that input E5 is wired as shown on Figure 1: Typical the tank is 7°C less than the setpoint temperature. Wiring of External Devices. The setpoint can be either a "reduced"... -

Page 22: Output Test Mode

Heat Pump, Split System, Single Service, 3 phase 3.6.2 Output Test Mode LINE OUTPUT WATERSTAGE 7700 QX23 (1) Circuit 1 heating pump or swimming pool selection valve QX21 (1) Open mixing valve 1 QX22 (1) Close mixing valve 1 DHW heating circuiting pump (if connected) Circuit 2 heating pump DHW selection valve Boiler selection valve (or heater 1) -

Page 23: Faults

Heat Pump, Split System, Single Service, 3 phase 4 Faults Fault List 4.1.1 Hydraulic Unit Fault Faults which occur on the Hydraulic Unit are shown Manual delete: the text displayed when pressing the info key shows "reset ?". Press OK once, the by the symbol . - Page 24 Heat Pump, Split System, Single Service, 3 phase Faults external to the heat pump Any safety device (e.g. thermostat pressure switch) stopped. For example, a safety thermostat on the wired to input Ex6 (E20) allows external problems to heating floor can be wired to input Ex6 (E20) to avoid be reported and the heat pump to be immediately excessively high temperatures in the floor.

-

Page 25: Outdoor Unit Fault

Heat Pump, Split System, Single Service, 3 phase 4.1.2 Outdoor Unit Fault When the system is switched back on after a power If it doesn't, if a fault has occurred on the outdoor unit outage, the Hydraulic Unit may display fault 370 for a as indicated by the Hydraulic Unit, you must remove few tens of seconds. -

Page 26: Outdoor Unit Clearing

Heat Pump, Split System, Single Service, 3 phase Outdoor Unit Clearing This section describes the techniques which can be used to identify the failure. 4.2.1 Failures with Error Code Clear 1: Serial reverse transfer error Hydraulic Unit LED: Green 1 flash / Red 1 flash Outdoor Unit LED: Off Probable causes: •... - Page 27 Heat Pump, Split System, Single Service, 3 phase Clear 2: Serial forward transfer error Hydraulic Unit LED: Green 1 flash / Red 1 flash Outdoor Unit LED: 1 flash Probable causes: • Misconnection. • External cause. • Interface PCB failure. Check: 1-1.

- Page 28 Heat Pump, Split System, Single Service, 3 phase Clear 4: Heat pump capacity signal error Hydraulic Unit LED: Green 4 flashes / Red 1 flash Outdoor Unit LED: 22 flashes Probable causes: • Misconnection. • Sensor failure. • Interface PCB failure. Check: 1.

- Page 29 Heat Pump, Split System, Single Service, 3 phase Clear 5: Hydraulic Unit Heat exchanger thermistor error Hydraulic Unit LED: Green 4 flashes / Red 2 flashes Outdoor Unit LED: 22 flashes Probable causes: • Misconnection. • Sensor failure. • Interface PCB failure. Check: 1.

- Page 30 Heat Pump, Split System, Single Service, 3 phase Clear 7: Discharge thermistor error Hydraulic Unit LED: Green 7 flashes / Red 1 flash Outdoor Unit LED: 2 flashes Probable causes: • Misconnection. • Sensor failure. • Main PCB failure. Check: 1.

- Page 31 Heat Pump, Split System, Single Service, 3 phase Clear 8: Heat-exchange thermistor (outlet) error : Hydraulic Unit LED: Green 7 flashes / Red 3 flashes Outdoor Unit LED: 4 flashes Probable causes: • Misconnection. • Sensor fault. • Main PCB failure. Check: 1.

- Page 32 Heat Pump, Split System, Single Service, 3 phase Clear 9: Outdoor temperature thermistor error Hydraulic Unit LED: Green 7 flashes / Red 4 flashes Outdoor Unit LED: 7 flashes Probable causes: • Misconnection. • Sensor failure. • Main PCB failure. Check: 1.

- Page 33 Heat Pump, Split System, Single Service, 3 phase Clear 10: Heat Sink Thermistor (inverter) error Hydraulic Unit LED: Green 7 flashes / Red 7 flashes Outdoor Unit LED: 9 flashes Probable causes: • Misconnection. • Sensor failure. • Inverter PCB failure. Check: 1.

- Page 34 Heat Pump, Split System, Single Service, 3 phase Clear 11: Compressor thermistor error Hydraulic Unit LED: Green 7 flashes / Red 2 flashes Outdoor Unit LED: 8 flashes Probable causes: • Misconnection. • Sensor failure. • Main PCB failure. Check: 1.

- Page 35 Heat Pump, Split System, Single Service, 3 phase Clear 12: Heat-exchange thermistor (intermediate) error Hydraulic Unit LED: Green 7 flashes / Red 3 flashes Outdoor Unit LED: 5 flashes Probable causes: • Misconnection. • Sensor failure. • Main PCB failure. Check: 1.

- Page 36 Heat Pump, Split System, Single Service, 3 phase Clear 13: Heat sink thermistor (P.F.C.) error Hydraulic Unit LED: Green 7 flashes / Red 7 flashes Outdoor Unit LED: 10 flashes Probable causes: • Misconnection. • Sensor failure. • Main PCB failure. Check: 1.

- Page 37 Heat Pump, Split System, Single Service, 3 phase Clear 14: Expansion valve thermistor error Hydraulic Unit LED: Green 7 flashes / Red 8 flashes Outdoor Unit LED: 6 flashes Probable causes: • Misconnection. • Sensor failure. • Main PCB failure. Check: 1.

- Page 38 Heat Pump, Split System, Single Service, 3 phase Clear 15: Current trip (permanent stoppage) Hydraulic Unit LED: Green 9 flashes / Red 4 flashes Outdoor Unit LED: 13 flashes Probable causes: • Connection failure. • Outdoor Heat Exchanger clogged. • Outdoor Fan operation failure.

- Page 39 Heat Pump, Split System, Single Service, 3 phase Clear 17: Compressor startup error (permanent stoppage) Hydraulic Unit LED: Green 9 flashes / Red 5 flashes Outdoor Unit LED: 15 flashes Probable causes: • Misconnection of the various electrical components. • Inverter PCB failure.

- Page 40 Heat Pump, Split System, Single Service, 3 phase Clear 18: Fan motor error (permanent stoppage) Hydraulic Unit LED: Green 9 flashes / Red 7 flashes Outdoor Unit LED: 16 flashes (fan 1), 17 flashes (fan 2) Probable causes: • Fan motor failure. •...

- Page 41 Heat Pump, Split System, Single Service, 3 phase Clear 20: Inverter error Hydraulic Unit LED: Green 6 flashes / Red 3 flashes Outdoor Unit LED: 18 flashes Probable causes: • Connection failure. • Main PCB failure. • Inverter PCB failure. Check: 1.

- Page 42 Heat Pump, Split System, Single Service, 3 phase Clear 22: Discharge temperature protection (permanent stoppage) Hydraulic Unit LED: Green 10 flashes / Red 1 flashes Outdoor Unit LED: 11 flashes Probable causes: • Valve is close. • EEV failure. • Gas leak, less.

- Page 43 Heat Pump, Split System, Single Service, 3 phase Clear 24: Pressure sensor error Hydraulic Unit LED: Green 8 flashes / Red 6 flashes Outdoor Unit LED: 3 flashes Probable causes: • Connector connection failure. • Pressure Sensor failure. • Main PCB failure. Check: 1.

- Page 44 Heat Pump, Split System, Single Service, 3 phase Clear 25: Compressor temperature protection (permanent stoppage) Hydraulic Unit LED: Green 10 flashes / Red 3 flashes Outdoor Unit LED: 12 flashes Probable causes: • Valve is close. • EEV failure. • Gas leak, less.

- Page 45 Heat Pump, Split System, Single Service, 3 phase Clear 26: Low pressure abnormal Hydraulic Unit LED: Green 10 flashes / Red 5 flashes Outdoor Unit LED: 20 flashes Probable causes: • Connector connection failure. • Pressure Sensor failure. • Main PCB failure. •...

- Page 46 Heat Pump, Split System, Single Service, 3 phase Clear 27: P.F.C. error Hydraulic Unit LED: Green 6 flashes / Red 4 flashes Outdoor Unit LED: 19 flashes Probable causes: • Connector connection failure. • Main PCB failure. • PFC PCB failure. Check: 1.

- Page 47 Heat Pump, Split System, Single Service, 3 phase Clear 33: Detection of compressor position error (permanent stoppage) Hydraulic Unit LED: Green 9 flashes / Red 5 flashes Outdoor Unit LED: 14 flashes Probable causes: • Misconnection. • Inverter PCB failure. Check: 1.

-

Page 48: Failures With No Error Code

Heat Pump, Split System, Single Service, 3 phase 4.2.2 Failures With No Error Code Clear 35: No voltage on Hydraulic Unit Probable causes: • Power supply fault. • External causes. • Faulty electrical components. Check: 1. Check the installation : - Is the circuit breaker cut off? - Check the wiring. - Page 49 Heat Pump, Split System, Single Service, 3 phase Clear 36: No voltage on outdoor unit Probable causes: • Power supply fault. • External cause. • Faulty electrical components. Check: 1. Check the installation - Is the circuit breaker cut off? - Check the wiring.

- Page 50 Heat Pump, Split System, Single Service, 3 phase Clear 38: No heat Probable causes: • Hydraulic Unit error. • Outdoor unit error. • Influence from the outdoor environment. • Misconnections of connectors and cables. • Refrigeration system fault (not enough gas, clogging, dirty filters). Check: 1.

- Page 51 Heat Pump, Split System, Single Service, 3 phase Clear 39: Abnormal noise Probable causes: • Abnormal installation (outdoor) • Fan failure • Compressor failure. Checks: 1. The noise comes from the outdoor unit: - Is the unit stable? - Is the protection screen properly mounted? - Is the propeller broken or distorted? - Has the propeller screw been lost? - Is any object blocking the propeller rotation?

-

Page 52: Outdoor Unit Temperature Sensors

Heat Pump, Split System, Single Service, 3 phase Sensor Values 4.3.1 Outdoor Unit Temperature Sensors Outdoor Heat Exchanger (outlet), Outdoor Heat Exchanger (middle) Temperature (°C) Resistance value (kΩ) 27,5 20,9 16,1 12,4 9,73 7,67 3,95 Outdoor Discharge Pipe / Compressor / Expansion valve inlet Temperature (°C) 26,3 17,8... -

Page 53: Compressor

Heat Pump, Split System, Single Service, 3 phase Service parts information 4.4.1 Service parts information 1 : Compressor Diagnosis method of compressor (if outdoor unit LED displays error, refer to Failures and clears) Does not start up Stops soon after starting up Abnormal noise Check if vibration noise by Is there open or loose... -

Page 54: Compressor

Heat Pump, Split System, Single Service, 3 phase 4.4.2 Service parts information 2 : Inverter compressor Check point 1 : Check connection Check terminal connection of compressor Check connection of inverter PCB (Loose or incorrect wiring) (Loose or incorrect wiring) Check point 2 : check winding resistance Check winding resistance on each terminal If the resistance value is 0Ω... -

Page 55: Unit Electronic Expansion Valve (Eev,

Heat Pump, Split System, Single Service, 3 phase 4.4.3 Service parts information 3 : Outdoor unit electronic expansion valve (EEV, EEV(INJ)) Check point 1 : Check connection Check connection of connector (Loose connector or open cable) Check point 2 : Check coil of EEV Check point 3 : Check voltage from main PCB Remove connector, check each winding resistance of Remove connector and check voltage (DC12V) -

Page 56: Unit Solenoid Valve (Sv)

Heat Pump, Split System, Single Service, 3 phase 4.4.4 Service parts information 4 : Outdoor unit solenoid valve (SV) Check point 1 : Check connections Check point 2 : Check solenoid coil Check connection of connector Remove connector and check if coil is open (Loose connector or open cable) (normal resistance value of each coil : 1495+/- If resistance value is abnormal, replace... -

Page 57: Operating Limits

Heat Pump, Split System, Single Service, 3 phase Operating Limits WATERSTAGE WATERSTAGE WATERSTAGE HEAT PUMP Min/max OT in heat mode (°C)*** -20/35 Heating floor maximum water temperature (°C) LT radiator maximum water temperature (°C) Min/max OT in cooling mode(°C) 8/43 Cooling floor minimum water temperature (°C) Fan coil minimum water... -

Page 58: Failures

Heat Pump, Split System, Single Service, 3 phase 5 Failures Hydraulic, Electric and Refrigeration Systems 5.1.1 Hydraulic System If the installation is fitted with a heating floor, the most common failures are those listed below: APPLIED FAILURE CASES CONSEQUENCES SOLUTIONS Flow pressure too high clean filter or desludge Installer... -

Page 59: Electrical System

Heat Pump, Split System, Single Service, 3 phase 5.1.2 Electrical System Outdoor Unit Overvoltage Check for possible causes in the list below (this list is Steps to be followed before performing any work not exhaustive): on the Inverter module: • •... - Page 60 Heat Pump, Split System, Single Service, 3 phase 5.1.3 Refrigeration System Unit produces no heat The unit remains in continuous scanning mode. Initial checks: Check the settings Are the data sent by the user interface received by the heat pump? Hydraulic unit electronic circuit Hydraulic unit electronic system faulty...

- Page 61 Heat Pump, Split System, Single Service, 3 phase Outdoor unit does not defrost • condensation drain properly discharged • (outdoor unit directly on the ground)? charge correct (refer • temperature/pressure curve)? Are the auxiliaries powered? Insufficient charging will result in frequent icing. •...

-

Page 62: Compressor Operating Checks

Heat Pump, Split System, Single Service, 3 phase b. Defrost ending conditions With all models, defrosting stops if the exchanger temperature is above 10 °C or if the defrosting time is over 15 minutes). Crankcase heater When the outdoor exchanger temperature is below When operation has started and the temperature -5°C and the heating mode has been stopped for becomes higher than -3°C, heating stops. -

Page 63: Control Settings

Heat Pump, Split System, Single Service, 3 phase 6 Control Settings General The settings described below are those which can be modified by the user. There are 4 access levels: We wish to remind you that changing the settings U: end-user level below may cause the heat pump to behave in an I: commissioning level (installer start-up) undesirable way. - Page 64 Heat Pump, Split System, Single Service, 3 phase COMMAND ACCESS FACTORY FUNCTION SETTING RANGE LINE LEVEL SETTING phase on 00:00…--:-- --:-- phase off 00:00…--:-- --:-- phase on 00:00…--:-- --:-- phase off 00:00…--:-- --:-- Default values No/yes Time program 4 / DHW Mon-Sun ¦...

- Page 65 Heat Pump, Split System, Single Service, 3 phase COMMAND ACCESS FACTORY FUNCTION SETTING RANGE LINE LEVEL SETTING Actuator running time 30…873s 240s Floor curing function 0…5 Floor curing setpoint manually 0°C…95°C 25°C Floor curing day current 0…32 Floor curing days completed 0…32 Optg mode changeover Protection mode...

- Page 66 Heat Pump, Split System, Single Service, 3 phase COMMAND ACCESS FACTORY FUNCTION SETTING RANGE LINE LEVEL SETTING 1156 Floor curing day current 0…32 1157 Floor curing days completed 0…32 1200 Optg mode changeover Protection mode Domestic hot water 1610 Nominal setpoint Thc…65°C 50°C 1612...

- Page 67 Heat Pump, Split System, Single Service, 3 phase COMMAND ACCESS FACTORY FUNCTION SETTING RANGE LINE LEVEL SETTING HC+DHW op mode change HC op mode change Dewpoint HC1 op mode change 6046 Function Input H2 HC2 op mode change monitoring Error/alarm msg Dewpoint monitoring Pool release Normally closed...

- Page 68 Heat Pump, Split System, Single Service, 3 phase COMMAND ACCESS FACTORY FUNCTION SETTING RANGE LINE LEVEL SETTING 7711 Voltage signal UX 0…10volt 0 volt No test All OFF 7720 Digital output test No test Digital output DO1 Digital output DO2 Cooling mode 7721 Digital output DO1...

- Page 69 Heat Pump, Split System, Single Service, 3 phase COMMAND ACCESS FACTORY FUNCTION SETTING RANGE LINE LEVEL SETTING 8730 heating circuit pump 1 Off/on 8731 Heating circ mix valve 1 open Off/on 8732 Heat circ mix valve I close Off/on … °...

-

Page 70: Adjustment Function Details

Heat Pump, Split System, Single Service, 3 phase Adjustment Function Details 6.3.1 Date and Time Functions The controller has an annual clock which contains the In order for the function to operate, the time and date time, the day of the week and the date. must be set properly on the clock. -

Page 71: User Interface Functions

Heat Pump, Split System, Single Service, 3 phase 6.3.2 User Interface Functions LINE NO. PROGRAMMING LINE Language Info Operation lock Programming lock Direct adjustment Info (22): • Temporary Suspension of Programming • programming lock temporarily Temporary: deactivated at programming level. To do this, After pressing the Info key, the information display returns to the basic "predefined"... - Page 72 Heat Pump, Split System, Single Service, 3 phase Programming line Room unit 1 Heating circuit 1 Heating circuits 1 and 2 Heating circuits 1 and P All HCs Room unit 2 Room unit P Operator unit 1 Heating circuit 1 Heating circuits 1 and 2 Heating circuits 1 and P All HCs...

-

Page 73: 2, Dhw, Cooling)

Heat Pump, Split System, Single Service, 3 phase 6.3.3 Time Program Functions (heating circuit 1 & 2, DHW, cooling) Several control programs are available for the heating Enter changeover times: circuits and the production of DHW. They are initiated Changeover times can be adjusted in a combined in "Automatic"... -

Page 74: Heating Circuit 1 & 2 Functions

Heat Pump, Split System, Single Service, 3 phase Holidays: Line no. Programming line Start Operating level The holiday program enables changing the heating Important ! circuits over to a selected operating level according to The holiday program can be used only in the the date (calendar). - Page 75 Heat Pump, Split System, Single Service, 3 phase Heating Curve Line no. Programming line 1020 Heating curve slope 1021 Heating curve displacement 1026 Heating curve adaptation Heating curve slope: Based on the heating characteristic, the controller Increase the setting: computes the flow temperature setpoint which will be The flow temperature is increased mainly when the used controlling...

- Page 76 Heat Pump, Split System, Single Service, 3 phase Information: Heating curve displacement To ensure operation, the following requirements must be met: curve shift (offset) modifies flow A room sensor must be connected. temperature in a general and even manner over the The "room influence"...

- Page 77 Heat Pump, Split System, Single Service, 3 phase 24-Hour heating limit The 24-hour heating limit is used to switch the Thus, in the following example the changeover heating on and of in the course of the day, depending temperature will be 18°C, computed as follows: on the outside temperature.This function is used mainly during intermediate seasons (spring and fall) to react rapidly in case of fluctuating temperatures.

- Page 78 Heat Pump, Split System, Single Service, 3 phase The influence of the difference is defined as a percentage. The better the installation in the reference room (accurate room temperature, correct installation location, etc.) the higher will be the value that can be set. Example: Approx 60%: the reference room is appropriate...

- Page 79 Heat Pump, Split System, Single Service, 3 phase Optimisation at switch-on and switch-off Line no. Programming line 1090 Optimum start control max 1091 Optimum stop control max Optimum start control max Optimum stop control max The change in temperature levels is optimised in The change in temperature levels is optimised in such a way as to reach the comfort setpoint during such a way as to reach the comfort setpoint -1/4 °C...

- Page 80 Heat Pump, Split System, Single Service, 3 phase Mixing Valve Control Line no. Programming line 1130 Mixing valve boost 1134 Actuator running time Mixing valve boost The controller adds the increase set here to the current flow setpoint and uses the result as the temperature setpoint for the heat generator.

- Page 81 Heat Pump, Split System, Single Service, 3 phase Heat pump flow temp Days Fh + Bh X : Starting day "Manual controlled curing" setpoint Current day of controlled curing The flow temperature setpoint for the "Manual" Displays the current day of the controlled floor drying controlled floor drying function can be adjusted function separately for each heating circuit.

-

Page 82: Cooling Circuit 1 Functions

Heat Pump, Split System, Single Service, 3 phase 6.3.5 Cooling Circuit 1 Functions The cooling sequence is automatically started when The following settings apply to the hydraulic circuit in the room temperature is higher than the comfort zone 1 (HC1). setpoint in cooling mode (line 902). - Page 83 Heat Pump, Split System, Single Service, 3 phase Cooling Characteristic Line no. Programming line Flow temp setp at OT 25°C Flow temp setp at OT 35°C The controller computes the flow temperature required for a given averaged outdoor temperature Flow temp setp at OT 35°C based on the cooling characteristic.

- Page 84 Heat Pump, Split System, Single Service, 3 phase Summer Compensation Line no. Programming line Summer comp start at OT Summer comp end at OT Summer comp setp increase In summer the "cooling comfort setpoint" (902) is gradually increased according outdoor Summer compensation end at OT temperature.

- Page 85 Heat Pump, Split System, Single Service, 3 phase Flow Setpoint Limitation Line no. Programming line Flow temp setp min at OT 25°C Flow temp setp min at OT 35°C It is possible to assign a lower limit to the cooling flow temperature.

- Page 86 Heat Pump, Split System, Single Service, 3 phase Control according to outdoor conditions with Control according to room temperature only room influence The flow temperature is adjusted according to the The difference between the room temperature and room temperature setpoint, current room the setpoint value is measured and taken into...

- Page 87 Heat Pump, Split System, Single Service, 3 phase Mixing Valve Control Line no. Programming line Mixing valve cooling offset Actuator running time Mixing valve in heating mode If there is a second zone, this reduction should Mixing valve cooling offset enable the second zone to be cooled.

- Page 88 Heat Pump, Split System, Single Service, 3 phase Dewpoint Monitoring Line no. Programming line Lock time dewpoint limiter Flow temp setp incr hygro Flow setp incr start at r.h. Flow temp diff. dewpoint These settings are useful only when a dewpoint sensor (hygrostat).

-

Page 89: Dhw Functions

Heat Pump, Split System, Single Service, 3 phase With prim controller/system pump Line no. Programming line With prim contr/system pump (no / yes) This setting specifies whether the cooling circuit is Warning: supplied from the primary controller or from the In the case of a radiator or any other emitter which primary pump (depending on the installation). - Page 90 Heat Pump, Split System, Single Service, 3 phase Release Line no. Programming line 1620 Release (24h/day / Heating circ time pgm / Time program 4/DHW / Low-tariff/ Time pgm 4/DHW or Low-tariff) 24h/day (Not recommended) Regardless of the time programs, the temperature of the domestic hot water is continuously maintained at the DHW nominal setpoint temperature.

- Page 91 Heat Pump, Split System, Single Service, 3 phase DHW mode Holiday Release Time pgm Low tariff DHW mode level status (settings 1620) status (Pgm 4) status (Ex5) Frost protection Frost protection … … … Low tariff (OPK) Inactive Reduced Low tariff (OPK) Active Nominal Time pgm 4 or OPK...

-

Page 92: Heat Pump Functions

Heat Pump, Split System, Single Service, 3 phase Circulation Pump Line no. Programming line 1660 Circulation pump release Circulation pump release "DHW release" setting switches circulation pump when DHW production is released. 6.3.7 Swimming Pool Functions Line no. Programming line 2056 Setpoint source heating The controller enables a swimming pool to be heated... -

Page 93: Dhw Tank Functions

Heat Pump, Split System, Single Service, 3 phase 6.3.9 DHW Tank Functions DHW charging at the nominal setpoint temperature enough heat to reach the setpoint value, it switches (1610) always takes place in two stages. In the first on the DHW tank auxiliary if authorised. The auxiliary stage, only the heating pump heats the DHW tank. - Page 94 Heat Pump, Split System, Single Service, 3 phase Heater Line no. Programming line 5060 El imm heater optg mode 5061 Electric immersion heater release • Always El imm heater optg mode DHW charging is always carried out by means of the •...

-

Page 95: Configuration Functions

Heat Pump, Split System, Single Service, 3 phase • Time program 4/DHW Time program 4/DHW of the local controller is taken into account for the heater. Information: Switch-on will actually be in effect only if the heater is able to operate according to the "heater operating mode"... - Page 96 Heat Pump, Split System, Single Service, 3 phase Input H2 Function Input H2 is available only on the control extension contact H2 will be assigned to the module with module. No more than two extension modules can be address 1. Only one function can be assigned to fitted into an installation.

-

Page 97: Error Functions

Heat Pump, Split System, Single Service, 3 phase Installation Frost Protection Line no. Programming line 6120 Frost protection for the plant According to the outdoor temperature, the heating circuit pump and the condenser pump are switched on although there is no demand for heat Outdoor Pump Diagram... - Page 98 Heat Pump, Split System, Single Service, 3 phase Fault Indication Function Line no. Programming line 6740 Flow temp 1 alarm 6741 Flow temp 2 alarm 6745 DHW charging alarm 6746 Flow temp cooling 1 alarm The difference between the setpoint value and the current temperature value...

- Page 99 Heat Pump, Split System, Single Service, 3 phase Table of error messages which can be displayed: Reset No. Designation of error Location HP oper. Priority Manual Automatic 0: No fault 10: Outdoor sensor 30: Flow sensor 1 31: Cooling flow sensor 1 32: Flow sensor 2 33: Heat pump flow temp sensor error...

- Page 100 Heat Pump, Split System, Single Service, 3 phase Reset 360: no process reversing valve 364: Heat pump cooling system error 369: External fault 370: Outdoor unit fault Number* If such statuses or events occur for the first Only if the anomaly occurs repeatedly over a time, they will not directly generate a fault message, predefined time period and at a given frequency but only a status message.

-

Page 101: Maintenance / Special Operating Mode Functions

Heat Pump, Split System, Single Service, 3 phase 6.3.12 Maintenance / Special Operating Mode Functions Maintenance Maintenance functions can be used as a preventive The controller automatically generates maintenance step for periodically monitoring the installation. All messages if the settings defined are either exceeded maintenance functions individually... - Page 102 Heat Pump, Split System, Single Service, 3 phase DHW stor tank since maint (7091): The time elapsed (in months) since the last maintenance. If the value is greater than the setting "DHW tank interval" (Line 7090), this symbol will be displayed and a maintenance message will appear in the Info section: 11: TWW DHW tank period (Priority 6)

-

Page 103: Input / Output Testing Functions

Heat Pump, Split System, Single Service, 3 phase 6.3.13 Input / Output Testing Functions Input/output testing is used to ensure that the connected components are in working order. Relay Output Testing Selection of a setting from relay testing closes the check that the relays are in working order and that corresponding relay and therefore switches on the the wiring has been performed correctly. -

Page 104: Status Functions

Heat Pump, Split System, Single Service, 3 phase Input Testing Line no. Programming line 7914 Input EX4 7915 Input EX5 7916 Input EX6 If a test setting is selected, the associated input is "230 V" display indicates that a 230 V voltage is displayed and can thus be checked. - Page 105 Heat Pump, Split System, Single Service, 3 phase State heating circuit End user (Info level) Startup, heating engineer Thermostat response Thermostat response Manual action active Manual action active Controlled drying active Controlled drying active Heating mode restriction Overeating protection active Restriction, Boiler protection Restriction, DHW priority Restriction, storage tank...

- Page 106 Heat Pump, Split System, Single Service, 3 phase State DHW (8003): End user (Info level) Startup, heating engineer Thermostat response Thermostat response Manual action active Manual action active Draw-off mode Draw-off mode Adiabatic cooling active Adiabatic cooling by collector adiabatic cooling via gen/HC Charging lock active Discharge protection active Charging duration limit.

- Page 107 Heat Pump, Split System, Single Service, 3 phase State cooling circuit (8004): End user (Info level) Startup, heating engineer Dewpoint sensor activated Dewpoint sensor activated Manual action active Manual action active Fault Fault Frost protection active Flow frost protection active Cooling mode locked Locked, heating mode Lock time after heating...

- Page 108 Heat Pump, Split System, Single Service, 3 phase State heat pump (8006): End user (Info level) Startup, heating engineer Emergency mode Emergency mode Fault Fault Locked Locked, outdoor temperature Locked, external Locked, economy mode Lim. time active Consumer flow rate controller Min outdoor temp use limit Max outdoor temp use limit Max switchoff temp lim...

-

Page 109: Generator Diagnosis Functions

Heat Pump, Split System, Single Service, 3 phase State supplementary source (8022): End user (Info level) Startup, heating engineer Locked Locked, solid fuel boiler Locked, outside temperature Locked, economy mode In operation for HC, DHW In operation for HC, DHW Released for HC, DHW Released for HC, DHW In operation for DHW... -

Page 110: Consumer Diagnosis Functions

Heat Pump, Split System, Single Service, 3 phase Setpoints and Measured Values Line no. Programming line 8410 Return temp HP 8412 Flow temp HP 8413 Compressor modulation 8425 Temp diff condenser These lines allow the various setpoints and measured values for the heat pump to be viewed. Hour / Startup Counter Line no. - Page 111 Heat Pump, Split System, Single Service, 3 phase Cooling Circuit Line no. Programming line 8756 Flow temperature cooling 1 The actual values of the cooling mode are displayed. The cooling mode room setpoint is displayed on programming line 8741. Domestic Hot Water Line no.

- Page 112 Heat Pump, Split System, Single Service, 3 phase Status of Relays for Extension Modules 1 and 2 Line no. Programming line 9050 Relay output QX21 module 1 9051 Relay output QX22 module 1 9052 Relay output QX23 module 1 9053 Relay output QX21 module 2 9054 Relay output QX22 module 2...

-

Page 113: Annual Maintenance Services

Heat Pump, Split System, Single Service, 3 phase 7 Annual Maintenance Services Hydraulic Circuit Electrical • clean filter (if any) • Inspect connections tighten where • inspect heating system (system pressure, appropriate purging, leak test) • Check condition of wires and boards •... -

Page 114: Connection Diagrams

Heat Pump, Split System, Single Service, 3 phase 8 Connection Diagrams Connection Diagram of Hydraulic Unit Maintenance Document 1394-1... -

Page 115: Connection Diagram Of Outdoor Unit

Heat Pump, Split System, Single Service, 3 phase Connection Diagram of Outdoor Unit Heat exchanger Maintenance Document 1394-1... -

Page 116: Disassembly Process Of Outdoor Unit

Heat Pump, Split System, Single Service, 3 phase Disassembly Process of Outdoor Unit > Warning ! < Before servicing the unit, turn the power supply switch OFF, then, do not touch electric parts for 10 minutes due to the risk of electric shock. Appearance Service panel removal Insulation sheet removal... -

Page 117: Main Pcb Removal

Heat Pump, Split System, Single Service, 3 phase Main PCB removal INVERTER, PFC, FILTER, and CAPACITOR PCB removal Maintenance Document 1394-1... -

Page 118: Inverter Pcb Removal

Heat Pump, Split System, Single Service, 3 phase 9.5.1 INVERTER PCB removal 9.5.2 PFC PCB removal 9.5.3 FILTER PCB removal Maintenance Document 1394-1... -

Page 119: Capacitor Pcb Removal

Heat Pump, Split System, Single Service, 3 phase 9.5.4 CAPACITOR PCB removal Maintenance Document 1394-1... -

Page 120: Fan Motor Removal

Heat Pump, Split System, Single Service, 3 phase FAN MOTOR removal TOP PANEL removal PIPE COVER FRONT removal Maintenance Document 1394-1... -

Page 121: Thermistor Removal

Heat Pump, Split System, Single Service, 3 phase RIGHT PANEL removal 9.10 REACTOR removal 9.11 THERMISTOR removal 9.11.1 HEAT EXCHANGER (OUT) THERMISTOR 9.11.2 EXPANSION VALVE THERMISTOR Maintenance Document 1394-1... -

Page 122: 4Way Valve

Heat Pump, Split System, Single Service, 3 phase 9.12 SOLENOID COIL removal 9.12.1 4WAY VALVE 9.12.2 INJECTION 9.13 EEV COIL removal 9.13.1 MAIN 9.13.2 INJECTION 9.14 PRESSURE SENSOR removal > Warning ! < Wear gloves to prevent the frostbite, because a small amount of refrigerant leaks during work. -

Page 123: Compressor Removal

Heat Pump, Split System, Single Service, 3 phase 9.15 COMPRESSOR removal Precautions for exchange of compressor. Do not allow moisture or debris to get inside refrigerant pipes during work. Procedure for compressor removal. 1 Turn off the power 2 Remove the service panel 3 Fully close the 3Way valve (gas) and 3Way valve (liquid) 4 Collect the refrigerant from the 3Way valve. - Page 124 Heat Pump, Split System, Single Service, 3 phase Procedure for compressor installation Reverse procedure to removing the compressor. Precautions for installation of compressor. 1 When brazing, do not apply the flame on the terminal. 2 When brazing, be sure to replace the air in the pipe with nitrogen gas to prevent forming oxidization scale.

-

Page 125: Precautions For Exchange Of Refrigerant-Cycle-Parts

Heat Pump, Split System, Single Service, 3 phase 9.16 Precautions for exchange of refrigerant-cycle-parts Maintenance Document 1394-1... -

Page 126: Spare Parts

Heat Pump, Split System, Single Service, 3 phase Spare Parts The data is being prepared. 1394-1... -

Page 127: Accessories

Heat Pump, Split System, Single Service, 3 phase Accessories 11.1 DHW kit See installation instructions "DHW kit" no. 1316. 11.2 Swimming pool kit See installation instructions "Swimming Pool Kit" no. 1341. 11.3 2nd circuit kit Management of 2 heating circuits requires installation One or two room thermostats may be installed, on of the 2 zone kit, which includes a controller... - Page 128 Heat Pump, Split System, Single Service, 3 phase Connection: The room thermostat must be connected to one of If the cable is shielded, the shielding can be the terminals b (CL+, CL-) of the heat pump controller connected to the controller CL- terminal. It may under board.

-

Page 129: Remote Control

Heat Pump, Split System, Single Service, 3 phase 11.4.2 Remote control The remote control includes the functions of the room status of the heat pump, to enter the pump settings unit together with those of the user interface mounted appropriate to the house and to the application's in series on the Hydraulic Unit. -

Page 130: Balancing Vessel

Heat Pump, Split System, Single Service, 3 phase Connections The room central unit must be connected to terminal If the cable is shielded, the shielding can be b (CL+, CL-, G+) of the heat pump controller board. connected to the controller CL- terminal. It may under To do this, you can use a 0.5mm²... -

Page 131: Related Documents

Heat Pump, Split System, Single Service, 3 phase 12 Related Documents 12.1 Quick-Start Procedure Before switching on the Hydraulic Unit: 1. Check the electric wiring 2. Check the refrigeration circuit and make sure the gas supply has been performed 3. Check the hydraulic circuit, with 1-2 bar pressure, check that the heat pump is purged, as well as the rest of the installation. -

Page 132: Startup Checklist

Heat Pump, Split System, Single Service, 3 phase 12.2 Startup Checklist Date: ............ Installation identification: ....................................After Sales Service identification: Installer identification: ................................................... Unit reference number: ...... Serial number: ................BEFORE STARTING UP Sight Checks Outdoor unit: (See "Outdoor unit Installation"... - Page 133 Heat Pump, Split System, Single Service, 3 phase STARTING UP Switching On (See "Starting up" section of "Installation" instructions) NON COMPLIANT Switching on Initialisation for a few seconds Operation of the pumps Outdoor unit starts after 3mins Checks on Outdoor Unit NON COMPLIANT VALUE Operation of fan(s), compressor...

-

Page 134: Settings Sheet

Heat Pump, Split System, Single Service, 3 phase 12.3 Settings Sheet Setting Description set to Menus Setting Description set to Menus Preliminary settings Boiler backup language 3700 Release below out. temp Op. section Suppl. source. hour / minutes 3705 Overrun time time and date Suppl. -

Page 135: Startup Data Sheet

Heat Pump, Split System, Single Service, 3 phase 12.4 Startup Data Sheet Site: Installer: Outdoor unit Serial no.: Hydraulic Unit Serial no.: Model: Model: Refrigerant type: Refrigerant charge: Checks Operating voltage and current on Outdoor Unit Compliance with positioning distances L1/N, L2/N, L3/N : Condensate evacuation correct L1/E, L2/E, L3/E :... - Page 136 Heat Pump, Split System, Single Service, 3 phase Fujitsu General (Euro) GmbH Werftstrasse 20 40549 Düsseldorf - Germany Maintenance Document 1394-1...

Need help?

Do you have a question about the WATERSTAGE 112 and is the answer not in the manual?

Questions and answers