Summary of Contents for Dalsa Spyder3 Color SG-34

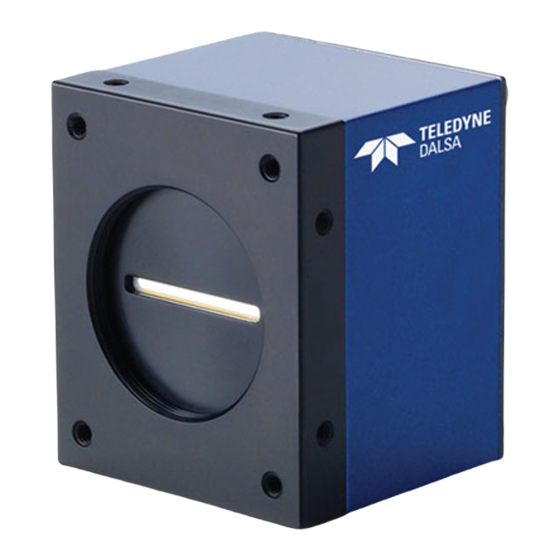

- Page 1 Spyder3 Color SG-34 Camera User’s Manual SG-34-04k80-00-R and SG-34-02k80-00-R sensors | cameras | frame grabbers | processors | software | vision solutions P/N: 03-032-20124-03 www.teledynedalsa.com...

- Page 2 All information provided in this manual is believed to be accurate and reliable. No responsibility is assumed by Teledyne DALSA for its use. Teledyne DALSA reserves the right to make changes to this information without notice. Reproduction of this manual in whole or in part, by any means, is prohibited without prior permission having been obtained from Teledyne DALSA.

-

Page 3: Table Of Contents

Contents The Spyder3 SG-34 Cameras ______________________________________________________________________________ 6 Camera Highlights ..........................6 Features and Programmability ..................... 6 Description and Applications ....................6 Part Numbers and Model Requirements ..................... 7 Camera Performance Specifications ....................7 Certifications ............................9 Image Sensor ............................9 Responsivity ............................ - Page 4 Verify Temperature and Voltage ......................29 Saving and Restoring Camera Settings ....................29 Timing: Exposure and Synchronization ....................31 Timing ..........................32 Exposure Controls ..........................33 Set the Exposure Mode ....................... 33 Exposure Modes in Detail ....................34 Line Rate ............................. 36 Exposure Time ............................

- Page 5 PLC Control ............................81 The PLC Control Block ......................82 GPIO Output Labels ......................86 Signal Routing Block ........................... 87 How the Signal Routing Block Works .................. 88 How the Lookup Table Works ....................90 Appendix C: EMC Declaration ______________________________________________________________________________ 91 Appendix D: Setting up the FVAL ___________________________________________________________________________ 92 Examples: Setting the FVAL ........................

-

Page 6: The Spyder3 Sg-34 Cameras

The GigE Vision interface eliminates the need for a frame grabber, resulting in significant system cost savings. The Spyder3 GEV Color is also Teledyne DALSA’s first dual line scan color camera. The Spyder3 GEV Color camera is ideal for: Cotton and textile inspection •... -

Page 7: Part Numbers And Model Requirements

Part Numbers and Model Requirements The Spyder3 GEV color camera is available in the following configurations: Table 1: Spyder3 GigE Vision Color Camera Models Overview Model Number Description SG-34-02K80-00-R 2k resolution, 80 MHz data rate, 18 KHz line rate. SG-34-04K80-00-R 4k resolution, 80 MHz data rate, 9 KHz line rate. - Page 8 Optical Interface Back Focal Distance 6.56 ± 0.25 mm Lens Mounts M42 x 1, C and F (2k) M58 x 0.75, F (4k) Sensor Alignment ±50 µm ±50 µm ±0.25 mm Υz ±0.2° Electrical Interface Input Voltage +12 V to +15 V Power Dissipation <...

-

Page 9: Certifications

Table 5: EMC Compliance Standards Compliance The CE Mark, FCC Part 15, and Industry Canada ICES-003 Evaluation of the Teledyne DALSA Spyder GigE SG-34 cameras meet the following requirements: EN 55022 Class A, and EN 61326 Emissions Requirements, EN 55024, and EN 61326 Immunity to Disturbances Image Sensor This color bilinear camera is based on Teledyne DALSA’s bilinear CCD sensor. - Page 10 CCD Readout Shift Register N Pixels (14 µm x 14 µm or 10 µm x 10 µm) N Pixels (14 µm x 14 µm or 10 µm x 10 µm) CCD Readout Shift Register N= 2048, 4096 Pixel 1, 1 Figure 1: Bilinear sensor used in Spyder3 Color (block diagram) Please note that interpolation procedure does not work on the first and last pixels;...

-

Page 11: Responsivity

Responsivity Figure 2: Spyder3 GigE Vision Responsivity The Spyder3 SG-34 Cameras • 11... -

Page 12: Mechanicals

Mechanicals 30 0.05 (65) CENTER OF (56) IMAGE AREA 6 0.2 M4x0.7 MAX TORQUE 25 IN-LB M42x1 36 0.05 CENTER OF IMAGE AREA M4x0.7 46 0.2 (BOTH SIDES) 60 0.2 MAX TORQUE 25 IN-LB 6.56 0.25 IMAGE AREA [OPTICAL DISTANCE] 38 0.2 M4x0.7 (BOTH SIDES) - Page 13 36 0.05 CENTER OF 6 0.2 IMAGE AREA M4x0.7 MAX TORQUE 25 IN-LB M58x0.75 M4x0.7 30 0.05 57 0.2 (BOTH SIDES) CENTER OF IMAGE AREA MAX TORQUE 25 IN-LB 72 0.2 M4x0.7 (BOTH SIDES) 6.56 0.25 MAX TORQUE 25 IN-LB IMAGE AREA 38 0.2 [OPTICAL DISTANCE]...

-

Page 14: Mounting

Mounting Heat generated by the camera must be allowed to move away from the camera. Mount the camera on the frontplate (using the provided mounting holes) with maximum contact to the area for best heat dissipation. Figure 5: Spyder3 Mounting Example 14 •... -

Page 15: Software And Hardware Setup

Software and Hardware Setup Host System Requirements To achieve best system performance, the following minimum resquirements are recommended: • Operating system: Windows XP Professional, Windows Vista, Windows 7 (either 32-bit or 64-bit for all) are supported. Network Adapter Requirements GigE network adapter (either PCI card or LOM): For high performance you must use a •... -

Page 16: Connect Power, Ethernet And I/O Cables

2. Connect Power, Ethernet and I/O Cables Connect a power cable from the camera to a +12 VDC to +15 VDC power supply. • • Connect the Ethernet cable from the camera to the computer Ethernet jack. • If using the external signals connect the external control cable to the camera. 3. -

Page 17: Step 1. Ethernet Network Card: Install And Configure

Step 1. Ethernet Network Card: Install and Configure Install Network Card The following network card has been tested and is recommended for use with this camera: Intel Pro/1000 MT Desktop Adapter (33-MHz, 32-bit PCI). Order Code: PWLA8391GT (single packs). Follow the manufacturer’s recommendations to install this card in the host PC. Configure Network Card The configuration shown here uses the Windows XP operating system as the host platform. - Page 18 5. Select “Use the following IP address” and set the IP address to any address in this subnet other than 192.168.5.100, which is used by the camera. In the example below, the address 192.168.5.50 is used. Alternatively, select “Obtain an IP address automatically”...

- Page 19 Figure 8. Jumbo Frames 10. Click “OK” to save settings The Spyder3 SG-34 Cameras • 19...

-

Page 20: Step 2. Connect Power, Ethernet, And Trigger Cables

Step 2. Connect Power, Ethernet, and Trigger Cables WARNING! Grounding Instructions Static electricity can damage electronic components. Please discharge any static electrical charge by touching a grounded surface, such as the metal computer chassis, before performing any hardware installation. The use of cables types and lengths other than those specified may result in increased emission or decreased immunity and performance of the camera. -

Page 21: Ethernet Connector And Ethernet Led

WARNING: When setting up the camera’s power supplies follow these guidelines Apply the appropriate voltages. • Protect the camera with a 2 amp slow-blow fuse between the power supply and • the camera. Do not use the shield on a multi-conductor cable for ground. •... -

Page 22: Gpio Connector

Priority Color of Status LED Meaning Flashing Green Camera initialization or executing a long command. Solid Green Camera is operational and functioning correctly. GPIO Connector: A single 15-pin general purpose input / output (GPIO) connector is used to receive or control external signals. -

Page 23: Gpio Isolation

GPIO Isolation All of the GPIOs are isolated from the rest of the camera and the camera case. They are not isolated with respect to each other and share a common return (ground) through pin 5 of the GPIO connector. Note: The shell connection of the GPIO connector is not isolated and it should not be used as a return (ground) for the GPIO signals. -

Page 24: Step 3. Establish Communication With The Camera

LVDS Inputs and Outputs (LVDS compliant) 100Ω Figure 13: LVDS Input Figure 14Figure 15: LVDS Output Step 3. Establish Communication with the Camera Power on the camera Turn on the camera’s power supply. You may have to wait up to 60 seconds while the camera warms up and prepares itself for operation. -

Page 25: Using Sapera Camexpert With Spyder3 Cameras

Using Sapera CamExpert with Spyder3 Cameras CamExpert is the camera interfacing tool supported by the Sapera library. When used with a Spyder3 camera, CamExpert allows a user to test all Spyder3 operating modes. Additionally CamExpert saves the Spyder3 user settings configuration to the camera or saves multiple configurations as individual camera parameter files on the host system (*.ccf). - Page 26 The CamExpert application uses 5 windows to simplify choosing and configuring camera files or acquisition parameters for the installed device. Device Selector pane: View and select from any installed Sapera acquisition device. • Once a device is selected CamExpert will only present acquisition parameters applicable to that device.

-

Page 27: Step 4. Camera Test Patterns

Step 4. Camera Test Patterns Review a Test Pattern Image The camera is now ready to retrieve a test pattern. The Spyder3 cameras include a built-in test pattern generator that can be used to confirm camera Ethernet connections without the need for a camera lens or proper lighting. -

Page 28: Camera Operation

At this point you are ready to start operating the camera in order to acquire images, set camera functions, and save settings. Camera Operation Factory Settings The camera ships and powers up for the first time with the following factory settings: •... -

Page 29: Verify Temperature And Voltage

Verify Temperature and Voltage To determine the voltage and temperature at the camera, use the Read Voltage and Temperature feature found in the Camera Information set. The temperature returned is the internal chip case temperature in degrees Celsius. For proper operation, this value should not exceed 80 °C. If the camera exceeds the designated temperature it will shut down and will not turn on until the camera’s temperature is 73 ºC or less. - Page 30 Figure 19. Relationship between the Camera Settings Current Session Active Setting The active setting for the current session is the set of configurations that are operating while the camera is currently running, including all unsaved changes you have made to the settings before saving them.

-

Page 31: Timing: Exposure And Synchronization

Calibrate White Balance Target • PRNU Calibration Target • Color Correction Input Channel • Color Correction Output Channel • • Color • Also note: By default, the user settings are set to the factory settings. Timing: Exposure and Synchronization Image exposures are initiated by an event. The trigger event is either the camera's programmable internal clock used in free running mode, an external input used for synchronizing exposures to external triggers, or a programmed function call message by the controlling computer. -

Page 32: Timing

parameters and modify on-board buffer allocation if the buffer size has changed since the last acquisition. Timing tLine Period twSYNC twSYNC_INT EXSYNC tPR_INT twPR_HIGH twPR_LOW PRIN tREADOUT tTRANSFER tOVERHEAD Internal Line Valid tEthernet Latency Valid Data From Diagramed Ethernet Latency to PC ExSync Memory Table 8: Timing Parameter Table... -

Page 33: Exposure Controls

Table 10: tOverhead Values tOVERHEAD Sensor Size # Taps Readout Time 1024 725ns 1024 450ns 2048 1400ns 2048 725ns Overhead Delay Overhead_Delay can range from 5 to 6μs and depends on the internal operations of your computer. Exposure Controls The camera can grab images in one of seven ways. The camera’s line rate (synchronization) can be generated internally through the Acquisition Line Rate feature (a member of the Sensor Control set of features) or set externally with an EXSYNC signal, depending on your mode of operation. -

Page 34: Exposure Modes In Detail

Programmable Line Rate Programmable Exposure Time Mode LineTriggerMode ExposureMode Description Off (Internal) Timed Internal line rate and exposure (Internal) time. Exposure mode enabled. On (External) Off (Internal) Maximum exposure time. Exposure mode disabled. On (External) TriggerWidth Smart EXSYNC. Exposure mode (Internal) enabled. - Page 35 Example 1: Exposure Time less than Line Period Programmable Period ( ExposureTimeAbs command) Programmable Period Waiting Waiting Exposure Time Readout Readout Exposure Time Line Period Line Period Programmable Period Programmable Period ( AquisitionLineRateAbs command) CR=Charge Reset Mode B. External Trigger with Maximum Exposure: ExposureMode Off and LineTriggerMode On (External) Line rate is set by the period of the external trigger pulses.

-

Page 36: Line Rate

Line Period Line Period Exposure Time Exposure Time Waiting Waiting Readout Readout Programmable period Programmable period using ExposureTimeAbs command using ExposureTimeAbs command EXSYNC CR=Charge Reset Figure 20: EXSYNC controls Line Period with Internally controlled Exposure Time Mode E. Internally Programmable Line Rate, Maximum Exposure Time: ExposureMode Off and LineTriggerMode Off (Internal) In this mode, the line rate is set internally with a maximum exposure time. -

Page 37: Exposure Time

Exposure Time To set the camera’s exposure time, use the Exposure Time feature found in the Sensor Control set. This feature is used to set the exposure time in µs. This feature is only available when the Timed Exposure Mode. The allowable range is from 3 µs to 3300 µs. GigE Vision Input Controls Sensor Control Parameter... -

Page 38: Input / Output Control

Frame Start Trigger Mode Specifies whether the external fixed length frame trigger is on or off. If the FrameTriggerActiveMode is on then it takes precedence.To turn On, please DeviceScanType to Linescan (Start Mode). Frame Start Trigger Activation Specifies what type of signal(i.e. high, or low) causes a fixed length frame trigger when Frame Start Trigger Mode is On. -

Page 39: Gain, Black Level, And Background

encoder is used, Line0 -- Phase A , Line2 -- Phase B Line Format This feature returns or sets (if possible) the current electrical format of the selected physical input Line: No connect, TTL, LVDS Line Connector Pin Enumeration of the physical line (or pin) on the device connector. - Page 40 White LED Halogen Fluorescent Tungsten Selects the tap to control. Tap 1 Tap 2 Color Selects which color to control. Green Blue Color Gain (DB) The gain, in dB, for a selected color and tap. Color Gain Reference Update Provides a new baseline for the colour gain. Sets the current colour gain value to 0.0 dB Calibrate White Balance Adjust the color gain so that each color's average is equal...

-

Page 41: Image Size

Table 11: Gain Range by Camera Model Gain 1K /2K Cameras 4K Cameras Color Gain -20.0 dB to +20.0 dB (0 dB default) Image Size To set the height of the image, and therefore the number of lines to scan and transmit, use the parameters grouped under the Image Format Control set. -

Page 42: Pixel Format

Bayer BG Sensor Color Type Monochrome or color. Color types are: Bayer, CYGM, CYYM, RGBW, RGBE, RBGG Pixel Format Use the Pixel Format feature found in the Image Format Control set to select the format of the pixel to use during image acquisition as either Mono 8 or Mono 12 bit depth. GigE Vision Input Controls Image Format Control Parameter... -

Page 43: Sensor Shift Direction

Sensor Shift Direction You can select either forward or reverse CCD shift direction. Selectable direction accommodates object direction change on a web and allows you to mount the camera “upside down”. Figure 22: Object Movement and Camera Direction Example using an Inverting Lens Resetting the Camera The feature Camera Reset, part of the Camera Information set, resets the camera. -

Page 44: Camera Calibration

Camera Calibration Processing Chain Overview and Description The following diagram shows a simplified block diagram of the camera’s digital processing chain. The digital processing chain contains the FPN correction, the PRNU correction, the background subtract, and the digital gain and offset adjustments. These elements are user programmable and most are members of the Analog Controls and Advance Processing sets. -

Page 45: Calibrating The Camera To Remove Non-Uniformity (Flat Field Correction)

(Background Subtract (DN) 2048) and then multiply by 2 (Digital Gain (DN) 8192) to get an output range from 0 to 255. 6. The Color Correction Value (as part of the Color Matrix feature, see page 51.) adds color space conversion functionality to the camera, allowing you to improve the color response. - Page 46 Background background subtract value Subtract System Gain digital gain value The algorithm is performed in two steps. The fixed offset (FPN) is determined first by performing a calibration without any light. This calibration determines exactly how much offset to subtract per pixel in order to obtain flat output when the CCD is not exposed. The white light calibration is performed next to determine the multiplication factors required to bring each pixel to the required value (target) for flat, white output.

-

Page 47: Digital Signal Processing

Digital Signal Processing The FPN and PRNU calibration parameters are available as members of the Advanced Processing set and are only available to Guru users. Figure 25. Advanced Processing / Calibration Parameters Camera Calibration • 47... - Page 48 GigE Vision Input Controls Advanced Processing Parameter Description FFC Coefficient Set No. Selects the pixel set to load, save, or configure. There are 8 user sets available. Load FFC Coefficient Loads the Flat Field Correction Coefficients (specified by the Pixel Set Selector) from the cameras non-volatile memory.

- Page 49 Prepare for Calibration For best results, the camera should be setup for calibration with similar conditions as to those in which it will be used. For example, data mode, exposure times and line rates, scan direction, etc. For example, set the color gain for the current color using the Color Gain command. Step 1: White Balance Calibration 1.

- Page 50 3. Set the PRNU target value using the Target to Calibrate PRNU command. The target value (always counted as 12-bit) and is 1024 to 4055 DN. For example, if you want to set the target to 255 x 80% = 204 DN in 8-bit mode, then the target value is (204/255) x 4096 = 3277 DN in 8-bit mode.

-

Page 51: Color Correction Matrix

Color Correction Matrix The color matrix adds color space conversion functionality to the camera, allowing you to improve the color response. A color space is a way to manage the display of image color using a three-dimensional coordinate system. Different color spaces are best for different devices, such as RGB (red-green-blue) for CRT monitors or YCbCr (luminance-chrominance) for digital television. - Page 52 An example on how to use the color matrix After calibrating the camera and reviewing the output, you determine that you need to increase and add more green to your red output. The color matrix commands are found in the Analog Controls set of parameters. The registers Color Correction Input Channel (Red, Green, Blue) and Color Correction Output Channel (Red, Green, Blue) are used to choose locations in the table: Color CorrectionInput Channel specifies the input channel and Color Correction...

-

Page 53: Appendix A: Clear Dark Current

The modes of operation selected by the command are: Auto, On, or Off. Auto Mode (srm 0) Note: Teledyne DALSA recommends Auto mode for most users. In this mode camera will automatically start and stop dark current clear based on the line rate. DC Clear ON... -

Page 54: Immediate Read Out Mode (Default, Srm 2)

Immediate read out mode (default, srm 2) In this mode the image is read out, including accumulated dark current, immediately following the trigger or the EXSYNC falling edge. There are no line rate limitations other than the amount of gate dark current that can be tolerated at low line rates. - Page 55 : Immediate readout. Does then srm 1 is selected, the following warning will be displayed, but the ssf not clear dark current. value will not be changed: Warning 09: (Default mode all models) Internal line rate inconsistent with readout time> The effect in both internal and external line rate modes is that an EXSYNC is skipped and, therefore, the output will be at least twice as bright.

-

Page 56: Appendix B: Gpio Control

Appendix B: GPIO Control The camera’s General Purpose Input / Output (GPIO) connector allows the camera to receive (and in some cases output) direct, real-time control signals that are independent from the Ethernet communications. For example, the GPIO connector can be used to control EXSYNC, PRIN (pixel reset), and direction signals. -

Page 57: Configure Gpio Signal Levels

Signal Description INPUT_0- LVDS (negative) INPUT_1+ LVDS/TTL format (positive) INPUT_1- LVDS (negative) INPUT_2+ LVDS/TTL format (positive) INPUT_2- LVDS (negative) INPUT_3 TTL auxiliary input OUTPUT_3 TTL auxiliary output OUTPUT_2+ LVDS/TTL auxiliary output OUTPUT_0+ LVDS/TTL auxiliary output OUTPUT_0- LVDS (negative) OUTPUT_1+ LVDS/TTL auxiliary output OUTPUT_1- LVDS (negative) OUTPUT_2-... -

Page 58: Examples: Setting The Camera Modes

Examples: Setting the Camera Modes Free Run Mode: Internal Line Trigger, Internal Direction Control, Internal frame trigger In the Line Trigger Function Group > set the parameter Line Trigger Mode value to Off. Figure 29: Line Trigger In the Direction Control Group > set the parameter Sensor Scan Direction > to Forward or Reverse, depending on your application. - Page 59 Figure 31: Rotary Encoder Group In the Start Mode > set the Frame Start Trigger value Off. Figure 32: Start Mode Appendix B: GPIO Control • 59...

- Page 60 In the Active Mode > set the Frame Active Trigger value Off. Figure 33: Active Mode In the Sensor Control Group > set the desired exposure mode, exposure time and line rate. Figure 34: Exposure Mode, Time, and Line Rate Settings 60 •...

-

Page 61: Internal Line Trigger, External Direction Control, Internal Frame Trigger

Internal Line Trigger, External Direction Control, Internal frame trigger Set the Frame Start Trigger and Frame Active Trigger values to off, as described above. Set the Line Trigger Mode value to Off and the Exposure Mode, Exposure Time and Line Rate as above. -

Page 62: External Line Trigger, External Direction Control From Rotary Encoder

Figure 37: Rescaler If the rescaler is enabled, the external line frequency will be modified using the Trigger Multiplier and Trigger Divider commands, as shown above. For details, please refer to the Rescaler section in the GURU section. Note: the Trigger Multiplier takes the following three values only: 0 = frequency x 256 1 = frequency x 16 2 = frequency x 4096... - Page 63 Rescale the line trigger signal The rotary encoder has its own built-in rescaler. Setting Rotary Encoder Multiply Factor to 0 produces an output frequency that is 4 times the rotary encoder output. To set the output to be the same as rotary encoder output, set the Rotary Encoder Multiply Factor to 1 and Rotary Encoder Drop Factor to 4.

- Page 64 Figure 41: Encoder Backash Control If the Backlash Control is disabled, the camera will respond to both directions. This may cause image artefacts when the direction changes. To avoid this, increase the Rotary Encoder Debounce Factor, as shown in the following figure. Figure 42: Rotary Encoder Debounce Factor Figure 43: Shaft Encoder Module 64 •...

-

Page 65: External Frame Trigger: Frame Start Trigger Mode

External Frame Trigger: Frame Start Trigger mode In the Frame Trigger Function Group > set the Device Scan Type to Linescan. Figure 44: Device Scan Type In the Active Mode group > ensure that the Frame Active Trigger Mode value is Off. Figure 45: Frame Trigger Mode In the Start Mode group >... - Page 66 Note on the Frame Start Trigger When the frame trigger goes high the software grabs a predefined number of lines, as defined in width and height in Image Format Control. For a software trigger toggle Frame software trigger from a False value to a True value, or from True to False depending on the Frame Active Trigger Mode.

- Page 67 Figure 50: Frame Trigger Source In the Active Mode group > set the Frame Active Trigger Mode value to ON. Figure 51: Frame Trigger Mode: On Note on the Frame Active Trigger When the frame trigger goes high, the PC will collect data until either, the signal goes low, or the frame buffer is filled.

-

Page 68: Outputs

Outputs Outputs are used to control external devices and monitor internal signals. Step 1 Select the output line. Step 2 Set the Signal Routing Block parameter. Refer to section “PLC Input Signal Routing Block” for more detail about PLC settings. Important Note: Signals PLC_10 to PLC_15 should not be changed unless you are very experienced with triggers and PLC settings. - Page 69 Figure 54: Signal Routing Block Figure 55: Signal Q0 linked to the value of parameter PLC_10 Appendix B: GPIO Control • 69...

-

Page 70: Trigger Settings: Guru Mode

Trigger Settings: GURU Mode In most use-cases the camera mode settings described in the Beginner section will suffice. The commands and parameters available in the Guru level allow you to perform finer adjustments to the triggers or create different use-cases from the ones predefined in the Beginner level. - Page 71 PLC_Q7 is fed to a rescaler input. So the rescaler will rescale line trigger signals: PLC_Q16 is set to Line1, which is frame trigger: PLC_Q16 is fed into delayer, so the frame trigger signal can be delayed: PLC_Q6 is direction and is fed by line2: Appendix B: GPIO Control •...

- Page 72 PLC_Q4_Variable0 can be PLC_I0 or PLC_I3, depending on whether or not the rescaler is enabled: PLC_Q12_Variable0 can be PLC_I1 or PLC_I4 depending on whether or not the delayer is enabled: PLC_Q14_Variable0 can be PLC_I1 or PLC_I4 depending on whether or not the delayer is enabled: 72 •...

-

Page 73: Pulse Generator

Pulse Generator The behavior of the Pulse Generator is defined by their delay and width. The delay is the amount of time the pulse is inactive prior to the pulse, and the width is the amount of time the pulse is active. The Pulse Generator signals can be set in either triggered or periodic mode. - Page 74 Delay Indicates the number of cycles (also determined by the granularity) that the pulse remains at a low level before rising to a high level. Trigger Mode Indicates how a triggered pulse generator will handle its triggers. The possible settings are: Triggered on rising edge: Indicates if a triggered pulse generator is triggered on the •...

-

Page 75: Rescaler

in the accompanying diagrams, the delay is the time between the trigger and the pulse transitions. The width is the time the pulse stays at the active level before transitioning. The periodic mode, the delay determines the low time of the pulse. Each pulse generator generates a signal that can be used as an input to the GPIO Control Block. - Page 76 0.00000024 0.00786 83,333 0.00000096 0.03146 20,833 0.00001536 0.50332 1,302 The “Min. Frequency” is a fixed minimum, otherwise the incoming signal period • counter gets saturated (reach the maximum count). The “Max. Freq.” is a recommended maximum to get Error less than 1%. •...

-

Page 77: Counter

sig_in_period_counter [15:0] = MIN( INT( Signal_In_Period / Granularity ), 65535) • multiplier_out [31:0] = sig_in_period_counter[15:0] x Multiplier_setting[15:0] • divider_ou t[27:0] = INT ( multiplier_out[31:0] / Divider_setting ) • Signal_Out_Period = MAX( divider_out[27:0], 2 ) x Granularity • Counter The counter maintains a count value that can be increased, decreased, or cleared based on input signals. -

Page 78: Input Debouncing

Counter Reset Activation Same as above, but for the clear event. The clear event input of the counter does not have a predefined label on the GPIO LUT. Counter Reset Source Indicates which label from the GPIO LUT that will be associated with the clear event input of the counter. -

Page 79: Timestamp Counter

Timestamp Counter Counter Select Timestamp Counter (default), General Purpose Counter. Granularity Indicates the value of each timestamp unit of the timestamp counter. Available values are: 480 nanoseconds, 1 microsecond, 100 microseconds, 10 milliseconds. Set Mode Indicates how the timestamp module handles the “set event”. Possible values are: Disabled On Apply-The specified value is set when the user clicks the Apply button. - Page 80 3: Q9 4: Q10 5: Q11 6: Q16 7: Q17 Clear Mode Indicates how the timestamp module handles the “clear event”. The possible values are: Disabled On Apply: The timestamp count is cleared when the user clicks the Apply button Rising edge input signal: Then the signal on the clear event input rises, the timestamp module clears the timestamp counter value Clear Input...

-

Page 81: Delayer

Delayer The delayer is used to delay an input signal. The output of the delayer is the delayed version of the input signal. A delayer is defined by: Delay: The delay is a value expressed in the number of rising edges from the reference signal. -

Page 82: The Plc Control Block

The following sections provide details on the LUT control block, the LUT programming language and the advanced features of the PLC. Note: the screenshots in this section are from the CamExpert GUI. Other GUI’s should contain a similar arrangement to what is shown. The PLC Control Block All signals pass through the PLC Control Block. - Page 83 Note that all external inputs (from the camera, TTL inputs, and PLC controls) are resynchronized. The outputs from the look-up table are synchronous. The LUT is programmed using a simple language. This language allows you to create logical equations that specify the conditions that set particular outputs Note: There is a delay of two clock cycles between the inputs of the LUT and its outputs.

- Page 84 PLC Input Signal Routing Block The following code sets the first entry in the PLC’s signal routing block: Setting the Signal Routing Block is complicated by the fact that each entry in the table has a different set of enumerated inputs. So for example, a value of 0 for i0(i.e. GPIO Input 0) means something different for i6 (i.e.

- Page 85 Valu GPIO GPIO GPIO GPIO GPIO GPIO Pulse Pulse Input 0 Input 1 Input 2 Input 3 Control Control Generator Generator Bit 1 Bit 0 1 Output 0 Output Frame Line Valid GPIO GPIO Data Spare Rescaler Pulse Valid Control Control Valid 0 Output...

-

Page 86: Gpio Output Labels

GPIO Output Labels Signal Label Description GPIO OUTPUT 0 GPIO output 0 GPIO OUTPUT 1 GPIO output 1 GPIO OUTPUT 2 GPIO output 2 GPIO OUTPUT 3 GPIO output 3 EXSYNC EXSYNC PRIN PRIN DIRECTION Camera forward and reverse control. CAM_CTRL (NOT CC4 signal. -

Page 87: Signal Routing Block

Signal Label Description Counter 0 clear event input • Timestamp counter set event input • Timestamp counter clear event input Output to the internal grabber to replace or mix with the camera’s FVAL signal. Depending on the camera, GPIO_FVAL the FVAL signal can be replaced or combined with the signal of this output. -

Page 88: How The Signal Routing Block Works

The Signal Routing Block lets you redirect signals from the IO Block, the Video IO Block, Lookup Table, and the Enhanced Function Block back into the Lookup Table for further processing. Because most of the other blocks in the PLC use preconfigured inputs and outputs, the Signal Routing Block is the primary method of routing a signal from one block to another. - Page 89 You can manipulate your inputs using simple or complex Boolean expressions. The following expressions are both valid: Q0 = I6 Q6 = !(I4 & I6) & ((I2 ^ I5) | I1) Correct Lookup Table Syntax Syntax Valid Construction Sample Line Line Output = Expression EOL (end of line)

-

Page 90: How The Lookup Table Works

Coyote) \r\n \n\r Incorrect Lookup Table Usage Rule Incorrect Syntax Correct Syntax The output must be on the I5 = Q4 Q4 = I5 left hand side of the equation (the value is being assigned to Q4, not I5). Outputs may not be on the Q1 = I7 &... -

Page 91: Appendix C: Emc Declaration

Models: SG-34-04K80, SG-34-02k40, and SG-34-02k80 The CE Mark, FCC Part 15, and Industry Canada ICES-003 evaluation of the Teledyne DALSA Spyder3 GigE cameras, which are manufactured by Teledyne DALSA Inc., satisfied the following requirements: EN 55022 Class A (1998) and EN 61326 (1997) Emissions Requirements... -

Page 92: Appendix D: Setting Up The Fval

Appendix D: Setting up the FVAL This setup only works with fixed frame trigger mode. Setup Signal Routing Block Figure 58: Signal Routing Block Step 1 Match counter duration with image height Figure 59: Setting counter duration, under Counters and Timers Controls 92 •... - Page 93 Figure 60: Setting image height, under Image Format Controls Step 2 Setup counter incremental source to line valid (PLC_A5) Figure 61: Setting PLC_I7 to PLC_A5 under Signal Routing Block Figure 62: Setting PLC_Q17_Variable0 to PLC_I7 under Q17 Appendix D: Setting up the FVAL •...

- Page 94 Figure 63: Setting Counter Incremental Source to PLC_Q17_RisingEdge under Counters Timers Control Step 3 Setup Counter Reset Source to external fixed frame trigger Figure 64: Setting PLC_I1 to Line1 Figure 65: Setting PLC_Q3_Variable0 to PLC_I1 94 • Appendix D: Setting up the FVAL...

-

Page 95: Examples: Setting The Fval

Figure 66: Setting Counter Reset Source to PLC_Q3 Examples: Setting the FVAL Line rate 5000, image height 100, input frequency is 40 hz. In the Frame Trigger Function Group > set the parameter Device Scan Type value to Linescan In the Inputs Group > set the parameter Line Selector value to Line1 Appendix D: Setting up the FVAL •... - Page 96 In the StartMode > set the parameter Frame Start Trigger value to On In the Sensor Control > set the parameter Accqusition Line value to 5000.000 In the Q0 > set the parameter PLC_Q0_Variable0 value to PLC_I5_Not In the Outputs > set the parameter Output Selector value to Line0 96 •...

- Page 97 The output from GPIO output line0 is shown below: Figure 68: FVAL signal waveform Appendix D: Setting up the FVAL • 97...

-

Page 98: Appendix E: Using The Rgb12 Mode In Camexpert

Appendix E: Using the RGB12 Mode in CamExpert Data Format The RGB12 mode (color 12-bit) is now available for the 2k and 4k GigE cameras. The following example uses the 2k camera to explain how to configure the RGB12 mode using CamExpert. - Page 99 Figure 60. 8-bit color image and its line profile of a dull object. This image above is, purposefully, a dull object image. Each color level was differentiated to make for easy distinguishing. Currently CamExpert does not provide a feature that reconstructs the 12-bit color image. However, it is able to display the color as mono.

- Page 100 Figure 62. 12-bit color-as-mono image of the same dull object in Figure 60. (The imaging condition is exactly the same as Figure 60.) If the striped image shown above is converted to a color image, it will be identical to the image in the screen capture with the exception that the bit depth is 12 rather than 8.

-

Page 101: Revision History

Revision History Rev Number Change Description Date Preliminary release. February 1, 2012 - Added Appendix D: Setting Up the FVAL May 31, 2013 - Revision to the Clearing Dark Current section. - Revised EMC Declaration section. -Operating temperature range revised from 0 – 50 July 28, 2014 °C to 0 –... -

Page 102: Index

Index background subtraction, 48 factory settings, 27 black level flat field correction control, 37 restrictions, 44 frame triggers, 35 calibration, 42, 43 calibration steps, 47 gain, 48 digital, 48 camera dimensions, 11 Gain camera information, 27 control, 37 GenICam camera interfacing tool, 24 description of, 2 certifications, 9 website, 2... - Page 103 rebooting, 41 requirements Ethernet switch, 14 LED, 20 network adapter, 14 line rate, 7 requirments lookup table, 88 PC, 14 rescaler, 73 resolution, 7 responsivity, 10 mechanical revision history, 96 drawing, 11 routers, 20 specifications, 7 models, 6 modes default, 34 sensor, 9 settings current, 29...

Need help?

Do you have a question about the Spyder3 Color SG-34 and is the answer not in the manual?

Questions and answers