Subscribe to Our Youtube Channel

Summary of Contents for KNF SIMDOS 10

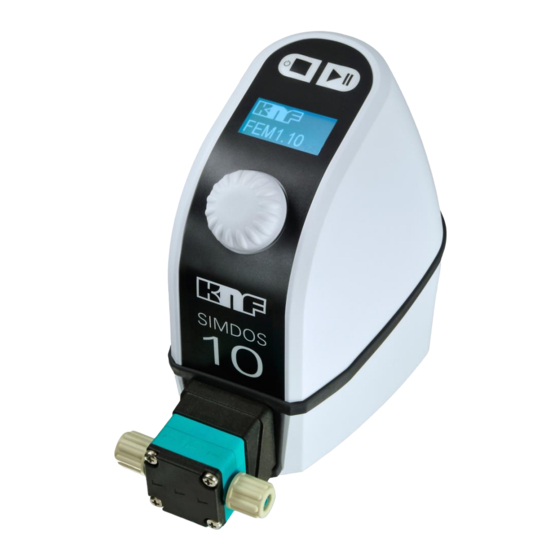

- Page 1 FEM1.10_ _.18_ _2 OPERATING INSTRUCTIONS ® SIMDOS DIAPHRAGM METERING PUMP Before operating the pump and the accessories, please read the operating instructions and pay attention to the safety precautions.

- Page 2 KNF Flodos AG Wassermatte 2 6210 Sursee, Switzerland Tel +41 (0)41 925 00 25 Fax +41 (0)41 925 00 35 www.knf.com...

-

Page 4: Table Of Contents

Pump diaphragm Pump head Operating controls Operating modes Shipment ..................30 Checking delivery Registering a complaint Arranging for return Installation and initial start-up ............31 Safety Installation System setup Initial start-up KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 5 Spare parts and accessories ............73 13.1 Spare parts 13.2 Hoses 13.3 Connection nipple 13.4 Pressure control valve 13.5 Liquid pulsation damper 13.6 Filter 13.7 Foot switch 13.8 Fastening material Decontamination declaration ............75 KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 6: General Points

It is listed with the other applicable documents. Illustrations in the instructions Illustrations in these operating instructions may be to scale, but do not have be. The illustrations may differ slightly from the actual product. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 7: Warnings

Indicates a dangerous situation which may lead to moderate or minor injuries if it is not avoided. NOTE Indicates a situation which may cause damage to property if it is not avoided. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 8: Symbols

Further details of the nature of the danger are provided in the warning highlighted by this symbol. Electrical danger Danger of caustic burns or burns Danger of automatic start-up This symbol calls for disconnection from the mains. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 9: Wassermatte

1.6 Year of manufacture The year of manufacture is shown on the device's type plate. 1.7 Other applicable documents The documents listed must also be taken into consideration. ▪ Chemical resistance list (www.knf.com/downloads) ▪ Sales documents ▪ General Trade Conditions 1.8 Copyright... -

Page 10: Safety

▪ used to transfer media containing solids with a particle size exceeding 70 µm. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 11: Owner's Responsibility

Individuals whose reactions have been impaired by the consump- Unauthorised personnel tion of medicines, alcohol, drugs or by other causes and conditions are not authorised to perform activities on the device. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 12: Product-Specific Dangers

➢ Place the pump in a suitable collecting vessel ➢ Never close the discharge outlet ➢ If medium escapes from the pump's discharge outlet, stop using the pump and contact your KNF dealer WARNING Danger of serious injuries or property damage caused by... -

Page 13: Personal Protective Equipment

➢ Never close the discharge outlet (see Fig. 1) ➢ If medium escapes from the pump's discharge outlet, stop using the pump and contact your KNF dealer In the event that the pump diaphragm ruptures, the safety dia- phragm prevents the transferred medium from penetrating into the pump. -

Page 14: Environmental Protection Considerations

The danger area of the pump is to be limited by means of safety work stations complying with DIN EN 12469 and DIN 12980, and collecting tanks. 2.10 Declaration of conformity KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 15: Technical Data

Valve plate / seals FFKM Diaphragm PTFE-coated EPDM membrane Included Filter PVDF* Housing PP, TPE, PC Tab. 2: TT materials according to DIN ISO 1629 and 1043.1 *material for housing and filter mesh KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 16: Product Key

KT / TT / FT / ST Head material Laboratory device with housing S2 / RC2 / RCP2 without remote control with remote control (Remote Control) RCP2 with RS 232 interface Tab. 5: Product key KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 17: Dimensions

▪ ▪ Manufacturer's CE mark address ▪ Year of manufacture ▪ Type ▪ Electrical connection data ▪ Serial Number ▪ Design pressure Differences are possible depending on the project KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 18: Installation Location Requirements

24 V DC Max. current consumption, DC RMS 24 V [A] Max. short-term peak current [A] 1,0 Max. power consumption [W] Pump protection Electronic overload protection Pump protection type IP 65 KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 19: Remote Control (Rc Version Only)

RS 232 interface TX – RS232 RX – RS232 Ground Settings (factory) Baud rate 9600 Kbit/s Data Bits 8 Parity Stop Bit 1 Mode Half duplex Tab. 8: RS 232 interface KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 20: Flow Rates

4mm / o.d. 6mm Hose fitting, UFEM 1.10 KT, TT i.d 1/8“ / o.d. 1/4"mm Internal thread NPT 1/8, UFEM 1.10 FT, ST Hose fitting, i.d 1/8“ / o.d. 1/4"mm Tab. 11: Hydraulic connections KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 21: Transferred Medium

➢ Operate the pump in a suitably protected area ➢ Check the resistance of any parts which come into con- tact with the fluid (see chemical resistance list or consult your local KNF dealer) WARNING Poisoning and caustic burns caused by bromine... -

Page 22: Accuracy/ Reproducibility

➢ Check resistance, see chemical resistance list and Sec- tion 4.3 ➢ Clarify resistance with KNF (see last page) 3.14 Accuracy/ reproducibility The accuracy of the metering pump is appropriately characterised by the maximum absolute error A and the maximum relative error ... -

Page 23: Assembly And Function

(2). In the upward stroke, the diaphragm pushes the medium out of the pump head via the outlet valve (1). The diaphragm hermetically seals off the working chamber (3) from the pump drive (7). KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 24: Valves

➢ Check the resistance of any parts which come into con- tact with the fluid (see chemical resistance list or consult your local KNF dealer, or contact lab@knf-flodos.ch) ➢ Avoid transferring media containing fluorine ➢ Regularly check that the pump is working properly and is... - Page 25 Valve Kit (see Section 13.1) is required for the liquids in Tab. 13. ➢ The resistance of the individual materials can be found in the chemical resistance list provided. ➢ In case of doubt, please contact your local KNF dealer. ® Fig. 6: Kalrez...

-

Page 26: Pump Diaphragm

• Start and interrupt transfer process Display • Display operating parame- ters Control knob • Set flow rate (turn) • Navigate through program (turn) • Confirm (press) Fig. 9: Operating controls KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 27 (3) is incremented until the programmed cycle num- ber (4) is reached. ▪ During metering, the transfer time remaining for the current dose is displayed. ▪ During the pause the pump counts down the pause time remaining. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 28 500 cSt Cal. 100% To calibrate the pump Cycle Set cycle metering mode (several volumes) Repetitions (Off, 2…999, Inf) Quantity: Pause: pause time (1s...99 min 59s) System Switch to system menu KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 29 Maintenance position for diaphragm replacing Back Switch to main menu NOTE * RC functions are available for RC pumps only (see Section 3.4). See Chapter 9 for further details of the external drive system. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 30: Operating Modes

Transferring of a specified volume in a specified time. Fig. 13: Metered volume with timeout Cycle metering mode The pump meters n repetitions of a defined metering cycle with pause time. metering several volumes Fig. 14: Cycle metering mode KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 31: Shipment

5.3 Arranging for return ▪ Prior requirements Device damaged or incomplete Procedure Contact KNF before returning the device Flush and decontaminate pump Fill out decontamination declaration Send the pump in its original packaging to a service location or one of our product centres... -

Page 32: Installation And Initial Start-Up

▪ Prior requirements Device is in perfect working order ▪ The system is operated with water ▪ Personnel Must be assembled by specialist personnel ▪ Personal protective equipment Not required KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 33: Installation

When connecting the device to a power source, the relevant norms, directives, regulations and technical standards must be observed. Use suitable adapters in the power supply unit Connect power supply unit to pump Fig. 15: Electrical connection KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 34 If there are no air bubbles in the system, the pump can be put into operation. NOTE Fig. 16: Prime pump vertically Air in the pump head causes inaccurate metering. Empty pump Refill pump KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 35 Push the hoses onto the connectors as far as they will go. Hand-tighten the union nut (2). Check that the hoses and hose/connector transitions are correctly and securely attached. Check that the system is leak-tight (see Section 8.5) KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 36 Check that the hoses and hose/connector transitions are correctly and securely attached. Check that the system is leak-tight (see Section 8.5) Fig. 19: Position of cutting ring and sealing ring on hose KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 37: System Setup

Keep suction hose as short as possible ▪ Select a suction hose with a large cross-section ▪ Vent the pump ▪ For constant results, keep the level of liquid constant (use a container with a large base) KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 38 (see Section 7.11) 6.3.5 Protection against overpressure In order to protect the system against overpressure, a safety valve must be fitted immediately downstream of the pump (see Fig. 23). Fig. 23: Overpressure protection KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 39: Initial Start-Up

➢ Do not transfer against shut-off devices or closed sys- tems, or ➢ install pressure relief/safety valves and set them to 6 bar (in the KNF product range) CAUTION Danger of unexpected chemical reactions with water Water residues left in the pump from testing in the factory may react with the transferred medium. -

Page 40: Operation

➢ Clean valve disk/pump head (see Section 8.4) ➢ Vent the pump and system thoroughly ➢ Set the type of liquid in the case of high-viscosity and vol- atile media (see Section 7.11) KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 41: Switching Pump On / Off

This swelling will cause errors in metering accuracy ➢ Check the resistance of any parts which come into con- tact with the fluid (see chemical resistance list or consult your local KNF dealer) The following requirements apply to all the activities described in this chapter: ▪... -

Page 42: Entering Settings

Press the “STOP” button: The pump will stop when this operation is carried out. This ends the input operation, and the display switch- es back to the main display. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 43: Setting The Operating Mode

Press the control knob to confirm the input Input Unit Setting range Flow rate Millilitres per minute [ml/min] 1 - 100 Metering volume Millilitres [ml] 1 - 1000.0 Fig. 31: Flow unit Tab. 16: Operating mode setting ranges KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 44: Priming The Pump

NOTE In "Pause" operating mode: ➢ when restarted, any interrupted transfer is continued. ➢ the pump responds to external control signals. Fig. 34: Interrupting a transferring operation KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 45: Stopping The Transferring Operation

Transferring after a Master Stop is only possible if: ▪ the Master Stop is manually cancelled using the "START" button; ▪ or if a "Reset" command is present at digital input 2. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 46: Transferring Fluid

▪ the time counter cannot be deactivated. The setting [- - min - - sec] is not possible. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 47: Setting The Fluid Type

500 cSt. This setting alters the characteristics of the pump as follows: The pump suction rate is significantly reduced Fig. 42: "Visc500cSt" fluid type The maximum flow rate is limited to 20 ml/min KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 48: To Calibrate The Pump

This means the pump can always be calibrated for the current operating point. NOTE If the target flow rate still cannot be achieved after several calibra- tion attempts, see "Troubleshooting" (Chapter 12). KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 49: Cycle Metering Mode

The pump starts when this operation is carried out ➢ Wait for 10 seconds without entering any inputs The pump ends the input operation and switches back to the main display KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 50: Select Language Setting

“AS” symbol (see Fig. Fig. 52). Fig. 52: Autostart symbol in display 7.18 Set contrast Display contrast adjustment. Adjust the contrast if the display is difficult to read. Fig. 53: Contrast KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 51: Resetting The Pump (Reset)

7.20 Shutting down the pump in an emergency In order to shut the pump down in an emergency, pull out the mains plug. Or shut the pump down using the "Stop" button KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 52: Cleaning And Maintenance

▪ The type of protective equipment required will depend on Personal protective equipment the medium to be transferred. ▪ Observe the safety data sheets for the media to be trans- ferred. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 53: Cleaning The Pump

➢ Flush pump with 10% hydrogen peroxide in a circular flow for 10 minutes ➢ Then flush with distilled water for 10 minutes NOTE The procedure described in Section 8.2.4 is not a sterilisation KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 54: Maintenance Plan

1,000 hours of Pump diaphragm, Specialist per- Replace pump diaphragm, valves operation valves and seal sonnel and seal Specialist per- as required Pump head Replace pump head sonnel Tab. 21: Servicing schedule KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 55: Cleaning / Replacing Valve Plates And Pump Diaphragm

Torque screwdriver that can be set to 0.55 Nm. Tab. 22: Tools/materials Always replace valve disks, valve seats and seals at the same Information on procedure time, to maintain satisfactory flow rate performance. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 56 Check that the pump is leak-tight (see Section 8.5) Head screws Head plate Connecting plate Sealing washer Valve seat O-ring Valve disk Intermediate plate Fig. 55: Head, KT, TT Head, FT KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 57 Completely remove head (10) Remove head plate (2) and head screws (1) Check diaphragms (20) for damage and replace where nec- essary Fold the connecting plate (3) and the intermediate plate (8) apart KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 58 Check valve material before using. For further information, see Section 4.3 DuPont™Kalrez ® ® CHEMRAZ Place pre-assembled valve seats (5) in connecting plate (3) Fit the connecting plate (2) and the intermediate plate (1) togeth- KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 59 Once fitted together, the seals and O-rings must not be moved again ➢ Hold the complete head together Fully assemble head (10) Tighten head screws (1) to 0.55 Nm. 0.55 Nm Check that the pump is leak-tight (see Section 8.5) KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

- Page 60 Hoses must be disconnected from the pump head ▪ Pump is connected to the mains ▪ Personnel specialist personnel trained by KNF ▪ Personal protective equipment The type of protective equipment required will depend on the medium to be transferred.

-

Page 61: Checking That Pump Is Leak-Tight

Check tightening torque of head screws. Check that elastomer parts are clean. Check leak-tightness again. If these actions have no effect, contact your local KNF dealer and do not under any circumstances continue to use the pump. KNF Flodos BA_SIMDOS10_EN_05_167721.docx... -

Page 62: Rc Version (Remote Control)

Digital input 1 • White Digital input 2 • Blue Open collector output • Black Ground • Grey Fig. 58: KNF Flodos RC cable pin assignment Pin Wire colour Description Function max. value brown Analog input 1% to 100% 10 V DC... -

Page 63: Remote Control Analog Input

Tab. 25: On/off thresholds If the input is less than 2 mA, the pump will go into alarm mode, and the alarm is automatically reset as soon as the input exceeds 2 mA. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 64 “START” once to cancel Master Stop. For an external restart after a power cut, use autostart (see Section 7.17) or Reset on digital input 2 (see Section 9.3). KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 65: Digital Input 1, Start / Stop

The pump will start to operate if the level is below 0.8 V, and stop if it is above 2.0 V (see Fig. 63). Fig. 63: Start / Stop level actuation KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 66 Fig. 65: Start ml/min with time counter level control NOTE If timeout / time counter is activated ➢ to stop the pump, use digital input 2, “Reset” (see Section 9.3) ➢ For precise dosing use pulse-mode KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 67: Digital Input 2 Reset / Prime / Foot Switch

Start / Stop according to signal < 0.8V = On level > 2.0V = Off Pulse Start / Stop on signal pulse < 0.8V = On > 2.0V = Off Tab. 27: Digital input 2 options KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... - Page 68 Press “START” – the pump goes into “Pause” condition. The pump will keep operating as long as the foot switch is pressed. NOTE If time counter is switched on, pump will perform a complete metering cycle. KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English...

-

Page 69: Digital Output

Signal when volume metering ends Level Mot.Pul. 10 pulses per revolution of the pump motor Pulse Vol.Pul. One pulse per 100 µl of fluid transferred Pulse Tab. 28: Digital output options KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 70: Rc Plus Version (Serial Communication)

Connect the RC cable to the pump. The commands and protocol are available on (search: “communication protocol”) www.knf.com/downloads Master Pumpside D-Sub 9 connector Fig. 70: KNF Flodos RC cable pin assignment KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 71: Shutdown

Flush the whole system including the pump with a neutral liquid Pump the pump empty (see Section 8.2). Press the STOP button to end the transferring operation Unplug the pump from the power supply Dispose of pump properly KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 72: Troubleshooting

System pressure exceeds 7 bar ➢ Check pump for closed Overpressure valves and blocked fil- ters If the fault cannot be rectified, please contact your local KNF dealer (see last page for address) KNF Flodos BA_SIMDOS10_EN_05_167721.docx Translation of original operating instructions, English... -

Page 73: Rectifying Transfer Problems

Send pump to KNF dealer for safety check Tab. 29: Pump does not work If the fault cannot be rectified, please contact your local KNF dealer (see last page for address) Returning the pump Flush the pump to clear the pump head of any hazardous or aggressive liquids (see Cleaning the pump). -

Page 74: Spare Parts And Accessories

Standard, Kalrez® (without diaphragm) 167670 SIMDOS 10 ST Complete Head Kit; Option, Chemraz® (without diaphragm) 167671 SIMDOS 10 UFEM KT Complete Head Kit; Standard Kalrez® (without diaphragm) 167674 SIMDOS 10 UFEM TT Complete Head Kit; Standard Kalrez® (without diaphragm) 167675 SIMDOS 10 UFEM FT Complete Head Kit;... -

Page 75: Liquid Pulsation Damper

13.5 Liquid pulsation damper Liquid pulsation damper kit Order No. SIMDOS 10 Accessory Set FPD10 KT 167817 SIMDOS 10 Accessory Set FPD 10 TT 167818 SIMDOS 10 Accessory Set FPD 10 FT 167819 SIMDOS 10 Accessory Set UFPD 10 KT... -

Page 76: Decontamination Declaration

Decontamination declaration Decontamination declaration NOTE KNF shall only undertake to repair the pump on condition that the customer provides certification of the transferred media and the cleaning of the pump (decontamination declaration). Copy this page, or print out the decontamination declaration from our website http://www.knf.com/downloads. - Page 77 www.knf.com...

Need help?

Do you have a question about the SIMDOS 10 and is the answer not in the manual?

Questions and answers