Advertisement

Table of Contents

- 1 About These Instructions

- 2 General Safety Instructions

- 3 Safety Instructions for Personnel

- 4 Cleaning

- 5 Product Liability and Warranty

- 6 CE-Conformity

- 7 Description

- 8 Technical Data

- 9 Function

- 10 Starting up and Operation

- 11 Earthing

- 12 Starting-Up the Control Unit/ Spray Gun

- 13 Troubleshooting and Maintenance

- 14 Product Disposal

- 15 Spare Parts

- 16 Spare Parts List VM2000

- Download this manual

Advertisement

Table of Contents

Summary of Contents for WAGNER VM 2000

- Page 1 Translation of the original Operating manual VM 2000 Edition 03 / 2007 Electrostatic control unit for E-Static manual sprayguns...

- Page 3 Safety instructions for the operator 2.1.1 Electrical equipment 2.1.2 Personnel qualifi cations 2.1.3 A safe work environment Safety instructions for personnel 2.2.1 Safe handling of WAGNER spray units 2.2.2 Earth the unit 2.2.3 Material hoses 2.2.4 Cleaning 2.2.5 Handling hazardous liquids, varnishes and paints 2.2.6...

-

Page 4: About These Instructions

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL ABOUT THESE INSTRUCTIONS LANGUAGES 0388870 0388871 0388872 0388873 0388874 0388875 0388877 0388876 0388878 0179796 0179797 WARNINGS, NOTES AND SYMBOLS IN THESE INSTRUCTIONS... -

Page 5: General Safety Instructions

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL GENERAL SAFETY INSTRUCTIONS SAFETY INSTRUCTIONS FOR THE OPERATOR 2.1.1 ELECTRICAL EQUIPMENT 2.1.2 PERSONNEL QUALIFICATIONS 2.1.3 A SAFE WORK ENVIRONMENT... -

Page 6: Safety Instructions For Personnel

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL SAFETY INSTRUCTIONS FOR PERSONNEL 2.2.1 SAFE HANDLING OF WAGNER SPRAY UNITS 2.2.2 EARTH THE UNIT 2.2.3 MATERIAL HOSES... -

Page 7: Cleaning

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL 2.2.4 CLEANING 2.2.5 HANDLING HAZARDOUS LIQUIDS, VARNISHES AND PAINTS 2.2.6 TOUCHING HOT SURFACES CORRECT USE SAFETY-RELEVANT INFORMATION ABOUT DISCHARGES... -

Page 8: Product Liability And Warranty

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL PRODUCT LIABILITY AND WARRANTY IMPORTANT NOTES ON PRODUCT LIABILITY WARRANTY... -

Page 9: Ce-Conformity

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL CE-CONFORMITY Herewith we declare that the supplied version of 0179109 Control unit VM 2000 Complies with the following provisons apllying to it: 73/23/EWG 89/336/EWG 92/31/EWG 93/68/EWG 98/37/EG 94/9/EG Applied standards, in particular:... -

Page 10: Description

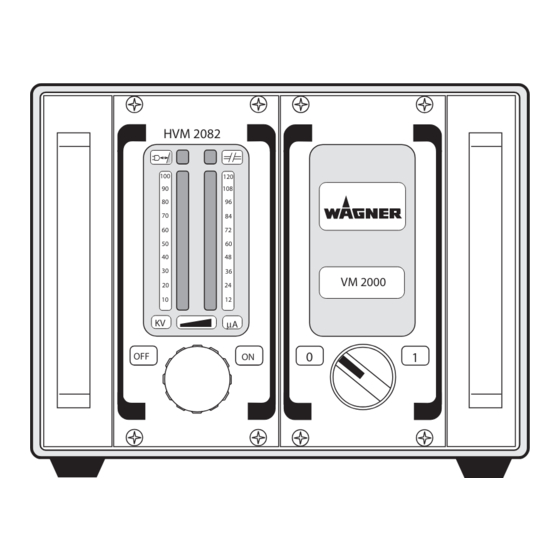

WAGNER‘s electrostatic control unit VM 2000 controls the high voltage supply to the spray guns used to apply liquid coating media GM 2000EA, GM 2000EAC and GM 2800EA. The VM 2000 electrostatic control unit can only be used in conjunction with spray guns of type GM 2000EAC, GM 2000EA or GM 2800EA. -

Page 11: Technical Data

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL TECHNICAL DATA Input voltage: 115VAC 50/60Hz 230VAC 50/60 Hz k Input power: max. 30 W Output voltage: max. 17 Vpp Output current: max. 0.9 A High voltage limit 80 kV DC Corona current limiting: 100 µA DC... -

Page 12: Function

Red LED display (left) Not in operation Grounding guard circuit (LED - red) gun cable fault Lights up when the connecting cable from VM 2000 to the spray gun is not plugged in or is faulty. HVM goes into fault mode, i.e.: •... -

Page 13: Starting Up And Operation

This control unit is used to complete an electrostatic spraying system,with an spray gun and various other components (see WAGNER accessories), e.g. paint supply equipment. With the electrostatic control unit VM 2000 may be used the spray guns: ➞ GM 2000EAC ➞... -

Page 14: Earthing

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL EARTHING Perfect earthing of all system components (workpieces, conveyor, paint supply system, control unit, spray booth or spraying stand, see illustration) is a prerequisite for optimum coating effi ciency and safety. - Page 15 VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL Earthing scheme (example) Conveyor Control modul Workpiece Earthing cable Pump Spraying stand Paint container System earth Floor, antistatic System earth Minimum cable cross-section Control unit 4 mm² (AWG 12) Pump 4 mm²...

-

Page 16: Starting-Up The Control Unit/ Spray Gun

Note: The local mains voltage must com-play with the voltage quoted for the VM 2000. 1. Connect the electrostatic control unit VM 2000 to the mains socket (15). The mains socket should be interlocked with the extraction system. 2. Connect the earth cable to the earthing screw (12) and to system earth. -

Page 17: Troubleshooting And Maintenance

• 0.5 / 1.6 A slow-blow fuses • Replace fuses defective Red LED (5) lights up (no • HVM-mdule defective • Inform your local WAGNER Service high-voltage supply) Center Red LED (6) lights up (no • Open circuit in the connecting •... -

Page 18: Product Disposal

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL PRODUCT DISPOSAL... -

Page 19: Spare Parts

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL SPARE PARTS HOW TO ORDER SPARE PARTS? -

Page 20: Spare Parts List Vm2000

VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL SPARE PARTS LIST VM2000 Item K Part No. Description 0241270 Mains cable standard 3 m; 9.8 ft 0264626 Mains cable USA 2 m; 6.6 ft 0130215 Earth cable assy. 10 m; 32.8 ft ◆... - Page 21 VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL...

- Page 22 VM 2000 EDITION 03 /2007 PART NO. DOC0388871 OPERATING MANUAL...

- Page 24 0388871...

Need help?

Do you have a question about the VM 2000 and is the answer not in the manual?

Questions and answers