Table of Contents

Summary of Contents for SEWOO LK-B30

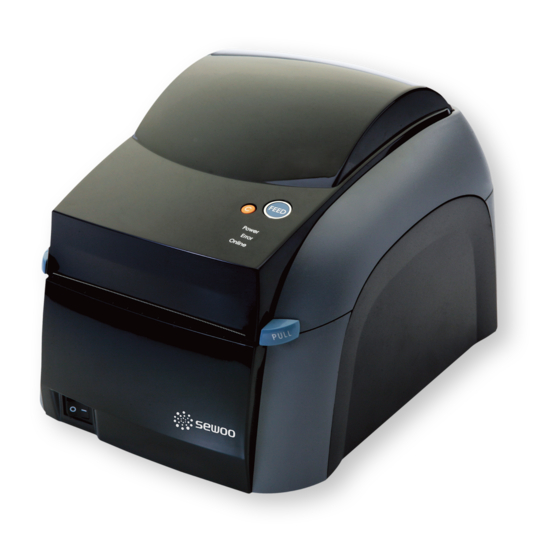

- Page 1 SEWOO TECH CO.,LTD. 374-2, Gajang-dong, Osan-si, Gyeonggi-do, 447-210, Korea TEL : +82-31-459-8200 FAX : +82-31-459-8880 www.miniprinter.com MODEL : LK-B30 4” DESKTOP LABEL PRINTER All specifications are subject to change without notice B30 Rev. B 06/13...

-

Page 2: Table Of Contents

Table of Contents 1. SAFETY CAUTION 2. UNPACKING 3. PRINTER IDENTIFICATION 4. CONNECTING POWER SUPPLY 5. HOOKING UP THE PRINTER AND COMPUTER 6. LOADING THE MEDIA 7. THE TREATMENT WHEN YOU RUN SHORT OF PAPER AND ENCOUN- 8. SETTING UP THE SENSORS 9. -

Page 3: Safety Caution

1. Safety Caution For higher reliability and safety, consider the following precautionary measures. WARNING Read and follow the instructions carefully before running of the product. Failure to follow these instructions could result in fire, electric shock, or other injuries, or property damage Indication Prohibition Must follow... -

Page 4: Unpacking

2. Unpacking 3. Printer identification Printer Interface cable (selected optionally) Interface Connectors Power Connectors Printer Head Notch Sensor Paper width Guide Power supply Power Cord(1EA) Black Mark Sensor Button CD (Manual and Software) Quick Manual Paper Spindle Power Switch Upper Cover Knob... -

Page 5: Connecting Power Supply

4. Connecting power supply Opening the printer 220VAC Power Connectors 115VAC Open the upper cover by pushing the knob in the Make sure to be careful of the HOT head after direction of the arrow. using long time. Please check the specification of the AC power Turn off the power of the printer and connect cord if it is correct with your power system. -

Page 6: Hooking Up The Printer And Computer

5. Hooking up the printer and computer 6. Loading the media -Printer- Serial Parallel -Computer- Turn off the printer and open the upper cover by Please open the upper cover as shown above pushing the knob in the direction of the arrow After making sure the printer is turned off, connect the printer to the PC. -

Page 7: The Treatment When You Run Short Of Paper And Encoun

The treatment when you run short of paper and encounter cutter jam problem While you are printing with continuous media, please press PULL lever to the direction of the arrow. Insert the paper roll into the printer Adjust the paper width guide to meet the paper width **Installation of the new paper when **Remove of the paper seized by... -

Page 8: Setting Up The Sensors

9. Self Test 8. Setting up the sensors Black Mark Sensor Notch Sensor Note Power switch sig Turn off the printer Press and hold the feed button while turning on Set Black Mark Sensor right to the size of roll paper Locate notch sensor on the same number point- as the the printer with power switch black mark sensor is indicating on. -

Page 9: Auto Setup For Label Size

11. Pause and cancel function 10. Auto setup for label size Note Power switch sig When you would pause on the printing process, press the ‘P’ key. Turn off the printer While you are pressing and holding ‘P’ button, turn off the power of printer. When you would cancel printing, you should proceed the cancel on your PC at first. -

Page 10: Printer Cleaning

12. Printer cleaning 13. Connector If the interior of the printer is dusty, printing quality can lowered. Interface Connectors In such a case, follow the instructions below to clean up the printer. NOTE Standard 1. Make sure to turn the printer power off prior to cleaning 2. -

Page 11: Standard Roll Media Specification

14. Standard roll media specification Centronics Parallel Interface Signal Description STROBE- Input Synchronize signal Data received DATA0~7 Input/Output Data bit Transmitted 0~7 ACK- Output Data receiving completed. BUSY Output Impossible to print of data receiving. Output Paper empty SELECT Output Printer status for ON/OFF line AUTO FEED- Input... -

Page 12: Standard Label Specification

16. Label specification with Through-hole 15. Standard label specification Tag or strip width <-- a --> <-- a --> Media width (inch, liner) Maximum 118 mm Maximum 118 mm Minimum 18 mm Minimum 18 mm Tag length <-- b --> <-- b -->... -

Page 13: Label With Black Mark

18. Continuous stock specification 17. Label with Black Mark The printer can use continuous paper without any detection gap or black marks. <-- a --> Tag or strip width The printer must be set for continuous paper by the Q command. The length of each copy is decided by the size of the print image and any additional media feed is Maximum 118 mm... -

Page 14: Specifications

19. Specifications Product Specifications Certification (1) FCC PART15 CLASS A Print method Direct Thermal CE EMCD (CE-EMCD Class B should use Parallel shield Cable complied with IEEE-1284 standards) Print speed(max) 152mm/sec (3) UL/cUL (UL 60950-1) Print width(max) 104mm ♣“This equipment is indoor use and all the communication wiring are limited to inside of the Print length(max) 630mm building”... -

Page 15: Command List

20. Command List Command Description Command Description ASCⅡ Text Options Select AUTOFR Automatic Form Printing OEPL1 Set Line Mode Bar Code Print RSS-14 Bar Code Print Automatic Data Matrix Set Form Length MaxiCode Transmissive(Gap)Sensor PDF417 Black Line Sensor Counter Continuous Stock Set Form Width Cut Immediate Set Double Buffer Mode...

Need help?

Do you have a question about the LK-B30 and is the answer not in the manual?

Questions and answers