Heatilator ECO-WINS18 Owner's Manual

Hide thumbs

Also See for ECO-WINS18:

- Owner's manual (48 pages) ,

- Owner's manual (48 pages) ,

- Owner's manual (48 pages)

Table of Contents

Advertisement

Quick Links

Model:

ECO-WINS18

WOOD BURNING INSERT

•

If the information in these instruc-

tions is not followed exactly, a

fire may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other appliance.

• Do not over fire - If heater or chimney

connector glows, you are over firing. Over

firing will void your warranty.

• Comply with all minimum clearances to

combustibles as specified. Failure to

comply may cause house fire.

WARNING

Fire Risk.

For use with solid wood fuel only.

Other fuels may over fire and generate

poisonous gases (i.e. carbon monoxide).

Consumer Care 1-877-427-3316 - Prior to calling, please

have the model and serial number of the unit you are call-

ing about. This information can be found at the front of the

unit.

www.heatilatorecochoice.com

DO NOT DISCARD THIS MANUAL

• Read, understand and

Important operating

a n d m a i n t e n a n c e

instructions included.

WARNING

7065-132I • May 18, 2017

CAUTION

follow these instructions

for safe installation and

operation.

Hot glass will cause burns.

•

Do not touch glass until it is cooled

•

NEVER allow children to touch glass

•

Keep children away

• CAREFULLY SUPERVISE children in same room as

fireplace.

•

Alert children and adults to hazards of high

temperatures.

High temperatures may ignite clothing or other

flammable materials.

•

Keep clothing, furniture, draperies and other

flammable materials away.

Installation and service of this appliance should be performed by

qualified personnel. Hearth & Home Technologies recommends

HHT Factory Trained or NFI certified professionals.

Owner's Manual

Installation and Operation

• Leave this manual with

party responsible for

use and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are

hot during operation AND

cool down.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Heatilator ECO-WINS18

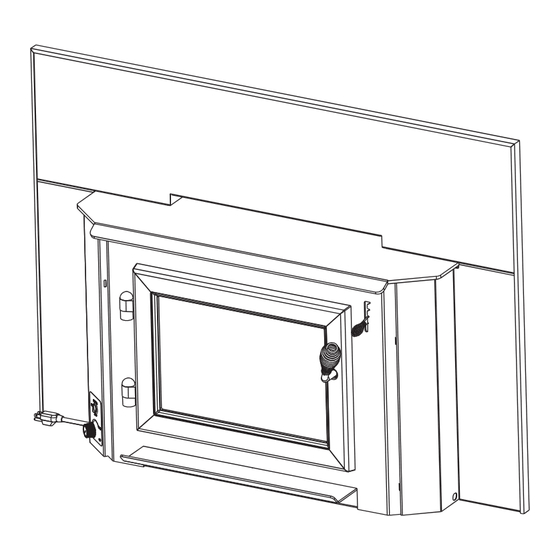

- Page 1 Owner’s Manual Installation and Operation Model: ECO-WINS18 WOOD BURNING INSERT CAUTION DO NOT DISCARD THIS MANUAL • • Read, understand and • Leave this manual with Important operating follow these instructions party responsible for a n d m a i n t e n a n c e for safe installation and use and operation.

-

Page 2: Sample Of Serial Number / Safety Label

L'INSTALLATION. LE CONTACT PEUT CAUSER DES BRÛLURES À LA PEAU. VOIR L'ÉTI- QUETTE ET LES INSTRUCTIONS. Serial No. / N° de série Test Lab & Report Model / Modèle: ETL4001508 ECO-WINS18 Number BARCODE LABEL WOOD INSERT Tested to / Testé a: UL 1482, ULC S628-93 Serial Number APPAREIL DE CHAUFFAGE DE PIÈCE, DE TYPE DE COMBUSTIBLE SOLIDE. -

Page 3: Table Of Contents

Safety Alert Key: • DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury. • WARNING! Indicates a hazardous situation which, if not avoided may result in death or serious injury. CAUTION! Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury. •... -

Page 4: Warranty Policy

HEATILATOR ECO-CHOICE WARRANTY Hearth & Home Technologies Inc., on behalf of its hearth brands (“HHT”), extends the following warranty for ECO- CHOICE by heatilator wood and pellet hearth appliances that are purchased from an HHT authorized dealer. WARRANTY COVERAGE: HHT warrantes to the original owner of the HHT appliance at the site of installation, and to any transferree taking own- ership of the appliance at the site of installation within two years following the date of original purchase, that the HHT appliance will be free from defects in materials and workmanship at the time of manufacture. - Page 5 WARRANTY COVERAGE: • This warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor. A list of HHT authorized dealers is available on th HHT branded websites. • This warranty is only valid while the HHT appliance remains at the site of original installation. •...

-

Page 6: Listing And Code Approvals

EPA emissions test. **Weighted average HHV efficiency using Douglas Fir dimen- The Heatilator ECO-WINS18 meets the U.S. Environmental sional lumber and data collected during EPA emissions test. Protection Agency’s crib wood emission limits for wood ap- ***A range of BTU outputs based on EPA Default Efficiency and pliances sold after May 15, 2015. -

Page 7: User Guide

User Guide Operating Instructions WARNING HOT SURFACES! Glass and other surfaces are hot during operation AND cool down. Hot glass will cause burns. DO NOT touch glass until it is cooled • • NEVER allow children to touch glass • Keep children away •... -

Page 8: Fire Safety

B. Fire Safety D Combustible/Non-Combustible Materials • Combustible Material To provide reasonable fire safety, the following should be given serious consideration: Material made of or surfaced with wood, compressed Install at least one smoke detector on each floor of paper, plant fibers, plastics, or any material capable your home to ensure your safety. -

Page 9: Burning Process

2. Second Stage G. Burning Process In the secondary stage wood gives off flammable gases which In recent years there has been an increasing concern about burn above the fuel with bright flames. air quality. Much of the blame for poor air quality has been placed on the burning of wood for home heating. -

Page 10: Burn Rate Air Controls

H. Burn Rate Air Controls I. Burn Rates and Operating Efficiency This wood appliance has a manufacturer-set minimum low • The air supply enters at the upper front of the firebox, burn rate that must not be altered. It is against federal regula- near the top of the glass door. -

Page 11: Correct Baffle & Blanket Placement

INCORRECT POSITIONS J. Correct Baffle & Blanket Placement WARNING Fire Risk Improper baffle placement may cause: • Overheating of firebox • Overheating the chimney Baffle must be placed properly (see instructions) Replace baffle if damaged or missing. NOTE: A missing, damaged or improperly positioned baffle Ceramic Blanket and Baffle Board are NOT is dangerous and may cause damage and poor efficiency. -

Page 12: Building A Fire

K. Building A Fire 9. When ready to reload, It is best to set the Burn Rate Air Control in the High position before reloading. WARNING • This livens up the coal bed and reduces excessive emis- sions (opacity/smoke). Fire Risk. Keep combustible materials, gasoline •... -

Page 13: Wood Fuel & Storage

Moisture L. Wood Fuel & Storage The majority of the problems appliance owners experience are caused by trying to burn wet, unseasoned wood. WARNING • Wet, unseasoned wood requires energy to evaporate the Fire Risk. water instead of heating your home, and •... -

Page 14: Blower Control Box & Snap Disc Operating Instructions

M. Blower Control Box & Snap Disc Operat- ing Instructions 1. The blower will turn on/off automatically when set to AUTO. Figure 14.1. 2. When set to MANUAL, the fan will turn on/off only when you turn it on or off. This setting over-rides the internal snap disc. -

Page 15: Clear Space

Q. Opacity (Smoke) O. Clear Space Opacity is the measure of how cleanly your appliance is Do NOT place combustible objects within 4 ft (1.2 m) of the burning. front of fireplace. Figure 15.1. Opacity is measured in percent: • 100% opacity is when an object is totally obscured by WARNING the smoke column from a chimney, and... -

Page 16: Quick Start Guide

R. Quick Start Guide 10 Pieces of Newspaper, 10-20 Pieces of Dry Kindling ITEMS NEEDED FOR FIRST FIRE: and a Few Pieces of Dry Split Wood. OPEN AIR ADD NEWSPAPER LOAD WOOD CONTROL HIGH ADD KINDLING WARNING! Risk of Fire Close and securely latch the door after prevent: •... -

Page 17: Maintenance And Service

Maintenance and Service Creosote - Formation and Need for Removal A. Disposal of Ashes • When wood is burned slowly, it produces tar and other organic vapors, which combine with expelled moisture to • Frequency: When ash is within 1-3/4 inch (44mm) of form creosote. -

Page 18: Glass Cleaning

D. Glass Cleaning E. Firebrick Inspection & Replacement • Frequency: As desired • Frequency: After each ash removal • By: Homeowner • By: Homeowner • Clean glass with a non-abrasive glass cleaner. Abrasive cleaners may scratch and cause glass to crack. Replace the firebrick if they become crumbly and/or if there •... -

Page 19: Quick Reference Maintenance Guide

F. Quick Reference Maintenance Guide Start the first inspection after the first 2 months of use, or if performance changes, and adjust your schedule accord- CAUTION! Allow the appliance to completely cool ingly. Maintenance is required for safe operation and must down before performing any cleaning or maintenance. -

Page 20: Troubleshooting Guide

Troubleshooting Guide With proper installation, operation, and maintenance your wood appliance will provide years of trouble-free service. If you do experience a problem, this troubleshooting guide will assist you or a qualified service person in the diagnosis of a problem and the corrective action to be taken. -

Page 21: Service Parts Replacement

• Do NOT operate with glass cracked, broken or Power Cord Black White Black scratched. Heatilator appliances are equipped with ceramic super heat- resistant glass, which can only be broken by impact or misuse. Switch B. Snap Disc Replacement Rheostat 1. Remove surround from appliance. -

Page 22: Baffle Removal

C. Baffle Removal 1. Remove surround from appliance. 2. Using a Phillips head screwdriver, remove 8-32 screw, 8-32 MACHINE washer and bushing assemblies holding left side panel SCREWS in place. Remove panel. Figure 21.1 on page 21 (x4) 3. Disconnect the wires from the blower. 4. -

Page 23: Baffle And Ceramic Blanket Removal

E. Baffle and Ceramic Blanket Removal Remove all ash from the firebox, and extinguish all hot embers before disposal into a metal container. Remove the baffle protection channel by rotating it down from the front tube. Figure 23.1. The baffle board has 2 pieces. With the ceramic blanket still in place, slide one baffle piece over the top of other one and pull out top piece through the door opening and then remove bottom baffle piece. -

Page 24: Tube Channel Assembly Replacement

G. Tube Channel Assembly Replacement Removing Tube Channel Assembly is off the threads. Drop the right side down, then slide 1. Remove the right side bricks (3 pieces). the assembly back to right. 2. Remove the baffle protection channel by rolling forward 5. -

Page 25: Installer's Guide

• During a low burn, the chimney draft (static pressure) should be approximately -.04 inch water column (W.C.) Heatilator wood inserts are designed for factory-built non- • During a high burn the chimney draft should be approximately combustible fireplaces that have been installed in accor- -.10 inch (W.C.) -

Page 26: Negative Pressure

C. Negative Pressure WARNING Asphyxiation Risk. • Negative pressure can cause spillage of com- bustion fumes, soot and carbon monoxide. • Appliance needs to draft properly for safety. Negative pressure results from the imbalance of air avail- able for the appliance to operate properly. It can be stron- gest in lower levels of the house. -

Page 27: Locating Your Appliance & Chimney

D. Locating Your Appliance & Chimney • Consider the appliance location in order to avoid floor and ceiling attic joists and rafters. Location of the appliance and chimney will affect perfor- mance. As shown in Figure 27.1 the chimney should: •... -

Page 28: 2-10-3 Rule

F. 2-10-3 Rule These are safety requirements and are not meant to assure proper flue draft. This appliance is made with a 6 inch (152mm) diameter chimney connector as the flue collar on the appliance. • Changing the diameter of the chimney can affect draft and cause poor performance. •... -

Page 29: Tools And Supplies Needed

G. Tools and Supplies Needed Pre-Burn Check List Before beginning the installation be sure the following tools and building supplies are available: Place the appliance in a location near the final 7/16 Socket Framing materia installation area and follow the procedures below: Reciprocating saw High temp caulking material l Open the appliance and remove all the parts and... -

Page 30: Dimensions And Clearances

Dimensions and Clearances A. Appliance Dimensions NOTE: Flue Collar size is 6 inch (152mm) diameter (ID) 7-5/16 in. 10-1/2 in. (186mm) (267mm) 24-1/4 in. 5-3/16 in. (616mm) (132mm) 15-11/16 in. (398mm) 10-1/2 in. (267mm) 21-1/16 in. 9-7/16 in. 20 in. (534mm) (240mm) (508mm) -

Page 31: Clearances To Combustibles (Ul And Ulc)

B. Clearances to Combustibles (UL and ULC) TOP TRIM (3/4” max depth) 22 7/8 29 3/8 (579mm) (746mm) 34 (864 mm) HEARTH EXTENSION (MINIMUM EMBER PROTECTION) USA 31 5/8 CANADA 39 5/8 (1006mm) Figure 31.1 Top Trim & Hearth Extension Width Mantel Optional Mantel... -

Page 32: Alternate Floor Protection Calculation

Factory-Build Solid Fuel Fireplace Floor Protection Under Hearth Extension USA & CANADA ONLY CANADA ONLY Hearth Height Hearth Height 0 to 7 inches 0 to 7 inch (0 to 178mm) Thermal Protection Thermal Required Protection Required Minimum Minimum R value = 0.52 R value = 0.52 0 to 7inch (0 0 to 7 inch (0... -

Page 33: Venting And Chimney Systems

Venting and Chimney Systems A. Venting Systems D. Chimney Systems • Must meet minimum standards of NFPA 211. Chimney Connector: • Must have at least 5/8 inch (16mm) fireclay lining joined It is also known as flue pipe or liner. It must be 6 inches with refractory cement. -

Page 34: Chimney Systems (Cont'd)

D. Chimney Systems (Cont’d) NOTE: In Canada, this fireplace insert must be installed with a continuous chimney liner of a 6 inch (152mm) diam- This insert conforms with the UL 1482 and ULC S628 eter extending from the fireplace insert to the top of the (Canada) in all respects, and is approved to UL &... -

Page 35: Metal Heat Circulating Masonry

E. Metal Heat Circulating Masonry Inches Millimeters Minimum Width of Cavity Opening - Front 24 1/2* 622* This insert conforms with the safety standard UL-1482 and ULC S628 (Canada) in all respects and is approved to UL & Minimum Width of Cavity Opening - Rear 24 1/2* 622* ULC safety standards for installation and use within a fire-... -

Page 36: Securing Chimney Components

G. Securing Chimney Components I. Factory-Built Solid Fuel Fireplace All joints should be secured with 3 sheet metal screws or A permit may be required for installations, final approval is rivets per pipe manufacturers instructions. The sections must contingent of the authority having local jurisdiction. Consult be attached to the insert and to each other with the crimped insurance carrier, local building, fire officials or authorities... -

Page 37: Ovalizing Round Stainless Steel Liners

• Lose protection to combustible surfaces from the K. Chimney Height / Rise and Run liner in case of fire. To be sure that your Heatilator insert burns properly, the • Poor performance and start-ups. chimney draft (static pressure) should be approximately -0.10 •... -

Page 38: Appliance Set-Up

Appliance Set-up A. Outside Air Kit Installation WARNING A source of air (oxygen) is necessary in order for combustion to take place. Whatever combustion air is consumed by the fire Fire Risk. must be replaced. Air is replaced via air leakage around win- Asphyxiation Risk. -

Page 39: Securing Appliance Pipe/Liner To Flue Collar

B. Securing Appliance Pipe/Liner to Flue Col- Cast Iron Flue Located on Appliance 1. There are 4 pre-drilled holes in the flue collar 90 degrees apart. Attach the flue collar to the appliance pipe/liner. If the seal is questionable use appliance mastic Figure 39.1. -

Page 40: Securing Appliance To Appliance Pipe/Liner

D. Securing Appliance to Appliance Pipe/ E. Standard Surround & Trim Kit Installation Liner Standard Size: 43 in. W x 31 in. H Large Size: 51 in. W x 34 in. H 1. Once you have the appliance in place and secured, remove the tube channel assembly, baffle board and 1. -

Page 41: Mobile Home Installation

Mobile Home Installation An outside air inlet must be provided for combustion and must remain clear of leaves, debris, ice and/or snow. It must be unrestricted while appliance is in use to prevent WARNING room air starvation which can cause smoke spillage and an inability to maintain a fire. -

Page 42: Reference Materials

Reference Materials A. Service and Maintenance Log Date of Service Performed By Description of Service 7065-132I • May 18, 2017 www.heatilatorecochoice.com... - Page 43 Date of Service Performed By Description of Service 7065-132I • May 18, 2017 www.heatilatorecochoice.com...

-

Page 44: Expanded View

B. Expanded View ECO-WINS18 Service Parts Beginning Manufacturing Date: May 2011 Wood Insert Ending Manufacturing Date: Active 16 17 Part number list on following page. 05/11 7065-132I • May 18, 2017 www.heatilatorecochoice.com... -

Page 45: Service Parts And Accessory List

C. Service Parts and Accessory List ECO-WINS18 Service Parts Beginning Manufacturing Date: May 2011 Ending Manufacturing Date: Active IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement Stocked parts for your appliance please provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer. - Page 46 ECO-WINS18 Service Parts Beginning Manufacturing Date: May 2011 Ending Manufacturing Date: Active IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement Stocked parts for your appliance please provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer.

- Page 47 ECO-WINS18 Service Parts Beginning Manufacturing Date: May 2011 Ending Manufacturing Date: Active IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement Stocked parts for your appliance please provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer.

- Page 48 Hearth & Home Technologies 352 Mountain House Road Halifax, PA 17032 Division of HNI INDUSTRIES Please contact your Heatilator dealer with any questions or concerns. For the number of your nearest Heatilator dealer log onto www.heatilator.com CAUTION DO NOT DISCARD THIS MANUAL...

Need help?

Do you have a question about the ECO-WINS18 and is the answer not in the manual?

Questions and answers