Table of Contents

Advertisement

Quick Links

Fix-EZ

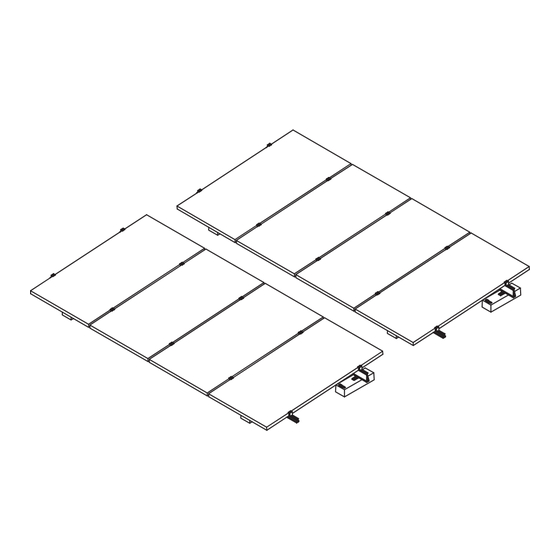

Designed for flat roof applications, the multifunction Fix-EZ solar mounting system mounts solar photovoltaic (PV) modules on

roof tops with minimal load and materials, thereby reducing installation time and costs. The Fix-EZ is specifically designed to meet

or exceed applicable IBC, ASCE, and UL standards.

Features

•

Conforms to UL 2703

•

Certified to ULC/ORD Std C1703

•

Fire class resistance rating: Class A when used with

Type I or Type II photovoltaic modules in landscape orientation only

•

Multiple module tilt options available

•

Portrait or landscape module orientation

•

Ballast block included

Includes Rapid5K

•

TM

•

Wind tunnel tested

•

Optional wire management

•

30 Amp fuse series rating

Provided as a complete mounting system, the Fix-EZ includes several multifunction components to maximize functionality and

minimize cost. Ballast blocks act as ballast weight as well as system support. Module mounting rails support modules⁵ and act as

windbreak with Rapid5K™ module clamps securely holding modules in place while bonding/grounding them to the system. The

following is a guide to properly install a Fix-EZ in order to meet design and test standards.

Key Components

7

1.

Concrete ballast blocks

2.

Adjustable L-foot

3.

Module support rails (purlins)

4.

Rapid5K

grounding module clamps

TM

1

The Fix-EZ is evaluated for electrical bonding only. The Fix-EZ meets all IBC and ASCE requirements for structural loading; it was not evaluated for loading under UL 2703.

2

Special consideration needs to be taken during design phase if system requires protective fire barrier.

3

Module tilt will vary depending on module manufacturer's connection requirements: tilt options range from 7 degrees to 15 degrees

4

Maximum number of modules shall not exceed maximum system voltage.

5

This racking system may be used to ground and/or mount a PV module complying with UL1703 only when the specific module has been evaluated for grounding and/or mounting in

compliance with the included manual

6

Installer is responsible for verifying that photovoltaic system meets applicable NEC standards.

Individual parts and components may vary from system-to-system. Please reference system specific drawings.

7

© Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805

E-mail: mail@schletter.ca • www.schletter.ca

Fix-EZ™ Installation Manual

1

3

4

grounding module clamps

1

2

2

3

6

4

3

1/12

MI-018CA

072216

Advertisement

Table of Contents

Summary of Contents for Schletter Fix-EZ

- Page 1 The Fix-EZ is evaluated for electrical bonding only. The Fix-EZ meets all IBC and ASCE requirements for structural loading; it was not evaluated for loading under UL 2703. Special consideration needs to be taken during design phase if system requires protective fire barrier.

- Page 2 2/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca...

-

Page 3: Installation Tool List

Ratchet and/or rechargeable power drill • Chop saw 3/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca... - Page 4 Due to the variety of roofing material, protective padding composition will vary based on substrate compatibility. Consult certified roofing contractor for best practices. 4/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca •...

- Page 5 18 feet on all rear rails. Attach labels to rails using self-drilling screws 5/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216...

-

Page 6: Optional Accessories

(Part #135003-003) grounding lug by at least 1/4 inch 6/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca... - Page 7 4. Ground Path Diagram Grounding Module Clamp Frame Purlin 7/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca...

-

Page 8: Module Mounting

• Use of impact driver is not recommended. 8/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca... - Page 9 Position modules Secure all connections with module clamps 9/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca...

-

Page 10: Equipment Grounding

Camcar Corp. division of Textron Industries. ® 10/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216... -

Page 11: Maintenance

For more information Fix-EZ Product Sheet Installation Video 11/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca... - Page 12 TSM-PD14 TSM-PD05 TSM-PD05.08 TSM-PD05.05 TSM-PEG5 TSM-PEG5.07 TSM-PEG14 TSM-PEG40.07 12/12 © Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805 MI-018CA 072216 E-mail: mail@schletter.ca • www.schletter.ca...

Need help?

Do you have a question about the Fix-EZ and is the answer not in the manual?

Questions and answers