Table of Contents

Advertisement

© 2016 TE Connectivity Ltd. family of companies.

All Rights Reserved.

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

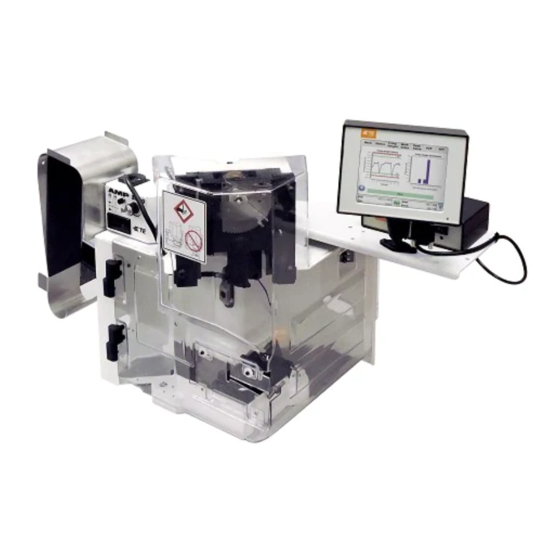

AMP 3K/40* CE Terminating Machines

PN 2161400-[ ] and AMP 5K/40* CE

Terminating Machines PN 2161500-[ ]

SAFETY PRECAUTIONS - AVOID INJURY - READ THIS FIRST! ...................................... 2

1. INTRODUCTION .................................................................................................................. 3

2. DESCRIPTION ..................................................................................................................... 5

2.1.Functional Description .................................................................................................... 5

2.2.Electrical Description ...................................................................................................... 8

2.3.Machine Guard ............................................................................................................... 8

3. RECEIVING INSPECTION AND INSTALLATION ............................................................... 8

3.1.Receiving Inspection ...................................................................................................... 8

3.2.Installation ...................................................................................................................... 9

3.3.Considerations Affecting Placement of Bench Machines (Figure 8) ............................ 10

4. OPERATION ...................................................................................................................... 11

4.1.Control Panel Operation ............................................................................................... 11

4.2.Applicator Installation ................................................................................................... 11

4.3.Setup ............................................................................................................................ 13

4.4.Mode Selection and Operation ..................................................................................... 13

4.5.Adjusting the Motor Speed ........................................................................................... 14

4.6.Crimp Height Adjustment ............................................................................................. 14

4.7.End-Feed/Side-Feed Applicator Conversion ................................................................ 14

5. PREVENTIVE MAINTENANCE ......................................................................................... 14

5.1.Cleaning ....................................................................................................................... 14

5.2.Lubrication .................................................................................................................... 15

6. ADJUSTMENTS ................................................................................................................. 15

6.1.Measuring the Shut Height ........................................................................................... 16

6.2.Shut-Height Adjustment ............................................................................................... 16

6.3.Crimp Height Adjustment Using Precision Adjustment Mechanism ............................. 17

6.4.Guard Insert Adjustment .............................................................................................. 18

ASSEMBLY ........................................................................................................................ 19

8. TROUBLESHOOTING ....................................................................................................... 21

8.1.Error Codes .................................................................................................................. 21

8.2.Diagnostics ................................................................................................................... 22

9. SOTWARE VERSION IDENTIFICATION .......................................................................... 22

10. DISPOSAL ......................................................................................................................... 22

11. REPLACEMENT AND REPAIR ......................................................................................... 23

12. RoHS INFORMATION ........................................................................................................ 23

13. REVISION SUMMARY ....................................................................................................... 23

PRODUCT INFORMATION 1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com.

Customer Manual

409-10204

16 SEP 16 Rev G

1 of 23

Advertisement

Table of Contents

Need help?

Do you have a question about the AMP 3K/40 and is the answer not in the manual?

Questions and answers