Summary of Contents for Parker Series V14

- Page 1 Bulletin HY30-5510-M1/UK Service Manual Series V14 Effective: October 2014 Supersedes: May 2012...

-

Page 2: Table Of Contents

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice. Offer of Sale Please contact your Parker representation for a detailed ”Offer of Sale”. -

Page 3: New Features V14

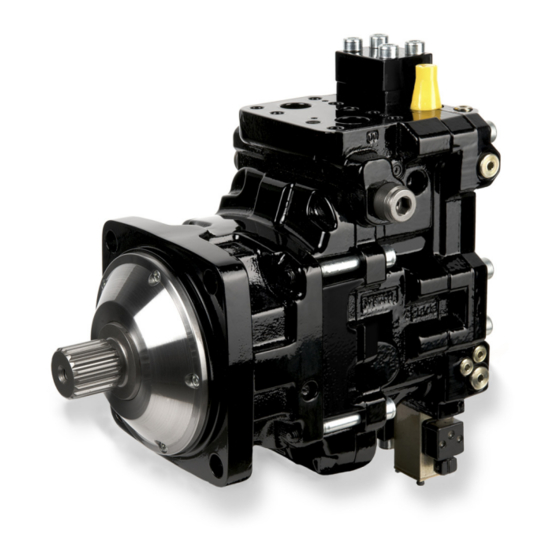

Bulletin HY30-5510-M1/UK Series V14 General information Important features carried over from previous motors: Series V14 is a new generation of variable displacement motors developed and ma- • Operating pressures to 480 bar nufactured by Parker Hannifin, Pump and Motor Division. -

Page 4: Specifications / Cross Section

Service Manual Bulletin HY30-5510-M1/UK Series V14 Specifications V14 frame size Displacement [cm³/rev] at 35° (max) at 6,5° (min) Operating pressure [bar] max intermittent max continuous Operating speed [rpm] 3400 3900 max intermittent at 35° ¹ max continuous at 35° 3000 3400 max intermittent at 6.5°-20°... -

Page 5: Displacement Limiter

Service Manual Bulletin HY30-5510-M1/UK Series V14 Displacement limiter V14-110 Setting Displace- Shim Shim mini- Setting Displace- Shim Shim mini- angle ment maximum mum side angle ment maximum mum side [degree] [cm³/varv] [degree] [cm³/varv] side [mm] side [mm] [mm] [mm] 58,5... -

Page 6: Displacement Limiter

Service Manual Bulletin HY30-5510-M1/UK Series V14 Displacement limiter V14-160 Setting Displace- Setting Displace- Shim Shim mini- Shim Shim mini- angle ment angle ment maximum mum side maximum mum side [degree] [cm³/varv] side [mm] [degree] [cm³/varv] side [mm] [mm] [mm] 31,6... -

Page 7: Ordering Code

Service Manual Bulletin HY30-5510-M1/UK Series V14 Ordering code Example: V14 - 110 - S V S - EP I 1 A - P 350 - N - 00 - 110 / 032 - 210 - 000 2 3 4 5 6 7 8... -

Page 8: Installation

[rpm]. the fluid to stay above the minimum visco- sity requirements. Note: Contact Parker Hannifin (Pump and A flushing valve and restricting nozzle, av- Motor Div.) for information on other shaft ailable as an option, provide the necessary seals. -

Page 9: Pump And Motor Division

Fig. 3. The ideal operating range for the V14 series is 15 to 30 mm²/s. Drain port The following information (available from Parker Hannifin, Pump and Motor Div.) pro- Check vide additional information about: valve Fig. 4. - Hydraulic fluid specifications... -

Page 10: Controls And Gauge Ports

Service Manual Bulletin HY30-5510-M1/UK Series V14 Controls - general information The displacement angle (between output The following controls satisfy most application shaft and cylinder barrel) ranges from 35° requirements: (max) to 6.5° (min). • AC (automatic pressure compensator) Servo supply pressure is obtained from the •... -

Page 11: 2 Parker Hannifin

Service Manual Bulletin HY30-5510-M1/UK Series V14 AC control function Refer to the illustration below left: Refer to the illustration below right: When pressure in port A (or B) increases, When pressure in port A (or B) decreases, the servo valve spool is pushed to the... -

Page 12: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Gauge ports AC/AD/AH control Pressure setting procedure The pressure setting procedure is valid for Start to turn the threshold adjustment all pressure compensators (AC, AD and screw clockwise until the pressure in AH). gauge X2 starts to increase. Right threshold pressure setting has been reached. -

Page 13: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 EO/EP/HO/HP control description Basically, the controls function in a similar In comparison with EP and HP, the EO and way. At increasing solenoid current (EP) or HO controls have no modulating spring or increasing pilot pressure (HP) the control feedback arm;... -

Page 14: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 EP control function HP control function (solenoid current increasing) (decreasing pilot pressure) Refer to the illustration below right: Refer to the illustration below left: At an increasing current (above the threshold When the pilot pressure decreases, the pilot... -

Page 15: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Gauge ports EO/EP/HO/HP Standard factory setting is 400 mA (12 VDC) The pressure/current setting procedure is 200 mA (24 VDC) valid for all proportional and two-position con- trols (EO, EP, HO and HP). Start to turn the threshold adjustment... -

Page 16: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 HPC, HP control with pressure cut off - The pressure cut off overlays the HP control. Max 100 bar - If the system pressure increase, due to the load or reduced motor displacement, to the setting of the pressure cut off valve, the control increases displacement. -

Page 17: Displacement Limiter

Service Manual Bulletin HY30-5510-M1/UK Series V14 V14 Displacement limiter Max and min displacement limiter consists of a socket head cap screw and a displacement spacer or spacers, see fig. 1. Suitable screw lengths for a particular max or min displacement range are shown in the table 1 below. -

Page 18: Disassembling

Service Manual Bulletin HY30-5510-M1/UK Series V14 Disassembling Remove the hexagon screws and lift the control module off. Important! Lift the control module straight up so the two check valve balls don’t fall down into the motor. Remove the check valve balls. -

Page 19: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Remove the hexagon screws and lift the connection module. Lift the valve segment. Remove the cylinder barrel. Note! The support pin assembled between cylinder barrel and joint shaft might fall down into the motor. -

Page 20: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Remove the joint shaft. Make sure all joint rollers follows. Remove the support pin assembled bet- ween joint shaft and guide pin. Remove the guide pin. Parker Hannifin Pump and Motor Division Trollhättan, Sweden... - Page 21 Service Manual Bulletin HY30-5510-M1/UK Series V14 Remove the compression spring. Remove the pistons and the O-ring fitted on the intermediate housing. The pistons should be fitted in the same ball sockets as before if you don’t exchange the pistons. Remove the intermediate housing.

-

Page 22: 2 Parker Hannifin

Service Manual Bulletin HY30-5510-M1/UK Series V14 Remove the retaining ring. Remove the seal carrier with shaft seal off. Change the shaft seal. Use the old shaft seal and press down the new shaft seal into the seal carrier. Remove the O-ring. - Page 23 Service Manual Bulletin HY30-5510-M1/UK Series V14 Remove the retaining ring. Use a hydraulic press to remove the shaft. Place something soft under the shaft to avoid damageing it. Lift the bearing. For disassembling the bearing on the shaft use a withdrawing tool.

-

Page 24: Assembling

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assembling Install the bearing housing on the shaft. Note! Place the shaft on a distance. Lubricate the shaft with oil. Place the bearing on the shaft and press it down. Note! Be careful when you press so you acheive correct bearing setting, no back- lash and a low rolling friction. -

Page 25: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assemble the spacer washer and the re- taining ring. Assemble the O-ring. Lubricate the sealing surface with oil on the shaft. Parker Hannifin Pump and Motor Division Trollhättan, Sweden... -

Page 26: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assemble the seal ring carrier with shaft seal. Assemble the retaining ring. Assemble the compression spring. Parker Hannifin Pump and Motor Division Trollhättan, Sweden... -

Page 27: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assemble the guide pin. Assemble the intermediate housing with O- ring. Assemble the pistons. If the pistons isn’t ex- changed, assemble them in the same ball sockets as before. Parker Hannifin Pump and Motor Division... -

Page 28: Assembling

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assemble the lower support pin. Assemble the joint shaft. Put some grease on the joint shaft so the rollers don’t fall off. Assemble the rollers with the chamfer in- wards. Assemble the upper support pin in the cylinder barrel. -

Page 29: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assemble the cylinder barrel. The sliding plate is assembled with the steel side towards the cylinder barrel and the bronze side towards the valve segment. Make sure that the support pin is in the correct position by using a thin pin and feel that it is in correct position. -

Page 30: Pump And Motor Division

Service Manual Bulletin HY30-5510-M1/UK Series V14 Assemble the check valve balls. Make sure that the guide pins are in place. Assemble the control module, fit the setting piston arm into the valve segment. Tighten the hexagon screws, 105 ± 20Nm. -

Page 31: Control Spring Kit And Filter

Service Manual Bulletin HY30-5510-M1/UK Series V14 Change of Control Spring Kit and Filter (AC, AH, AD) Turn the adjustment screw counter clock- wise. Remove the spring kit. Change the spring(s). Put the new spring kit in position and turn the adjustment screw clockwise until the spring is preloaded. -

Page 32: Spare Parts

Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview/Spare Parts V14-110 ISO Valve segment 413x3 3781307 3793185 3793183 3793192 449x2 3709889 415 (included in 3793192) 448x6 3706393 3781043 482 (included in sealkit) 483x2 118162 3709886 3792387 453x3 3788147 Item 451 and 453 is included in 3709887 a kit with part no. - Page 33 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview/Spare Parts 413x3 3793185 V14-110 SAE/Cartridge Valve segment 3793183 3781307 3793192 449x2 3709889 415 (included in 3793192) 448x6 3706393 3781043 482 (included in sealkit) 483x2 118162 3709886 3792387 453x3 3788147 3709887 Item 451 and 453 is included in a kit with part no.

-

Page 34: Spare Parts

Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview/Spare Parts 413x3 3793185 V14-160 3793440 Valve segment 3782362 3709756 449x2 3708046 415 (included in 3709756) 448x6 3706669 3782233 482 (included in sealkit) 483x2 3782630 3709761 914525 453x3 3788146 3709754 Item 451 and 453 is included in a kit with part no. - Page 35 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview A-module 117x2 116x3 ISO: 60 ± 10 Nm SAE: 110 ± 22 Nm 3781307 V14-110 3782362 V14-160 828 13 ± 3 Nm 116x3 823x2 824x2 825x2 50 ± 10 Nm 133x2 105 ± 20 Nm 8 ±...

- Page 36 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview AC Control Item Torque (Nm) 105 ± 20 1.2 ± 0.2 14 ± 4 26 ± 6 1.2 ± 0.2 1.2 ± 0.2 38 ± 8 ISO 25 ± 5 SAE 105 ± 20 13 ±...

- Page 37 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview AH Control Item Torque (Nm) 105 ± 20 1.2 ± 0.2 14 ± 4 26 ± 6 1.2 ± 0.2 1.2 ± 0.2 38 ± 8 ISO 25 ± 5 SAE 105 ± 20 13 ±...

- Page 38 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview EP/EO Control Item Torque (Nm) 105 ± 20 1.2 ± 0.2 14 ± 4 26 ± 6 1.2 ± 0.2 1.2 ± 0.2 105 ± 20 13 ± 2 38 ± 8 ISO 25 ±...

- Page 39 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview HP/HO Control Item Torque (Nm) 105 ± 20 1.2 ± 0.2 14 ± 4 26 ± 6 1.2 ± 0.2 1.2 ± 0.2 38 ± 8 ISO 25 ± 5 SAE 105 ± 20 13 ±...

- Page 40 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview HPC Control Item Torque (Nm) 105 ± 20 1.2 ± 0.2 1.2 ± 0.2 14 ± 4 26 ± 6 1.2 ± 0.2 1.2 ± 0.2 B-side 38 ± 8 ISO 25 ± 5 SAE 105 ±...

- Page 41 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview ADH Control Item Torque (Nm) 105 ± 20 1.2 ± 0.2 14 ± 4 26 ± 6 1.2 ± 0.2 1.2 ± 0.2 38 ± 8 ISO 25 ± 5 SAE 105 ± 20 13 ±...

-

Page 42: Spare Parts

Service Manual Bulletin HY30-5510-M1/UK Series V14 Spare Part Kits for V14-110/160 Parts Specification Item Description 110/160 Items included in the Seal Kit. Stop Washer 221, 225, 227, 233, 482, 711, 712, 713, O-ring 144,5*3 V70 / 168*3 V70 732, 743, 744, 745, 748, 749, 751, 753,... -

Page 43: Test Procedure

Service Manual Bulletin HY30-5510-M1/UK Series V14 Test procedure Use a test stand that supplies a flow of about 30 l/min. and pressures of up to 300 bar. A secondary flow of 3-5 l/min. at a pressure of 25 bar is required to supply low pressure for externally supplied controls. - Page 44 Parker Hannifin Pump and Motor Division Flygmotorvägen 2 SE-461 82 Trollhättan Sweden Tel: +46 (0)520 40 45 00 Fax: +46 (0)520 371 05 www.parker.com...

Need help?

Do you have a question about the Series V14 and is the answer not in the manual?

Questions and answers