Subscribe to Our Youtube Channel

Summary of Contents for Parker V14 Series

- Page 1 MSG30-5510-M1/UK Service/ Visit our homepage for additional support parker.com/pmde Spare Parts Manual Series V14 Effective: October, 2021 Supersedes: April, 2019...

-

Page 2: Table Of Contents

2.2046 lb 0.22481 lbf 1 bar 14.504 psi 0.21997 UK gallon 0.26417 US gallon 1 cm 0.061024 in 3.2808 feet 1 mm 0.03937 in 1 °C = 1.8 °F + 32 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... -

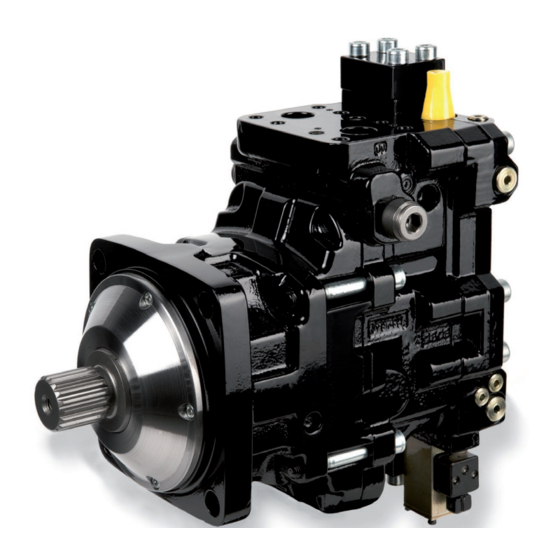

Page 3: General Information/New Features V14

Important features carried over from previous motors: Series V14 is a new generation of variable displacement motors developed and manufactured by Parker Hanni- • Operating pressures to 480 bar fin, Pump and Motor Division. • High speeds, thanks to low weight pistons with lami-... -

Page 4: Specifications / Cross Section

Synchronizing shaft Inner roller bearing 12. Synchronizing shaft Outer roller bearing 13. Inner roller bearing Bearing housing Shaft seal with retainer 14. Outer roller bearing Output shaft 15. Bearing housing 16. Shaft seal with retainer 17. Output shaft Parker Hannifin Pump and Motor Division Trollhättan, Sweden Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... -

Page 5: Displacement Limiter

35,0 Note! There always have to be a shim on the minimum side of the -110cc motor. (9 mm) The -110cc motor will be damaged if set below angles of 6,5°. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... - Page 6 64,5 18,8 42,5 26,5 33,7 65,5 34,0 19,0 42,0 27,0 66,0 19,2 41,5 27,5 34,2 67,0 34,5 19,5 41,0 28,0 67,5 19,7 40,5 28,5 34,7 68,5 35,0 19,9 40,0 29,0 69,0 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

-

Page 7: Ordering Code

2 – 0,8 HPC, EPC: Select cut off pressure 3 – 1,0 (standard) between 75 – 400 [bar] 4 – 1,2 5 – HPC Valid at max utilized displacement range x – special Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... -

Page 8: Installation

Contact Parker Hannifin (Pump & Motor Div.) for more specific information on inlet pressure requirements Size 1500 3000 4000 5000 6000 A 10 µm (absolute) filter is recommended. - Page 9 To reservoir above 8 mm²/s (cSt). Check valve At start-up, the viscosity should not exceed 1500 mm²/s. The ideal operating range for the V14 series is 15 to 30 mm²/s. Drain port The following information (available from Parker Han- nifin, Pump & Motor Div.) provide additional information...

-

Page 10: Controls And Gauge Ports

AC control module cross section (as seen from motor intermediate Leif A./01-03-12 intermediate housing / control module interface). er (min displ.) housing / control module interface). r location, servo supply Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden ap is factory mounted. Red seal cap is available as spare part, part no. 3797065. - Page 11 Restrictor position, min-to-max servo pressure (M5) Restrictor position, min-to-max servo pressure (M5) Restrictor location, max-to-min servo pressure (M5) Restrictor location, max-to-min Restrictor location, servo supply (refer to cross section page 10) servo pressure (M5) Restrictor location, servo supply V14_AC_module.eps (refer to cross section page 10) Leif A./01-03-12 Parker Hannifin Parker Hannifin Pump and Motor Division Pump & Motor Division Europe Trollhättan, Sweden Trollhättan, Sweden...

- Page 12 1 5. Start to turn the threshold adjustmentscrew clock- wise until the pressure ingauge X2 starts to increase. Increase the system pressure (e.g. Rightthreshold pressure setting has beenreached. by blocking the motor shaft) to desi red pressure setting (read the pres sure in port X5). Parker Hannifin Pump and Motor Division Trollhättan, Sweden Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 13 End cover (max displ. limit) *Yellow seal cap is factory mounted. Red sealcap is av- (min displ. limit) Max displ. limiting screw/bushing ailable as spare part, part no. 3797065. Restrictor location, servo supply Parker Hannifin Pump and Motor Division Trollhättan, Sweden Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 14 Restrictor position, min-to-max Restrictor location, servo supply Restrictor location, servo supply servo pressure (refer to cross section page 13) (refer to cross section page 13) Restrictor location, servo supply (refer to cross section page 13) V14_EP_module.eps V14_EP_module.eps Leif A./01-03-13 Leif A./01-03-13 Parker Hannifin Parker Hannifin Parker Hannifin Pump and Motor Division Pump and Motor Division Pump & Motor Division Europe Trollhättan, Sweden Trollhättan, Sweden Trollhättan, Sweden...

- Page 15 5. Start to turn the threshold adjustmentscrew clock- wise until the pressure ingauge X1 starts to increase. HO/HP control Rightthreshold pressure setting has beenreached. HO/HP control Parker Hannifin Pump and Motor Division Parker Hannifin Trollhättan, Sweden Pump and Motor Division Trollhättan, Sweden Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 16 2. Set the cut off pressure to minimum by turning the inport X1 reaches the same pressure level as in X4. setting screw counter-clockwise until a distinct stop is Desired cut off pressure has been reached. reached. 3. Set the motor displacement to minimum by applying required pressure to port X5. 4. Increase the pressure in one of the main ports A/B (e.g. by blocking the motor shaft) to desired cut off pressure level. 5. Turn the setting screw clockwise, until the pressure in port X1 reaches the same pressure level as in X4. Desired cut off pressure has been reached. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

-

Page 17: Displacement Limiter

5. Assembly the end cover. The tightening torque have fig. 1. fig. 1 to be 60 ± 10 Nm for the fourscrews. Choose spacer (s) to obtain right displacement, see page 5 and 6, and place them on the socket head cap screw. Tighten the socket head cap screw in the setting piston. The tightening torque have to be 105 ± 20 Nm. Assembly the end cover. The tightening torque have to be 60 ± 10 Nm for the four screws. Parker Hannifin Pump and Motor Division Trollhättan, Sweden Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... -

Page 18: Disassembling

Parker Hannifin Parker Hannifin 3. Be careful, the guide pins can be loose 4. Remove the hexagon screws and lift the connection Pump and Motor Division Pump and Motor Division module. Trollhättan, Sweden Trollhättan, Sweden Parker Hannifin Parker Hannifin Parker Hannifin Pump and Motor Division Pump and Motor Division Trollhättan, Sweden Trollhättan, Sweden Pump & Motor Division Europe Trollhättan, Sweden... - Page 19 Pump and Motor Division Trollhättan, Sweden Trollhättan, Sweden 7. Remove the joint shaft. Make sure all joint rollers fol- 8. Remove the support pin assembled between joint lows. shaft and guide pin. Remove the support pin assembled bet- Remove the support pin assembled bet- ween joint shaft and guide pin. ween joint shaft and guide pin. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 20 Remove the pistons and the O-ring fitted on the 12. Remove the intermediate housing. intermediate housing. The pistons should be fitted in the same ball sock- ets as before if you don’t exchange the pistons. Remove the intermediate housing. Remove the intermediate housing. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 21 Bulletin HY30-5510-M1/UK Bulletin HY30-5510-M1/UK Remove the seal carrier with shaft se Remove the seal carrier with shaft se Change the shaft seal. Use the old sh Change the shaft seal. Use the old sh seal and press down the new shaft se seal and press down the new shaft se Remove the O-ring. Remove the O-ring. the seal carrier. the seal carrier. 15. Remove the O-ring. 16. Remove the retaining ring. Parker Hannifin Parker Hannifin Pump and Motor Divisio Pump and Motor Divisio Trollhättan, Sweden Trollhättan, Sweden Parker Hannifin Plac Plac Pump & Motor Division Europe Remove the O-ring. Remove the O-ring. Trollhättan, Sweden...

- Page 22 For disassembling the bearing on the shaft use a withdrawing tool. Lift the bearing. Lift the bearing. For disassembling the bearing on the shaft For disassembling the bearing on the shaft use a withdrawing tool. use a withdrawing tool. Parker Hannifin Parker Hannifin Pump and Motor Division Pump and Motor Division Trollhättan, Sweden Trollhättan, Sweden Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

-

Page 23: Assembling

Note! Be careful when you press so you Parker Hannifin Parker Hannifin Pump and Motor Division Pump and Motor Division Note: Be careful when you press so you acheive cor- acheive correct bearing setting, no back- Trollhättan, Sweden Trollhättan, Sweden rect bearing setting, no backlash and a low rol- lash and a low rolling friction. ling friction. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden Parker Hannifin... - Page 24 6. Lubricate the sealing surface with oil on the shaft. Service Manual Bulletin HY30-5510-M1/UK Series V14 Lubricate the sealing surface with oil shaft. Assemble the seal ring carrier with shaf Parker Hannifin Pump and Motor Divi Trollhättan, Sweden 7. Assemble the seal ring carrier with shaft seal. 8. Assemble the retaining ring. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 25 Assemble the intermediate housing with O ring. 11. Assemble the intermediate housing with O-ring 12. Assemble the pistons. If the pistons isn’t exchan- ged, assemble them in the same ball sockets as before. Assemble the pistons. If the pistons isn’t e Parker Hannifin changed, assemble them in the same bal Pump & Motor Division Europe Trollhättan, Sweden sockets as before.

- Page 26 The sliding plate is assembled with the steel side Parker Hannifin when assembling the cylinder barrel. Assemble the upper support pin in the towards the cylinder barrel and the bronze side Pump and Motor Division Trollhättan, Sweden cylinder barrel. Put some grease on the pin towards the valve segment. so it don’t fall down when assembling the cylinder barrel. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 27 19. Assemble the check valve balls. Make sure that the 20. Assemble the control module, fit the setting piston guide pins are in place. arm into the valve segment. Tighten the hexagon screws, 115 ± 10Nm. Parker Hannifin Assemble the control module, fit the setting Pump & Motor Division Europe Trollhättan, Sweden piston arm into the valve segment. Tighten...

-

Page 28: Control Spring Kit And Filter

Put the new spring kit in position and turn the ad- changed. justment screw clockwise until the spring is preloa- ded. If you need to change the filter remove it and place the new filter with the rounded/ meash surface upwards (i.e. the same wa as the oil flows). When the filter has been disassembled it has to be changed. filter Parker Hannifin Parker Hannifin Pump and Motor Division Pump & Motor Division Europe Trollhättan, Sweden Trollhättan, Sweden... - Page 29 MSG30-5510-M1/UK Service/Spare Parts Manual Series V14 Notes Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

-

Page 30: Split Views V14-110/-160

MSG30-5510-M1/UK Service/Spare Parts Manual Series V14 Splitview Splitview V14-110/-160 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... -

Page 31: Spare Parts V14-110/-160

Shaft Kit JOINT COUPLING Shaft Kit TAP ROL BEARING Bearing Kit TAP ROL BEARING Bearing Kit SPACER WASHER Bearing Kit RETAINING RING Bearing Kit INTERMEDIATE HOUSING O-RING 197*3/ O-RING 220.0*3.0 Seal Kit Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... - Page 32 Pos. 311, 433, 434, 451, 453, 454, 455 Part no. Description Remarks 3723167 V14-110 Typ C 3723169 V14-160 Typ C On request V14-110 Typ D On request V14-160 Typ D 3723168 V14-110 Typ S 3723170 V14-160 Typ S Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 33 Intermediate housing Plug position Pos. Part no. Description 115, 722, 828 VSTI10X1EDVITCF 250, 520 VSTI22X1.5EDVITCF VSTI12X1EDVITCF 708, 723, 747 VSTI14X1.5EDVITCF 250, 520 12 HP5ON-S 1-1/16» 708, 723, 747 6 HP5ON-S 9/16»-18 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

-

Page 34: Split Views Ac/Ah; Ho/Hp/Hpc And Eo/Ep/Epc Control

746x4 748 Service Manual Bulletin HY30-5510-M1/UK Series V14 Splitview HO/HP/HPC Control EO/EP/EPC Control Splitview HO/HP/HPC Control EO/EP/EPC Control A-side B-side EO/EP/EPC Parker Hannifin Pump and Motor Division 746x4 Trollhättan, Sweden 769 (screws and o-rings are included in this item) HO/HP/HPC 716x6 701x2 712x2 757x2 Parker Hannifin Parker Hannifin Pump & Motor Division Europe Pump and Motor Division Trollhättan, Sweden Trollhättan, Sweden... -

Page 35: Spare Parts Ac/Ah; Ho/Hp/Hpc And Eo/Ep/Epc Control

SPRING SEAT Adjusting kit AC/AH and EO/EP SPRING SEAT Adjusting kit AC/AH and EO/EP ADJUSTING SCREW Adjusting kit AC/AH and EO/EP SEAL NUT Adjusting kit AC/AH and EO/EP / Seal Kit Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... - Page 36 Remarks 3723156 V14-110/ V14-160 5 each diam. AH control kit SAE including Pos. 741, 743, 744, 745, 746,747, 748, 749, 750, 751, 752, 753 Part no. Description Remarks 3723175 V14-110/ V14-160 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

-

Page 37: Splitview A-Module

Pos: 111, 116, 117, 520 V14-110 V14-160 On request On request On request On request Valve Cartridge Part no. P300 9120029264 P330 9120029265 P350 9120029266 P380 9120029267 P400 9120029268 P420 9120029269 P450 3766886 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... -

Page 38: Test Procedure

3. Check the drain flow andcompare with the table. ~ 30 l/min Max 150 bar / 2150 psi Servo oil Servolja Max 220 bar / 3100 psi Pump V14-110, -160 Drain flow (l/min.), control not activated. Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden... - Page 39 MSG30-5510-M1/UK Service/Spare Parts Manual Series V14 Parker Hannifin Pump & Motor Division Europe Trollhättan, Sweden...

- Page 40 Position notification regarding Machinery Directive 2006/42/EC: Products made by the Pump & Motor Division Europe (PMDE) of Parker Hannifin are excluded from the scope of the machinery directive following the “Cetop” Position Paper on the implementation of the Machinery Directive 2006/42/ EC in the Fluid Power Industry.

Need help?

Do you have a question about the V14 Series and is the answer not in the manual?

Questions and answers