Advertisement

Quick Links

Download this manual

See also:

Service Manual

INSTALLATION MANUAL

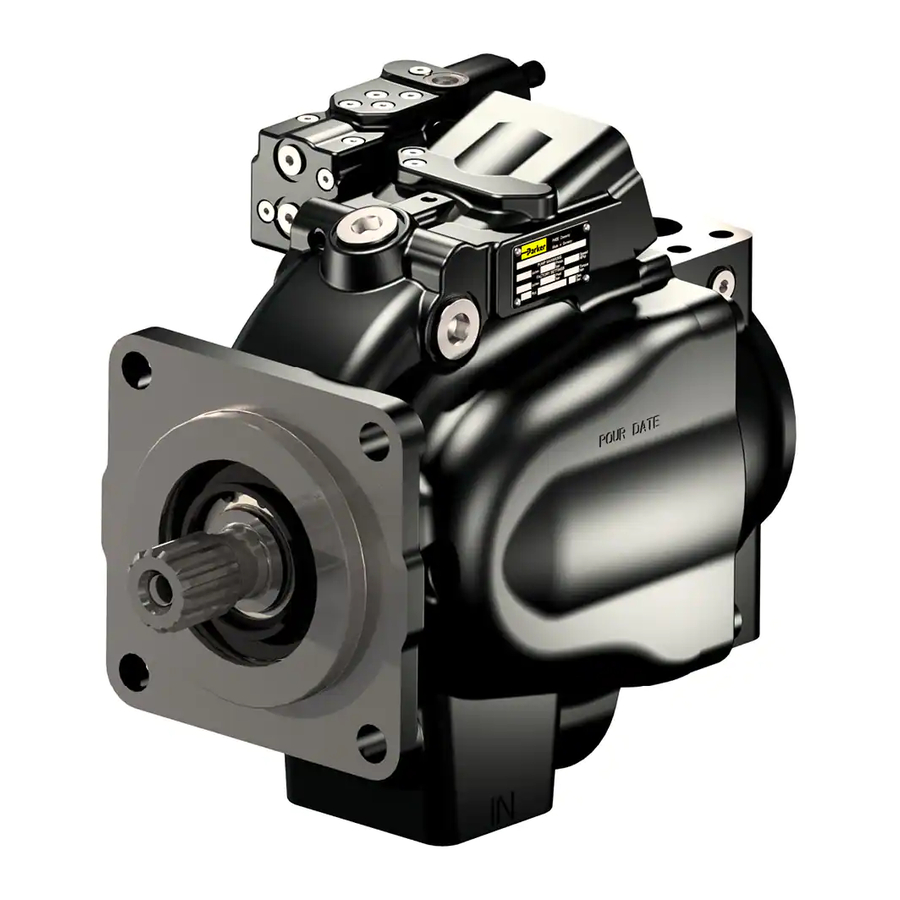

SERIES P2 and P3

MOBILE PISTON PUMP

PUMP AND MOTOR DIVISION

Neefestraße 96

09116 Chemnitz, Germany

www.comoso.com

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Parker P2 Series

- Page 1 INSTALLATION MANUAL SERIES P2 and P3 MOBILE PISTON PUMP PUMP AND MOTOR DIVISION Neefestraße 96 09116 Chemnitz, Germany www.comoso.com...

- Page 2 Check model code / compare with your paper work Nameplate of the pump Ordering / Sales Acknowledgement Check rotation of the pump Clockwise rotation (right) - side ported P2 Counter clockwise rotation (right) - side ported P2 Clockwise rotation (right) – thru drive P3 Counter clockwise rotation (right) –...

- Page 3 Suction, pressure and drain line connection Connection P2 Minimum pump inlet pressure under static and dynamic load: = 0,8 bar absolute in min Maximum pump inlet pressure: = 10 bar in max 3.1.1 Arrangements P2 Arrangement outside tank. Arrangement outside tank. Fill pump case with oil before start.

- Page 4 Arrangement outside tank. Arrangement outside tank. Fill pump case with oil before start. Fill pump case with oil before start. Do not restrict suction line. Do not restrict suction line. Preferred arrangement for best suction characteristics + low noise level operation 3.1.2 Drain line connection P2 OPTION!

- Page 5 WARNING! Don not combine drain lines. Maximum continuous case pressure: = 0,5 bar case Maximum intermittent peak case pressure: = 2 bar case WARNING! Don not restrict drain line. A restricted drain line can damage the pump. PUMP AND MOTOR DIVISION Neefestraße 96 09116 Chemnitz, Germany www.comoso.com...

- Page 6 Connection P3 Minimum pump inlet pressure under static and dynamic load: = 0,8 bar absolute in min Maximum pump inlet pressure: = 1 bar in max 3.2.1 Arrangements P3 Arrangement outside tank. Arrangement outside tank. Fill pump case with 0.5 l of fluid prior to start up. Fill pump case with 0.5 l of fluid prior to start up.

- Page 7 3.2.2 Drain line connection P3 OPTIONAL AIRBLEED CONNECTION Connect compensator drain line with the reservoir. Keep inlet and drain line separate (hot loop). ATTENTION! Combination and restriction of compensator drain line may result an back pressure. Maximum continuous drain line pressure: = 2 bar drain Maximum intermittent peak drain line pressure:...

- Page 8 3.2.3 P3 pumps with drain port in the rear cover The main benefit of this version is a continuous cooling flow through the case. Thus a better volumetric efficiency is provided. Flow out of the drain port can be up to ~ 50 l/min and is depending on back pressure in the drain line as well as drive speed.

- Page 9 Start up Prior to start up, the pump case must be filled with hydraulic fluid (use case drain port). Initial start up should be at zero pressure with an open circuit to enable the pump to prime. Pressure should only be increased once the pump has been fully primed.

Need help?

Do you have a question about the P2 Series and is the answer not in the manual?

Questions and answers