Summary of Contents for GORMAN-RUPP 03H1-GR

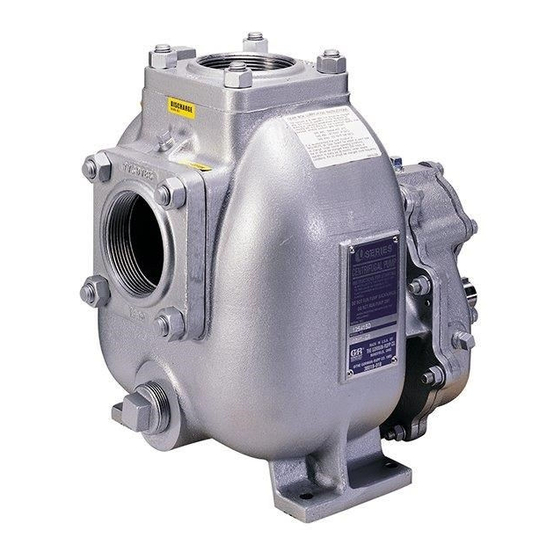

- Page 1 OM-01194-02 April 9, 1981 Rev. H 03‐30‐15 INSTALLATION, OPERATION, AND MAINTENANCE MANUAL WITH PARTS LIST 0 SERIES PUMP MODEL 03H1-GR GORMAN‐RUPP PUMPS www.grpumps.com 1981 Gorman‐Rupp Pumps Printed in U.S.A.

- Page 2 Register your new Gorman‐Rupp pump online at www.grpumps.com Valid serial number and e‐mail address required. RECORD YOUR PUMP MODEL AND SERIAL NUMBER Please record your pump model and serial number in the spaces provided below. Your Gorman‐Rupp distributor needs this information when you require parts or service. Pump Model: Serial Number:...

-

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ..........PAGE I - 1 SAFETY ‐... - Page 4 TABLE OF CONTENTS (continued) PUMP AND SEAL REASSEMBLY ..........PAGE E - 7 Seal Reassembly and Installation .

-

Page 5: Introduction

0 SERIES OM-01194 INTRODUCTION Thank You for purchasing a Gorman‐Rupp pump. HAZARD AND INSTRUCTION Read this manual carefully to learn how to safely DEFINITIONS install and operate your pump. Failure to do so could result in personal injury or damage to the The following are used to alert maintenance per... -

Page 6: Safety - Section A

0 SERIES OM‐01194 SAFETY - SECTION A This information applies to 0 Series power take‐off pumps. Refer to the man ual accompanying the power source be fore attempting to begin operation. If this pump is used with volatile and/or flammable liquids, be certain proper Because pump installations are seldom safety practices are followed before op... - Page 7 OM-01194 0 SERIES can catch clothing, fingers, or tools, maintenance, block the wheels and set causing severe injury to personnel. the emergency brake before attempting to disconnect the drive shaft or remove the pump. Be sure the pump is properly reinstalled and secure before opera...

-

Page 8: Installation - Section B

0 SERIES OM-01194 INSTALLATION - SECTION B Review all SAFETY information in Section A. coming pressure to 50% of the maximum permissi ble operating pressure as shown on the pump per Since pump installations are seldom identical, this formance curve (see Section E, Page 1). section offers only general recommendations and practices required to inspect, position, and ar... -

Page 9: Preinstallation Inspection

OM-01194 0 SERIES PREINSTALLATION INSPECTION VEHICLE REQUIREMENTS The following instructions apply equally to new in The pump assembly was inspected and tested be stallations, rebuilds or retrofits. fore shipment from the factory. Before installation, inspect the pump for damage which may have oc Tank Preparation curred during shipment. -

Page 10: Lifting

0 SERIES OM-01194 Lifting The alignment of the pump and its power source is critical for trouble‐free mechanical operation. Be Pump unit weights will vary depending on the fore checking alignment, make sure that the gear mounting and drive provided. Check the shipping box mounting bolts are tight. -

Page 11: Suction And Discharge Piping

OM-01194 0 SERIES LUGS MUST BE IN LINE, REGARDLESS OF OPERATING ANGLE SHOWN BELOW LUG ALIGNMENT SHAFTS PARALLEL, ANGLES EQUAL SHAFTS NOT PARALLEL, ANGLES EQUAL Figure 2. Proper Installation And Alignment of Universal Assembly SUCTION AND DISCHARGE PIPING tors, related piping and safety accessories. Some of the accessories are available from Gorman‐... -

Page 12: Piping

0 SERIES OM-01194 SCHEMATIC SYSTEM USING EDUCTOR FOR DISPENSING AND FILLING Figure 3. Typical Installation Using Educator For Filling And Dispensing SCHEMATIC SYSTEM USING PUMP FOR DISPENSING AND FILLING Figure 4. Typical Installation Using Pump For Filling And Dispensing Piping A suction strainer was not furnished with this pump since it is not designed to handle liquids containing All piping material must be compatible with the liq... -

Page 13: Sealing

OM-01194 0 SERIES suction line to ensure an adequate supply of liquid Sealing to the pump. Since even a slight leak will affect priming, head, and capacity, especially when operating with a high suction lift, all connections in the suction line should be sealed with pipe dope to ensure an air... -

Page 14: Siphoning

0 SERIES OM-01194 Siphoning FDF valve to increase dispensing rates and im prove efficiency. An educator may also be used to Do not terminate the discharge line at a level lower collapse the tank service hose after the tank has than that of the liquid being pumped unless a si... -

Page 15: Operation - Section C

OM-01194 0 SERIES OPERATION - SECTION C Review all SAFETY information in Section A. Add liquid to the pump casing when: 1. The pump is being put into service for the Follow the instructions on all tags, labels and first time. decals attached to the pump. -

Page 16: Drive

OM-01194 0 SERIES be damaged and performance adversely affected Liquid Temperature And Overheating by incorrect rotation. If pump performance is not within the specified limits (see the curve on Page The maximum liquid temperature for this pump is E-1), check the direction of rotation before further F (71 C). -

Page 17: Pump Vacuum Check

OM-01194 0 SERIES Pump Vacuum Check Since this pump does not have a suction check valve, the discharge line must be fitted with a check If the application involves a high discharge valve if a pump vacuum reading is to be taken. head, gradually close the discharge throttling valve before stopping the pump. -

Page 18: Troubleshooting - Section D

0 SERIES OM-01194 TROUBLESHOOTING - SECTION D Review all SAFETY information in Section A. Before attempting to open or service the pump: 1. Familiarize yourself with this manual. 2. Switch off the vehicle ignition and re move the key, or take other precau tions to ensure that the pump will re... - Page 19 OM-01194 0 SERIES TROUBLE POSSIBLE CAUSE PROBABLE REMEDY Impeller or other wearing parts worn Replace worn or damaged parts. PUMP STOPS OR FAILS TO DELIVER or damaged. Check that impeller is properly cen RATED FLOW OR tered and rotates freely. PRESSURE (cont.) Suction lift or discharge head too high.

-

Page 20: Preventive Maintenance Schedule

0 SERIES OM-01194 equipped) between regularly scheduled inspec PREVENTIVE MAINTENANCE tions can indicate problems that can be corrected Since pump applications are seldom identical, and before system damage or catastrophic failure oc pump wear is directly affected by such things as curs. -

Page 21: Pump Maintenance And Repair - Section E

OM-01194 PUMP MAINTENANCE AND REPAIR ‐ SECTION E MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK OPERATING PERFORMANCE. STANDARD PERFORMANCE FOR PUMP MODEL 03H1-GR Based on 70 F (21 C) clear water corrected to Contact the Gorman‐Rupp Company to verify per... - Page 22 OM-01194 0 SERIES SECTION DRAWING PARTS PAGE Figure 1. Pump Model 03H1-GR PAGE E - 2 MAINTENANCE & REPAIR...

-

Page 23: Parts Lists

0 SERIES OM-01194 PARTS LIST Pump Model 03H1-GR (From S/N 287634 Up) If your pump serial number is followed by an “N”, your pump is NOT a standard production model. Contact the Gorman‐Rupp Company to verify part numbers. ITEM PART... -

Page 24: Gearbox Assembly

OM-01194 0 SERIES Figure 2. 44161-014 Gearbox Assembly PAGE E - 4 MAINTENANCE & REPAIR... - Page 25 0 SERIES OM-01194 PARTS LIST 44161-014 Gearbox Assembly ITEM PART MAT'L PART NAME NUMBER CODE WEAR RING 62ZL6 14000 PINION SHAFT 8896 16020 OIL SEAL S1764 AIR VENT S1530 REDUCING PIPE BUSHING AP0602 15079 SHIPPING PLUG 11495A 15079 BALL BEARING S390 BALL BEARING S390...

-

Page 26: Pump And Seal Disassembly And Reassembly

OM-01194 0 SERIES PUMP AND SEAL DISASSEMBLY AND REASSEMBLY Before attempting to open or service the Review all SAFETY information in Section A. pump: 1. Familiarize yourself with this man Follow the instructions on all tags, label and de ual. cals attached to the pump. -

Page 27: Removing Pump And Gearbox

0 SERIES OM-01194 Pump Casing and Wear Ring Removal moved from the pump before lifting. Lift the pump or component only as high as (Figure 1) necessary and keep personnel away To service the impeller, wear ring or seal assembly, from suspended objects. - Page 28 OM-01194 0 SERIES Use a pair of stiff wires with hooked ends to hook precautions printed solvent the stationary element from the back side, and pull containers. the element and O‐ring from the seal plate bore. The seal is not normally reused because wear pat Remove the sleeve O‐ring (17).

- Page 29 0 SERIES OM-01194 DRIVE BAND SEAL GUARD SEAL PLATE O‐RING SPRING STATIONARY SEAT AND SEAL IMPELLER SHAFT SLEEVE IMPELLER SHAFT IMPELLER SLEEVE BELLOWS O‐RING ROTATING RETAINER ELEMENT Figure 3. Seal Assembly Subassemble the rotating element into the retainer and bellows, and slide this subassembly over the shaft sleeve until the rotating element is just flush with the chamfered end of the sleeve.

- Page 30 OM-01194 0 SERIES press the replacement ring into the pump casing impeller or binding and/or excessive wear until it seats squarely against the shoulder bore. will result. Align the impeller and key (20) with the shaft key way, and press the impeller onto the shaft until fully seated.

- Page 31 0 SERIES OM-01194 Refer to OPERATION, Section C, before putting ment is required, remove them from the gear hous the pump back into service. ing. After removing the shafts and bearings, clean and inspect the bearings in place as follows. GEARBOX DISASSEMBLY (Figure 2) When the pump is properly operated and main...

- Page 32 OM-01194 0 SERIES shafts, gear housing, or seal plate if the proper bearing fit is not achieved. If the bearings, pinion shaft, or helical drive gear re Use caution when handling hot bear quire replacement, use a suitable puller to remove ings to prevent burns.

- Page 33 0 SERIES OM-01194 justing shims (13 and 17) as previously removed, Gearbox and slide the cover plate over the drive shaft. (Figures 2 and 5) The gearbox was fully lubricated when shipped from the factory. Check the oil level regularly at the oil level pipe plug(s) as shown in Figure 5.

- Page 34 OM-01194 0 SERIES Figure 5. Gearbox Lubrication Positions PAGE E - 14 MAINTENANCE & REPAIR...

- Page 35 For U.S. and International Warranty Information, Please Visit www.grpumps.com/warranty or call: U.S.: 419-755-1280 International: +1-419-755-1352 For Canadian Warranty Information, Please Visit www.grcanada.com/warranty or call: 519-631-2870 GORMAN‐RUPP PUMPS...

Need help?

Do you have a question about the 03H1-GR and is the answer not in the manual?

Questions and answers