Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for WÄRTSILÄ WÄRTSILÄ 34DF

- Page 1 WÄRTSILÄ 34DF PRODUCT GUIDE...

- Page 2 © Copyright by WÄRTSILÄ FINLAND Oy All rights reserved. No part of this booklet may be reproduced or copied in any form or by any means (electronic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written permission of the copyright owner.

- Page 3 Wärtsilä 34DF Product Guide Introduction Introduction This Product Guide provides data and system proposals for the early design phase of marine engine installations. For contracted projects specific instructions for planning the installation are always delivered. Any data and information herein is subject to revision without notice. This 2/2016 issue replaces all previous issues of the Wärtsilä...

-

Page 4: Table Of Contents

Table of contents Wärtsilä 34DF Product Guide Table of contents Main Data and Outputs ........................Technical main data ........................Maximum continuous output ....................... Output limitations in gas mode ....................Reference conditions ........................Operation in inclined position ..................... Principal dimensions and weights ....................Operating Ranges .......................... - Page 5 Wärtsilä 34DF Product Guide Table of contents Compressed Air System ........................Instrument air quality ........................Internal compressed air system ....................External compressed air system ....................Cooling Water System ......................... Water quality ..........................Internal cooling water system ...................... External cooling water system ....................10.

- Page 6 Table of contents Wärtsilä 34DF Product Guide 18.2 Space requirements for maintenance ..................18-8 18.3 Transportation and storage of spare parts and tools ..............18-8 18.4 Required deck area for service work ................... 18-8 19. Transport Dimensions and Weights ....................19-1 19.1 Lifting of main engines ........................

-

Page 7: Main Data And Outputs

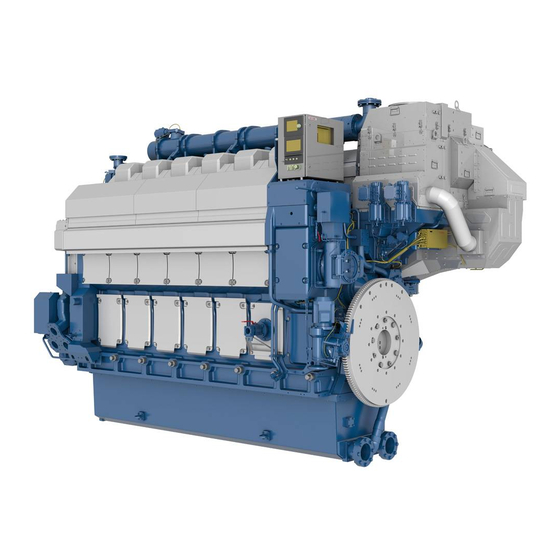

Wärtsilä 34DF Product Guide 1. Main Data and Outputs Main Data and Outputs Technical main data The Wärtsilä 34DF is a 4-stroke, non-reversible, turbocharged and inter-cooled dual fuel engine with direct injection of liquid fuel and indirect injection of gas fuel. The engine can be operated in gas mode or in diesel mode. -

Page 8: Output Limitations In Gas Mode

1. Main Data and Outputs Wärtsilä 34DF Product Guide Output limitations in gas mode 1.3.1 Output limitations due to methane number and charge air receiver temperature Fig 1-1 Output limitations due to methane number and charge air receiver temperature Wärtsilä 34DF Product Guide - a16 - 23 September 2016... - Page 9 Wärtsilä 34DF Product Guide 1. Main Data and Outputs NOTE Compensating a low methane number gas by lowering the charge air receiver temperature below 45 °C is not allowed. Minimum charge air receiver temperature is 35°C. Compensating a higher charge air receiver temperature than 55 °C by a high methane number gas is not allowed.

- Page 10 1. Main Data and Outputs Wärtsilä 34DF Product Guide 1.3.2 Output limitations due to gas feed pressure and lower heating value Fig 1-2 Output limitations for gas feed pressure and LHV, 480/500kW per cylinder NOTE The above given values for gas feed pressure is before the engine (after the gas regulating unit).

-

Page 11: Reference Conditions

Wärtsilä 34DF Product Guide 1. Main Data and Outputs Reference conditions The output is available within a range of ambient conditions and coolant temperatures specified in the chapter Technical Data. The required fuel quality for maximum output is specified in the section Fuel characteristics. -

Page 12: Principal Dimensions And Weights

1. Main Data and Outputs Wärtsilä 34DF Product Guide Principal dimensions and weights 1.6.1 Main engines Fig 1-3 In-line engines (DAAF065806B) Engine kW/Cyl Wärtsilä 6L34DF 5325 2550 2380 2345 1155 3670 Wärtsilä 8L34DF 5960 2550 2610 2345 1155 4230 Wärtsilä 9L34DF 6869 2550 2610... - Page 13 Wärtsilä 34DF Product Guide 1. Main Data and Outputs Fig 1-4 V-engines (DAAF066203) Engine kW/Cyl Wärtsilä 12V34DF 6865 2435 2900 2120 1210 4150 1225 Wärtsilä 16V34DF 7905 2570 3325 2120 1210 5270 1225 Engine kW/Cyl Weight Wärtsilä 12V34DF 1450 1985 1915 1590 Wärtsilä...

- Page 14 1. Main Data and Outputs Wärtsilä 34DF Product Guide 1.6.2 Generating sets Fig 1-5 In-line engines (DAAE082427) Fig 1-6 V engines (DAAE082975) Engine k W / c y l LA1** LA2** LA4** Weight** W 6L34DF 8765 6900 1215 3160 2290 1910 1600 4000...

-

Page 15: Operating Ranges

Wärtsilä 34DF Product Guide 2. Operating Ranges Operating Ranges Engine operating range Below nominal speed the load must be limited according to the diagrams in this chapter in order to maintain engine operating parameters within acceptable limits. Operation in the shaded area is permitted only temporarily during transients. -

Page 16: Loading Capacity

2. Operating Ranges Wärtsilä 34DF Product Guide Remarks: The maximum output may have to be reduced depending on gas properties and gas pressure, refer to section "Derating of output in gas mode". The permissible output will in such case be reduced with same percentage at all revolution speeds. Restrictions for low load operation to be observed. - Page 17 Wärtsilä 34DF Product Guide 2. Operating Ranges 2.2.1 Mechanical propulsion, controllable pitch propeller (CPP) Fig 2-2 Maximum load increase rates for variable speed engines The propulsion control must not permit faster load reduction than 20 s from 100% to 0% without automatic transfer to diesel first.

- Page 18 2. Operating Ranges Wärtsilä 34DF Product Guide The propulsion control and the power management system must not permit faster load reduction than 20 s from 100% to 0% without automatic transfer to diesel first. In electric propulsion applications loading ramps are implemented both in the propulsion control and in the power management system, or in the engine speed control in case isochronous load sharing is applied.

-

Page 19: Operation At Low Load And Idling

Wärtsilä 34DF Product Guide 2. Operating Ranges ● Maximum speed drop 10 % ● Recovery time ≤ 5 s ● Time between load steps of maximum size ≥ 8 s 2.2.2.1.3 Start-up A stand-by generator reaches nominal speed in 50-70 seconds after the start signal (check of pilot fuel injection is always performed during a normal start). - Page 20 This page intentionally left blank...

-

Page 21: Technical Data

Wärtsilä 34DF Product Guide 3. Technical Data Technical Data Wärtsilä 6L34DF Wärtsilä 6L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Engine speed Engine output 2880 3000 2880 3000 3000 3000... - Page 22 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 6L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Total energy consumption at 75% kJ/kWh 7850 7850 7850 7850 7850 7590 load Total energy consumption at 50%...

- Page 23 Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 6L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Suction ability priming pump, in- cluding pipe loss, max. Temperature before bearings, °C nom.

- Page 24 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 6L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Pressure from expansion tank 70...150 70...150 70...150 70...150 70...150 70...150 Delivery head of stand-by pump Starting air system (Note 6) Pressure, nom.

-

Page 25: Wärtsilä 8L34Df

Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 8L34DF Wärtsilä 8L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Engine speed Engine output 3840 4000 3840 4000 4000 4000 Mean effective pressure Speed mode... - Page 26 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 8L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Fuel gas consumption at 85% kJ/kWh 7527 7527 7527 7527 7527 7471 load Fuel gas consumption at 75%...

- Page 27 Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 8L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Temperature before bearings, °C nom. (TE 201) Temperature after engine, ap- °C prox.

- Page 28 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 8L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Pressure drop in external sys- tem, max. Pressure from expansion tank 70...150 70...150 70...150...

-

Page 29: Wärtsilä 9L34Df

Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 9L34DF Wärtsilä 9L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Engine speed Engine output 4320 4500 4320 4500 4500 4500 Mean effective pressure Speed mode... - Page 30 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 9L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Fuel gas consumption at 85% kJ/kWh 7527 7527 7527 7527 7527 7471 load Fuel gas consumption at 75%...

- Page 31 Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 9L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Temperature before bearings, °C nom. (TE 201) Temperature after engine, ap- °C prox.

- Page 32 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 9L34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Pressure drop in external sys- tem, max. Pressure from expansion tank 70...150 70...150 70...150...

-

Page 33: Wärtsilä 12V34Df

Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 12V34DF Wärtsilä 12V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Engine speed Engine output 5760 6000 5760 6000 6000 6000 Mean effective pressure Speed mode... - Page 34 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 12V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Fuel gas consumption at 85% kJ/kWh 7488 7488 7488 7488 7488 7431 load Fuel gas consumption at 75%...

- Page 35 Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 12V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Pump capacity (main), electrically driven Priming pump capacity (50/60Hz) 38.0 / 45.9 38.0 / 45.9 38.0 / 45.9 38.0 / 45.9...

- Page 36 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 12V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Pressure at engine during start, 1500 1500 1500 1500 1500 1500 min.

-

Page 37: Wärtsilä 16V34Df

Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 16V34DF Wärtsilä 16V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Engine speed Engine output 7680 8000 7680 8000 8000 8000 Mean effective pressure Speed mode... - Page 38 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 16V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Fuel gas consumption at 85% kJ/kWh 7488 7488 7488 7488 7488 7431 load Fuel gas consumption at 75%...

- Page 39 Wärtsilä 34DF Product Guide 3. Technical Data Wärtsilä 16V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Temperature before bearings, °C nom. (TE 201) Temperature after engine, ap- °C prox.

- Page 40 3. Technical Data Wärtsilä 34DF Product Guide Wärtsilä 16V34DF Diesel Diesel Diesel Diesel Diesel Diesel mode mode mode mode mode mode mode mode mode mode mode mode Cylinder output Pressure drop in external sys- tem, max. Pressure from expansion tank 70...150 70...150 70...150...

-

Page 41: Description Of The Engine

Wärtsilä 34DF Product Guide 4. Description of the Engine Description of the Engine Definitions Fig 4-1 In-line engine and V-engine definitions (1V93C0029 / 1V93C0028) Main components and systems The dimensions and weights of engines are shown in section 1.6 Principal dimensions and weights. -

Page 42: Cylinder Liner

4. Description of the Engine Wärtsilä 34DF Product Guide The crankshaft is forged in one piece and mounted on the engine block in an under-slung way. In V-engines the connecting rods are arranged side-by-side on the same crank pin in order to obtain a high degree of standardization. -

Page 43: Camshaft And Valve Mechanism

Wärtsilä 34DF Product Guide 4. Description of the Engine cooling water led from the periphery radially towards the centre of the head. The bridges between the valves cooling channels are drilled to provide the best possible heat transfer. 4.2.9 Camshaft and valve mechanism There is one campiece for each cylinder with separate bearing pieces in between. - Page 44 4. Description of the Engine Wärtsilä 34DF Product Guide 4.2.11.2 Main fuel oil injection system The main fuel oil injection system is in use when the engine is operating in diesel mode. When the engine is operating in gas mode, fuel flows through the main fuel oil injection system at all times enabling an instant transfer to diesel mode.

-

Page 45: Cooling System

Wärtsilä 34DF Product Guide 4. Description of the Engine 4.2.12 Exhaust pipes The exhaust manifold pipes are made of special heat resistant nodular cast iron alloy. The connections to the cylinder head are of the clamp ring type. The complete exhaust gas system is enclosed in an insulating box consisting of easily removable panels fitted to a resiliently mounted frame. - Page 46 4. Description of the Engine Wärtsilä 34DF Product Guide All necessary engine control functions are handled by the equipment on the engine, bus communication to external systems, a more comprehensive local display unit, and fuel injection control. Conventional heavy duty cables are used on the engine and the number of connectors are minimised.

-

Page 47: Cross Section Of The Engine

Wärtsilä 34DF Product Guide 4. Description of the Engine Cross section of the engine Fig 4-2 Cross section of the in-line engine Wärtsilä 34DF Product Guide - a16 - 23 September 2016... - Page 48 4. Description of the Engine Wärtsilä 34DF Product Guide Fig 4-3 Cross section of the V-engine Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

-

Page 49: Overhaul Intervals And Expected Life Times

Wärtsilä 34DF Product Guide 4. Description of the Engine Overhaul intervals and expected life times The following overhaul intervals and lifetimes are for guidance only. Actual figures will be different depending on operating conditions, average loading of the engine, fuel quality used, fuel handling system, performance of maintenance etc. - Page 50 This page intentionally left blank...

-

Page 51: Piping Design, Treatment And Installation

Wärtsilä 34DF Product Guide 5. Piping Design, Treatment and Installation Piping Design, Treatment and Installation This chapter provides general guidelines for the design, construction and planning of piping systems, however, not excluding other solutions of at least equal standard. Installation related instructions are included in the project specific instructions delivered for each installation. -

Page 52: Trace Heating

5. Piping Design, Treatment and Installation Wärtsilä 34DF Product Guide Table 5-1 Recommended maximum velocities on pump delivery side for guidance Piping Pipe material Max velocity [m/s] LNG piping Stainless steel Fuel gas piping Stainless steel / Carbon steel Fuel oil piping (MDF and HFO) Black steel Lubricating oil piping Black steel... -

Page 53: Pipe Class

Wärtsilä 34DF Product Guide 5. Piping Design, Treatment and Installation The pressure in the system can: ● Originate from a positive displacement pump ● Be a combination of the static pressure and the pressure on the highest point of the pump curve for a centrifugal pump ●... -

Page 54: Insulation

5. Piping Design, Treatment and Installation Wärtsilä 34DF Product Guide ● Ship Rules Part 6 Chapter 13, Gas Fuelled Engine Installations Table 5-2 Classes of piping systems as per DNV rules Media Class I Class II Class III MPa (bar) °C MPa (bar) °C... -

Page 55: Flexible Pipe Connections

Wärtsilä 34DF Product Guide 5. Piping Design, Treatment and Installation System Methods Starting air A,B,C Cooling water A,B,C Exhaust gas A,B,C Charge air A,B,C In case of carbon steel pipes Methods applied during prefabrication of pipe spools A = Washing with alkaline solution in hot water at 80°C for degreasing (only if pipes have been greased) B = Removal of rust and scale with steel brush (not required for seamless precision tubes) D = Pickling (not required for seamless precision tubes) Methods applied after installation onboard... -

Page 56: Clamping Of Pipes

5. Piping Design, Treatment and Installation Wärtsilä 34DF Product Guide Fig 5-1 Flexible hoses Clamping of pipes It is very important to fix the pipes to rigid structures next to flexible pipe connections in order to prevent damage caused by vibration. The following guidelines should be applied: ●... - Page 57 Wärtsilä 34DF Product Guide 5. Piping Design, Treatment and Installation Fig 5-2 Flange supports of flexible pipe connections (4V60L0796) Fig 5-3 Pipe clamp for fixed support (4V61H0842) Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 58 This page intentionally left blank...

-

Page 59: Fuel System

Wärtsilä 34DF Product Guide 6. Fuel System Fuel System Acceptable fuel characteristics 6.1.1 Gas fuel specification As a dual fuel engine, the Wärtsilä 34DF engine is designed for continuous operation in gas operating mode or diesel operating mode. For continuous operation without reduction in the rated output, the gas used as main fuel in gas operating mode has to fulfill the below mentioned quality requirements. - Page 60 6. Fuel System Wärtsilä 34DF Product Guide Table 6-2 Pilot fuel oils Property Unit ISO-F- ISO-F- ISO-F- Test method ref. Cetane index, min. ISO 4264 6.1.2.2 Marine Diesel Fuel (MDF) Distillate fuel grades are ISO-F-DMX, DMA, DMZ, DMB. These fuel grades are referred to as MDF (Marine Diesel Fuel).

- Page 61 Wärtsilä 34DF Product Guide 6. Fuel System Property Unit ISO-F-DMA ISO-F-DMZ ISO-F-DMB Test method ref. Water, max. % volume — — ISO 3733 Ash, max. % mass 0.01 0.01 0.01 ISO 6245 Lubricity, corrected wear scar diameter (wsd 1.4) at µm ISO 12156-1 60°C , max.

- Page 62 6. Fuel System Wärtsilä 34DF Product Guide Property Unit Limit HFO 1 Limit HFO 2 Test method ref. Vanadium, max. mg/kg ISO 14597 or IP 501 or IP 470 Sodium, max. mg/kg IP 501 or IP 470 Sodium before engine, max. 1) 5) mg/kg IP 501 or IP 470...

- Page 63 Wärtsilä 34DF Product Guide 6. Fuel System 6.1.3 Liquid bio fuels The engine can be operated on liquid bio fuels according to the specifications in tables "6-5 Straight liquid bio fuel specification" or "6-6 Biodiesel specification based on EN 14214:2012 standard".

- Page 64 6. Fuel System Wärtsilä 34DF Product Guide Table 6-6 Biodiesel specification based on EN 14214:2012 standard Property Unit Limit Test method ref. Viscosity at 40°C, min...max. 3.5...5 ISO 3104 Viscosity, before injection pumps, min. Density at 15°C, min...max. kg/m³ 860...900 ISO 3675 / 12185 Cetane number, min.

-

Page 65: Operating Principles

Wärtsilä 34DF Product Guide 6. Fuel System Operating principles Wärtsilä 34DF engines are usually installed for dual fuel operation meaning the engine can be run either in gas or diesel operating mode. The operating mode can be changed while the engine is running, within certain limits, without interruption of power generation. -

Page 66: Fuel Gas System

6. Fuel System Wärtsilä 34DF Product Guide Fuel gas system 6.3.1 Internal fuel gas system Fig 6-1 Internal fuel gas system for in-line engines, double wall (DAAF283528) System components Safety filter Venting valve Turning device Gas admission valve Camshaft Cylinder Flywheel Sensorns and indicators ST173... - Page 67 Wärtsilä 34DF Product Guide 6. Fuel System Fig 6-2 Internal fuel gas system for V-engines, double wall (DAAF283160) System components Safety filter Venting valve Turning device Gas admission valve Camshaft Cylinder Flywheel Sensors and indicators ST173 Engine speed 1 ST197P Engine phase, primary PT901 Main gas pressure...

- Page 68 6. Fuel System Wärtsilä 34DF Product Guide When operating the engine in gas mode, the gas is injected through gas admission valves into the inlet channel of each cylinder. The gas is mixed with the combustion air immediately upstream of the inlet valve in the cylinder head. Since the gas valve is timed independently of the inlet valve, scavenging of the cylinder is possible without risk that unburned gas is escaping directly from the inlet to the exhaust.

- Page 69 Wärtsilä 34DF Product Guide 6. Fuel System 6.3.2 External fuel gas system 6.3.2.1 Fuel gas system, with instrument cabinet Fig 6-3 Example of fuel gas system with instrument cabinet (DAAF022750D) System components Pipe connections Gas detector Gas inlet Gas double wall system ventilation fan Gas system ventilation 10N05 Gas valve unit...

- Page 70 6. Fuel System Wärtsilä 34DF Product Guide 6.3.2.2 Fuel gas system, with solenoid valve cabinet Fig 6-4 Example of fuel gas system with solenoid valve cabinet (DAAF077105) System components Pipe connections Gas detector Gas inlet Gas double wall system ventilation fan Gas system ventilation 10N05 Gas valve unit...

- Page 71 Wärtsilä 34DF Product Guide 6. Fuel System The fuel gas can typically be contained as CNG, LNG at atmospheric pressure, or pressurized LNG. The design of the external fuel gas feed system may vary, but every system should provide natural gas with the correct temperature and pressure to each engine. 6.3.2.3 Double wall gas piping and the ventilation of the piping The annular space in double wall piping is ventilated artificially by underpressure created by...

- Page 72 6. Fuel System Wärtsilä 34DF Product Guide 6.3.2.4 Gas valve unit (10N05) Before the gas is supplied to the engine it passes through a Gas Valve Unit (GVU). The GVU include a gas pressure control valve and a series of block and bleed valves to ensure reliable and safe operation on gas.

- Page 73 Wärtsilä 34DF Product Guide 6. Fuel System Fig 6-6 Gas valve unit P&I diagram (DAAF051037C) Unit components: Gas filter First block valve Shut off valve Control air filter Vent valve Shut off valve Inert gas filter Second block valve Pressure regulator Manual shut off valve Gas control valve CV-V0#...

- Page 74 6. Fuel System Wärtsilä 34DF Product Guide Pipe size DN65 DN80 DN100 PN10 10mm 10mm 10mm Fig 6-7 Main dimensions of the GVU (DAAF020519) 6.3.2.5 Master fuel gas valve For LNG carriers, IMO IGC code requires a master gas fuel valve to be installed in the fuel gas feed system.

- Page 75 Wärtsilä 34DF Product Guide 6. Fuel System In case the DF-engine is stopped in gas operating mode, the ventilation valves will open automatically and quickly reduce the gas pipe pressure to atmospheric pressure. The pressure drop in the venting lines are to be kept at a minimum. To prevent gas ventilation to another engine during maintenance vent lines from gas supply or GVU of different engines cannot be interconnected.

-

Page 76: Fuel Oil System

6. Fuel System Wärtsilä 34DF Product Guide Fuel oil system 6.4.1 Internal fuel oil system Fig 6-8 Internal fuel oil system for inline engines, LFO (DAAF282780A) System components Injection pump Pilot fuel filter Fuel leakage collector Injection valve with pilot solenoid Pilot fuel pump Pulse damper and nozzle... - Page 77 Wärtsilä 34DF Product Guide 6. Fuel System Pipe connections 112 / 117 Pilot fuel inlet OD22 Wärtsilä 34DF Product Guide - a16 - 23 September 2016 6-19...

- Page 78 6. Fuel System Wärtsilä 34DF Product Guide Fig 6-9 Internal fuel oil system for in-line engines, CRO / HFO / BIO (DAAF283161A) System components Injection pump Pilot fuel filter Fuel leakage collector Injection valve with pilot solenoid Pilot fuel pump Pulse damper and nozzle Pressure control valve...

- Page 79 Wärtsilä 34DF Product Guide 6. Fuel System Fig 6-10 Internal fuel oil system for V-engines (DAAF283159) System components Injection pump Pilot fuel filter Fuel leakage collector Inj. valve with pilot solenoid and nozzle Pilot fuel pump Pulse damper Pressure control valve Pilot fuel safety valve Sensors and indicators PT101...

- Page 80 6. Fuel System Wärtsilä 34DF Product Guide There are separate pipe connections for the main fuel oil and pilot fuel oil. Main fuel oil can be Marine Diesel Fuel (MDF) or Heavy Fuel Oil (HFO). Pilot fuel oil is always MDF and the pilot fuel system is in operation in both gas- and diesel mode operation.

-

Page 81: Fuel Tanks

Wärtsilä 34DF Product Guide 6. Fuel System Fig 6-11 Fuel oil viscosity-temperature diagram for determining the pre-heating temperatures of fuel oils (4V92G0071b) Example 1: A fuel oil with a viscosity of 380 cSt (A) at 50°C (B) or 80 cSt at 80°C (C) must be pre-heated to 115 - 130°C (D-E) before the fuel injection pumps, to 98°C (F) at the separator and to minimum 40°C (G) in the bunker tanks. - Page 82 6. Fuel System Wärtsilä 34DF Product Guide To ensure sufficient time for settling (water and sediment separation), the capacity of each tank should be sufficient for min. 24 hours operation at maximum fuel consumption. The tanks should be provided with internal baffles to achieve efficient settling and have a sloped bottom for proper draining.

- Page 83 Wärtsilä 34DF Product Guide 6. Fuel System 6.4.2.3 Fuel treatment 6.4.2.3.1 Separation Heavy fuel (residual, and mixtures of residuals and distillates) must be cleaned in an efficient centrifugal separator before it is transferred to the day tank. Classification rules require the separator arrangement to be redundant so that required capacity is maintained with any one unit out of operation.

- Page 84 6. Fuel System Wärtsilä 34DF Product Guide ● Feed pump (1P02) ● Pre-heater (1E01) ● Sludge tank (1T05) ● Separator (1S01/1S02) ● Sludge pump ● Control cabinets including motor starters and monitoring Fig 6-12 Fuel transfer and separating system (V76F6626F) 6.4.2.3.3 Separator feed pumps (1P02) Feed pumps should be dimensioned for the actual fuel quality and recommended throughput...

- Page 85 Wärtsilä 34DF Product Guide 6. Fuel System 6.4.2.3.4 Separator pre-heater (1E01) The pre-heater is dimensioned according to the feed pump capacity and a given settling tank temperature. The surface temperature in the heater must not be too high in order to avoid cracking of the fuel.

- Page 86 6. Fuel System Wärtsilä 34DF Product Guide 6.4.2.3.7 Sludge tank (1T05) The sludge tank should be located directly beneath the separators, or as close as possible below the separators, unless it is integrated in the separator unit. The sludge pipe must be continuously falling.

- Page 87 Wärtsilä 34DF Product Guide 6. Fuel System Fig 6-14 Example of fuel oil system (MDF) multiple engine installation (DAAE085364B) System components 1E04 Cooler (MDF) 1P03 Circulation pump (MDF) 1V10 Quick closing valve (fuel oil tank) 1F05 Fine filter (MDF) 1P11 Black start pump (MDF) 1F07 Suction strainer (MDF)

- Page 88 6. Fuel System Wärtsilä 34DF Product Guide If the engines are to be operated on MDF only, heating of the fuel is normally not necessary. In such case it is sufficient to install the equipment listed below. Some of the equipment listed below is also to be installed in the MDF part of a HFO fuel oil system.

- Page 89 Wärtsilä 34DF Product Guide 6. Fuel System 6.4.2.4.4 MDF cooler (1E04) The fuel viscosity may not drop below the minimum value stated in Technical data. When operating on MDF, the practical consequence is that the fuel oil inlet temperature must be kept below 45°C.

- Page 90 6. Fuel System Wärtsilä 34DF Product Guide 6.4.2.5 Fuel feed system - HFO installations Fig 6-15 Example of FO system (HFO), multiple engine installation (DAAE085365E) System components: 1E02 Heater (booster unit) 1P06 Circulation pump (booster unit) 1E03 Cooler (booster unit) 1P12 Circulation pump (HFO, MDF) 1E04...

- Page 91 Wärtsilä 34DF Product Guide 6. Fuel System Pipe connections: L34DF L34DF V34DF V34DF 435/450kW/cyl 480/500kW/cyl 435/450kW/cyl 480/500kW/cyl 1044 Leak fuel drain, dirty fuel DN32 DN32 112 / Pilot fuel inlet / Pilot fuel outlet OD22 OD18 OD18 OD18 117A/B HFO pipes shall be properly insulated. If the viscosity of the fuel is 180 cSt/50°C or higher, the pipes must be equipped with trace heating.

- Page 92 6. Fuel System Wärtsilä 34DF Product Guide ● Two circulating pumps, same type as the fuel feed pumps ● Two heaters, steam, electric or thermal oil (one heater in operation, the other as spare) ● One automatic back-flushing filter with by-pass filter ●...

- Page 93 Wärtsilä 34DF Product Guide 6. Fuel System A suction strainer with a fineness of 0.5 mm should be installed before each pump. There must be a positive static pressure of about 30 kPa on the suction side of the pump. Design data: Total consumption of the connected engines added with Capacity...

- Page 94 6. Fuel System Wärtsilä 34DF Product Guide 6.4.2.5.4.4 Flow meter, booster unit (1I01) If a fuel consumption meter is required, it should be fitted between the feed pumps and the de-aeration tank. When it is desired to monitor the fuel consumption of individual engines in a multiple engine installation, two flow meters per engine are to be installed: one in the feed line and one in the return line of each engine.

- Page 95 Wärtsilä 34DF Product Guide 6. Fuel System heater capacity (kW) total fuel consumption at full output + 15% margin [l/h] ΔT = temperature rise in heater [°C] 6.4.2.5.4.8 Viscosimeter, booster unit (1I02) The heater is to be controlled by a viscosimeter. The viscosimeter should be of a design that can withstand the pressure peaks caused by the injection pumps of the diesel engine.

- Page 96 6. Fuel System Wärtsilä 34DF Product Guide Design data: Fuel viscosity according to fuel specification Design temperature 150°C Design flow Equal to circulation pump capacity Design pressure 1.6 MPa (16 bar) Filter fineness 37 μm (absolute mesh size) Maximum permitted pressure drops at 14 cSt: - clean filter 20 kPa (0.2 bar) - alarm...

- Page 97 Wärtsilä 34DF Product Guide 6. Fuel System 6.4.2.6 Flushing The external piping system must be thoroughly flushed before the engines are connected and fuel is circulated through the engines. The piping system must have provisions for installation of a temporary flushing filter. The fuel pipes at the engine (connections 101 and 102) are disconnected and the supply and return lines are connected with a temporary pipe or hose on the installation side.

- Page 98 This page intentionally left blank...

-

Page 99: Lubricating Oil System

Wärtsilä 34DF Product Guide 7. Lubricating Oil System Lubricating Oil System Lubricating oil requirements 7.1.1 Engine lubricating oil The lubricating oil must be of viscosity class SAE 40 and have a viscosity index (VI) of minimum 95. The lubricating oil alkalinity (BN) is tied to the fuel grade, as shown in the table below. BN is an abbreviation of Base Number. - Page 100 7. Lubricating Oil System Wärtsilä 34DF Product Guide 7.1.2 Oil in speed governor or actuator An oil of viscosity class SAE 30 or SAE 40 is acceptable in normal operating conditions. Usually the same oil as in the engine can be used. At low ambient temperatures it may be necessary to use a multigrade oil (e.g.

-

Page 101: Internal Lubricating Oil System

Wärtsilä 34DF Product Guide 7. Lubricating Oil System Internal lubricating oil system Fig 7-1 Internal LO system for L-engines, dry sump (DAAF291395) System components Lubricating oil main pump Centrifugal filter On/Off control valve for VIC Prelubricating oil pump Pressure control valve Oil mist detector NS700 Lubricating oil cooler Turbocharger... - Page 102 7. Lubricating Oil System Wärtsilä 34DF Product Guide Pipe connections Size Inert gas inlet DN50 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 103 Wärtsilä 34DF Product Guide 7. Lubricating Oil System Fig 7-2 Internal LO system for L-engines, wet sump (DAAF290118) System components Lubricating oil main pump Centrifugal filter On/Off control valve for VIC CV381 Prelubricating oil pump (M201 Pressure control valve Oil mist detector NS700 motor) Lubricating oil cooler Turbocharger...

- Page 104 7. Lubricating Oil System Wärtsilä 34DF Product Guide Pipe connections Size Lube oil from separator and filling DN40 Lube oil to separator and drain DN40 Lube oil filling DN40 plug Lube oil drain M22 * 1.5 plug Crankcase air vent DN100 Inert gas inlet DN50...

- Page 105 Wärtsilä 34DF Product Guide 7. Lubricating Oil System Fig 7-3 Internal LO system for V-engines, wet sump (DAAF290119) System components Lubricating oil main pump Centrifugal filter On/Off control valve for VIC CV381 Prelubricating oil pump Pressure control valve Oil mist detector NS700 Lubricating oil cooler Turbocharger Oil sample...

- Page 106 7. Lubricating Oil System Wärtsilä 34DF Product Guide Pipe connections Size Lubricating oil from el.driven pump DN125 Lubricating oil from separator and filling (wet sump) DN40 Lubricating oil to separator and drain (wet sump) DN40 Lubricating oil filling (wet sump) DN40 plug Lubricating oil drain (wet sump) M22 x 1.5...

- Page 107 Wärtsilä 34DF Product Guide 7. Lubricating Oil System Fig 7-4 Internal LO system for V-engines, dry sump (DAAF291394) System components Lubricating oil main pump Centrifugal filter On/Off control valve for VIC CV381 Prelubricating oil pump Pressure control valve Oil mist detector NS700 Lubricating oil cooler Turbocharger Oil sample...

- Page 108 7. Lubricating Oil System Wärtsilä 34DF Product Guide Pipe connections Size Lube oil to engine driven pump DN250 Lube oil to priming pump DN125 Lube oil from electrical driven pump DN125 Crankcase air vent DN125 Inert gas inlet DN50 7-10 Wärtsilä...

- Page 109 Wärtsilä 34DF Product Guide 7. Lubricating Oil System The lubricating oil sump is of wet sump type. Dry sump is an option for main engines. The direct driven lubricating oil pump is of gear type and equipped with a pressure control valve.

-

Page 110: External Lubricating Oil System

7. Lubricating Oil System Wärtsilä 34DF Product Guide External lubricating oil system Fig 7-5 Example of lubricating oil system, wet oil sump (DAAE055757C) System components Pipe connections L34DF V34DF 2E02 Heater (separator unit) Lubricating oil to el.driven pump DN150 DN200 2F03 Suction filter (separator unit) Lubricating oil from el. - Page 111 Wärtsilä 34DF Product Guide 7. Lubricating Oil System Fig 7-6 Example of lubricating oil system, dry oil sump (DAAE055758C) System components Pipe connections L34DF V34DF 2E02 Heater (separator unit) Lube oil outlet DN150 2F01 Suction strainer (main lube oil pump) Lube oil to engine driven pump DN200 2F03...

- Page 112 7. Lubricating Oil System Wärtsilä 34DF Product Guide 7.3.1 Separation system 7.3.1.1 Separator unit (2N01) Each main engine must have a dedicated lubricating oil separator and the separators shall be dimensioned for continuous separating. If the installation is designed to operate on gas/MDF only, then intermittent separating might be sufficient.

- Page 113 Wärtsilä 34DF Product Guide 7. Lubricating Oil System engine output [kW] number of through-flows of tank volume per day: 5 for HFO, 4 for MDF operating time [h/day]: 24 for continuous separator operation, 23 for normal dimensioning 7.3.1.1.4 Sludge tank (2T06) The sludge tank should be located directly beneath the separators, or as close as possible below the separators, unless it is integrated in the separator unit.

- Page 114 7. Lubricating Oil System Wärtsilä 34DF Product Guide not allow fuel gas to exit the tank (e.g. overflow pipe arrangement with water lock). The system oil tank breathing pipes of engines located in the same engine room must not be combined. The structure and the arrangement of the system oil tank may need to be approved by a Classification Society project-specifically.

-

Page 115: Crankcase Ventilation System

Wärtsilä 34DF Product Guide 7. Lubricating Oil System 7.3.4 Suction strainers (2F01, 2F04, 2F06) It is recommended to install a suction strainer before each pump to protect the pump from damage. The suction strainer and the suction pipe must be amply dimensioned to minimize pressure losses. - Page 116 7. Lubricating Oil System Wärtsilä 34DF Product Guide The size of the ventilation pipe (D2) out from the condensate trap should be bigger than the ventilation pipe (D) com- ing from the engine. For more information about ventilation pipe (D) size, see the external lubricating oil system drawing.

-

Page 117: Flushing Instructions

Wärtsilä 34DF Product Guide 7. Lubricating Oil System Flushing instructions Flushing instructions in this Product Guide are for guidance only. For contracted projects, read the specific instructions included in the installation planning instructions (IPI). 7.5.1 Piping and equipment built on the engine Flushing of the piping and equipment built on the engine is not required and flushing oil shall not be pumped through the engine oil system (which is flushed and clean from the factory). - Page 118 7. Lubricating Oil System Wärtsilä 34DF Product Guide 7.5.3.4 Lubricating oil sample To verify the cleanliness a LO sample shall be taken by the shipyard after the flushing is completed. The properties to be analyzed are Viscosity, BN, AN, Insolubles, Fe and Particle Count.

-

Page 119: Compressed Air System

Wärtsilä 34DF Product Guide 8. Compressed Air System Compressed Air System Compressed air is used to start engines and to provide actuating energy for safety and control devices. The use of starting air for other purposes is limited by the classification regulations. To ensure the functionality of the components in the compressed air system, the compressed air has to be free from solid particles and oil. - Page 120 8. Compressed Air System Wärtsilä 34DF Product Guide Fig 8-1 Internal CA system for in-line engines (DAAF283526) System components Main starting air valve Stop solenoid valve Starting air distributor Stop solenoid valve Starting air valve in cylinder head Solenoid valve for gas venting valve Blocking valve, when turning gear engaged Drain valve Air container...

- Page 121 Wärtsilä 34DF Product Guide 8. Compressed Air System Fig 8-2 Internal compressed air system for V-engines (DAAF283527) System components Main starting air valve Stop solenoid valve Starting air distributor Stop solenoid valve Starting air valve in cylinder head Solenoid valve for gas venting valve Blocking valve, when turning gear engaged Drain valve Air container...

-

Page 122: External Compressed Air System

8. Compressed Air System Wärtsilä 34DF Product Guide External compressed air system The design of the starting air system is partly determined by classification regulations. Most classification societies require that the total capacity is divided into two equally sized starting air receivers and starting air compressors. - Page 123 Wärtsilä 34DF Product Guide 8. Compressed Air System 8.3.2 Oil and water separator (3S01) An oil and water separator should always be installed in the pipe between the compressor and the air vessel. Depending on the operation conditions of the installation, an oil and water separator may be needed in the pipe between the air vessel and the engine.

- Page 124 8. Compressed Air System Wärtsilä 34DF Product Guide The required total starting air vessel volume can be calculated using the formula: where: total starting air vessel volume [m normal barometric pressure (NTP condition) = 0.1 MPa air consumption per start [Nm ] See Technical data required number of starts according to the classification society maximum starting air pressure = 3 MPa...

-

Page 125: Cooling Water System

Wärtsilä 34DF Product Guide 9. Cooling Water System Cooling Water System Water quality The fresh water in the cooling water system of the engine must fulfil the following requirements: p H ....... min. 6.5...8.5 Hardness ..... max. 10 °dH Chlorides ..... max. -

Page 126: Internal Cooling Water System

9. Cooling Water System Wärtsilä 34DF Product Guide Internal cooling water system Fig 9-1 Internal CW system for in-line engines (DAAF287663) System components: HT-cooling water pump Lubricating oil cooler Connection piece LT-cooling water pump HT-thermostatic valve Charge air cooler (LT) Charge air cooler (HT) Sensors and indicators: PT401... - Page 127 Wärtsilä 34DF Product Guide 9. Cooling Water System Fig 9-2 Internal CW system for V-engines, 2-stage CAC Integrated (DAAF287665) System components: HT-cooling water pump Lubricating oil cooler HT thermostatic valve LT-cooling water pump Charge air cooler (HT) Charge air cooler (LT) Shut-off valve Sensors and indicators: PT401...

- Page 128 9. Cooling Water System Wärtsilä 34DF Product Guide The fresh water cooling system is divided into a high temperature (HT) and a low temperature (LT) circuit. The HT water circulates through cylinder jackets, cylinder heads and the 1st stage of the charge air cooler, while the LT water circulates through the 2nd stage of the charge air cooler and through the lubricating oil cooler.

-

Page 129: External Cooling Water System

Wärtsilä 34DF Product Guide 9. Cooling Water System External cooling water system Fig 9-4 External cooling water system, in-line engines (DAAE055760C) System components: 1E04 Cooler (MDF) 4P09 Transfer pump 4E05 Heater (preheater) 4P11 Circulating pump (sea water) 4E08 Central cooler 4P15 Circulating pump (LT) 4E10... - Page 130 9. Cooling Water System Wärtsilä 34DF Product Guide Fig 9-5 External cooling water system, V-engines (DAAE084914B) System components: 1E04 Cooler (MDF) 4P15 Circulating pump (LT) 4E05 Heater (preheater) 4S01 Air venting 4E08 Central cooler 4T04 Drain tank 4E15 Cooler (generator) 4T05 Expansion tank 4N01...

- Page 131 Wärtsilä 34DF Product Guide 9. Cooling Water System Fig 9-6 External cooling water system, V-engines (DAAE089099B) System components: 1E04 Cooler (MDF) 4P15 Circulating pump (LT) 1E03 Heat recovery (evaporator) 4P19 Circulating pump (evaporator) 4E05 Heater (preheater) 4S01 Air venting 4E08 Central cooler 4T04 Drain tank...

- Page 132 9. Cooling Water System Wärtsilä 34DF Product Guide It is recommended to divide the engines into several circuits in multi-engine installations. One reason is of course redundancy, but it is also easier to tune the individual flows in a smaller system.

- Page 133 Wärtsilä 34DF Product Guide 9. Cooling Water System NOTE Max LT cooling water temperature before engine is 38 ºC. 9.3.5 Charge air temperature control valve (4V09) The temperature of the charge air is maintained on desired level with an electrically actuated temperature control valve in the external LT circuit.

- Page 134 9. Cooling Water System Wärtsilä 34DF Product Guide Fig 9-7 Central cooler main dimensions. Example for guidance only Number of cylinders A [mm] B [mm] C [mm] D [mm] Weight [kg] 2150 1200 2150 1230 2150 1250 2150 1310 As an alternative to central coolers of plate or tube type, a box cooler can be installed. The principle of box cooling is very simple.

- Page 135 Wärtsilä 34DF Product Guide 9. Cooling Water System Venting pipes to the expansion tank are to be installed at all high points in the piping system, where air or gas can accumulate. The vent pipes must be continuously rising. 9.3.11 Expansion tank (4T05) The expansion tank compensates for thermal expansion of the coolant, serves for venting of the circuits and provides a sufficient static pressure for the circulating pumps.

- Page 136 9. Cooling Water System Wärtsilä 34DF Product Guide 9.3.12 Drain tank (4T04) It is recommended to collect the cooling water with additives in a drain tank, when the system has to be drained for maintenance work. A pump should be provided so that the cooling water can be pumped back into the system and reused.

- Page 137 Wärtsilä 34DF Product Guide 9. Cooling Water System The formula above should not be used for P < 3.5 kW/cyl 9.3.13.2 Circulation pump for preheater (4P04) Design data: Capacity 0.4 m /h per cylinder Delivery pressure 80...100 kPa (0.8...1.0 bar) 9.3.13.3 Preheating unit (4N01) A complete preheating unit can be supplied.

- Page 138 9. Cooling Water System Wärtsilä 34DF Product Guide 9.3.14 Throttles Throttles (orifices) are to be installed in all by-pass lines to ensure balanced operating conditions for temperature control valves. Throttles must also be installed wherever it is necessary to balance the waterflow between alternate flow paths. 9.3.15 Thermometers and pressure gauges Local thermometers should be installed wherever there is a temperature change, i.e.

-

Page 139: Combustion Air System

Wärtsilä 34DF Product Guide 10. Combustion Air System Combustion Air System 10.1 Engine room ventilation To maintain acceptable operating conditions for the engines and to ensure trouble free operation of all equipment, attention to shall be paid to the engine room ventilation and the supply of combustion air. -

Page 140: Combustion Air System Design

10. Combustion Air System Wärtsilä 34DF Product Guide It is good practice to provide areas with significant heat sources, such as separator rooms with their own air supply and extractors. Under-cooling of the engine room should be avoided during all conditions (service conditions, slow steaming and in port). - Page 141 Wärtsilä 34DF Product Guide 10. Combustion Air System 10.2.1 Charge air shut-off valve, "rigsaver" (optional) In installations where it is possible that the combustion air includes combustible gas or vapour the engines can be equipped with charge air shut-off valve. This is regulated mandatory where ingestion of flammable gas or fume is possible.

- Page 142 This page intentionally left blank...

-

Page 143: Exhaust Gas System

Wärtsilä 34DF Product Guide 11. Exhaust Gas System Exhaust Gas System 11.1 Internal exhaust gas system Fig 11-1 Charge air and exhaust gas system for in-line engines with manual cleaning device (DAAF288661) System components Air filter Cylinder Charge air wastegate valve Turbocharger (TC) Exh gas wastegate valve Charge air shut-off valve... - Page 144 11. Exhaust Gas System Wärtsilä 34DF Product Guide Fig 11-2 Charge air and exhaust gas system for V-engines with manual cleaning device (DAAF288662) System components Air filter Cylinder Charge air wastegate valve Turbocharger Exhaust gas wastegate valve Charge air shut-off valve Charge air cooler (2-stage) Charge air bypass valve Silencer...

-

Page 145: Exhaust Gas Outlet

Wärtsilä 34DF Product Guide 11. Exhaust Gas System 11.2 Exhaust gas outlet Fig 11-3 Exhaust pipe connections (DAAF068270A) TC in free end TC in driving end Engine TC type NT1-10 0° W 6L34DF A145 0°, 45°, 90° 0°, 45°, 90° NT1-10 0°... - Page 146 11. Exhaust Gas System Wärtsilä 34DF Product Guide Engine TC type ØB [mm] NT1-10A DN500 W 6L34DF A145 DN350 A155 W 8L34DF NT1-10A DN500 A145 W 9L34DF DN450 A155 Fig 11-4 Exhaust pipe, diameters and support (DAAF068269) Fig 11-5 Exhaust pipe, diameters and support (DAAF068200A, -04A) Engine TC type ØB [mm]...

-

Page 147: External Exhaust Gas System

Wärtsilä 34DF Product Guide 11. Exhaust Gas System 11.3 External exhaust gas system Each engine should have its own exhaust pipe into open air. Backpressure, thermal expansion and supporting are some of the decisive design factors. Flexible bellows must be installed directly on the turbocharger outlet, to compensate for thermal expansion and prevent damages to the turbocharger due to vibrations. - Page 148 11. Exhaust Gas System Wärtsilä 34DF Product Guide ● The combustion in all cylinders is continuously monitored and should it be detected that all cylinders are not firing reliably, then the engine will automatically trip to diesel mode. ● The exhaust gas system is ventilated by a fan after the engine has stopped, if the engine was operating in gas mode prior to the stop.

- Page 149 Wärtsilä 34DF Product Guide 11. Exhaust Gas System 11.3.4 Piping The piping should be as short and straight as possible. Pipe bends and expansions should be smooth to minimise the backpressure. The diameter of the exhaust pipe should be increased directly after the bellows on the turbocharger.

- Page 150 11. Exhaust Gas System Wärtsilä 34DF Product Guide The supporting must allow thermal expansion and ship’s structural deflections. 11.3.6 Back pressure The maximum permissible exhaust gas back pressure is stated in chapter Technical Data. The back pressure in the system must be calculated by the shipyard based on the actual piping design and the resistance of the components in the exhaust system.

- Page 151 Wärtsilä 34DF Product Guide 11. Exhaust Gas System Fig 11-8 Exhaust gas silencer (DAAE087980) Table 11-1 Typical dimensions of exhaust gas silencers, Attenuation 35 dB (A) L [mm] D [mm] A [mm] B [mm] Weight [kg] 5510 1300 1690 6550 1500 2330 6530...

- Page 152 This page intentionally left blank...

-

Page 153: Turbocharger Cleaning

Wärtsilä 34DF Product Guide 12. Turbocharger Cleaning Turbocharger Cleaning Regular water cleaning of the turbine and the compressor reduces the formation of deposits and extends the time between overhauls. Fresh water is injected into the turbocharger during operation. Additives, solvents or salt water must not be used and the cleaning instructions in the operation manual must be carefully followed. -

Page 154: Compressor Cleaning System

12. Turbocharger Cleaning Wärtsilä 34DF Product Guide 12.2 Compressor cleaning system The compressor side of the turbocharger is cleaned with the same equipment as the turbine. 12-2 Wärtsilä 34DF Product Guide - a16 - 23 September 2016... -

Page 155: Exhaust Emissions

Wärtsilä 34DF Product Guide 13. Exhaust Emissions Exhaust Emissions Exhaust emissions from the dual fuel engine mainly consist of nitrogen, carbon dioxide (CO2) and water vapour with smaller quantities of carbon monoxide (CO), sulphur oxides (SOx) and nitrogen oxides (NOx), partially reacted and non-combusted hydrocarbons and particulates. 13.1 Dual fuel engine exhaust components Due to the high efficiency and the clean fuel used in a dual fuel engine in gas mode, the exhaust... - Page 156 13. Exhaust Emissions Wärtsilä 34DF Product Guide Table 13-1 ISO 8178 test cycles D2: Constant-speed Speed (%) auxiliary engine applica- Power (%) tion Weighting 0.05 0.25 factor E2: Constant-speed Speed (%) main propulsion applica- Power (%) tion including diesel- electric drive and all Weighting 0.15 0.15...

- Page 157 Wärtsilä 34DF Product Guide 13. Exhaust Emissions The IMO Tier 3 NO emission standard effective date starts from year 2016. The Tier 3 standard will apply in designated emission control areas (ECA). The ECAs are to be defined by the IMO. So far, the North American ECA and the US Caribbean Sea ECA have been defined and will be effective for marine diesel engines installed in ships constructed on or after 1.1.2016.

- Page 158 13. Exhaust Emissions Wärtsilä 34DF Product Guide The IMO Tier 3 NO emission level corresponds to an 80% reduction from the IMO Tier 2 NOx emission standard. The reduction can be reached by applying a secondary exhaust gas emission control system. A Selective Catalytic Reduction (SCR) system is an efficient way for diesel engines to reach the NOx reduction needed for the IMO Tier 3 standard.

-

Page 159: Methods To Reduce Exhaust Emissions

Wärtsilä 34DF Product Guide 13. Exhaust Emissions 13.2.2 Other Legislations There are also other local legislations in force in particular regions. 13.3 Methods to reduce exhaust emissions All standard Wärtsilä engines meet the NOx emission level set by the IMO (International Maritime Organisation) and most of the local emission levels without any modifications. - Page 160 This page intentionally left blank...

-

Page 161: Automation System

Wärtsilä 34DF Product Guide 14. Automation System Automation System Wärtsilä Unified Controls – UNIC is a modular embedded automation system. UNIC C3 is used for engines with electronically controlled fuel injection and has a hardwired interface for control functions and a bus communication interface for alarm and monitoring. 14.1 UNIC C3 UNIC C3 is a fully embedded and distributed engine management system, which handles all... - Page 162 14. Automation System Wärtsilä 34DF Product Guide Local Display Unit offers a set of menus for retrieval and graphical display of operating data, calculated data and event history. The module also handles communication with external systems over Modbus TCP. Power Distribution Module handles fusing, power distribution, earth fault monitoring and EMC filtration in the system.

-

Page 163: Power Unit

Wärtsilä 34DF Product Guide 14. Automation System Fig 14-2 Local control panel and local display unit 14.1.2 Engine safety system The engine safety module handles fundamental safety functions, for example overspeed protection. It is also the interface to the shutdown devices on the engine for all other parts of the control system. - Page 164 14. Automation System Wärtsilä 34DF Product Guide The power unit contains redundant power converters, each converter dimensioned for 100% load. At least one of the two incoming supplies must be connected to a UPS. The power unit supplies the equipment on the engine with 2 x 24 VDC and 2 x 110 VDC. Power supply from ship's system: ●...

- Page 165 Wärtsilä 34DF Product Guide 14. Automation System Cable From <=> To Cable types (typical) Engine <=> Propulsion Control System 1 x 2 x 0.75 mm Engine <=> Power Management System / Main Switch- 1 x 2 x 0.75 mm board 1 x 2 x 0.75 mm 24 x 0.75 mm 24 x 0.75 mm...

- Page 166 14. Automation System Wärtsilä 34DF Product Guide Fig 14-4 Signal overview (Main engine) 14-6 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

-

Page 167: Functions

Wärtsilä 34DF Product Guide 14. Automation System Fig 14-5 Signal overview (Generating set) 14.2 Functions 14.2.1 Engine operating modes The operator can select four different fuel operating modes: ● Gas operating mode (gas fuel + pilot fuel injection) ● Diesel operating mode (conventional diesel fuel injection + pilot fuel injection) ●... - Page 168 14. Automation System Wärtsilä 34DF Product Guide automatically trip from gas- into diesel operating mode (gas trip) in several alarm situations. Request for diesel operating mode will always override request for gas operating mode. The engine control system automatically forces the engine to backup operating mode (regardless of operator choice of operating mode) in two cases: ●...

- Page 169 Wärtsilä 34DF Product Guide 14. Automation System The engine efficiency change depending on fuel mix ratio and engine load, please contact Wärtsilä for further information. Fig 14-7 Fuel mixing ratio 14.2.1.2 Low load optimization (optional) During low load operation in gas mode (below 25% load), up to one third of the cylinders can be deactivated.

- Page 170 14. Automation System Wärtsilä 34DF Product Guide ● Charge air shut-off valve closed (optional device) 14.2.2.2 Start in gas operating mode If the engine is ready to start in gas operating mode the output signals "engine ready for gas operation" (no gas trips are active) and "engine ready for start" (no start blockings are active) are activated.

-

Page 171: Shutdown Mode

Wärtsilä 34DF Product Guide 14. Automation System The engine can run in backup operating mode in case the engine has been started with the blackout start input active or a pilot trip has occurred. A transfer to gas operating mode can only be done after a combustion check, which is done by restarting the engine. -

Page 172: Speed Control

14. Automation System Wärtsilä 34DF Product Guide In shutdown mode the clutch/generator breaker is opened immediately without unloading. The actions following a shutdown are similar to normal engine stop. Shutdown mode must be reset by the operator and the reason for shutdown must be investigated and corrected before re-start. -

Page 173: Alarm And Monitoring Signals

Wärtsilä 34DF Product Guide 14. Automation System 14.3 Alarm and monitoring signals Regarding sensors on the engine, please see the internal P&I diagrams in this product guide. The actual configuration of signals and the alarm levels are found in the project specific documentation supplied for all contracted projects. - Page 174 14. Automation System Wärtsilä 34DF Product Guide 14.4.1.3 Exhaust gas ventilation unit The exhaust gas ventilating unit is engine specific and includes an electric driven fan, flow switch and closing valve. For further information, see chapter Exhaust gas system. 14.4.1.4 Gas valve unit (GVU) The gas valve unit is engine specific and controls the gas flow to the engine.

-

Page 175: Foundation

Wärtsilä 34DF Product Guide 15. Foundation Foundation Engines can be either rigidly mounted on chocks, or resiliently mounted on rubber elements. If resilient mounting is considered, Wärtsilä must be informed about existing excitations such as propeller blade passing frequency. Dynamic forces caused by the engine are listed in the chapter Vibration and noise. - Page 176 15. Foundation Wärtsilä 34DF Product Guide 15.2.1.1 Resin chocks The recommended dimensions of resin chocks are 150 x 400 mm. The total surface pressure on the resin must not exceed the maximum permissible value, which is determined by the type of resin and the requirements of the classification society. It is recommended to select a resin type that is approved by the relevant classification society for a total surface pressure of 5 N/mm .

- Page 177 Wärtsilä 34DF Product Guide 15. Foundation Fig 15-1 Main engine seating and fastening, in-line engines, steel chocks (DAAE085777) Wärtsilä 34DF Product Guide - a16 - 23 September 2016 15-3...

- Page 178 15. Foundation Wärtsilä 34DF Product Guide Number of pieces per engine W 6L34DF W 8L34DF W 9L34DF Fitted bolt Clearance bolt Round nut Lock nut Distance sleeve Lateral support Chocks 15-4 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 179 Wärtsilä 34DF Product Guide 15. Foundation Fig 15-2 Main engine seating and fastening, in-line engines, resin chocks (DAAE085778) Wärtsilä 34DF Product Guide - a16 - 23 September 2016 15-5...

- Page 180 15. Foundation Wärtsilä 34DF Product Guide Number of pieces per engine W 6L34DF W 8L34DF W 9L34DF Fitted bolt Clearance bolt Round nut Lock nut Distance sleeve Lateral support Chocks 15-6 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 181 Wärtsilä 34DF Product Guide 15. Foundation Fig 15-3 Main engine seating and fastening, V-engines, steel chocks (DAAE085776) Wärtsilä 34DF Product Guide - a16 - 23 September 2016 15-7...

- Page 182 15. Foundation Wärtsilä 34DF Product Guide Number of pieces per engine W 12V34DF W 16V34DF Fitted bolt Clearance bolt Round nut Lock nut Distance sleeve Lateral support Chocks 15-8 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 183 Wärtsilä 34DF Product Guide 15. Foundation Fig 15-4 Main engine seating and fastening, V-engines, resin chocks (DAAE085781) Wärtsilä 34DF Product Guide - a16 - 23 September 2016 15-9...

- Page 184 15. Foundation Wärtsilä 34DF Product Guide Number of pieces per engine W 12V34DF W 16V34DF Fitted bolt Clearance bolt Round nut Lock nut Distance sleeve Lateral support Chocks 15-10 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 185 Wärtsilä 34DF Product Guide 15. Foundation 15.2.2 Resilient mounting In order to reduce vibrations and structure borne noise, main engines can be resiliently mounted on rubber elements. The transmission of forces emitted by the engine is 10-20% when using resilient mounting. Two different mounting arrangements are applied.

- Page 186 15. Foundation Wärtsilä 34DF Product Guide Fig 15-6 Principle of resilient mounting, W9L34DF (V69A0247A) Fig 15-7 Principle of resilient mounting, W12V34DF and W16V34DF (DAAE041111A) 15-12 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

-

Page 187: Mounting Of Generating Sets

Wärtsilä 34DF Product Guide 15. Foundation 15.3 Mounting of generating sets 15.3.1 Generator feet design Fig 15-8 Distance between fixing bolts on generator (DAAE084469) W 6L34DF W 8L34DF W 9L34DF W 12V34DF W 16V34DF H [mm] Rmax [mm] Rmax [mm] Rmax [mm] Rmax [mm] Rmax [mm]... - Page 188 15. Foundation Wärtsilä 34DF Product Guide Engine G [mm] E [mm] D [mm] C [mm] B [mm] W L34DF M24 or Ø35 W V34DF Ø48 15-14 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 189 Wärtsilä 34DF Product Guide 15. Foundation 15.3.2 Resilient mounting Generating sets, comprising engine and generator mounted on a common base frame, are usually installed on resilient mounts on the foundation in the ship. The resilient mounts reduce the structure borne noise transmitted to the ship and also serve to protect the generating set bearings from possible fretting caused by hull vibration.

- Page 190 15. Foundation Wärtsilä 34DF Product Guide Fig 15-9 Recommended design of the generating set seating (3V46L0295d, DAAE020067a) 15.3.2.1 Rubber mounts The generating set is mounted on conical resilient mounts, which are designed to withstand both compression and shear loads. In addition the mounts are equipped with an internal buffer to limit the movements of the generating set due to ship motions.

-

Page 191: Flexible Pipe Connections

Wärtsilä 34DF Product Guide 15. Foundation Fig 15-10 Rubber mount, In-line engines (DAAE004230c) Fig 15-11 Rubber mount, V-engines (DAAE018766b) 15.4 Flexible pipe connections When the engine or generating set is resiliently installed, all connections must be flexible and no grating nor ladders may be fixed to the engine or generating set. When installing the flexible pipe connections, unnecessary bending or stretching should be avoided. - Page 192 This page intentionally left blank...

-

Page 193: Vibration And Noise

Wärtsilä 34DF Product Guide 16. Vibration and Noise Vibration and Noise Wärtsilä 34DF generating sets comply with vibration levels according to ISO 8528-9. Main engines comply with vibration levels according to ISO 10816-6 Class 5. 16.1 External forces and couples Some cylinder configurations produce external forces and couples. - Page 194 16. Vibration and Noise Wärtsilä 34DF Product Guide Table 16-2 External couples Engine Speed Frequency Frequency Frequency [rpm] [Hz] [Hz] [Hz] [kNm] [kNm] [kNm] [kNm] [kN] [kN] W 6L34DF – – – – – – 12.5 – – – – –...

-

Page 195: Torque Variations

Wärtsilä 34DF Product Guide 16. Vibration and Noise 16.2 Torque variations Table 16-3 Torque variation at 100% load Engine kW / Cyl Speed Frequency Frequency Frequency [rpm] [Hz] [kNm] [Hz] [kNm] [Hz] [kNm] W 6L34DF 37.5 W 8L34DF W 9L34DF 56.25 W 12V34DF 37.5... -

Page 196: Exhaust Noise

16. Vibration and Noise Wärtsilä 34DF Product Guide Fig 16-3 Typical sound power level for engine noise, W V34DF 16.5 Exhaust noise Fig 16-4 Typical sound power level for exhaust noise, W L34DF 16-4 Wärtsilä 34DF Product Guide - a16 - 23 September 2016... - Page 197 Wärtsilä 34DF Product Guide 16. Vibration and Noise Fig 16-5 Typical sound power level for exhaust noise, W V34DF Wärtsilä 34DF Product Guide - a16 - 23 September 2016 16-5...

- Page 198 This page intentionally left blank...

-

Page 199: Power Transmission

Wärtsilä 34DF Product Guide 17. Power Transmission Power Transmission 17.1 Flexible coupling The power transmission of propulsion engines is accomplished through a flexible coupling or a combined flexible coupling and clutch mounted on the flywheel. The crankshaft is equipped with an additional shield bearing at the flywheel end. Therefore also a rather heavy coupling can be mounted on the flywheel without intermediate bearings. -

Page 200: Torque Flange

17. Power Transmission Wärtsilä 34DF Product Guide Fig 17-2 Directives for generator end design (4V64F0003a) 17.2 Torque flange In mechanical propulsion applications, a torque meter has to be installed in order to measure the absorbed power. The torque flange has an installation length of 300 mm for all cylinder configurations and is installed after the flexible coupling. -

Page 201: Power-Take-Off From The Free End

Wärtsilä 34DF Product Guide 17. Power Transmission Fig 17-3 Shaft locking device and brake disc with calipers 17.5 Power-take-off from the free end The engine power can be taken from both ends of the engine. For in-line engines full engine power is also available at the free end of the engine. -

Page 202: Input Data For Torsional Vibration Calculations

17. Power Transmission Wärtsilä 34DF Product Guide Engine Rating PTO shaft connected to [mm] [mm] [mm] [mm] [mm] [kW] In-line 4500 extension shaft with support bearing engines 4500 coupling, max weight at distance L = 900 kg 4500 coupling, max weight at distance L = 800 kg V-engines 5000 extension shaft with support bearing... -

Page 203: Turning Gear

Wärtsilä 34DF Product Guide 17. Power Transmission ● Material of the shaft including tensile strength and modulus of rigidity ● Drawing number of the diagram or drawing Flexible coupling/clutch If a certain make of flexible coupling has to be used, the following data of it must be informed: ●... - Page 204 This page intentionally left blank...

-

Page 205: Engine Room Layout

Wärtsilä 34DF Product Guide 18. Engine Room Layout Engine Room Layout 18.1 Crankshaft distances Minimum crankshaft distances have to be followed in order to provide sufficient space between engines for maintenance and operation. 18.1.1 Main engines Fig 18-1 Crankshaft distances, in-line engines (DAAE082974B) Engine type A [mm] W 6L34DF... - Page 206 18. Engine Room Layout Wärtsilä 34DF Product Guide Fig 18-2 Crankshaft distances, V-engines (DAAF073294) Engine type A [mm] TC with air filter/silencer on turbocharger 3700 Air duct connected to TC 3800 18-2 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 207 Wärtsilä 34DF Product Guide 18. Engine Room Layout 18.1.2 Generating sets Fig 18-3 Crankshaft distances, in-line engines (DAAE082973A) Engine type A *** B *** C *** D *** W 6L34DF 1800 1860 2110 2800 1700 W 8L34DF 1800 1860 2110 2800 1700 W 9L34DF...

- Page 208 18. Engine Room Layout Wärtsilä 34DF Product Guide Fig 18-4 Crankshaft distances, V-engines (DAAF073293) Engine type W 12V34DF 2200 2620 min. 3800 W 16V34DF 2200 2620 min. 3800 All dimensions in mm. 18.1.3 Father-and-son arrangement When connecting two engines of different type and/or size to the same reduction gear the minimum crankshaft distance has to be evaluated case by case.

- Page 209 Wärtsilä 34DF Product Guide 18. Engine Room Layout Fig 18-5 Example of father-and-son arrangement, TC in free end (DAAF073307) All dimensions in mm. *) 50mm for clearance included. 18.1.4 Distance from adjacent intermediate/propeller shaft Some machinery arrangements feature an intermediate shaft or propeller shaft running adjacent to engine.

- Page 210 18. Engine Room Layout Wärtsilä 34DF Product Guide Fig 18-6 Main engine arrangement, in-line engines (DAAE086973B) Notes: Engine type All dimensions in mm. W 6L34DF 1880 2700 1480 Intermediate shaft diameter to be determined case by case * Depending on type of shaft bearing W 8L34DF 1880 2700...

- Page 211 Wärtsilä 34DF Product Guide 18. Engine Room Layout Fig 18-8 Main engine arrangement, V-engines (DAAE083977, DAAF068349) Fig 18-9 Main engine arrangement, V-engines (DAAE083975, DAAF068345) Notes: All dimensions in mm. Intermediate shaft diameter to be determined case by case * Depends on type of gearbox ** Depends on type of shaft bearing Wärtsilä...

-

Page 212: Space Requirements For Maintenance

18. Engine Room Layout Wärtsilä 34DF Product Guide 18.2 Space requirements for maintenance 18.2.1 Working space around the engine The required working space around the engine is mainly determined by the dismounting dimensions of engine components, and space requirement of some special tools. It is especially important that no obstructive structures are built next to engine driven pumps, as well as camshaft and crankcase doors. - Page 213 Wärtsilä 34DF Product Guide 18. Engine Room Layout 18.4.1 Service space requirement for the in-line engine Fig 18-10 Service space requirement, turbocharger in free end (DAAF070676B) Wärtsilä 34DF Product Guide - a16 - 23 September 2016 18-9...

- Page 214 18. Engine Room Layout Wärtsilä 34DF Product Guide Fig 18-11 Service space requirement, turbocharger in driving end (DAAF088437B) 18-10 Wärtsilä 34DF Product Guide - a16 - 23 September 2016...

- Page 215 Wärtsilä 34DF Product Guide 18. Engine Room Layout 18.4.2 Service space requirement for the V-engine Fig 18-12 Service space requirement, turbocharger in driving end (DAAF308339) Table 18-1 Positions in space requirement drawing (DAAF308339) Description Height needed for overhauling cylinder head Width needed for overhauling cylinder head Heigth needed for overhauling cylinder liner Width needed for overhauling cylinder liner...

- Page 216 18. Engine Room Layout Wärtsilä 34DF Product Guide Minimum width needed for dismantling CAC from B-bank when CAC is divided into 3 parts before turning 90º. (Pressure test in place) Minimum width needed for dismantling CAC from A-bank when CAC is divided into 3 parts before turning. (Pressure test in place) Width needed for removing main bearing side screw Width needed for dismantling connecting rod big end bearing...

- Page 217 Wärtsilä 34DF Product Guide 18. Engine Room Layout 18.4.3 Service space requirement for the genset Fig 18-13 Service space requirement, genset (DAAF066517A) Wärtsilä 34DF Product Guide - a16 - 23 September 2016 18-13...

- Page 218 This page intentionally left blank...

-

Page 219: Transport Dimensions And Weights

Wärtsilä 34DF Product Guide 19. Transport Dimensions and Weights Transport Dimensions and Weights 19.1 Lifting of main engines Fig 19-1 Lifting of main engines, in-line engines (DAAF068506A) Engine W 6L34DF 2990 1520 2940 2940 W 8L34DF 3970 2010 3430 3920 W 9L34DF 4460 2010... - Page 220 19. Transport Dimensions and Weights Wärtsilä 34DF Product Guide Fig 19-2 Lifting of main engines, V-engines (DAAF068506) Engine W 12V34DF 3430 1090 3330 3330 1706 1594 W 16V34DF 4550 1090 4450 4450 2266 2154 All dimensions in mm. Transport bracket weight: dry oil sump = 935 kg, wet oil sump = 1060 Rear side (B-bank) Operating side (A-bank) 19-2...

-

Page 221: Lifting Of Generating Sets

Wärtsilä 34DF Product Guide 19. Transport Dimensions and Weights 19.2 Lifting of generating sets Fig 19-3 Lifting of generating sets (DAAE083966A, -69B) Engine H [mm] L [mm] W [mm] W L34DF 6595...6685 4380...6000 2240...2645 W V34DF 6900...9400 5500...9400 2940...3275 Wärtsilä 34DF Product Guide - a16 - 23 September 2016 19-3... -

Page 222: Engine Components

19. Transport Dimensions and Weights Wärtsilä 34DF Product Guide 19.3 Engine components Table 19-1 Lubricating oil insert (DAAE083974) Engine Dimensions [mm] Weight [kg] W 6L34DF 369.4 W 9L34DF 1140 369.4 W 12V34DF 1338 479.4 W 16V34DF 1338 479.4 Table 19-2 Charge air cooler insert (DAAE083974) Engine Dimensions [mm]... - Page 223 Wärtsilä 34DF Product Guide 19. Transport Dimensions and Weights Fig 19-4 Major spare parts (DAAF073204) Item Description Weight [kg] Item Description Weight [kg] Connecting rod Starting valve Piston Main bearing shell Cylinder liner Split gear wheel Cylinder head Small intermediate gear Inlet valve Large intermediate gear Exhaust valve...

- Page 224 This page intentionally left blank...

-

Page 225: Product Guide Attachments

Wärtsilä 34DF Product Guide 20. Product Guide Attachments Product Guide Attachments This and other product guides can be accessed on the internet, from the Business Online Portal at www.wartsila.com. Product guides are available both in web and PDF format. Drawings are available in PDF and DXF format, and in near future also as 3D models. - Page 226 This page intentionally left blank...

-

Page 227: Annex

Wärtsilä 34DF Product Guide 21. ANNEX ANNEX 21.1 Unit conversion tables The tables below will help you to convert units used in this product guide to other units. Where the conversion factor is not accurate a suitable number of decimals have been used. Length conversion factors Mass conversion factors Convert from... -

Page 228: Collection Of Drawing Symbols Used In Drawings

21. ANNEX Wärtsilä 34DF Product Guide 21.2 Collection of drawing symbols used in drawings Fig 21-1 List of symbols (DAAE000806c) 21-2 Wärtsilä 34DF Product Guide - a16 - 23 September 2016... - Page 232 Wärtsilä is a global leader in complete lifecycle power solutions for the marine and energy markets. By emphasising technological innovation and total efficiency, Wärtsilä maximises the environmental and economic performance of the vessels and power plants of its customers. Wärtsilä is listed on the NASDAQ OMX Helsinki, Finland. WÄRTSILÄ...

Need help?

Do you have a question about the WÄRTSILÄ 34DF and is the answer not in the manual?

Questions and answers

Subject: Urgent Technical Support Request – DG1 Reverse Power and Shutdown Issue Dear Wärtsilä Support Team, I hope this message finds you well. We are currently facing a critical issue with one of our generators (DG1) operating within a four-generator parallel system. Below is a summary of the observed problem: --- Problem Summary: DG1 was operating at approximately 20% load in parallel mode with other generators. Severe load fluctuations were noticed between DG1 and the generator operating in parallel with it. A reverse power alarm was triggered on DG1, followed by an overspeed alarm, and the unit subsequently shut down. The issue was replicated when DG1 was synchronized with a different generator (DG3), and the same symptoms reappeared within approximately 10 minutes. Notably, DG2 functioned normally when operated in parallel with DG3.