Scheppach PL75 Original Instruction Manual

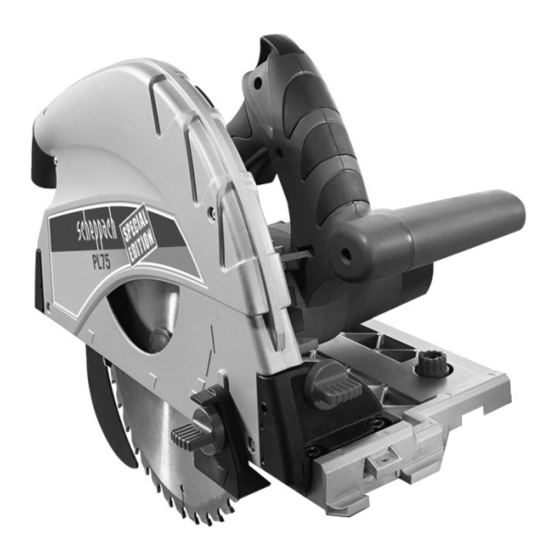

Plunge cut saw

Hide thumbs

Also See for PL75:

- Translation of original instruction manual (264 pages) ,

- Translation from the original instruction manual (137 pages) ,

- Original instruction manual (85 pages)

Summary of Contents for Scheppach PL75

- Page 1 Art.No. 5901804906 Version 5901804852 07/07/2015 PL75 Plunge Cut Saw Original instruction manual...

- Page 2 2 І 16...

- Page 3 18 19 2-3 mm 3 І 16...

- Page 4 4 І 16...

- Page 5 Explanation of symbol on the product Caution - Read the operating instructions to reduce the risk of inquiry Wear ear-muffs! Wear safety goggles! Wear a breathing mask! Protection class II 5 І 16...

-

Page 6: Dear Customer

1. Introduction 2. Device description Fig.1a, 1b DESIGNED & ENGINEERED: Handle/hand grip scheppach Front handle Fabrikation von Holzbearbeitungsmaschinen GmbH Plunge-cut trigger Günzburger Straße 69 On/off switch D-89335 Ichenhausen Base plate Made in China Adjustment screw for depth of cut Scale for depth of cut... -

Page 7: General Safety Instructions For Power Tools

3) Personal safety • The machine may only be used, maintained, and ope- rated by persons familiar with it and instructed in its a) Be attentive, watch what you are doing and use the operation and procedures. Arbitrary alterations to the power tool sensibly. -

Page 8: Additional Safety Instructions For All Saws

king conditions and the work being performed. the saw back in the direction of the operator. The use of power tools other than those intended for • If the saw blade twists in the saw groove or is incor- the tool itself can lead to dangerous situations. rectly positioned, the teeth at the rear side of the saw blade edge catch in the surface of the work piece. -

Page 9: Special Safety Instructions

FURTHER SPECIAL SAFETY INSTRUCTIONS FOR the protective covering. Have the saw repaired before use if the protective covering and spring do not work CIRCULAR SAWS perfectly. Damaged parts, sticky residuals or piles of a) Only use the recommended saw blades which corre- saw dust can interfere with the working of the lower spond to EN 847-1. -

Page 10: Remaining Hazards

ces are not to be expected. (Should you have difficulties, lowing electrical specifications of the machine stated on please consult your local dealer.) the motor. 12. Remaining hazards 15. ADJUSTING The machine has been built using modern technolo- Caution: Prior to carrying out one of the following ad- gy in accor dance with recognized safety rules. -

Page 11: Electrical Connection

16. Operations This physical injuries or damage to the machine can be avoided. After having performed all the above procedures and opera tions, you may begin cutting. Sawing with dust suction ATTENTION: Always keep hands away from the cutting Connect the suction hose to the exhaust nozzle - Ø 38 area and do not try to approach it when the machine is mm (12). -

Page 12: Regular Maintenance

REGULAR MAINTENANCE Only a qualified electrician is permitted to connect the machine and complete repairs on its electrical equip- The regular maintenance decribed above and in the ment. para graph below can be carried out by unskilled person- In the event of enquiries please specify the following da- nel. - Page 14 14 І 16...

- Page 15 Garantie DE Offensichtliche Mängel sind innerhalb von 8 Tagen nach Erhalt der Ware anzuzeigen, andern- Teile, die wir nicht selbst herstellen, leisten wir nur insoweit Gewähr, als uns Gewährleistungsan- falls verliert der Käufer sämtliche Ansprüche wegen solcher Mängel. Wir leisten Garantie für sprüche gegen die Vorlieferanten zustehen.

- Page 16 Aanspraken voor wijzigingen, bieden wij garantie door elk machineonderdeel, dat tijdens deze periode door materiaal- of waardevermindering en overige schadeloosstelling zijn uitgesloten. scheppach Fabrikation von Holzbearbeitungsmaschinen GmbH | Günzburger Str. 69 | D-89335 Ichenhausen | www.scheppach.com...

Need help?

Do you have a question about the PL75 and is the answer not in the manual?

Questions and answers