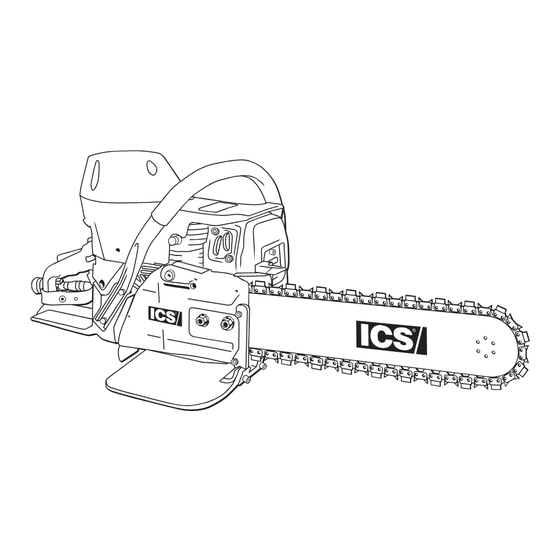

ICS 613GC Operator's Manual

Oregon operator's manual cut-off saw 613gc

Hide thumbs

Also See for 613GC:

- Service manual (82 pages) ,

- Operator's manual (27 pages) ,

- Operator's manual (27 pages)

Summary of Contents for ICS 613GC

- Page 1 613GC CUT-OFF SAW OPERATOR’S MANUAL ICS, Blount Inc. 4909 SE International Way Portland, OR 97222 www.icsbestway.com © Copyright ICS 2003 P/N 70701 May 03...

- Page 2 613GC OPERATOR’S MANUAL...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SYMBOLS & LABELS SAFETY TECHNICAL SPECIFICATIONS SET-UP OPERATION MAINTENANCE TROUBLESHOOTING REFERENCE 613GC OPERATOR’S MANUAL... -

Page 4: Symbols & Labels

THE FOLLOWING SYMBOLS & LABELS MAY BE FOUND IN THIS MANUAL OR ON THE CUT-OFF Read the operator’s manual carefully and understand the contents before you use this equipment. Always use: • Protective helmet • Ear protection • Protective glasses or full face protection Wear hand protection 613GC OPERATOR’S MANUAL SYMBOLS & LABELS... -

Page 5: Safety

• DO NOT operate a chain-based cut off saw with a damaged, modified, broken, or missing side cover, bottom guard, or guard flap. The side cover, bottom guard, and guard flap provides protection against contact with moving parts, ejected debris, broken diamond chain, thrown water and concrete slurry. -

Page 6: General Safety Precautions

• Turn engine OFF before refueling. Keep away from open flame. Always provide adequate ventilation when handling fuel. Move chain-based cut off saw at least 10 feet (3 m) away from refueling area before starting. • ®... -

Page 7: Engine Break-In

IMPORTANT product or property damage. Note: The chain-based cut off saw is equipped with a two-stroke engine and must always be run using a mixture of gasoline and ICS measure the amount of oil to be mixed to ensure that correct mixture is obtained. When mixing small amounts of fuel, even small inaccuracies can drastically affect the ratio of the mixture. -

Page 8: Technical Specifications

613GC OPERATOR’S MANUAL TECHNICAL SPECIFICATIONS Engine Type Displacement Horsepower Torque Engine Speed Diamond Chain Speed Weight Cut Depth Dimensions Air Filter Carburetor Starter Ignition Clutch Fuel ratio Fuel Capacity Water Supply Noise Level Vibration Level Engine Break-in Period Spark Plug 2-stroke Single Cylinder Air Cooled 4.88 cu-in (80cc) -

Page 9: Set-Up

Place bar onto studs and chain adjustment pin. STEP 3 Move chain adjuster pin back towards drive sprocket by turning chain-tensioning screw counter clockwise. 613GC OPERATOR’S MANUAL SET-UP STEP 4 Mount the diamond chain on the guide bar starting at the drive sprocket & continue over the guide bar nose. - Page 10 The diamond chain should be tight but be able to be pulled around the guide bar by hand. Note 3: To prevent chain tensioner breakage, be sure the side cover nuts are tightened to approximately 20 ft-lbs (27Nm). 613GC OPERATOR’S MANUAL SET-UP STEP 8 Hold the guide bar nose up and tension the chain.

-

Page 11: Operation

Do not mix more than one month’s supply of fuel. This helps prevent the separation of the two stroke oil from the gasoline (varnishing). • If the cut-off saw is not used for an extended period of time (3 months) the fuel tank should be emptied and cleaned. FUELING •... - Page 12 Press decompression valve (D). Open the water valve ¼ turn. Place the 613GC Cut-Off Saw on the ground making sure the chain is free of any obstructions. Place right foot on the base of the rear handle.

- Page 13 = 12”x12”x12” = 150 lbs. (30cm x 30cm x 30cm = 68kg). • Check for live electrical wiring near the cutting area or in the concrete to avoid electrocution. 613GC OPERATOR’S MANUAL OPERATION ® require a minimum water pressure of 20 psi (1.4 bar).

-

Page 14: Cutting Tips

As the cut-off saw begins to rotate up, feed force is developed down the line of the intended cut. Once the cut-off saw is fully rotated upwards, pull the cut-off saw out of the cut a few inches and re- engage the pick into the cut and repeat. -

Page 15: System Clean-Up

SYSTEM CLEAN-UP • After cutting, run the cut-off saw for at least 15 seconds with the water on to flush slurry and debris from diamond chain, guide bar and drive sprocket. • Wash concrete slurry from cut-off saw assembly. •... -

Page 16: After Each Use

Follow these simple maintenance guidelines and the 613GC Cut-Off Saw will keep running at its very best. AFTER EACH USE 1. Rinse the saw, guide bar and diamond chain with water. 2. Follow instructions on the Daily Maintenance Label, located on the air filter cover. - Page 17 AIR FILTER The air filter is made from a nylon micro mesh. It must be kept clean IMPORTANT for the engine to operate properly. If the cut-off saw is not reaching full RPM, most likely the air filter is dirty. •...

-

Page 18: Tensioning The Recoil Spring

(Figure 5). Slowly release the starter cord to enable the pulley to fit between the pawls. • Insert and tighten the screws. Use blue Loctite # 242. 613GC OPERATOR’S MANUAL MAINTENANCE Figure 4 Figure 5... - Page 19 Check the drive sprocket bearing by spinning clutch cup. Replace the bearing if it is worn out. • The needle bearing on the drive shaft must be greased regularly, use high quality water-resistant bearing grease. 613GC OPERATOR’S MANUAL MAINTENANCE Figure 1 Chain Tensioner...

-

Page 20: Spark Plug

• Remove the spark plug and insert the piston stop (supplied with each cut-off saw) into the spark plug hole. Pull the starter cord slowly until the piston stops. (Figure 1) Use a 19mm wrench to turn the clutch clockwise and remove. - Page 21 • If cut-off saw has been running satisfactorily and there is a gradual decrease in power and drop in RPM at full throttle, the filter may have become dirty or saturated with water. .

- Page 22 Periodically clean the water ports inside the groove of the guide bar using a small diameter piece of wire. • The guide bar is solely a guide track for the diamond chain. Never use the guide bar to lift, twist or pry concrete material. 613GC OPERATOR’S MANUAL MAINTENANCE...

-

Page 23: Troubleshooting

• CUT-OFF SAW WON’T REACH FULL RPM - Air filter or pre filter may be dirty. • SLOW DIAMOND CHAIN SPEED – Diamond chain tension too tight. Diamond chain should always be able to be pulled around the guide bar by hand. It is normal for the diamond chain drive links to hang below the guide bar. -

Page 24: Reference

For this example, 8 inches. 2. Determine the length of the cut in feet. 3+7+3+7=20 feet 3. Multiply the two numbers 8 in x 20 ft = 160 in-ft 613GC OPERATOR’S MANUAL REFERENCE Cutting Rate 15-25 sq-in/min (90-160 sq-cm/min) 20-30 sq-in/min (160-190 sq-cm/min) - Page 25 613GC OPERATOR’S MANUAL NOTES...

- Page 26 613GC OPERATOR’S MANUAL ICS, Blount Inc. 4909 SE International Way Portland, Oregon 97222 TEL 800-321-1240 FAX 503-653-4393 www.icsbestway.com...

Need help?

Do you have a question about the 613GC and is the answer not in the manual?

Questions and answers