Table of Contents

Advertisement

Quick Links

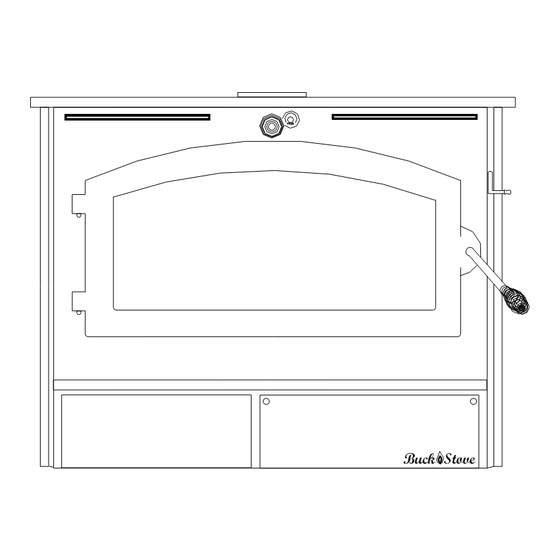

MODEL 20 Room Heater

"MEETS PHASE II EPA STANDARDS"

Buck Stove

FIREPLACE INSERT & FREESTANDING

Contact your insurance company for coverage and installation inspection

FEATURES

PREPARATIONS

INSTALLATION

OPERATION

MAINTENANCE

SAFETY

SAFETY NOTICE

IF THIS HEATER IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT.

FOR YOUR SAFETY, FOLLOW THE INSTALLATION INSTRUCTIONS. CONTACT

THE AUTHORITY HAVING JURISDICTION ( SUCH AS MUNICIPAL

BUILDING DEPARTMENT, FIRE DEPARTMENT, FIRE PREVENTION BUREAU,

etc.) CONSULT BEFORE INSTALLATION TO DETERMINE THE NEED TO

OBTAIN A PERMIT. KEEP THESE INSTRUCTIONS FOR FUTURE USE.

TESTED AND LISTED BY:

ITS/WARNOCK HERSEY, MIDDLETON, WI

MANUFACTURED BY NEW BUCK CORPORATION

200 ETHAN ALLEN DRIVE, PO BOX 69

SPRUCE PINE, N.C. 28777

www.buckstove.com

Revised January 2013

PN-PI-200660

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for BuckMaster MODEL 20

- Page 1 MODEL 20 Room Heater “MEETS PHASE II EPA STANDARDS” Buck Stove FIREPLACE INSERT & FREESTANDING Contact your insurance company for coverage and installation inspection FEATURES PREPARATIONS INSTALLATION OPERATION MAINTENANCE SAFETY SAFETY NOTICE IF THIS HEATER IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1: Room Heater Features ..............................3 Important Statements ..............................4 SECTION II: Masonry Insert Installation ............................6 Minimum Clearances ..............................7 Required Fireplace Dimensions ..........................8 Tools for Installation ..............................8 Installation Preparation: Fireplace ..........................8 Installation Preparation: Heater .......................... -

Page 4: Room Heater Features

SECTION I The New Buck Corporation room heater Model 20 is one of the safest and most efficient heating systems available when installed and operated as specified in these instructions and as stipulated on the operation and installation labels affixed to the unit. The unit is designed to burn wood fuel only. -

Page 5: Important Statements

EPA COMPLIANCE STATUS This manual describes the installation and operation of the New Buck Corporation, Model 20 wood heater. This heater meets the U.S. Environmental Protection Agency’s Emission limits for wood heaters sold after July 1, 1992. Under specific test conditions this heater has been shown to deliver heat at rates ranging from approximately 10,000 to 39,000 BTU/hr. -

Page 6: Catalyst Monitoring

CATALYST MONITORING It is important to periodically monitor operation of catalytic combustor to ensure that it is functioning properly and to determine when it needs to be replaced. A non-functioning combustor will result in a loss of heating efficiency and an increase in creosote and emissions. The following is a list of items that should be checked on a periodic basis. -

Page 7: Masonry Insert Installation

BEFORE YOU INSTALL YOUR STOVE. DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. FIGURE 1 FIREPLACE INSERT REQUIRED FIREPLACE DIMENSIONS Minimum and/or maximum fireplace dimensions: Height Width Depth Min. Max. Min. Max. Min. 22” 31” 26” 41” 16” Model 20 Page 5... -

Page 8: Minimum Clearances

MINIMUM CLEARANCES FLOOR PROTECTION Floor protector must be 3/8" minimum thickness non-combustible material or equivalent. How to use alternate materials and how to calculate equivalent thickness An easy means of determining if a proposed alternate floor protector meets requirements listed in the appliance manual is to follow this procedure: 1. -

Page 9: Required Fireplace Dimensions

POSSIBLE TOOLS NEEDED FOR INSTALLATION If you decide to install your own stove, there are several hand tools you may need to do the job. If you do not already have them, they are readily available at most hardware stores. Caulking gun Large adjustable wrench (may not be needed) Drop cloths or newspapers... -

Page 10: Installation Procedure-Direct Connect

SAFETY NOTICE If this appliance is not properly installed, a house fire may result. For your safety, follow the installation directions. Contact local building or fire officials about restrictions and installation inspection requirements in your area. OPTION (A) AIRTIGHT INSU- LATED CLEAN- STARTER PIPE SEAL TRIM PANELS AND UNDER... -

Page 11: Mounting The Trim Panels

INSTALLATION PROCEDURE (Use a chimney connector or a Listed Direct or Positive Connect) (See Page 9.) POSITIONING THE HEATER When positioning heater, following conditions MUST be met! (See Figure 2). The front of damper opening must be positioned BEHIND back edge of lintel to ensure proper draft. (See Figure 2). -

Page 12: Final Check

Obtain the brass trim kit provided with insert kit and slip over top and sides of trim panels. Top ends of brass may need to be trimmed to fit (See Figure 4). 10. Using insulation provided, peel and stick to back of panels overlapping fireplace dimensions by 1" on each side and top. - Page 13 CAUTION THE UNIT IS PAINTED WITH A SPECIALLY FORMULATED HIGH TEMPERATURE PAINT THAT CURES DURING THE FIRST TWO OR THREE FIRINGS. YOU MAY NOTICE A SLIGHT SMOKING EFFECT AND AN ODOR OF BURNING PAINT WHEN YOU BUILD THE FIRST FIRES. THIS IS NORMAL AND IS NOT A CAUSE FOR ALARM.

-

Page 14: Freestanding Installation

Satisfactory results have been reported with installations other than listed above. However, draft problems are possible if a hot chimney is not maintained. Use pedestal kits as follow: Model 20 Kit #P8 or #P21B CAUTION: Do not connect this unit to a chimney flue serving another appliance. -

Page 15: Minimum Clearances

MINIMUM CLEARANCES The New Buck Corporation Model 20 must be installed in compliance with instructions contained in this manual. CLEARANCE FROM COMBUSTIBLE WALLS AND CEILINGS (Using single wall chimney connector) The minimum lateral distance between any part of the room heater and combustible walls is shown in Figures 1 and 2. -

Page 16: Tools For Installation

Close clearance installations using listed Close Clearance pipe and 2100 HT chimney system from approved manufacturer’s list. (See page 18) 12” FIGURE 3 WALL INSTALLATION FIGURE 4 CORNER INSTALLATION TOOLS FOR INSTALLATION Drop Cloth Electric Drill with 3/32” drill bit 5/16”... -

Page 17: Determining The Chimney Location

PREPARING THE ROOM HEATER LOCATION Select an installation location that will give the best airflow from front of heater to remainder of home. Place protective floor pad in position. Place unit on pad making sure the minimum clearance specifications are met. If connecting to an existing masonry flue, first ensure that flue conforms to the NFPA-211 Code and/or consult your local code for proper procedures. - Page 18 After securing New Buck Corporation Chimney Connector to heater, secure pipe to connector with three (3) screws or rivets. C. Wall Exit Into Masonry (Using Single Wall Pipe) Before connecting Model 20 to a masonry chimney, determine that masonry fireplace wall pass-through connector thimble meets the NFPA-211 code and local building codes and is a minimum of 18”...

- Page 19 (b) Selected or fabricated in accordance with conditions and clearances as stated in NFPA-211 code. Any unexposed metal that is used as part of a wall pass-through system and is exposed to flue gases shall be constructed of stainless steel or other equivalent material that will resist corrosion, softening, or cracking from flue gases at temperatures up to 1800 In addition, a connector to a masonry chimney shall extend through wall to inner face or liner but not beyond.

-

Page 20: Final Check

FINAL CHECK Recheck specified clearances. Remove all foreign material from firebox area. Open primary air draft and damper bypass. Plug power cord into a 115V AC outlet. Set switch to “Manual” and rheostat to “High” position to ensure motor operates properly. Place crumpled pieces of newspaper in stove. -

Page 21: Mobile Home Installation

Parts Requirements: Part Description / Part - MODEL 20 Model 20 Room Heater New Buck Corporation New Buck Corporation Outside air pedestal kit #P21B 6” Chimney Connector #MA-6CHIMCNB... -

Page 22: Minimum Clearances

Clearance from combustible walls using listed Close Clearance pipe and 2100 HT chimney system from approved manufacturer’s list. (See page 18) FIGURE 1 WALL INSTALLATION FIGURE 2 CORNER INSTALLATION FLOOR PROTECTION If room heater is to be installed on a combustible floor, a non-combustible pad must be placed below it to protect floor from burning material from stove. -

Page 23: Installation Preparation

PREPARING THE HEATER FOR INSTALLATION Inspect unit for any obvious physical damage. Plug power cord into a 115V AC outlet. Set switch to “Manual” and rheostat to “High” position to ensure motor operates properly. Check primary air draft control to ensure that it operates freely. Check operation of damper bypass control to ensure that it will open and close properly. -

Page 24: Determining The Chimney Location

10. Using an electric drill and 3/8” masonry bit, drill four (4) holes in the protective pad using holes in bottom side lips of pedestal stand as a guide. Be careful to drill only through the pad and not into the floor. Change to a 1/4” metal bit and drill through floor. -

Page 25: Final Check

RAIN CAP RAIN CAP 2FT. 3 FT. TYPICAL STORM COLLAR 2FT. STORM COLLAR FLASHING FLASHING NEW BUCK CORP. NEW BUCK CORP. FIRESTOP FIRESTOP RADIATION RADIATION 20 FT. SHIELD SHIELD MAX. TYPICAL FIGURE 5 FINAL CHECK Recheck specified clearances. Remove all foreign material from firebox area. Open primary air draft and damper bypass. -

Page 26: Zero-Clearance Installation

NOTE: A preway unit has to use insert trim panels. Other models of those brands may also be acceptable for installation of the Model 20 unit into them. However, factory approval from New Buck Corporation and Warnock-Hersey Laboratories is required prior to installation. -

Page 27: Heater Preparation

Check primary air draft control to ensure that it operates freely. Check operations of damper control to ensure that it will open and close properly. Heater Installation There are three listed and tested methods of installation of the Model 20 heater into the specified Pre-Fab Models. A. 6” Increaser 1. -

Page 28: Minimum Clearances

MINIMUM CLEARANCE TO COMBUSTIBLES INCREASER FIGURE 2 PACK TIGHT WITH CERAMIC WOOL (DO NOT USE GLASS WOOL). 6” FLEX PIPE OR ADJUSTABLE ELBOW FIGURE 3 C. Sealing Trim Kit 1. This third method of installation is to use the masonry fireplace trim kit to seal the stove to the Pre-Fab fireplace. - Page 29 2. To complete this installation, follow the basic masonry fireplace trim kit installation instructions except: The trim kit may have to be cut down in size so as not to block any cooling vents/chambers of the Pre- Fab Fireplace. 3. To complete methods 1 and 2: Position heater into the Pre-Fab Fireplace and center flue exit under connector.

-

Page 30: Safety

SECTION VI WOOD HEATER SAFETY Certain safety hazards are inherent in any wood heater installation. You should be aware of these so that a safe and proper installation can be made. FAULTY CHIMNEY: An older masonry chimney should be thoroughly checked to be sure there are no holes or weak spots which could allow sparks or hot gases to escape. -

Page 31: Operation

NOTE: Do not use grate or elevate fire. Build wood fire directly on inner bottom of fire box. 5. The Model 20 is not designed for use of grates and irons or other methods of supporting fuel. 6. Lay several pieces of dry kindling on top of newspaper. - Page 32 C. Medium—High Burn Rate: Set the primary air control wide open. Set the Auto-Off-Manual switch to Auto position. Wood Loading—During refueling, open bypass damper, open door and add wood. Immediately close door and bypass damper. Open primary air control wide open for five minutes to charge wood.

-

Page 33: Operating And Safety Hints

OPERATING AND SAFETY HINTS: When preparing to refuel heater, open bypass damper (taking the heater out of catalytic mode) and wait for smoke to clear out of firebox before opening the door. Burn only natural seasoned hard wood in your catalytic heater. You should not burn trash or garbage, artificial or paper logs, gift wrapping, treated or painted wood, nor should you start a fire with lighter fluid or chemical starter. -

Page 34: Manufacturers Suggested Preventive Maintenance

SECTION VIII PREVENTIVE MAINTENANCE / PARTS REPLACEMENT Check Chimney A. The chimney should be cleaned as necessary to remove creosote, soot, leaves, birds nests, etc. (Refer to Page 27, #5 Creosote Formation.) B. A neglected chimney can eventually cause a draw restriction or can ignite and burn hot enough to cause damage to chimney. -

Page 35: Catalyst Replacement

Properly functioning catalysts will be exhibiting a uniform glow from one end to other (indicating ignition). Physically degraded catalysts will have cold places (areas not igniting) where plugging, crumbling or other degradation has occurred. If this occurs, monitor probe temperature will not increase at a normal rate. -

Page 36: Door Gasket Replacement

Using penetrating oil, generously lubricate four (4) bolt threads holding catalyst housing in place. Allow to penetrate. Using a 9/16” wrench or 9/16” socket, loosen four (4) bolts and remove catalyst housing (drop down) and place in a suitable work area. Using needle nose pliers, grasp front edge of stainless steel “can”... -

Page 37: Electrical Operation

(Changes refer to page 34 in your owners manual: Due to the Auto-Off-Manual switch replacing the Rheostat.) NOTE: When ordering replacement parts for your Model 20/ZC20 Room Heater, be sure to have the serial number available to insure that you receive the correct parts. -

Page 38: Troubleshooting Guide

SECTION IX CATALYTIC TROUBLESHOOTING CONTENTS Definitions Possible Problems Plugging Extreme Temperatures Flow Restrictions Creosote Build-up Chemical Deactivation Excessive Handling Condensation in Chimney Backpuffing Non-uniform flow Troubleshooting Heater Related Problems Sluggish Heater Performance Drop in Overall Efficiency High Fuel Consumption Backpuffing Smoke Rollout When Heater Door Is Opened Low Catalytic Temperature Creosote Running From Draft Inlet Openings... - Page 39 DEFINITIONS AIRTIGHT HEATER—In an airtight heater, all air enters in through inlets. Generally, non-airtight stoves are not as efficient and their level of heat output is less controllable than that of an airtight. BURN CYCLE—Time span between refueling in which wood is reduced to a bed of hot coals. BYPASS—Movable door inside a woodstove that is opened when stove door is opened to give a path of least resistance to smoke to prevent roll-out.

- Page 40 POSSIBLE PROBLEMS Problems encountered with operation of catalytic-combustor equipped wood heaters are usually the same as those experienced in operation of traditional wood heaters. Our experience has shown that adoption of good operating practices will eliminate most of these problems. In addition, it should be noted that problems with catalytic combustors are rare.

-

Page 41: Troubleshooting

Backpuffing-A hot combustor (above 1400 F) can sometimes act like a glow plug (spontaneous combustion igniter). Usually wood gas-to-air mixture is either too lean or too rich to form a highly flammable mixture. There are times when this mixture is just right within firebox during normal burning process. If combustor is running at or above ignition temperature of mixture, spontaneous combustion will result, causing stove to vent puffs of smoke. - Page 42 Problem Possible Cause Solution High Fuel Consumption Inexperience in catalytic Operate stove with desired operation heat output in mind. Do not be overly concerned with maintaining light-off temperatures Improper regulation of draft or Close inlet air control as much inlet air as possible to maintain desired heat output.

- Page 43 Possible Cause Problem Solution Heater dampered down too Ensure that proper air much mixture and draft are available for wood pyrolysis to continue Combustor not functioning See section on “Combustor- Related Problems” Burning wet, pitchy woods Creosote Running From Draft Burn dried, natural seasoned Inlet Openings hard wood...

- Page 44 Problem Possible Cause Solution Heavy Concentration of Water vapor. (On cold, still Water vapor is normal and Smoke Leaving Chimney days water vapor may be should be of little concern mistaken for smoke. The difference is that water vapor appears white and will tend to rise vertically and dissipate rapidly while smoke is usually dark or...

- Page 45 GREATER LESS THAN THAN 10 INCHES 10 FT. 10 FT. 2 FT. 3 FT. 2 FT. 3 FT. METAL CHIMNEY 2 FT. MINIMUM HEIGHT ABOVE THE ROOF WITHIN 10 FT. HORIZONTALLY MASONRY CHIMNEY CHIMNEY “10 FT.” RULE (MINIMUM HEIGHTS) Stack wood in criss-cross pattern under a shelter to allow air flow to dry wood and to keep wood from rain.

- Page 46 COMBUSTOR-RELATED PROBLEMS Problem Possible Cause Solution Plugging Burning materials that Do not burn materials such produce a lot of char and fly as garbage, gift wrap or cardboard Burning wet, pitchy wood or Burn dried, natural seasoned hard wood. Don’t place the burning large loads of small diameter wood with the combustor in the operating...

- Page 47 Problem Possible Cause Solution Substrate Cracking— Mishandling or abuse Handle with care Mechanical Substrate Crumbling Extreme thermal shock Combustor being continually over fired. Reduce burn rate. Do not exceed .06” of water High draft draft. Install a manual damper and draft gauge, or a barometric damper with free -standing units Color Variations...

-

Page 48: Zero-Clearance Cabinet Model Zc20

Do not attempt to build a fire in this product. It has been designed and safety tested for use only with Model 20 manufactured by New Buck Corporation. Read and follow installation and operating instructions for this model. Do not remove or cover this label. -

Page 49: Section I

(air spaces) to combustible materials. It is of utmost importance that these parts be installed only in accordance with these instructions. The Zero-Clearance cabinet and the Model 20 (hereafter referred to as the ZC20) is designed for installation in a family dwelling, where minimum clearance is desired. - Page 50 F. DO NOT build a fire directly inside the ZC Cabinet. It is designed solely for housing Model 20 Stove. G. WARNING: This fireplace has not been tested for use with a chase above roof. H. Do not connect this unit to a chimney serving another appliance.

- Page 51 Corner clearances request NOTE: Chase Installation: (See Figure 3). A chase is an enclosure built specifically to house a chimney. The interior of a chase is open from ZC20 to roof, eliminating need to cut through ceilings and roof. Normally, a chase is built outside and against exterior wall of a home.

- Page 52 Obtain listed and approved chimney installation instructions and follow exactly. a) Obtain starter section of pipe and install on ZC20 cabinet. It may be necessary to crimp the inside of starter pipe to ease installation into the ZC20 cabinet. b) Obtain the two short sheet metal “ell” brackets and sheet metal screws provided with ZC20 and secure starter section of pipe to the ZC20 cabinet.

- Page 53 NOTE: Maintain 1 1/2” clearance at side walls of cabinet and combustible material. b) 2”x4” framing above the unit must be turned flat. This allows proper clearance from framing to chimney (2” minimum). (See Figure 6). ZC20/Model 20 TOPPER Optional Fire Code...

- Page 54 Next construct hearth extension out of non-combustible inorganic building materials as follows: a) The hearth extension must extend 17” in front of rough framed opening on ZC20. b) The hearth extension width must be at least 37 15/16”. c) The hearth extension must be made of brick 2” thick, a listed “Hearth Extension” or “Floor Protector” or a hearth extension made of non-combustible inorganic material with a K* factor of: K = 2.5 BTU ((HR) (ft F/in.))

- Page 55 TOP FRONT TRIM PANEL BRASS TRIM RIGHT SIDE TRIM PANEL BLACK WHITE HEATER POWER CORD GROUND REAR COVER PLATE RECEPTACLE BOX FIGURE 7A POWER HOOK-UP FINISHED WALL MANTEL or SUPPORTS “A MINIMUM OF 12" FROM TOP OF UNIT TO TRIM OF 12"MIN.

-

Page 56: Mobile Home Installations

(air spaces) to combustible materials. It is of utmost importance that these parts be installed only in accordance with these instructions. The Zero-Clearance cabinet and Model 20 (hereafter referred to as the ZC20) is designed for installation in a family dwelling, where minimum clearance is desired. - Page 57 F. DO NOT build a fire directly inside the ZC20. It is designed solely for housing the Model 20. G. WARNING: Do not install in sleeping room. H. CAUTION: The structural integrity of mobile home floor, wall, and ceiling/roof must be maintained.

- Page 58 Obtain Listed and Approved Chimney Installation instructions and follow exactly. a) Obtain starter section of pipe and install on ZC20 cabinet. It my be necessary to crimp inside of starter pipe to ease installation into ZC20 cabinet. b) Obtain two short sheet metal “ell” brackets and sheet metal screws provided with ZC20 and secure starter section of pipe to ZC20 cabinet.

- Page 59 CAUTION: Refer to chim- ney manufactures instruc- Optional TOPPER tions for assembly and disas- Fire Code Sheet Rock sembly of chimney parts. Be And Metal Fire Stop STORM COLLAR sure to follow chimney instructions for proper clear- ROOF FLASHING ances to combustibles and proper air spacing required.

- Page 60 ZC20 cabinet. 11. The ZC20 and Model 20 fireplace are now ready for use. Refer to the Model 20 owners manual for operation, safety and chimney maintenance. Refer to the back of this manual for ZC20 warranty registration information.

-

Page 61: Safety Precautions

CLEANING THE UNIT A. The unit should be lightly sanded with fine sandpaper or steel wool, then repainted or touched up with high temperature black paint. B. If unit is located in a moist or damp location, check thoroughly for signs of condensation during times when unit is not in use. -

Page 62: Chimney Cleaning

PREVENTIVE MAINTENANCE/ SAFETY PRECAUTIONS CHIMNEY A. The chimney should be cleaned as necessary to remove creosote, soot, leaves, birds nests, etc. CREOSOTE-FORMATION AND NEED FOR REMOVAL When wood is burned slowly, it produces tar and other organic vapors, which combine with expelled moisture to form creosote. - Page 63 NEW BUCK CORPORATION (NBC) “LIMITED WARRANTY” FOR NBC RELATED PRODUCTS If for any reason you are dissatisfied with the PLEASE READ THIS WARRANTY CAREFULLY suggested procedures, you may contact us in writing PRODUCTS COVERED This warranty covers the new heating unit so long as it NEW BUCK CORPORATION is owned by the original purchaser, including optional Customer Service Department...

- Page 64 City: ________________________________________ State: _________________ Zip: ____________________ : ______________________________________________ CUSTOMER EMAIL Model 20 ______ Insert: __________ Residential: ___________ Mobile Home: __________ Model 20 ______ Freestanding: _____ Residential: ___________ Mobile Home: __________ Model 20ZC/20 __________________ Residential: ___________ Mobile Home: __________ Serial No. ________________________________________...

Need help?

Do you have a question about the MODEL 20 and is the answer not in the manual?

Questions and answers