Summary of Contents for GreenWorks 51152

- Page 1 1600 PSI / 1.3 GPM ELECTRIC PRESSURE WASHER 51152 OPERATOR’S MANUAL TOLL-FREE HELPLINE: 1-888-90WORKS (888.909.6757) Read all safety rules and instructions carefully before operating this tool.

- Page 2 Cleaning Units 2080 C.U 23.45 lbs (10.64 kg)

-

Page 3: Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS W A R N I N G Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious personal injury. W A R N I N G When using this product basic precautions should always be followed, including the following: READ ALL INSTRUCTIONS BEFORE USING THIS PRODUCT •... -

Page 4: Specific Safety Rules

SPECIFIC SAFETY RULES • Know your product. Read the operator’s manual carefully. Learn the machine’s applications and limitations as well as the specific potential hazards related to this product. • To reduce the risk of injury, keep children and visitors away. All visitors should wear safety glasses and be kept a safe distance from work area. - Page 5 SPECIFIC SAFETY RULES W A R N I N G High pressure jets can be dangerous if subject to misuse. The jet must not be directed at people, animals, electrical devices, or the machine itself. • Keep the motor away from flammables and other hazardous materials. •...

- Page 6 SYMBOLS Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer. SYMBOL NAME DESIGNATION/EXPLANATION Volts Voltage Amperes Current Hertz Frequency (cycles per second)

- Page 7 SYMBOLS SYMBOL NAME DESIGNATION/EXPLANATION To reduce the risk of injury or damage, DO NOT USE ACIDS, ALKALINES,BLEACHES, Chemical Burns SOLVENTS, FLAMMABLE MATERIAL, OR INDUSTRIAL GRADE SOLUTIONS in this product. The following signal words and meanings are intended to explain the levels of risk associated with this product.

-

Page 8: Electrical Connection

ELECTRICAL W A R N I N G The double insulated system is intended to protect the user from shock resulting from a break in the product’s internal insulation. Observe all normal safety precautions to avoid electrical shock. DOUBLE INSULATED Double insulation is a concept in safety in electric power tools, which eliminates the need for the usual three-wire grounded power cord. -

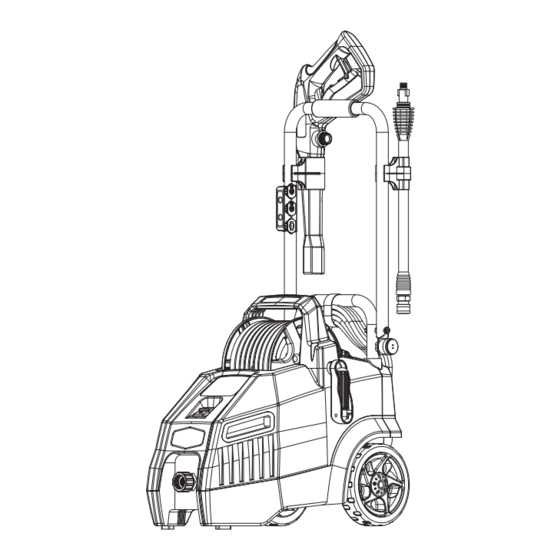

Page 9: Know Your Pressure Washer

KNOW YOUR PRESSURE WASHER The safe use of this product requires an understanding of the information on the tool and in this operator’s manual as well as a knowledge of the project you are attempting. Before use of this product, familiarize yourself with all operating features and safety rules. (See Figure 1.) Handle assembly Trigger Spray wand... -

Page 10: Packing List

ASSEMBLY UNPACKING This product requires assembly. • Carefully remove the product and any accessories from the box. Make sure that all items listed in the packing list are included W A R N I N G Do not use this product if any parts on the Packing List are already assembled to your product when you unpack it. - Page 11 ASSEMBLY OPERATING THE HANDLE ASSEMBLY (See Figure 2.) • Open for use: Lift up on the handle bar pivoting it towards the back into an upright position until it clicks and locks into place. • To fold the handle, pull the latch sideways again, and push the handle down and foward. OPEN CLOSE Fig.

- Page 12 ASSEMBLY ASSEMBLING WAND TO PRESSURE WASHER GUN See Figure 5.) • Installing Wand to Pressure Washer Gun Insert the male bayonet end(1) of the wand into the female bayonet outlet(3)firmly . While pushing in the wand firmly ,turn clockwise(2)until tabs lock into place to ensure a leak-free connection .

- Page 13 ASSEMBLY CONNECTING THE GARDEN HOSE (See Figure 5.) C A U T I O N : Always observe all local regulations when connecting hoses to the water main. Some areas have restrictions against connecting directly to public drinking water supply to prevent the feedback of preventer is usually permitted.

- Page 14 ASSEMBLY W A R N I N G : To reduce the risk of injury, user must read and understand the operator’s manual for this pressure washer and this accessory. Wear eye protection marked to comply with Z87.1. Ensure compatibility and fit before using this accessory. Turn off the pressure washer before changing or adjusting accessories.

-

Page 15: Operation

OPERATION W A R N I N G Do not allow familiarity with the product to make you careless. Remember that a careless fraction of a second is sufficient to inflict serious injury. W A R N I N G Always wear eye protection with side shields marked to comply with ANSI Z87.1. - Page 16 OPERATION DETERGENT ADDING AND USE (See Figure 6-1.) Use only detergents designed for pressure washers; household detergents, acids, alkalines, Many detergents may require mixing prior to use. Prepare cleani ng solution as instructed on the solution bottle. SOAP APPLICATION Soap is applied under low pressure high volume for optimum performance Soap can not be applied under high pressure with this machine To add: •...

- Page 17 OPERATION STARTING AND STOPPING THE PRESSURE WASHER (See Figure 7.) C A U T I O N : Do not run the pump without the water supply connected and turned on. • Connect the garden hose. • Turn the garden hose on then squeeze the trigger to relieve air pressure. Once a steady stream of water appears,release the trigger.

- Page 18 OPERATION USING THE SPRAY WAND TRIGGER (See Figure 8.) For greater control and safety, keep both hands on the trigger handle at all times. • Pull back and hold the trigger to operate the pressure washer. • TO ENGAGE THE LOCK-OUT: •...

-

Page 19: Operating/Moving

OPERATION • Turn off the pressure washer and shut off the water supply .Pull trigger to release water pressure. • Engage the lock-out on the trigger handle by pushing the trigger lock button to the right. • Pull back the quick-connect collar. •... -

Page 20: General Maintenance

MAINTENANCE W A R N I N G When servicing, use only identical replacement parts.Use of any other parts may create a hazard or cause product damage.. W A R N I N G Always wear eye protection marked to comply with ANSI Z87.1. Failure to do so could result in objects being thrown into your eyes, resulting in possible serious injury. -

Page 21: Quick Winterizing Procedure

MAINTENANCE • Unplug the pressure washer. • Turn off the pressure washer and shut off the water supply. Pull trigger to release water pressure. • Remove the nozzle from the spray wand. NOTE: Never point the spray wand at your face Using the nozzle cleaning tool provided, free any foreign materials clogging or restricting the nozzle opening. -

Page 22: Taking A Break

MAINTENANCE TAKING A BREAK • Engage gun safety lock. • Turn unit to “OFF” (O) position. • Unplug the power cord from the outlet. C A U T I O N : The use of a pump protector is recommended to prevent cold weather damage during storage over the winter months. -

Page 23: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Turn switch to the “ON” ( | ) position. Motor will not start. On/Off switch is in the “OFF” (O) position. Press the gun trigger ON. Power cord is not plugged in. Plug in power cord. Electrical outlet does not sup- Try a different outlet. - Page 24 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Output pressure varies Discharge nozzle is ob- Blow out or remove debris with a high and low. (contin- structed. ued) Run distilled vinegar through nozzle. detergent tank. Detergent is not Is detergent tank seletor on Select the correct tank, either coming out.

- Page 25 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Motor buzzes but fails Supply voltage below mini- Verify that only the pressure to run. mum. washer is running on this circuit. Turn unit “OFF”, squeeze trigger System has residual pres- sure. on spray wand to release pres- sure, then turn unit “ON”...

-

Page 26: Items Not Covered By Warranty

(1) years against defects in materials, parts or workmanship. GREENWORKS™, at its own discretion will repair or replace any and all parts found to be defective, through normal use, free of charge to the customer. This warranty is valid only for... -

Page 27: Exploded View

EXPLODED VIEW... -

Page 28: Parts List

PARTS LIST ITEM NO. PART NO. DESCRIPTION Main switch 6302301A Screw 32205302A 32201368 Screw Main switch cover 34110365 Wire cap 36511154A Main switch seal ring 34201365 Main switch box 34109365 Power cord grommet 34223302 Motor cable grommet 34208304 Water inlet filter 31901301A Water inlet nut connector 33177307... - Page 29 PARTS LIST ITEM NO. PART NO. DESCRIPTION Suction hose 34900365 Nylon strap 3411275 34211365 Ring O ring 34212363 Left panel 34111365 34201671 Suction hose cover Soap tank 34104671 Soap tank cover 34201363 34227302 O ring 31107661 High pressure hose assembly 32205316A Screw 32201661...

- Page 30 PARTS LIST ITEM NO. PART NO. DESCRIPTION Upper pull rod 33304671 Nozzle base 34101671 34202363 Pull rod sponge 34121365 Gun handle hook Wand hook 34120365 Washer 33305365 Power cord strap 34906363-1 31102661 Pin assembly Gun handle assembly 31206671 Gun wand assembly 31115661 33201671 Nozzle cleaning tool...

- Page 31 TOLL-FREE HELPLINE: 1-888-90WORKS (888.909.6757) Rev: 00 (03-31-11) Printed in China on 100% Recycled Paper...

Need help?

Do you have a question about the 51152 and is the answer not in the manual?

Questions and answers