Table of Contents

Advertisement

Quick Links

Para obtener un ejemplar en Español de este

Manual del propietario, visite www.heatnglo.com.

Models:

ST-36TRB-IPI

PIER-36TRB-IPI

LCOR-36TRB-IPI

RCOR-36TRB-IPI

• Important operating

a n d m a i n t e n a n c e

instructions included.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

• DO NOT store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of this

or any other appliance.

• What to do if you smell gas

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch. DO

NOT use any phone in your building.

- Leave the building immediately.

- Immediately call your gas supplier from

a neighbor's phone. Follow the gas sup-

plier's instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency, or the

gas supplier.

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas fi tter.

See Table of Contents for location of additional Commonwealth

of Massachusetts requirements.

Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15

NOTICE

DO NOT DISCARD THIS MANUAL

• Read, understand and follow

these instructions for safe

installation and operation.

Pour demander un exemplaire en français de ce Manuel

du propriétaire, visitez www.heatnglo.com.

Owner's Manual

Installation and Operation

• Leave this manual with

party responsible for use

and operation.

DANGER

DO NOT TOUCH GLASS

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of

burns from the hot viewing glass is provided

with this appliance and shall be installed for

the protection of children and other at-risk

individuals.

This appliance may be installed as an OEM

installation in manufactured home (USA

only) or mobile home and must be installed

in accordance with the manufacturer's

instructions and the Manufactured Home

Construction and Safety Standard, Title 24

CFR, Part 3280 in the United States, or the

Standard for Installation in Mobile Homes,

CAN/CSA Z240 MH Series, in Canada.

This appliance is only for use with the type(s)

of gas indicated on the rating plate. This

appliance is not convertible for use with other

gases, unless a certifi ed kit is used.

HOT GLASS WILL

CAUSE BURNS.

UNTIL COOLED.

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Heat & Glo ST-36TRB-IPI

- Page 1 See Table of Contents for location of additional Commonwealth gases, unless a certifi ed kit is used. of Massachusetts requirements. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 2: Congratulations

00,000 00,000 MIN. MIN. INPUT INPUT BTUH: BTUH: 00,000 00,000 00,000 00,000 Serial Serial ORIFICE ORIFICE SIZE: SIZE: #XXXXX #XXXXX #XXXXX #XXXXX XXXXXXXX XXXXXXXX (Serie): (Serie): Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 3: Table Of Contents

F. Wall Switch Installation for Fan (Optional) ... . 54 A. Vent Termination Minimum Clearances ....24 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 4 D. Contact Information ......85 = Contains updated information. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 5: Limited Lifetime Warranty

Firebox and heat exchanger Lifetime All replacement parts 90 Days beyond warranty period See conditions, exclusions, and limitations on next page. 4021-645H 10/15 Page 1 of 2 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 6 THE EXTENT PROVIDED BY LAW, HHT MAKES NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY SPECIFIED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF THE EXPRESSED WARRANTY SPECIFIED ABOVE. 4021-645H 10/15 Page 2 of 2 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 7: Listing And Code Approvals

A 110-120 VAC circuit for this product must be protected with ground-fault circuit-interrupter protection, compliance with the applicable electrical codes, when it is installed in locations such as in bathrooms or near sinks. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 8: Requirements For The Commonwealth Of Massachusetts

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OB- of the installation. STRUCTIONS”. See Gas Connection section for additional Common- wealth of Massachusetts requirements. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 9: User Guide

• Keep remote controls out of reach of children. • Never leave children alone near a hot fi replace, whether Figure 2.1 General Operating Parts operating or cooling down. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 10: Blower Kit (Optional)

For more information refer to the instructions supplied with your decorative decorative front. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 11: Lighting Instructions (Ipi)

Propane Installation code, CSA B149.1. tions accompanying appliance. For additional information on operating your 593-913i Hearth & Home Technologies fi replace, please refer to www.fi replaces.com. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 12: After Fireplace Is Lit

Noise is caused by metal expanding and contracting as it heats up and cools down, similar to Metallic noise the sound produced by a furnace or heating duct. This noise does not affect the operation or longevity of the fi replace. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 13: Maintenance And Service

• Carefully set fi xed glass assembly in place on fi replace. Hold glass in place with one hand and secure glass latches with the other hand. • Reinstall decorative front. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 14: Maintenance Tasks-Qualifi Ed Service Technician

• Confi rm there is no damage to glass or glass frame. Replace as necessary. • Verify that fi xed glass assembly is properly retained and attachment components are intact and not damaged. Replace as necessary. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 15 • Verify that there is not a short in fl ame sense circuit by checking continuity between pilot hood and fl ame- sensing rod. Replace pilot as necessary. Figure 3.1 IPI Pilot Flame Patterns Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

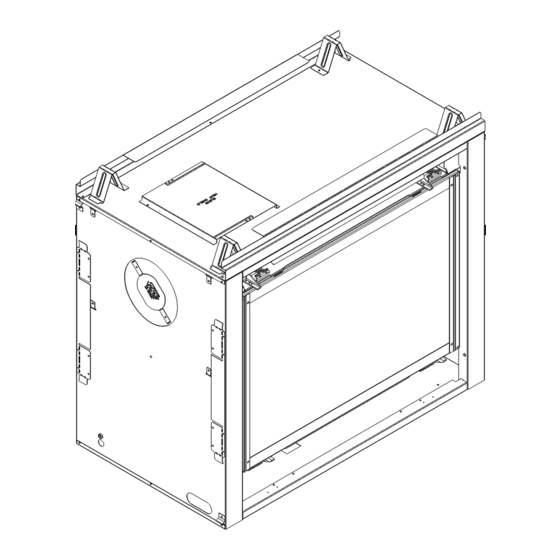

Page 16: Installer Guide

Note: Dual venting configurations ARE NOT allowed. Appliance MUST be vented EITHER vertically OR horizontally. SURROUND MANTEL AND MANTEL LEG (SECTION 5.D) Figure 4.1 Typical System Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 17: Design And Installation Considerations

Flat blade screwdriver 1/2 - 3/4 in. length, #6 or #8 Self-drilling screws Caulking material (300ºF minimum continuous exposure rating) One 1/4 in. female connection (for optional fan). Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 18: Inspect Appliance And Components

Call a qualifi ed service technician to inspect the appliance and to replace any part of the control system and/or gas control which has been under water. Figure 4.3 Do Not Remove Standoff Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 19: Framing And Clearances

914 mm 36 in. 914 mm 36 in. 914 mm 36 in. 914 mm RCOR 36 in. 36 in. 914 mm 914 mm Figure 5.1 Appliance Locations Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 20: Constructing The Appliance Chase

(Width) (Width) (Width) (Depth) Inches 8-5/8 38-1/8 34-1/8 Millimeters 1092 * Adjust framing dimensions for interior sheathing (such as sheetrock) Figure 5.2 Clearances to Combustibles ST-36TRB-IPI Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 21 (Width) (Depth) Inches 8-5/8 38-1/8 34-1/8 Millimeters 1016 * Adjust framing dimensions for interior sheathing (such as sheetrock) Figure 5.4 Clearances to Combustibles LCOR-36TRB-IPI and RCOR-36TRB-IPI Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 22: Mantel And Wall Projections

Figure 5.8 Minimum Vertical and Maximum Horizontal MEASUREMENT FROM FIREPLACE Dimensions of Non-Combustibles OPENING TO BOTTOM OF APPLIANCE= 33 1/2 IN Figure 5.6 Minimum Vertical and Maximum Horizontal Dimensions of Combustibles Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 23 3.5 in. = AIR SPACE REQUIRED Figure 5.10 Non-Combustible Zone (PIER and ST) SHEETROCK 3.5 in. = AIR SPACE REQUIRED Figure 5.11 Non-Combustible Zone (LCOR and RCOR) Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 24: Termination Locations

Over 18/12 to 20/12 ..........7.5 Over 20/12 to 21/12 ..........8.0 * 3 foot minimum in snow regions Figure 6.1 Minimum Height From Roof To Lowest Discharge Opening Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 25 2 sides beneath the fl oor. venting system does not meet these requirements. • Vinyl protection kits are suggested for use with vinyl siding. Figure 6.3 Minimum Clearances for Termination Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 26: Vent Information And Diagrams

Effective DVP24 Height/Length DVP36 DVP48 1219 DVP6A 3 to 6 76 to 152 DVP12A 3 to 12 76 to 305 Figure 7.2 DVP Pipe Effective Length Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 27: Vent Diagrams

Installation requirements to replace the fi rst 90° elbow with two 45° elbows: elbow on rear vent appliances. 4 ft min. (1.22 m) 1/4 in. max. (6 mm) 16 ft max. (4.87 m) Figure 7.3 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 28 4.6 m 6 ft. 1.8 m 18 ft. 5.5 m = 50 ft. (15.2 m) Maximum = 18 ft. (5.5 m) Maximum INSTALLED HORIZONTALLY Figure 7.5 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 29 3 ft. 914 mm 12 ft.* 3.7 m 6 ft 1.8 m = 18 ft. (5.5 m) Maximum = 50 ft. (15.2 m) Maximum Figure 7.6 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 30 15-60 feet, an exhaust restrictor may baffle and refractory panel after exhaust be needed. The exhaust restrictor can be located in the restrictor installation. appliance manual bag. Figure 7.8 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 31 MUST subtract one number from the table above. Example: Top vent 40 ft vertical with DVP pipe = 5-4 Top vent 40 ft vertical with SLP pipe = 4-3 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 32 5.5 m = 18 ft (5.5 m) Maximum *No specifi c restrictions on this value EXCEPT cannot exceed 50 ft (15.2 m) INSTALLED HORIZONTALLY Figure 7.12 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 33 = 16 in. (406 mm) Maximum No Elbow Figure 7.13 One 45° Elbow DO NOT use a 45º elbow in corner installations. Use two 90º elbow instead. Figure 7.14 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 34 12 ft. 3.7 m INSTALLED = 40 ft (12.2 m) Maximum = 3 ft (94 mm) Maximum HORIZONTALLY = 12 ft (3.7 m) Maximum Figure 7.16 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 35 10 ft. 6 ft. 1.8 m 12 ft. 3.7 m = 50 ft (15.2 m) Maximum = 16 ft (4.9 m) Maximum INSTALLED HORIZONTALLY Figure 7.18 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 36 1.8 m *No specifi c restrictions on this value EXCEPT cannot exceed 50 ft. (15.2 m) Maximum = 6 ft. (1.8 m) Maximum INSTALLED Figure 7.20 HORIZONTALLY Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 37: Vent Clearances And Framing

Top: 2-1/2 in. (64 mm) Bottom: 1/2 in. (13 mm) Sides: 1 in. (25 mm) Figure 8.1 Horizontal Venting Clearances To Combustible Materials Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 38: Wall Penetration Framing

Figure 8.5 Wall Penetration Note: When terminating horizontally off the top of the unit using SLP pipe, a 10 in. x 10 in. framing hole is required. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 39: Vertical Penetration Framing

INSTALL ATTIC INSULATION SHIELDS BEFORE OR AFTER INSTALLATION OF VENT SYSTEM CEILING FIRESTOP CEILING FIRESTOP INSTALLED BELOW CEILING INSTALLED ABOVE CEILING Figure 8.7 Installing the Attic Shield Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 40: Appliance Preparation

Remove screws to access vent. self-tapping screws found in the manual bag. Note: The vent gasket can found in the manual bag. Proceed to Section 9. C. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 41: Rear Vent

Secure the vent gasket to the appliance with two self-tapping screws found in the manual bag. Note: The vent gasket can found in the manual bag. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 42: Securing And Leveling The Appliance

4. Level the appliance from side to side and front to back. It CANNOT be changed at a later time. is acceptable to use wood shims under the appliance. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 43 Figure 9.13 Do Not Remove Refractory WARNING! Risk of Fire! DO NOT remove standoff. Appliance could overheat! DO NOT REMOVE STANDOFF DO NOT REMOVE STANDOFF Figure 9.14 Do Not Remove Standoff Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 44: Installing Vent Pipe (Dvp And Slp Pipe)

Use screws no longer than 1/2 in. (13 mm). If predrilling screw holes, DO NOT penetrate inner pipe. INCORRECT Figure 10.4 Seams Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 45: Assemble Vent Sections (Slp Pipe Only)

• Only outer pipes are sealed, sealing the inner fl ue is not Figure 10.5 Adding Venting Components required. • All unit collar, pipe, slip section, elbow and cap outer fl ues shall be sealed. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 46: Secure The Vent Sections

Figure 10.10 Rotate Seams for Disassembly connection point to appliance. 120º Figure 10.11 Align and Disassemble Vent Sections Figure 10.8 Securing Vertical Pipe Sections 120º Figure 10.9 Securing Horizontal Pipe Sections Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 47: Install Decorative Ceiling Components (Slp Only)

fl aps and the roof. Figure 10.13 WARNING! Risk of Fire! Clean out ALL materials from inside the support box and complete the vertical vent run and termination. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 48: Install Metal Roof Flashing

• Caulk the perimeter of the fl ashing where it contacts the roof surface. See Figure 10.15. • Caulk the overlap seam of any exposed pipe sections that are located above the roof line. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 49: Install Vertical Termination Cap

• Once the pipe section and the termination cap have been connected, slide the wall thimble up to the interior wall surface and attach with screws provided. See Figure 10.18. Figure 10.18 Wall Thimble Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 50: Install Horizontal Termination Cap (Dvp And Slp Pipe)

DVP-TRAP1 can adjust 1-1/2 in. (3-1/8 to 4-5/8 in.) DVP-TRAP2 can adjust 4 in. (5-3/8 to 9-3/8) DVP-HPC1 can adjust 2-1/8 in. (4-1/4 to 6-3/8) DVP-HPC2 can adjust 4-1/8 in. (6-3/8 to 10-1/2) Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 51: Gas Information

fl exible gas connector are connected to the 1/2 inch (13 mm) control valve inlet. • If substituting for these components, please consult local codes for compliance. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 52: Electrical Information

Remove batteries before using the transformer, and unplug the transformer before installing the batteries. Battery polarity must be correct or module damage will occur. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 53 WHITE GROUND TO FIREPLACE PLUG IN CHASSIS WIRES BATTERY PACK (TO BROWN) REMOTE PLUG IN VALVE Figure 12.2 Intellifi re Ignition Wiring Diagram with Remote Receiver Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 54: Junction Box Installation

Figure 12.4 Junction Box Wired to Wall Switch (1/4 in. male) as shown. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 55: Finishing

Step 3. Crease fl aps on left and right sides of splatter guard using the scored line as the guide. See Figure 13.3. Figure 13.5 Top slot Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 56 Figure 13.8 Opening Lower Access Panel on the left and right sides. Pull outward gently, but fi rmly, taking care not to tear or remove the inserted tabs. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 57: Mantel And Wall Projections

Figure 13.15 Minimum Vertical and Maximum Horizontal Dimensions of Non-Combustibles MEASUREMENT FROM FIREPLACE OPENING TO BOTTOM OF APPLIANCE= 33-1/2 IN. Figure 13.13 Minimum Vertical and Maximum Horizontal Dimensions of Combustibles Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 58: Facing Material

Top and Side Seal Joint Finishing materials 1 inch maximum thick. Figure 13.17 Noncombustible Facing Diagram Stop fi nishing material fl ush with opening. Figure 13.19 Overlap Fit Decorative Front Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 59 2 IN., DOORS WILL ONLY OPEN AS FAR AS PICTURED DOORS 37-1/4 IN. Finishing material between 1 and 2 inches thick. Figure 13.21 Operable hinge Decorative Front Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 60: Elevated Hearth Systems

Note 1. Add dimensions to Exterior Wall Hole (Figure 8.2) and Rough Opening Height (Figure 5.2). Note 2. Verify Marble Cut Lengths on site prior to cutting. Note 3. Dimensions assume use of a 3/4 in. Hearth Pad. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 61: Appliance Setup

Use this material to give the appliance a realistic ash bed. • Save the remaining ember materials for use during appliance servicing. The embers provided should be enough for 3 to 5 applications. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 62: Install The Log Assembly

Mate the notch on the end of log # 1 with the hump on top of log A. Set the other end of Log #1 onto the smooth area on top of Log C. 2128-935 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 63 The bottom end of log #3 should come in contact with the far left grate tine. Mate the bottom of log # 3 with the indentations on Log D and the top of Log #2. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 64: Fixed Glass Assembly

OPEN CLOSED LATCHES BOTH BOTTOM AND TOP) GLASS ASSEMBLY Figure 14.3 Fixed Glass Assembly Figure 14.4 Air Shutter Air Shutter Settings Burner 1/8 in. Fully open Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 65: Troubleshooting

Verify module is securely grounded to metal chassis of appliance. d. Module voltage output / Valve/Pilot Verify battery voltage is at least 2.7 volts. Replace batteries if volt- solenoid ohms readings. age is below 2.7. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 66 ON position. If there is no spark at “I” terminal module must be replaced. If there is a spark at “I” terminal, module is fi ne. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 67: Reference Materials

FRONT VIEW RIGHT VIEW LEFT VIEW Location Inches Millimeters Location Inches Millimeters 1-1/2 42-1/2 1080 24-1/2 33-1/2 9-1/2 2-1/8 4-1/8 34-5/8 4-1/4 Figure 16.1 See-Through Dimensions Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 68 FRONT VIEW RIGHT VIEW LEFT VIEW Location Inches Millimeters Location Inches Millimeters 1-1/2 40-1/2 1029 24-1/2 33-1/2 9-1/2 2-1/8 34-5/8 4-1/8 4-1/4 Figure 16.2 Pier Dimensions Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 69 RIGHT VIEW LEFT VIEW Location Inches Millimeters Location Inches Millimeters 1-1/2 40-1/2 1029 24-1/2 33-1/2 9-1/2 2-1/8 24-1/2 4-1/8 4-1/4 34-5/8 Figure 16.3 LCOR, RCOR Dimensions Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 70: Vent Components Diagrams

(356 mm) 5 in. 12 in. (127 mm) (305 mm) 6 in. (152 mm) DVP-HVS (Vent Support) DVP-WS (Wall Shield Firestop) Figure 16.4 DVP vent components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 71 117 mm Length 5-3/8 in. 9-3/8 in. DVP-TRAP Trap2 Horizontal Termination Cap 137 mm 238 mm DVP-TRAP2 DVP-TRAP1 DVP-TRAPK2 DVP-TRAPK1 DVP-HPC1 DVP-HPC2 Figure 16.5 DVP vent components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 72 9-1/2 in. 26 in. (352 mm) (241 mm) 660 mm 14 in. (356 mm) DVP-HSM-B Extended Heat Shield DRC-RADIUS Figure 16.6 DVP vent components Cap Shield Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 73 High Performance Cap 3/8 in. (10 mm) 1 in. (25 mm) 7-3/4 to 10-3/8 in. (197 to 264 mm) DVP-FBHT FireBrickTermination Cap Figure 16.7 DVP vent components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 74 13-5/8 IN. 16-11/16 IN. 16-11/16 IN. (346 mm) 424 mm (424 mm) SLP-LPC 12-1/2 IN. SLP Low Profi le Cap (318 mm) Figure 16.8 Vent Components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 75 1-1/2 in. 5-1/2 in. 12 in. 220 mm 38 mm 146 mm 305 mm SLP-WS SLP-FS Wall Shield Firestop Ceiling Firestop Figure 16.9 SLP Series Vent Components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 76 13-1/2 in. 343 mm 7-3/4 to 10-3/8 in. (197 to 264 mm) DVP-FBHT SLK-SNKD Horizontal Snorkel Termination Cap Termination Cap Figure 16.10 SLP Series Vent Components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 77 367 mm 26 in. 660 mm 2-5/16 in. 14-7/16 in. 59 mm 367 mm DVP-HSM-B SLP-WT-BK Extended Heat Shield Wall Thimble-Black Figure 16.11 SLP Series Vent Components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 78 100 FT PV Wire Harness PVI-WH100 separately. Use if the PVLP-SLP is installed in a high traffi c area. PVLP-HS PVLP-BEK Heat Shield Brick Kit Figure 12.6 PVLP-SLP Vent Components Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 79: Service Parts

Junction Box Bracket 2162-107 Non-Comb 2162-106 Refractory Bracket Surround Overlay (contains overlay for top, bottom and sides) SRV2132-FACE Additional service part numbers appear on following page. 12/15 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... -

Page 80: Service Parts

Sheetrock Ledge (End) 2130-126 Refractory Panel 2129-016 Surround Overlay (contains overlay for top, bottom and sides) SRV2130-FACE Additional service part numbers appear on following page. 12/15 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15... - Page 81 Sheetrock Ledge (End) 2130-126 Non-Comb 2162-107 Refractory Brackets 2162-106 Surround Overlay (contains overlay for top, bottom and sides) SRV2132-FACE Additional service part numbers appear on following page. 12/15 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 82 4021-013 2129-017 Refractory Left Refractory Right 2129-016 Surround Overlay (contains overlay for top, bottom and sides) SRV2128-FACE Additional service part numbers appear on following page. 12/15 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 83 17.8 Battery Pack 593-594A 17.9 Module Wire Assembly 593-590A 17.10 3 Volt Transformer 593-593A 17.11 Valve Bracket 2118-104 Additional service part numbers appear on following page. Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

- Page 84 2 in Jumper Wires 2012-206 Conversion Kit NG NGK-MS36 Conversion Kit LP LPK-MS36 Pilot Ori ce NG 593-528 Pilot Ori ce LP 593-527 Regulator NG NGK-DXV Regulator LP LPK-DXV Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

-

Page 85: Contact Information

5941237, 6006743, 6019099, 6053165, 6145502, 6374822, 6484712, 6601579, 6769426, 6863064, 7077122, 7098269, 7258116, 7470729, 8147240 or other U.S. and foreign patents pending. 2000-945C Printed in U.S.A. - Copyright 2015 Heat & Glo • ST-36TRB-IPI, PIER-36TRB-IPI, LCOR-36TRB-IPI, RCOR-36TRB-IPI • 2128-900 Rev. R • 12/15...

Need help?

Do you have a question about the ST-36TRB-IPI and is the answer not in the manual?

Questions and answers