Subscribe to Our Youtube Channel

Summary of Contents for Thermal Dynamics MERLIN 6000

-

Page 1: Service Manual

® MERLIN 6000 Plasma Cutting Master Power Supply A-01497 Service Manual Manual No. 0-2569 October 6, 1999... - Page 2 The publisher does not assume and hereby disclaims any liabil- ity to any party for any loss or damage caused by any error or omission in the MERLIN 6000 Plasma Cutting Master Power Supply Service Manual, whether such error results from negli- gence, accident, or any other cause.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1: GENERAL INFORMATION ....................1 1.01 Notes, Cautions and Warnings ..............1 1.02 Important Safety Precautions ................ 1 1.03 Publications ....................2 1.04 Note, Attention et Avertissement ..............3 1.05 Precautions De Securite Importantes ............3 1.06 Documents De Reference ................ - Page 4 APPENDIX VI: RECOMMENDED ROUTINE MAINTENANCE SCHEDULE FOR LIQUID COOLED PLASMA CUTTING SYSTEMS ............. 83 APPENDIX VII: MERLIN 6000 MASTER POWER SUPPLY - 120 VAC CIRCUIT DIAGRAM ..84 APPENDIX VIII: MERLIN 6000 SLAVE POWER SUPPLY - 120 VAC CIRCUIT DIAGRAM ..85 APPENDIX IX: LADDER DIAGRAM - 15 VDC ................

- Page 5 TABLE OF CONTENTS (continued) APPENDIX XIX: PARALLEL CABLE ..................96 APPENDIX XX: ARC STARTER BOX OPTION SYSTEM SCHEMATIC ........97 APPENDIX XXI: PARALLEL INTERFACE DIAGRAM ..............98 APPENDIX XXII: GAS CONTROL (GC3000) WIRING DIAGRAM ........... 100 APPENDIX XXIII: SYSTEM SCHEMATIC - Rev 'B' or Earlier ..........102 APPENDIX XXIV: SYSTEM SCHEMATIC - Rev 'C' or Later ............

- Page 6 TABLE OF CONTENTS (continued)

-

Page 7: General Information

SECTION 1: GASES AND FUMES GENERAL INFORMATION Gases and fumes produced during the plasma cutting process can be dangerous and hazardous to your health. 1.01 Notes, Cautions and Warnings • Keep all fumes and gases from the breathing area. Throughout this manual, notes, cautions, and warnings Keep your head out of the welding fume plume. -

Page 8: Publications

• Install and maintain equipment according to NEC • To protect your eyes, always wear a welding hel- code, refer to item 9 in Subsection 1.03, Publica- met or shield. Also always wear safety glasses with tions. side shields, goggles or other protective eye wear. •... -

Page 9: Note, Attention Et Avertissement

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR WELDING, CUTTING AND ALLIED PRO- AVERTISSEMENT CESSES, obtainable from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269 9. NFPA Standard 70, NATIONAL ELECTRICAL CODE, Toute procédure pouvant provoquer des blessures obtainable from the National Fire Protection Asso- de l’opérateur ou des autres personnes se trouvant ciation, Batterymarch Park, Quincy, MA 02269... - Page 10 • Les sortes de gaz et de fumée provenant de l’arc de plasma dépendent du genre de métal utilisé, des INCENDIE ET EXPLOSION revêtements se trouvant sur le métal et des différents procédés. Vous devez prendre soin lorsque vous Les incendies et les explosions peuvent résulter des scories coupez ou soudez tout métal pouvant contenir un chaudes, des étincelles ou de l’arc de plasma.

-

Page 11: Documents De Reference

• Utilisez la nuance de lentille qui est suggèrée dans 4. Norme ANSI Z87.1, PRATIQUES SURES POUR LA le recommendation qui suivent ANSI/ASC Z49.1: PROTECTION DES YEUX ET DU VISAGE AU TRAVAIL ET DANS LES ECOLES, disponible de Nuance Minimum Nuance Suggerée Courant Arc Protective Numéro... - Page 12 14. Norme AWSF4.1 de l’Association Américaine de Soudage, RECOMMANDATIONS DE PRA- TIQUES SURES POUR LA PRÉPARATION À LA COUPE ET AU SOUDAGE DE CONTENEURS ET TUYAUX AYANT RENFERMÉ DES PRODUITS DANGEREUX , disponible auprès de la American Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126 15.

-

Page 13: Declaration Of Conformity

Rigorous testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all design specifications. Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture. -

Page 14: Statement Of Warranty

None Warranty repairs or replacement claims under this limited warranty must be submitted by an authorized Thermal Dynamics® repair facility within thirty (30) days of the repair. No transportation costs of any kind will be paid under this warranty. Transportation charges to send products to an authorized warranty repair facility shall be the responsibility of the customer. -

Page 15: Introduction

C. Customer/Operator Responsibilities It is the customer/operators’ responsibility to maintain the equipment and peripheral Accessories provided by Thermal Dynamics in good operating order in accordance with the procedures outlined in the Operating Manual, and to protect the equipment from accidental or mali- cious damage. - Page 16 INTRODUCTION Manual 0-2569...

-

Page 17: Introduction & Description

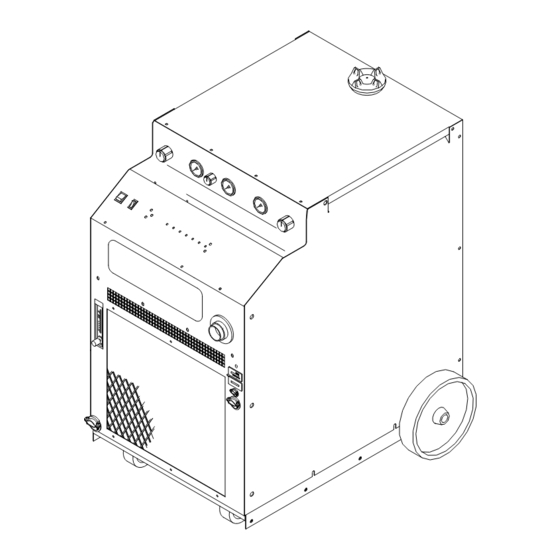

DESCRIPTION 3.01 Scope of Manual This manual contains descriptions, operating instructions and basic maintenance procedures for the Merlin 6000 Plasma Cutting Master Power Supply. Service of this equipment is restricted to Thermal Dynamics trained per- sonnel; unqualified personnel are strictly cautioned against attempting repairs or adjustments not covered in this manual, at the risk of voiding the Warranty. -

Page 18: Specifications & Design Features

5. Duty Cycle 3.03 Specifications & Design Features 100% 6. Pilot Modes The following apply to the Master Power Supply only: Auto-Restart, Pre-Flow Delay, "Recycle Required" 1. Controls 7. CNC Signals ON/OFF Switch, Output Current Control, RUN/ SET/PURGE Switch, Secondary Gas Regulator, Enable, Start/Stop, OK-To-Move, Pilot Sensing Relay Plasma Gas Regulator, Secondary Mode Switch, Sec- (PSR), Full CNC Available with Remote... -

Page 19: Theory Of Operation

13. Power Supply Dimensions NOTE Enclosure Only - For the arc to restart automatically, AUTO RE- START must be enabled at switch settings inside Width: 24.12 in (0.61 m) the Power Supply (Refer to Operating Manual 0- 2568, Section 4.07). Height: 38.38 in (0.98 m) D. -

Page 20: Options And Accessories

power to the main contactor. When the overheated C. Computer Control Cable Kits component cools down the switch will close again and For interfacing the power supply with a computer or allow operation of the system. auxiliary control device. Available in various cable G. -

Page 21: Service Troubleshooting Diagnostics

NOTE The troubleshooting contained in this manual is Coolant Filter Assembly for the Merlin 6000 Master Power Supply only. Troubleshooting other parts of the system is cov- ered in the separate manuals for that product. 4.02 Periodic Inspection &... -

Page 22: System Theory

An Optional Remote Dual Meter with Hour Meter and Arc Starts Counter is available with all Merlin 6000 Sys- Coolant Hose tems. The meters are mounted to the front panel of the unit. - Page 23 Board (PCB) configures the power supply for Merlin 6000 PWM signals are sent to the Driver PC Board, where they operation (refer to Switching Control PCB description for are converted into the current and voltage levels needed details). to drive the switching transistor.

- Page 24 Pulsing the pilot current allows higher transfer distances the capacitor discharge (CD) arc starting circuit to without increasing parts wear. The Merlin 6000 Pulser fire the spark gap producing the high voltage spark uses a transistor to momentarily short out a portion of which starts the DC pilot arc.

-

Page 25: Troubleshooting Guide

CUT RETRACT (%). There are also manual UP and surements. It is helpful for solving many of the common DOWN switches. The Standoff Control operates a problems that can arise with the Merlin 6000 Plasma Cut- lifter motor assembly moving the torch vertically to ting System. - Page 26 3. Locate your symptom in the appropriate Sub-Section. 6. Parallel cable not connected (Slave Power Supply) 4. Check the causes (easiest listed first) for the symptom. a. Install Parallel Cable 5. Check the remedies listed for each cause. 7. No ENABLE to Slave Power Supply 6.

- Page 27 Turn ON the power supply, if gas flows, the torch 2. Faulty pressure switch, PS1 head is clogged. a. In the Merlin 6000, connect a jumper wire across • Secondary Gas not flowing? the Pressure Switch (PS1) CAUTION •...

- Page 28 Turn ON the power supply, if gas flows, the torch 3. Faulty Logic PC Board head or leads are clogged. a. Refer to Section 4.05-J, Coolant Conductivity 6. Defective gas solenoids or control circuits Circuit. Replace Logic PC Board if necessary. a.

- Page 29 O. No Pilot Arc; Pilot indicator ON; PCR Energized 4. Shorted torch lead a. Check and replace if necessary 1. Faulty Arc Start Box or Shorted torch 5. Dirty or wet torch lead a. Refer to Section 4.05-O, Pilot Circuit Check a.

-

Page 30: Test Procedures

4. Main current control on remote or front panel set too A. Voltage Selection PC Board Check The Merlin transformer has three input voltage ranges a. Main current may not be high enough for metal (200-230, 380-460 and 500-575) selected by buss bars. thickness being pierced. - Page 31 120 VAC Test Merlin 3000, 6000 or 6000GST RC6010 NOTE Switching Control PCB Refer to Appendix VII for 120 V AC Circuit Dia- gram. J37-17 J15-5 J50-12 J1-5 1. Check the voltage input from F2 (wire #10) to J6-9 for 100 - 120 VAC. Check the input from F2 to J6- 10 for 120 - 140 VAC.

- Page 32 • If voltage is correct, then reinstall the connec- D. Motor Control Contactor Check (MC1, MC2 tors one at a time to isolate the problem. In the or MC3) case of a ribbon cable the cable itself may be NOTE shorted.

- Page 33 b. Check for about 220VAC between wires #86 and low), disconnect one end of the diode and recheck. If #87 on Motor Contactor, MC3. the diode reading is not correct with one end discon- nected, then replace the diode. Check all diodes be- •...

- Page 34 SOL5 Nitrogen Plasma G. Pressure Sensing Circuits SOL6 Oxygen Plasma The Merlin 6000 uses only a plasma gas pressure switch, SOL7 Argon/Hydrogen Plasma PS1, set for 35 psi (2.4 bar) and is located in the power supply. Normal operation is for one plasma gas solenoid to 1.

- Page 35 measure wire #9 to J2-5. If there is no voltage at or no pressure on the Secondary Pressure Gauge can J2-5, see Section 4.05-A, Voltage Select PCB Test, indicate a problem with the secondary water solenoid, 120 VAC test. regulator, clogged torch head and leads or the water supply.

- Page 36 The original Secondary Gas Select Switch, SW3, on The voltage is routed through the Power Supply the Merlin 6000 Front Panel is always set to the to J51-1, then to the Gas Control Connector, J63-1. GAS position and the Secondary Gas Select Switch, The voltage then is sent out to the Gas Control SW2, on the GC3000 front Panel is used instead.

- Page 37 coolant flow indicator is not lit, replace the LED • If the START LED is ON, even momentarily, go to PC board. If J3-2 measures greater than +12 vdc, Section 4.05-N, Main Contactor (W) Control Cir- replace the Logic PC Board. cuit.

- Page 38 nal. The signal goes to the Slave Power Supply for start. If it starts the problem is in the remote or CNC Logic PCB. Check for 0 vdc from TP1 (ground) to connections. If not refer to Section 4.05-K, Power Supply J4-9 on the Logic PCB.

- Page 39 WARNING Rear of Front Panel Both base and emitter are at -320 vdc potential. Use extreme caution when testing Driver PC Board output. If switching pulses are present at J8-1 and J8-3, check the Driver PC Board output between J27-3, Q1 base, and J27- 2, Q1 emitter.

- Page 40 c. If none of the above is cause of READY LED M). If contactor still drops out in less than 1/2 being OFF, then the Logic PCB is faulty. second, problem is not a loss of DC but may be a shorted torch.

- Page 41 NOTE b. If the problem persists, bypass the RC6010 by removing the CNC cable and connecting a start Measure the voltage while attempting to cut as the switch into the TB2 Start input and operate it voltage may be correct prior to cutting. manually.

- Page 42 tip to electrode voltage greater than 250 vdc. When the NOTE PCR contactor closes, power supply open circuit voltage There is a red LED indicator on the Arc Starter (280-350 volts) is connected across the torch plus (tip) and Box PC Board that will be ON when the 24 V AC is minus (electrode).

- Page 43 pilot lead, under where the gas and coolant The Remote Control (RC 6010) has front panel con- hoses attach. The wire then goes to the Arc trols for OUTPUT AMPS and CSD. The upper and Starter Box and on to the torch tip lower limits of the current control range are set by the POT HI (+10 vdc) and POT LOW (+3.3 vdc) signals •...

- Page 44 • Before cutting (preview) and with the three deci- put is 5.45 vdc for 150A and is sent to the Switching mals ON, the display indicates the CSD poten- Control PCB at J9-5 in each Power Supply. Each tiometer setting instead of the main current Switching Control PCB converts the voltage to 10 vdc control.

- Page 45 tor, turns ON the three decimals in the VOLTS dis- For the Remote Control (RC 6010), measure for +48 play and prevents the Standoff Control (SC10) from +/-5 vdc from J37-16, 35 and 37 (+) to J37-15,34 and changing torch height. 36 (-).

- Page 46 2. Locate and identify the pilot resistors (R16, R21 Slave Power Supplies: and R22) which are on a bracket in front of the • Merlin 6000 Master Power Supplies with the revi- fan. sion letter 'C' or later at the end of the serial num- ber on the data tag •...

- Page 47 example, 410 VAC and the pilot resistor setting Pilot Resistor Clamp should be 9 ohms to have a good pilot. The next Wire #99 time the system is turned ON, the input AC line Wire voltage may have gone up to 420VAC causing the #96A Pilot Resistor pilot to sputter because 420VAC requires setting...

- Page 48 The Isolation PCB in the Master Power Supply accom- plishes this using both digital and analog optoisolator intergated circuits (IC). A-01852 Pulser NOTE For a simplified diagram, refer to Appendix XXI, Parallel Interface Diagram. The circuits on each side of the isolation barrier require Wire #99 Wire #96 their own power supply.

-

Page 49: Repairs & Replacement Procedures

This Section describes parts replacement procedures and move the failed PC board. all repairs which may be performed on the Merlin 6000 Master Power Supply. 6. Carefully open the ESD protective bag and remove the replacement PC board. -

Page 50: External Parts Replacement

2. Loosen the two screws securing the bottom of the Side Panel to the base of the Power Supply. These WARNING two screws are in slotted holes in the Side Panel. 3. To remove the Side Panel from the Power Supply Disconnect primary power from the source before pull up and out on the Side Panel. -

Page 51: Front Panel/Chassis Parts Replacement

4. Place the replacement Current Knob on to the po- • LED/Current Control PC Board per paragraph tentiometer shaft with the location of the pointer 'D' above. the same as noted in step 1. 3. Remove the four screws securing the Access Panel 5. -

Page 52: Rear Panel Parts Replacement

5. On the top and bottom of the Radiator remove the 3. Disconnect the two wires connected to the Fuse six screws and star washers that secure the Radia- Holder. tor to the Front Panel. 3. Remove the two small screws securing the Fuse 6. - Page 53 3. Remove the Voltage Selection PC Board from the 6. Pull the old Secondary Water Solenoid Valve As- four PC Board Standoffs. sembly from the Rear Panel Assembly. 4. Install the replacement Voltage Selection PC Board 7. Install the replacement Secondary Water Solenoid Assembly by reversing the above procedure.

- Page 54 6. Remove the hose connected to the 90° Adapter Fit- 5. Secure the end of the hose to prevent coolant from ting near the bottom side (outlet hole) of the Cool- draining out of the Coolant Tank. ant Tank. 6. Remove the four nuts, washers and long screws 7.

-

Page 55: Base Assembly Parts Replacement

NOTE 5. Carefully slide the DC Inductor Assembly out the left side of the unit and onto the mechanical lift. The output of the replacement Check Valve should be pointing towards the rear of the unit when in- 6. Install the replacement DC Inductor Assembly by stalled. -

Page 56: Upper Chassis Parts Replacement

2. Loosen the allen set screw securing the Coupling 2. Locate the Thermostat Assembly to be replaced to the shaft of the Motor Assembly. and place a clean rag under the copper support. This will prevent debris from getting into the trans- 3. - Page 57 A. Power Driver PC Board Kit Replacement Upper PC Board Guide The Power Driver PC Board Replacement Kit is a di- rect parts replacement for the failed Driver PC Board Securing Tab and Switching Transistor (Q1) Assemblies in the Power Supply. Driver PC Board WARNING...

- Page 58 12. Note and label the wires connected to the Switch- 20. If the transistor thermstrate was not removed with ing Transistor Assembly. the transistor, it must be removed. NOTE 21. Clean the old transistor thermstrate from the tran- sistor mounting area. Verify that the Heatsink sur- The older style transistor will have two wire con- face under the transistor is smooth and free of de- nections to the transistor module and the newer...

- Page 59 B. Auxiliary Transformer (T2) Assembly NOTE Replacement Be sure that the Pressure Gauge orientation is the same as noted before removal. 1. Remove the Left Side Panel per Section 5.04-A. E. Pressure Switch Replacement 2. Disconnect the wiring connector from the wiring harness at the Auxiliary Transformer Assembly.

- Page 60 2. Disconnect the Torch connection to the fitting be- 2. Fasten the access cover open with string or rubber ing replaced at the Upper Chassis/Gauge Assem- band. bly. 3. Note where each connector is located on the old 3. Disconnect the gas Hose Assembly from the fitting Control Logic PC Board.

-

Page 61: Main Heatsink Assembly Parts Replacement

NOTE 5.10 Main Heatsink Assembly Parts Replacement The input of the replacement Check Valve should be pointing towards the rear of the unit when in- NOTE stalled. The output is designated by a symbol on the side of the part as shown in the following Fig- Refer to Section 6.09, Main Heatsink Assembly Re- ure. - Page 62 b. Position the thermal interface pad between the 1. Turn OFF main input power to the Power Supply diode and contact surface where the diode will both at the Power Supply ON/OFF switch and at be installed. the main power disconnect. 2.

-

Page 63: Hose Assembly Replacements

2. Wait at least two minutes to allow the input ca- NOTE pacitors to discharge. Refer to Subsection 6.08, Upper Chassis Replace- 3. Open the Power Supply to gain access to the faulty ment Parts for part numbers and detail drawing. Diode Assembly. - Page 64 3. Disconnect the other end of the Hose Assembly F. Plasma Gas Hose (PLASMA GAS to T- from the Pump Assembly. Fitting) Assembly Replacement 4. Remove the Hose Assembly from the unit. The Plasma Gas Hose Assembly goes from the front panel PLASMA GAS connector to the T-Fitting on the 5.

- Page 65 1. Drain the coolant from the Coolant Tank per Sec- NOTE tion 4.02-F. Refer to Subsection 6.08, Upper Chassis Replace- ment Parts for part numbers and detail drawing. CAUTIONS 1. Remove the Right Side Panel per Section 5.04-B. The coolant must be drained from the unit as the 2.

- Page 66 REPLACEMENT PROCEDURES Manual 0-2569...

-

Page 67: Parts Lists

B. Returns If a Thermal Dynamics product must be returned for ser- vice, contact your Thermal Dynamics distributor. Mate- rials returned to Thermal Dynamics without proper au- thorization will not be accepted. -

Page 68: External Power Supply Replacement Parts List

6.03 External Power Supply Replacement Parts List Item # Qty. Description Catalog # Complete Merlin 6000 Master Power Supply With Running Gear and Work Cable Without Gas Control 3-6800 With Gas Control 3-6802 Work Cable with Ring Lug - 25 ft (7.6 m) -

Page 69: Access Panel Replacement Parts

6.04 Access Panel Replacement Parts Item # Qty. Description Reference Catalog # Access Panel Assembly Includes: Access Panel With Overlay 9-7008 ON/OFF Rocker Switch, DPST 8-3258 LED/Current Control PC Board Assembly 9-5759 Knob, Inner Concentric 9-4146 RUN/SET Rocker Switch, DPST 8-3259 A-02340 Manual 0-2569... -

Page 70: Front Panel/Chassis Replacement Parts

6.05 Front Panel/Chassis Replacement Parts Item # Qty. Description Reference Catalog # Front Panel With Overlay 9-7009 Strain Relief 9-2179 Strain Relief 8-6307 Torch Leads Panel Boot 9-4210 Radiator 8-1347 #6 JIC x 3/8 NPT Male Union 8-6141 Coolant Filter 8-4276 Support, Inner Filter Lower 9-7010... - Page 71 A-02341 Manual 0-2569 PARTS LISTS...

-

Page 72: Rear Panel Replacement Parts

6.06 Rear Panel Replacement Parts Item # Qty. Description Reference Catalog # Rear Panel 9-7011 Fan, 16" Axial 8-6312 Relay, 25 amp, 120 AC 8-3390 3 PH Contactor 8-1373 4 mfd, Capacitor 9-3210 Capacitor Mounting Bracket 8-3391 330k Ohms Resistor Assembly 9-5545 Voltage Selection PC Board 8-5144... - Page 73 A-02342 Manual 0-2569 PARTS LISTS...

-

Page 74: Base Assembly Replacement Parts

6.07 Base Assembly Replacement Parts Item # Qty. Description Catalog # Base 9-6657 Caster, 5" Diameter 8-5578 Wheel, 8" Diameter 8-5579 Axle 9-1243 Retaining E-Ring, 1/2 Diameter Shaft 9-5539 Mat, Inductor Base 9-6662 DC Inductor Assembly 8-6145 29 KVA Transformer 8-6670 Main Contactor 9-1244... - Page 75 A-02048 NOTE Illustration is for Units with the letter 'C' or later at the end of the serial number of the unit. Manual 0-2569 PARTS LISTS...

-

Page 76: Upper Chassis Replacement Parts

6.08 Upper Chassis Replacement Parts Item # Qty. Description Catalog # Panel, Upper Chassis/Gauge 9-1302 Power Driver PC Board Assembly Includes: 7-3360 Thermstrate, Transistor (Refer to Section 6.09 Item # 7) 9-1406 Transistor, 300A, 550V Darlington (Refer to Section 6.09 Item # 8) 8-6154 Power Driver PC Board Assembly 9-4381... - Page 77 Item # Qty. Description Catalog # 3/8 NPT Close Nipple 9-2384 Valve, Check 3/8 NPT Female, Brass 9-1402 Check Valve, Male, 1/4 NPT, 5 PSI 8-4512 Hose Assembly, Secondary Water, Gauge To T-Fitting 8-4513 Hose Assembly, Secondary Gas/Water to Bulkhead 8-4514 Hose Assembly, Secondary Gas Inlet to Regulator 8-4515...

-

Page 78: Main Heatsink Assembly Replacement Parts

6.09 Main Heatsink Assembly Replacement Parts Item # Qty. Description Catalog # Main Heatsink 9-1404 Capacitor, 550 mfd, 400VDC 9-1303 Bracket, Capacitor/Heatsink 8-4521 Support, Air Foil 8-2176 Capacitor Clamp 9-4212 Support, Heatsink Assembly 9-6663 Thermstrate, Transistor 9-1406 Transistor, 300A, 550V Darlington (Refer to Section 6.08 Item #2) 8-6154 Capacitor, 10 mfd, 400V Poly., Hi-Current 9-1305... - Page 79 A-00971 Manual 0-2569 PARTS LISTS...

-

Page 80: Power Supply Options And Accessories

9-3053 Oxygen Regulator 9-4379 Water Regulator (Not required if item #4 is used) 8-6118 The following are not shown: Merlin 6000 Slave Power Supply 3-6801 Master to Slave Parallel Cable 9-6800 Remote Arc Starter Box 3-6820 Plasma Gas Supply Line - 10 ft (3.0 m) 9-2146 Secondary Gas Supply Line - 10 ft (3.0 m) - Page 81 FI ND P LA LI FT LI FT S TA 0. 2 0. 3 0. 1 0. 4 P LY 0. 5 0. 75 N TR 0. 25 PI ER (in ch 0. 5 T. H .C . es ) 0.

- Page 82 PARTS LISTS Manual 0-2569...

-

Page 83: Appendix I: Input Wiring Requirements

APPENDIX I: INPUT WIRING REQUIREMENTS In p u t P o w er In p u t C u r r en t S u g g ested S iz es (S ee N o te) V o ltag e F r eq . -

Page 84: Appendix Ii: Sequence Of Operation Block Diagram

APPENDIX II: SEQUENCE OF OPERATION BLOCK DIAGRAM ACTION ACTION ACTION ACTION RUN/SET/PURGE RUN/SET/PURGE Enable ON at Remote Close external switch to SET switch to RUN or TB2 disconnect switch ON/OFF switch to ON RESULT RESULT RESULT • Gas solenoids open, •... -

Page 85: Appendix Iii: Typical Mechanized System Work And Ground Cable Connections

APPENDIX III: TYPICAL MECHANIZED SYSTEM WORK AND GROUND CABLE CONNECTIONS Remote Control CNC Control Earth Standoff Control Ground Master Power 3-Phase Supply Input Work Cable Earth Ground Workpiece Slave Earth Power Ground Supply 3-Phase Input Work Cable A-01512 NOTE Work Cable(s) must connect direct to workpiece. DO NOT connect Work Cable(s) to earth ground and then to workpiece. -

Page 86: Appendix Iv: Typical Mechanized System Cable Interconnection Diagram

APPENDIX IV: TYPICAL MECHANIZED SYSTEM CABLE INTERCONNECTION DIAGRAM NOTE Refer to Appendix V for complete data on the Cables and Hoses. MASTER POWER SUPPLY RC 6010 Bulkhead RC 6010 Internal Ribbon Cable SC10 GAS CONTROL GC3000 3 Ø INPUT Parallel Cable SLAVE POWER SUPPLY 3 Ø... - Page 87 ARC STARTER BOX Arc Starter Control ARC STARTER PILOT CABLE SECONDARY GAS PLASMA GAS COOLANT COOLANT TORCH (-) CABLE SHIELD PILOT CABLE WORK CABLE WORKPIECE TORCH (-) CABLE WORK CABLE A-01517 Manual 0-2569 APPENDIX...

-

Page 88: Appendix V: Quick Reference To Interconnecting Cables And Hoses

APPENDIX V: QUICK REFERENCE TO INTERCONNECTING CABLES AND HOSES Cable/Hose Diameter Cable Description Catalog # Inches Power Supply CNC Cable 25 ft (7.6 m) 8-3380 50 ft (15.2 m) 8-3381 75 ft (22.9 m) 8-3382 100 ft (30.5 m) 8-3383 Remote Control Cable 25 ft (7.6 m) 9-5961... -

Page 89: Appendix Vi: Recommended Routine Maintenance Schedule For Liquid Cooled Plasma Cutting Systems

APPENDIX VI: RECOMMENDED ROUTINE MAINTENANCE SCHEDULE FOR LIQUID COOLED PLASMA CUTTING SYSTEMS This schedule applies to all types of liquid cooled plasma cutting systems. Some systems will not have all the parts listed and those checks need not be performed. NOTE The actual frequency of maintenance may need to be adjusted according to... -

Page 90: Appendix Vii: Merlin 6000 Master Power Supply - 120 Vac Circuit Diagram

APPENDIX VII: MERLIN 6000 MASTER POWER SUPPLY - 120 VAC CIRCUIT DIAGRAM SW1-A 5A, 250 VAC NEON IND1 VOLTAGE SELECTION BOARD SWITCHING CONTROL BOARD (Energized by Enable Switch) K4 (HV) K3 (LV) K3 (LV) K4 (HV) LOGIC BOARD K5 (LV) -

Page 91: Appendix Viii: Merlin 6000 Slave Power Supply - 120 Vac Circuit Diagram

APPENDIX VIII: MERLIN 6000 SLAVE POWER SUPPLY - 120 VAC CIRCUIT DIAGRAM SW1-A 5A, 250 VAC NEON IND1 VOLTAGE SELECTION PC BOARD SWITCHING CONTROL PC BOARD (Energized by Enable Switch) K4 (HV) K3 (LV) K3 (LV) K4 (HV) LOGIC PC BOARD... -

Page 92: Appendix Ix: Ladder Diagram - 15 Vdc

APPENDIX IX: LADDER DIAGRAM - 15 VDC LOGIC CONTROL BOARD PLASMA CONTROL CIRCUIT PURGE START/STOP (CNC) SECONDARY PRE-FLOW & POST-FLOW CIRCUIT START/STOP (Hand) SWITCH RECOGNITION START INDICATOR CONTACTOR CONTACTOR CONTROL W-ON J3-9 ENABLE CONTACTOR DISABLE SENSE BRIDGE (Only after main con- VOLTAGE tactor initially closes) <60VDC... -

Page 93: Appendix X: Signal Flow Block Diagram

SC 10 / RC 6010 Signal Flow Block Diagram Signals with SC 10 and RC 6010 Signals with SC 10 only Signals with RC 6010 only Merlin 6000 and 6000GST SC 10 Standoff Control CNC Control Master Power Supply START... -

Page 94: Appendix Xi: Start Circuit Diagram With Standoff Control Sc10

APPENDIX XI: START CIRCUIT DIAGRAM WITH STANDOFF CONTROL SC10 Start Circuit for Merlin 6000 and Merlin 6000GST with Remote Control RC 6010 and Standoff Control SC 10 Remote Control RC 6010 OPTO- Isolator CNC Controls J9-3 J29-3 START/STOP START J29-4... -

Page 95: Appendix Xii: Current Control And Display Diagram

APPENDIX XII: CURRENT CONTROL AND DISPLAY DIAGRAM Remote Control Cable Switching Control PCB Remote Control (RC6010) Master Power Supply Remote Pot High 10 VDC (86) J37-5 J15-20 J50-8 Remote Demand Output AMPS 3.3 - 10 VDC Adjustment (32) J37-21 J15-1 J7-17 Demand Signal 3.3 - 10 VDC... -

Page 96: Appendix Xiii: Corner Slowdown (Csd) Circuit Diagram

APPENDIX XIII: CORNER SLOWDOWN (CSD) CIRCUIT DIAGRAM A-01140 APPENDIX Manual 0-2569... -

Page 97: Appendix Xiv: Ok-To-Move Circuit Diagram

APPENDIX XIV: OK-TO-MOVE CIRCUIT DIAGRAM Merlin 3000 or Merlin 6000 or Merlin 6000GST with Remote Control RC6010 / Standoff Control SC10 OK-To-Move Circuit OFF = OK-To-Move PIERCE DELAY 0 - 3 seconds 24 VAC Source A-01081 Standoff Control SC11 OK OUT... -

Page 98: Appendix Xv: Arc Starter Box - 24 Vac Circuit Diagram

APPENDIX XV: ARC STARTER BOX - 24 VAC CIRCUIT DIAGRAM Merlin 6000 Power Supply Arc Starter Box Torch Control Panel Connector Arc Starter PC Board Connector (1A, 250V) (108) (14) J2-1 J14-5 J1-1 24 VAC Present 24 VAC (Red LED On) -

Page 99: Appendix Xvi: Power Supply Hose Block Diagram

APPENDIX XVI: POWER SUPPLY HOSE BLOCK DIAGRAM Manual 0-2569 APPENDIX... -

Page 100: Appendix Xvii: Interface Cable For Remote Control (Rc6010)

APPENDIX XVII: INTERFACE CABLE FOR REMOTE CONTROL (RC6010) Remote Control RC6010 RC6010 Remote Cable Merlin 6000 A-01513 APPENDIX Manual 0-2569... -

Page 101: Appendix Xviii: Cnc Interface Cable

APPENDIX XVIII: CNC INTERFACE CABLE Cable Connections Used With Remote Control RC6010 Remote Control CNC Cable Cutting Machine RC6010 * Refer to Remote Control RC6010 Manual for Station Select and CSD options 24 VAC Contact ** Source ** ** Selected inside the Remote Control RC6010 A-01514 Manual 0-2569... -

Page 102: Appendix Xix: Parallel Cable

APPENDIX XIX: PARALLEL CABLE Master Power Slave Power Cable Supply J54 Supply J15 DEMAND 3.3 - 10 VDC ENABLE START/STOP SLAVE IS ON SLAVE OUTPUT 0 - 10 VDC Signal Isolation PC Board Power Supply Shield Drain This Is Slave Remote Installed A-01516 APPENDIX... -

Page 103: Appendix Xx: Arc Starter Box Option System Schematic

APPENDIX XX: ARC STARTER BOX OPTION SYSTEM SCHEMATIC A-01575 Manual 0-2569 APPENDIX... -

Page 104: Appendix Xxi: Parallel Interface Diagram

APPENDIX XXI: PARALLEL INTERFACE DIAGRAM Slave Power Supply Master Power Supply Logic PCB +15 V. (123) J4-7 J4-9 (120) (124) J4-8 This is Slave J15-35 J4-10 (119) J3-29 This is Slave J15-36 Isolation PCB +15 V. J54-14 J15-17 Slave is On (131) J1-20 J71-1... - Page 105 Logic PCB +15 V. (123) J4-7 J4-8 J4-9 (120) J15-35 (124) This is Slave J4-10 (119) J3-29 This is Slave J15-36 +15 V. Slave is On J15-17 Slave is On J1-20 (129) J70-24 J4-4 (45) High sets Remote to Display 300A J4-3 14 V / 1 V J70-22...

-

Page 106: Appendix Xxii: Gas Control (Gc3000) Wiring Diagram

APPENDIX XXII: GAS CONTROL (GC3000) WIRING DIAGRAM A-01129 APPENDIX Manual 0-2569... - Page 107 Manual 0-2569 APPENDIX...

-

Page 108: Appendix Xxiii: System Schematic - Rev 'B' Or Earlier

APPENDIX XXIII: SYSTEM SCHEMATIC - Rev 'B' or Earlier A-01573 APPENDIX Manual 0-2569... - Page 109 NOTE System Schematic for units with the letter 'B' or earlier at the end of the serial number on the data tag. A-01573 Manual 0-2569 APPENDIX...

-

Page 110: Appendix Xxiv: System Schematic - Rev 'C' Or Later

APPENDIX XXIV: SYSTEM SCHEMATIC - Rev 'C' or Later A-01947 APPENDIX Manual 0-2569... - Page 111 NOTE System Schematic for units with the letter 'C' or later at the end of the serial number on the data tag. A-01947 Manual 0-2569 APPENDIX...

- Page 112 APPENDIX Manual 0-2569...

Need help?

Do you have a question about the MERLIN 6000 and is the answer not in the manual?

Questions and answers