Summary of Contents for Vetek WLC 1/A2

-

Page 1: User Manual

User Manual Precision scales – WLC series Manual number: LTI-05-11/01/09/A Vetek Weighing AB, Box 79, S-76040 Väddö, Sweden Phone +46 176 20 89 20 fax. +46 176 20 89 29 info@vetek.com www.vetek.com... - Page 2 JANUARY 2009 - 2 -...

-

Page 3: Table Of Contents

TABLE OF CONTENTS 1. INTENDET USE........................5 2. PRECAUTIONS........................6 2.1. Maintenance ........................6 2.2. Power supply ......................... 6 3. WARRANTY CONDITIONS....................6 4. MAIN DIMENSIONS ......................7 5. UNPACKING AND ASSEMBLY.................... 9 6. GETTING STARTED ......................10 7. BALANCE LEVELLING ...................... 11 8. - Page 4 16.5.1. Standard mass determined by its weighing............. 41 16.5.2. Mass of standard inscribed to scale memory ..........42 16.6. Automatic tare ......................43 16.7. Measurement of maximal force on the pan – latch............ 44 16.8. Totalizing ........................44 16.8.1. Enabling the w ork mode..................

-

Page 5: Intendet Use

1. INTENDET USE Scales are designed for fast and precise measurements of weighed loads masses and direct commercial settlements. Tarring in full weighing range enables to determine net mass of weighed loads. Additional display is additional equipment of scale. Functions: backlight of display level of filtration autozero function... -

Page 6: Precautions

2. PRECAUTIONS 2.1. Maintenance A. Please, read carefully this user manual before and use the device according to its intended use. B. Dead batteries (accumulators) should be utilized according to the law; C. Devices that are to be withdrawn from use age should be sent back to the producer or in case of own utilization do it according to the law. -

Page 7: Main Dimensions

D. Warranty does not cover: Mechanical failures caused by inappropriate maintenance of the device or failures of thermal or chemical origin or caused by atmospheric discharge, over voltage in mains or other random event, Inappropriate cleaning. E. Loss of warranty appears after: Access by an unauthorized service, Intrusion into mechanical or electronic construction of, unauthorized people,... - Page 8 Scales WLC/C1/R Scales WLC/C2/R Scales WLC/C1/K Scales WLC/C2/K - 8 -...

-

Page 9: Unpacking And Assembly

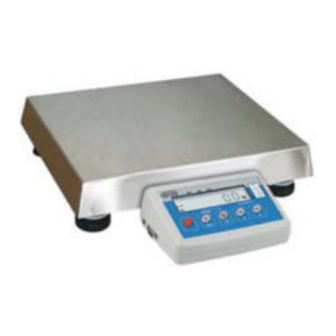

5. UNPACKING AND ASSEMBLY Unpack and put the scale on a flat even stable surface far away from sources of heat, Remove the transport protection: Scales WLC…/C/2: Scales WLC/B1: Scales WLC/C/K, WLC/C/R: Install the weight pan according to the drawings below: Scales WLC/A1/C/2: scales WLC/A2, WLC/A2/C/2: - 9 -... -

Page 10: Getting Started

scales WLC/B1: scales WLC/C/K: scales WLC/C/R: 6. GETTING STARTED After unpacking and mounting the scale level it out. Use levelling legs and the level condition indicator installed in the basis of the scale. Turn the device on using the key – keep pressing the key for about 0.5 sec, Wait for the test completion, Then you will see zero indication and pictograms:... -

Page 11: Balance Levelling

Caution: In case of verified scales in II OIML class with divisions e=10d (where: d – reading division, e – verified division) the last digit will be marked as shown below: 7. BALANCE LEVELLING Operation temperature range for this device is outlined as +15 C +30 C;... -

Page 12: Keys' Functions

Keypad of WLC C1…C2 series Keypad of WLC/B1 series Notice: Scales of WLC/A2 series are equipped with an additional key tarring and has no additional functions but the keypad of the WLC…/C/2 scale include an additional key for direct starting the process of internal calibration. -

Page 13: Inscriptions On The Display

10. INSCRIPTIONS ON THE DISPLAY Text string Description Filter level bAud Transmission baud rate Piece counting HiLo +/- control according to a standard mass rEPL Automatic printout The condition of printing data StAb Auto Autozero correction Power save – time to switch off while no operation Latch of the max measurement Totalizing AnLS... -

Page 14: User Menu

11. USER MENU 11.1. Submenus User’s menu is divided into 6 basic submenus. Each group has its own characteristic name preceded by the letter P and a number. P1 rEAd P 1.1 Fil P 1.2 Auto P 1.3 tArA P 1.4 Fnnd P2 Prnt P2.1 Pr_n... -

Page 15: Brows Ng User Menu

11.2. Browsing user menu Use scale’s keys to move inside the menu. 11.2.1. Keypad Entering main menu Inscribing tare value Increasing a digit value by „1” moving down in the menu Battery / accumulator state monitoring Toggling between gross / net values Selecting the parameter or changing the value of a selected parameter Entering the selected submenu... -

Page 16: Weighing

12. WEIGHING Put a load you want to weigh on the weighing pan. When the pictogram appears it means that the result is stable and ready to read. In order to assure long-term operation and appropriate measurements of weighted loads following precautions should be taken into consideration: Loads should be placed on the pan delicately and carefully in order to avoid mechanical shocks: Loads should be placed centrally on the pan (errors caused... -

Page 17: Tarring

12.1. Tarring In order to determine the net mass put the packaging on the pan. After stabilising press - (Net pictogram will be displayed in the left upper corner and zero will be indicated). After placing a load on the weight pan net mass will be shown. Tarring is possible within the whole range of the scale. -

Page 18: Zeroing

Using set the tare value, Press Program returns to weighings mode. The inscribed tare value can be seen on the display with „–” sign, Tare can be inscribed anytime in weighings mode. Notice: 1. You cannot inscribe a new tare value when the tare value in memory is greater than zero. -

Page 19: Selection Of Basic Weight Unit

12.5. Selection of basic weight unit This function is used to set weight unit the scale will start with. Procedure: Enter the submenu <P3.Unit> and then: press , until the expected unit appears on the display: Options: A. When the basic unit is [kg], users can toggle between: [kg, lb, N], for verified scales [lb] is not accessible, B. -

Page 20: Temporarily Selected Unit

After you select the unit press , the scale returns to: Return to weighing according to chapter - 11.2.2. Notice: After turning on the scale always sets the basic unit. 12.6. Temporarily selected unit This function is used to set weight unit the scale will use temporarily until the next power off or next selection. -

Page 21: Main Parameters

Options: A. When [kg] is a basic unit, users can select following units: [kg, lb, N], [lb] is not accessible for verified scales. B. When [g] is a basic unit, users can select following units: [g, ct, lb], [lb] is not accessible for verified scales. 13. -

Page 22: Median Filter

Notice: Filtering level influences the time of stabilization. The higher the filtering level is the longer stabilization time is needed. Return to weighing: See - 11.2.2. 13.2. Median filter This filter eliminates short changes (impulses) of measure signal (e.g. shocks). Procedure: Enter the submenu <P1.rEAd>... -

Page 23: Autozero Function

13.3. Autozero function The autozero function has been implemented in order to assure precise indications. This function controls and corrects „0” indication. While the function is active it compares the results continuously with constant frequency. If two sequentional results differ less than the declared value of autozero range, so the scale will be automatically zeroed and the pictograms will be displayed. -

Page 24: Tare Function

13.4. Tare function This parameters enables users to configure a tare function. Procedure: Enter the submenu <P1.rEAd> and then: tArA AtAr automatic tare function on and is stored in balance memory after unplugging it from mains (Description of function operating point 16.6 automatic tare) tArA automatic tare function off (user can turn on operating of automatic tare F6 AtAr –... -

Page 25: Rs 232 Parameters

14. RS 232 PARAMETERS External devices connected to RS 232C have to be supplied from the same mains and common electric shock protection. It prevents from appearing a potential difference between zero leads of the two devices. This notice does not apply to the devices that do not use zero leads. Transmission parameters: Baud rate - 2400 –... -

Page 26: Minimal Mass Threshold

immediate printout Pr_n noStAb (not accessible in verified scales) sending stable results Pr_n StAb Pr_n rEPL automatic operation continuous transmission in basic unit Pr_n CntA Pr_n Cntb continuous transmission in present unit Return to weighing: see 11.2.2. 14.2. Minimal mass threshold This function is necessary while working with automatic tare or automatic operation or weighing animals. -

Page 27: Baud Rate

Return to weighing: see 11.2.2. 14.3. Baud rate Procedure: Enter the submenu <P2.Prnt> and then: - 27 -... -

Page 28: Serial Transmission Parameters

Return to weighing: see 11.2.2. 14.4. Serial transmission parameters Procedure: Enter the submenu <P2.Prnt> and then: 7d2SnP - 7 data bits; 2 stop bits, no parity control 7d1SEP - 7 data bits; 1 stop bit, EVEN parity control 7d1SoP - 7 data bits; 1 stop bit, ODD parity control 8d1SnP - 8 data bits;... -

Page 29: Other Parameters

15. OTHER PARAMETERS The user can set parameters which influence the scale operation. They are gathered in the submenu <P5.othr> e.g. backlight and beep signal. Enter this submenu <P5.othr> according to chapter 11.2. 15.1. Backlight function Program recognises the way the scale is supplied (mains, battery) and automatically selects the way of operating on the backlight: –... -

Page 30: Backlight For Supplying From Batteries

Return to weighing: See 11.2.2. Notice: When bl=Auto, and the indication has not changed for 10s, the backlight is automatically switched off. The backlight is switched on again automatically after the result changes. 15.1.2. Backlight for supplying from batteries The user can change the intensity of backlight from 0% to 100%. The lower the intensity is the longer the scale operates without recharging or exchanging batteries. -

Page 31: Beep" Signal - After Pressing A Key

15.2. “Beep” signal – after pressing a key Procedure: Enter the submenu <P5.othr> and then: bEEP - switched off bEEP YES - switched on Return to weighing: See 11.2.2. 15.3. Automatic switch-off This function is essential to save the battery power. The scale is switched off automatically when (function t1 = YES) no weighing appears in 5 minutes. -

Page 32: Batter Voltage Level Check

automatic enabling/disabling according to the source of power. Procedure: Enter the submenu <P5.othr> and then: Returnto weighing: See 11.2.2. 15.4. Battery voltage level check While supplying from batteries too low level of voltage is measured by software the pictogram is displayed. It means that charging or exchanging batteries is required. -

Page 33: Battery Discharge Pictogram

Procedure: After displaying the level of batteries (in per cents) the program returns to weighing. 15.4.2. Battery discharge pictogram The symbol (bat low) switches on when the voltage level drops to 18% of the accepted level of voltage. It means that charging or exchanging batteries is required. -

Page 34: Formatting Rechargeable Battery Packs

Message <nImh> appears on the display (for scales of WLC C1…C2, WLC/B1 series) or <SLA> (for scales of WLC/A2, WLC…/C/2 series), In case of damaging accumulators or lack of it the pictogram blinks quickly (period about 0.5 sec). Notice: WLC C1…C2 and WLC/B1 scales are equipped with NiMH batteries packs, R6 (AA) size and Power adapters for supplying from mines. -

Page 35: Operation Modes

Procedure: 1. Supply the indicator from mains, 2. Charge batteries for 12 hours (time of charging 2200mAh batteries), 3. After 12 hours unplug from mains, 4. Use the device up to the moment of self powering down, 5. Repeat the process of charging starting from point 1. Notice: They reach their optima capacity after three cycles of full charging and discharging. -

Page 36: Selecting Quantity Of Operation Modes

Return to weighing: See 11.2.2. 16.2. Selecting quantity of operation modes This function enables user to set if ,after pressing key, all operating modes will be accessible (ALL) or only one from the list chosen and used by operator. Procedure: Enter the submenu <P4.Func>... -

Page 37: Counting Pieces Of The Same Mass

16.3. Counting pieces of the same mass Standard solution is equipped with option of counting small pieces of the same mass. Counting pieces does not operate with other scale functions. It is possible to execute a tare function in this operating mode in order to tare a container value. - Page 38 Using enter the required sample quantity, - selection of digit position, - setting the digit, where: Confirm the value by pressing You will see <LoAd> on the display and then: If weighing is performed in a container put the container on the pan first and then tare it.

-

Page 39: Control Referring To The Inscribed Standard Mass

Return to weighing: Press the key twice. 16.4. +/- control referring to the inscribed standard mass Procedure: Enter to <HiLo> function: The program enters the window of setting the lower threshold of weighing (Min): The inscribed value confirm by pressing , the program will automatically go to the higher threshold of weighing (Max): - 39 -... -

Page 40: Control Of % Deviation Referring To The Inscribed Standard Mass

The inscribed value confirm by pressing , the program will automatically go to the main window, During setting threshold values following cases take place: Notice: If a user erroneously enters a value of the lower threshold higher than the upper one, the scale will indicate an error message and will return to weighing. -

Page 41: Standard Mass Determined By Its Weighing

16.5.1. Standard mass determined by its weighing Procedure: Enter to <PrcA> function: You will see <LoAd> on the display and then: place an load on the pan which mass will be accepted as standard, press to confirm this operating mode, after few seconds the indication 100,00% will be displayed, From this moment display will not indicate mass of weighed load but deviation of load mass placed on the pan referring to the mass... -

Page 42: Mass Of Standard Inscribed To Scale Memory

16.5.2. Mass of standard inscribed to scale memory Procedure: Enter to <PrcB> function: Program wagowy przejdzie do wy wietlania okna: Using set standard mass, where: - digit selection, - digit setting, Confirm the entered value by pressing You will see the indication equal to 0,000%, From this moment display will not indicate the mass of weighed load but deviation of the load mass placed on the pan referring mass of standard (in %). -

Page 43: Automatic Tare

16.6. Automatic tare This function is useful for fast net mass determination of weighed load in case when tare value of is different for each load. In case when the function is active the cycle of scales operating looks as follows: press zeroing key when the pan is empty, place the container for pieces, when indication is stable automatic tarring of the container mass will... -

Page 44: Measurement Of Maximal Force On The Pan - Latch

16.7. Measurement of maximal force on the pan – latch Procedure: Enter to <toP> function: Confirmation of choice of <toP> function is indication of the Max pictogram: Apply a force to the weighing pan, The display of scale will latch the maximum value of the force, Remove loads from the pan, Before the next measurement press the key. -

Page 45: Enabling The Work Mode

16.8.1. Enabling the work mode Procedure: Enter to <Add> function: A letter „P” in the left side of the display is a confirmation that <Add> function have been selected: 16.8.2. Totalizing procedure Enter <Add> function according to ch. 16.8.1, Put the first load on the pan. If the weighing procedure is performed in a container put the container on the pan first and tare it. -

Page 46: Memory Of The Last Value Of Sum Of Weighed Goods

Take off the load from the pan, indication returns to ZERO and the letter „P” in the left part of the display appears, Put the next load on the pan, After stabilizing press , the sum of first and second weighing will appear on the display, the „... -

Page 47: Return To Weighing

- In order to continue the procedure press , the indication returns to ZERO and the letter „P” appears in the left part of the display. The scale is ready for weighing, - In order to terminate the previous totalizing procedure press key, , or . -

Page 48: Weighing Animals

16.9. Weighing animals Procedure: Enter to <AnLS> function: The <tinnE> message appears on the display for 1s, and then the program goes to the window of setting the duration time (in seconds) of the animal weighing process: Confirm the selected value by pressing You will see the following window: - 48 -... -

Page 49: Tare Memory

Load an animal to the platform, After exceeding the -LO- value (see 14.2), program starts the weighings process. The appearance of subsequent hyphens < - - - - - - - > showing the progress, After completing the process of weighings the result is latched on the display and additionally the OK pictogram is shown in the upper part of the display: You can start the procedure of weighing animals again by... - Page 50 The program goes to displaying the first value from the selection of tare values <tArE 0> (press to chose different values): After selecting the right position press and you will see an editing field: Enter the selected tare value to the scale memory - 50 -...

-

Page 51: Selecting A Tare Value From The Memory

The program returns to the following window: Return to weighing: Press 16.10.2. Selecting a tare value from the memory Enter <tArE> function according to the ch. 16.10.1 of the manual, The program goes to displaying the first value from the selection of tare values <tArE 0>... -

Page 52: Sca E Calibration

17. SCALE CALIBRATION In precise scales changes of gravitational acceleration have noticeable influence. The gravitational acceleration changes with altitude and latitude. Every scale has to be adjusted to the place of use especially when the place changes. Frequent calibration also prevents weighing process from the influence of humidity and temperature. -

Page 53: Manual Internal Calibration

17.1.1. Manual internal calibration Procedure: While in weighing mode press The scale program starts to check stability conditions for the calibration process and displays the following message: Then the program automatically goes to the internal calibration procedure which is signalled by the following message: After completion of the calibration process program returns to the weighing mode, Calibration process can be terminated anytime by pressing... -

Page 54: Automatic Internal Calibration

17.1.2. Automatic internal calibration The automatic calibration process can be triggered off by 3 different factors: Calibration after powering up After performing the start procedure the scale program starts to check stability conditions for the calibration process and displays the following message: Then the program automatically goes to the internal calibration procedure which is signalled by the following message: After completion of the calibration process program returns... - Page 55 Then the program automatically goes to the internal calibration procedure which is signalled by the following message: After completion of the calibration process program returns to the weighing mode. Calibration triggered off by timer The time condition for subsequent automatic calibration is 3 hours.

- Page 56 After completion of the calibration process program returns to weighing mode. Calibration process can be terminated anytime by pressing which is signalled by the following message on the display: Notice: 1. It should be remembered that internal calibration should be performed with unloaded pan with keeping possibly constant ambient conditions.

-

Page 57: External Calibration

17.2. External calibration Option only for non-verified scales Not accessible in WLC…/C/2 scales of WLC series Procedure: Enter submenu <P6.CAL> and then: Following messages will be displayed: During this time start mass is adjusted, and after completing the procedure calibration weight mass is displayed (e.g. 3.000kg), Place the required weight on the pan, Calibration process starts automatically after placing the adequate weight that is signalled by the following message:... -

Page 58: Start Mass Adjustment

The completion of the calibration procedure is signalled by the following message: Take off the weight from the pan, the message <donE> is displayed for 1s and the program returns to the calibration submenu: Calibration process can be terminated anytime by pressing which is signalled by the following message on the display: Return to weighing with saving changes that have been made. - Page 59 Procedure: Enter submenu <P6.CAL> and then: The following messages are displayed: The new start mass is adjusted and returns to the submenu: The process of start mass adjustment can be terminated by pressing , which is signalled on the display: Return to weighing with saving changes that have been made.

-

Page 60: Cooperation With Printer

18. COOPERATION WITH PRINTER Each time the key is pressed a current mass value together with mass units is sent to RS 232 interface. Depending on setting of STAB parameter it can be printed out with temporary or stable value. Depending on setting of REPL parameter, printout will be automatic or manual. -

Page 61: Cooperation With Computer

19. COOPERATION WITH COMPUTER Sending weighing results to the computer can be done: - manually after pressing key, - in continuous way after function activating or sending an appropriate command, - automatically After stabilizing the indication - on the request from the computer After sending a control command These scales can cooperate with „EDYTOR WAG”... -

Page 62: Communication Protocol

20. COMMUNICATION PROTOCOL 20.1. General information A. A character protocol scale-terminal has been designed for communication between RADWAG scales and external devices via RS-232 interface. B. It consists of commands sent from an external device to the scale and a responses from a scale. C. -

Page 63: Respond Message Format

20.3. Respond message format After sending a request message you can receive: XX_A CR LF command accepted and in progress XX_D CR LF command completed (appears only after XX_A) XX_I CR LF command comprehended but cannot be executed command comprehended but time overflow error appeared XX _ ^ CR LF XX _ v CR LF command comprehended but the indication below the... -

Page 64: Send The Stable Result In Basic Unit

- command accepted and in progress T_A CR LF - command comprehended but tare range overflow appeared T_v CR LF T_A CR LF - command accepted and in progress - time limit for stable result exceeded T_E CR LF - command comprehended but cannot be executed T_I CR LF 20.4.3. -

Page 65: Send The Stable Result In Current Unit

Frame format: 7-15 space stability space sign mass space unit Example: S I CR LF – computer command S I _ ? _ _ _ _ _ _ _ 1 8 . 5 _ k g _ CR LF - command done, mass value in basic unit is returned immediately. -

Page 66: Switch On Continuous Transmission In Basic Unit

- command comprehended but cannot be executed SUI_I CR LF SUI_A CR LF - command accepted and in progress - mass value in current unit is returned immediately MASS FRAME Frame format: 7-15 stability space sign mass space unit Example: S U I CR LF –... -

Page 67: Switch On Continuous Transmission In Current Unit

20.4.9. Switch on continuous transmission in current unit Syntax: CU1 CR LF Possible answers: - command comprehended but cannot be executed CU1_I CR LF CU1_A CR LF - command comprehended and in progress - mass value in current unit is returned MASS FRAME Frame format: 7-15... -

Page 68: Manual Printouts / Automatic Printouts

20.5. Manual printouts / automatic printouts Users can general manual or automatic printouts from the scale. Manual printouts can be performed after loading the pan and stabilizing indication by pressing Automatic printouts can be performed only after loading the pan and stabilizing indication. -

Page 69: Continuous Transmission

20.6. Continuous transmission The indicator can work in a continuous transmission mode. It can be switched on or off in parameters or using RS232 commands. The frame format sent by the indicator in case of setting <P2.Prnt> to CntA: 7-15 space stability space... -

Page 70: Error Commands

21. ERROR COMMANDS - Value beyond the zero range Err2 - Value beyond the tare range Err3 Err4 - Calibration mass or start mass beyond the acceptable range ( 1% for weight, 10 for start mass) - Mass of a single piece lower than the scale division Err5 Err8 - Exceeded the time for tarring, zeroing, start mass... -

Page 71: Technical Parameters

23. TECHNICAL PARAMETERS 23.1. Precisions scales of WLC series Scale type: 1/A2 2/A2 6/A2 10/A2 20/A2 Max capacity 10kg 20kg Readability 0,01g 0,1g Range of tare -1kg -2kg -6kg -10kg -20kg Repeatability 0,03g 0,3g Linearity ±0,03g ±0,3g Stabilization time 3 sec Pan size 195 ×... -

Page 72: Verified Precise Scales Of Wlc Series

23.2. Verified precise scales of WLC series Scale type: 0,6/B1 1,2/B1 1,2/3/A2 3/6/A2 6/12/A2 Max capacity 0,6kg 1,2kg 1,2/3kg 3/6kg 6/12kg Readability 0,01g 0,02g 0,02/0,05g 0,05/0,1g 0,1/0,2g Range of tare 0,6kg 1,2 kg 3 kg 6 kg 12kg Repeatability 0,01g 0,02g 0,02/0,05g 0,05/0,1g... -

Page 73: Precise Scales Of Wlc

23.3. Precise scales of WLC…/C/2 series Scale type: WLC 1/A2/C/2 Max capacity Readability 0,01g Range of tare -1kg Repeatability 0,03g Linearity ±0,03g Stabilization time 3 sec Pan size 195 × 195mm Operation temperature +15°C to +30°C Supply 230V AC 50Hz / 11V AC, internal accumulator 6V... -

Page 74: Additional Equipment

24. ADDITIONAL EQUIPMENT P0136 KAFKA printer cable for PUE C/31 indicators P0151 EPSON printer cable P0108 Computer cable - 74 -... - Page 75 - 75 -...

Need help?

Do you have a question about the WLC 1/A2 and is the answer not in the manual?

Questions and answers