Summary of Contents for Yazoo/Kees ZMMKW34170

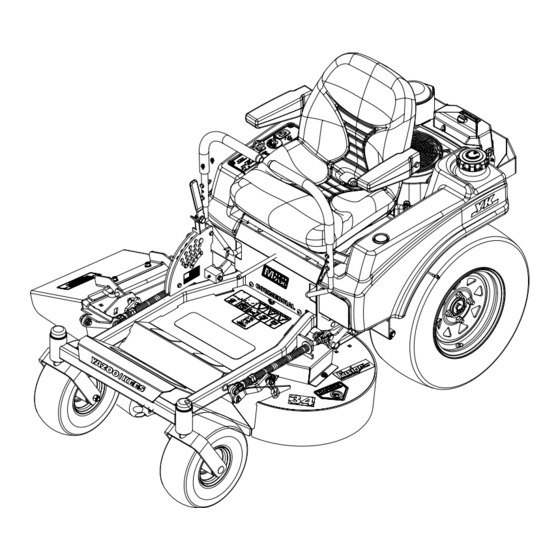

- Page 1 Operator's Manual ZMMKW34170 / 968999757 Please read the operator’s manual carefully and make sure you understand the instructions before using the machine. English...

- Page 2 WARNING! Failure to follow cautious operating practices can result in serious injury to the operator or other person. The owner must understand these instructions to operate the mower. Each person operating the mower must be of sound mind and body and must not be under the infl uence of any mind altering substance.

-

Page 3: Table Of Contents

CONTENTS INTRODUCTION ........... 4 MAINTENANCE .......... 30 Congratulations ........4 Maintenance Schedule ......30 General ........... 4 Battery ..........32 Driving and Transport on Public Roads .. 4 Ignition System ........33 Towing ............ 4 Safety System ........33 Operating ..........4 Fuel Filter .......... -

Page 4: Introduction

INTRODUCTION Congratulations Thank you for purchasing a Yazoo/Kees ride-on mower. This machine is built for superior effi ciency to rapidly mow in confi ned areas. A control panel easily accessible to the operator and a hydrostatic transmission regulated by steering controls both contribute to the machine’s performance. -

Page 5: Good Service

INTRODUCTION Good Service Yazoo/Kees’ products are sold only in specialized retail stores with complete service. This ensures that you as a customer receive only the best support and service. Before the product is delivered, the machine has, for example, been inspected and adjusted by your retailer. See the certifi cate in the Service Journal in this operator’s manual. -

Page 6: Symbols And Decals

SYMBOLS AND DECALS These symbols are found on the machine and in the operator’s manual. Study them carefully so that you know what they mean. WARNING! Xxxx xxxxxx xxxxx xxxx xxxxxxxxx xxxxxx xxxxxxxxx. xx xxxxxxxx xxxx xxxxxx. Used in this publication to notify the reader of a risk of personal injury or death, particularly if the reader should neglect to follow instructions given in the manual. - Page 7 SYMBOLS AND DECALS Read Shut off engine and Keep a safe Use on slopes No passengers Operator’s remove key before distance from no greater Manual performing any the machine than 10° maintenance or repair work Whole body Severing of fi ngers Do not open or Careful backing up, Careful going...

-

Page 8: Safety

SAFETY These instructions are for your safety. Read them carefully. WARNING! This symbol means that important safety instructions need to be emphasized. It concerns your safety. IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH. - Page 9 SAFETY • Disengage blades when not mowing. Shut off engine and wait for all parts to come to a complete stop before cleaning the machine, removing the grass catcher, or unclogging the discharge guard. • Operate machine only in daylight or good artifi...

-

Page 10: Personal Safety Equipment

SAFETY Personal Safety Equipment WARNING! When using the machine, approved personal protective equipment (shown in illustrations) shall be used. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your retailer for help in choosing the right equipment. - Page 11 SAFETY • Do not use on steep slopes. • Do not try to stabilize the machine by putting your foot on the ground. • Do not mow near drop-offs, ditches, or embankments. The machine could suddenly roll over if a wheel is over the edge or if the edge caves in.

- Page 12 SAFETY WARNING! The engine must not be started when the driver’s fl oor plate or any protective plate for the mower deck’s drive belt is removed. Safe Handling of Gasoline To avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely fl...

-

Page 13: General Maintenance

SAFETY General Maintenance • Never operate machine in a closed area. • Keep all nuts and bolts tight to be sure the equipment is in safe working condition. • Never tamper with safety devices. Check their proper operation regularly. • Keep machine free of grass, leaves, or other debris buildup. - Page 14 SAFETY • Ensure that nuts and bolts, especially the fastening bolts for the blade attachments, are properly tightened, torqued and that the equipment is in good condition. • Do not modify safety equipment. Check regularly to be sure it works properly. The machine must not be driven with defective or unmounted protective plates, protective cowlings, safety switches, or other protective...

-

Page 15: Transport

Follow a regular schedule in maintaining, the operator. caring for and using your mower. • Follow the instructions under “Maintenance” A spark arrester for the muffl er is available through and “Storage” sections of this owner’s your authorized Yazoo/Kees dealer. manual. English... -

Page 16: Controls

Recommended air pressure is 15 psi (1 bar). Tracking must be checked on a fl at and level concrete or blacktop surface. If unit still does not track straight, contact a Yazoo/Kees dealer for adjustment. 8011-791 1. -

Page 17: Seat Adjustment Lever

CONTROLS Seat adjustment lever The seat can be adjusted lengthways. When making adjustments, sit on the seat. Slide the lever to the side and maneuver seat to appropriate placement and release lever. Refueling 8050-165 The machine has one fuel tank, just behind the seat. Seat adjustment The tank capacity is 4.5 gallons (17 liters). -

Page 18: Hour Meter

CONTROLS Hour Meter The hour meter displays the total operating time. It will fl ash CHG OIL (Change Oil) at 50 hour intervals. The fl ash duration is one hour before and one hour after the interval. The CHG OIL icon will come on and shut off automatically. -

Page 19: Blade Switch

CONTROLS Blade switch In order to engage the mower deck, pull the knob out; the mower blades are disengaged when the knob is depressed. 8058-018 Blade switch Circuit breaker The circuit breaker provides protection for the electrical system by (1) 15 amp circuit breaker. If the circuit breaker trips, push the button to reset. -

Page 20: Mower Deck Cut Height Lift Lever

CONTROLS Mower Deck Cut Height Lift Lever Located to the right and front of the operator, the lift lever controls the cutting height. The deck cutting height is obtained by pressing the foot pedal forward to lift the deck. To lower the deck, apply pressure to the top side of the foot pedal and allow it to pivot while depressing the trigger and moving the lever forward. -

Page 21: Operation

OPERATION Operation Read “Safety Instructions” section and following pages, if you are unfamiliar with the machine. Training Zero turn mowers are far more maneuverable than typical riding mowers due to their unique steering capabilities. We suggest that this section be reviewed in its entirety prior to attempting to move the mower under its own power. -

Page 22: Before Starting

OPERATION Before Starting • Read the sections Safety Instructions and Controls before starting the machine. • Perform the daily maintenance before starting (see Maintenance Schedule in the Maintenance section). • Check that there is suffi cient fuel in the fuel tank. - Page 23 OPERATION • Move the steering controls outward to the locked (outer) neutral position. WARNING! Engine exhaust and certain vehicle components contain or emit chemicals considered to cause cancer, birth defects or other reproductive system damage. The engine exhaust contains carbon monoxide, which is a odorless, colorless, 8050-777 poisonous gas.

-

Page 24: Engine With Weak Battery

OPERATION To start an engine with a weak battery WARNING! Lead-acid batteries generate explosive gases. Keep sparks, fl ame and smoking materials away from batteries. Always wear eye protection when around batteries. If your battery is too weak to start the engine, it should be recharged. -

Page 25: Running

OPERATION Running 1. Release the parking brake by moving the lever downward. Your mower is equipped with an operator presence system. When the engine is running, any attempt by the operator to leave the seat without fi rst setting the parking brake will shut off the engine. -

Page 26: Operating On Hills

OPERATION Operating on hills Read the Safety Instructions “Driving on Slopes” in the “Safety Instructions”. WARNING! Do not drive up or down hills with slopes greater than 10 degrees. Do not drive across slopes. • The slowest speed possible should be used before starting up or down hills. -

Page 27: Mowing Tips

OPERATION Mowing Tips WARNING! • Observe and fl ag rocks and other fi xed objects to avoid collisions. Clear the lawn of stones and • Begin with a high cutting height and reduce other objects that can be thrown it until the desired mowing result is attained. out by the blades. -

Page 28: Stopping The Engine

OPERATION Stopping the Engine Allow the engine to idle a minute in order to attain normal operating temperature before stopping it, if it has been worked hard. Avoid idling the engine for longer periods, as there is a risk of the spark plugs fouling. -

Page 29: Moving By Hand

OPERATION IMPORTANT INFORMATION Before pushing or towing tractor, transmission dump valves must be opened and park brake released. The tractor should never be pulled at more than 2 miles per hour (3.2 km/h) or for distances over ¼ mile (.402 km). Trailer the unit for distances over ¼... -

Page 30: Maintenance

MAINTENANCE Maintenance Schedule The following is a list of maintenance procedures that must be performed on the machine. For those points not described in this manual, visit an authorized service workshop. An annual service carried out by an authorized service workshop is recommended to maintain your machine in the best possible condition and to ensure safe operation. - Page 31 MAINTENANCE Daily Weekly At Maintenance Interval Least In Hours Once Each Year Before After Maintenance Check/adjust throttle cable Check the condition of belts, belt pulleys, etc. Change the engine oil Replace the engine oil fi lter Clean/replace the spark plugs Replace the air fi...

-

Page 32: Battery

MAINTENANCE Battery Always use protective glasses Your mower is equipped with a maintenance free when handling the battery. battery and does not need servicing. However, periodic charging of the battery with an automotive type battery charger will extend its life. •... -

Page 33: Ignition System

MAINTENANCE Ignition System IMPORTANT INFORMATION The engine is equipped with an electronic ignition Fitting the wrong spark plug type can system. Only the spark plug requires maintenance. damage the engine. For recommended spark plug, see Technical Data. 1. Remove the ignition cable boot and clean Inadequately tightened spark plug can around the spark plug. - Page 34 MAINTENANCE Checking the Engine’s Cooling Air Intake Check that the engine’s cooling air intake is free from leaves, grass, and dirt. If the cooling air intake is clogged, engine cooling deteriorates, which can lead to engine damage. 8011-625 Check and clean the cooling air intake Checking and Adjusting the Throttle Cable Check that the engine responds to throttle increases and that a good engine speed is attained at full...

- Page 35 MAINTENANCE Replacing the Air Filter If the engine seems weak or runs unevenly, the air fi lter may be clogged. If run with a dirty air fi lter, the spark plugs can become fouled, disrupting operation. For this reason, it is important to replace the air fi lter regularly (see the heading Maintenance Schedule for the proper service interval).

-

Page 36: Fuel Filter

MAINTENANCE IMPORTANT INFORMATION! Do not use compressed air to clean the air fi lter. Do not wash the paper fi lter. Do not oil the paper fi lter. 4. Tap the paper fi lter against a fi xed surface to remove dust. -

Page 37: Fuel Pump Air Filter

Visually check that no damage is found on the lever, linkages, or switch belonging to the parking brake. Perform a stand still test and check that there is a braking action. To adjust the parking brake, contact the Yazoo/Kees service workshop. 8050-773 English... -

Page 38: V-Belts

MAINTENANCE Checking the V-belts Deck belt Inspect every 50 hours of operation. Check for severe cracking and large nicks. NOTE: The belt will show some small cracks in normal operation. Belt tension is manually adjustable. Turn bolt on deck eyebolt to adjustment tension. NOTE: Belt defl... -

Page 39: Pump Belt

MAINTENANCE Pump Belt Replacing pump belt Park the mower on a level surface. Engage the parking brake. Belt removal Remove the deck belt (see Deck Belt Removal in this section of the manual). Remove clutch stop to access the belt. Disconnect clutch wire. - Page 40 27-35 ft/lb (35-45 Nm) 3. Cutter housing 4. Blade bolt IMPORTANT INFORMATION 5. Lockwasher Special blade bolt is heat treated. Blade attachment Replace with a Yazoo/Kees bolt if required. Do not use lower grade hardware than specifi ed. English...

-

Page 41: Mower Deck

MAINTENANCE Adjusting the Mower Deck WARNING! Before performing any service or adjustment, check the following list: 1. Engage the parking brake. 2. Place the blade switch in the disengaged position. 3. Turn ignition switch to “OFF” position and remove the key. 4. -

Page 42: Nose Roller

MAINTENANCE 3. Turn both outer blades to align with the deck in front-to-rear manner. Reposition rear mounting bolts up or down until rear of mower deck is positioned level to " higher in the rear than the side-to-side measurement. 4. Confi rm measurements once again. Blade tips should be level in a side-to-side manner. -

Page 43: Cleaning And Washing

MAINTENANCE Cleaning and Washing Regular cleaning and washing, especially under the mower deck, will increase the machine’s lifespan. Make it a habit to clean the machine directly after use (after it is cooled), before the dirt sticks. Do not spray water on the top of the mower deck. Use compressed air to clean the top side of mower deck. -

Page 44: Lubrication

LUBRICATION 8011-672-3 12/12 Every year Lubricate with grease gun Lubricate with oil can 1/52 Every Week Oil change Level check 1/365 Every day Filter change *Change transaxles (transmission) fi lters. General Remove the ignition key to prevent unintentional Wipe away excess grease after lubrication. movements during lubrication. - Page 45 LUBRICATION Lubricating the Cables If possible, grease both ends of the cables and move the controls to end stop positions when lubricating. Refi t the rubber covers on the cables after lubrication. Cables with sheaths will bind if they are not lubricated regularly. If a cable binds, it can disrupt operation.

- Page 46 LUBRICATION Deck outer spindle Lubricate using a grease gun, one zerk, each side 2-3 strokes. Use only good quality bearing grease. Engine Oil Changing the Engine Oil The engine oil should be changed for the fi rst time 8011-733 after 5-8 hours of operation. Thereafter, it should be Deck outer spindle (belt shield removed) changed every 50 hours.

- Page 47 LUBRICATION Checking the Oil Level Check the oil level in the engine when the machine is standing level and the engine is stopped. Remove the dipstick, wipe it clean, and then replace it. The dipstick should be screwed into place. Take the dipstick out again and read the oil level.

-

Page 48: Troubleshooting

TROUBLESHOOTING Problem Cause The engine will not start. • The blade switch is engaged. • The steering controls are not locked in the neutral position. • The driver is not sitting in the driver’s seat. • The parking brake is not activated. •... - Page 49 TROUBLESHOOTING Problem Cause The engine overheats. • Clogged air intake or cooling fi ns. • Engine overloaded. • Poor ventilation around engine. • Defective engine speed regulator. • Too little or no oil in the engine. • Fouled spark plugs. Battery not charging.

-

Page 50: Storage

Always use genuine Yazoo/Kees spare parts. with open fl ames, sparks, or a An annual check-up at an authorized service workshop pilot light such as in a boiler,... -

Page 51: Schematics

SCHEMATICS FRONT HALF OF WIRING HARNESS CODE COLOR BLUE BLUE WHITE WHITE WHITE WHITE WHITE WHITE WHITE RED/WHT RED/WHT YELLOW YELLOW YELLOW YELLOW YELLOW GREEN GREEN GREEN WHT/GRN WHT/GRN WHT/GRN WHT/GRN BROWN BROWN English... - Page 52 SCHEMATICS REAR HALF OF WIRING HARNESS CODE COLOR WHITE WHITE WHITE BLUE GREEN YELLOW D B C English...

-

Page 53: Technical Data

TECHNICAL DATA Engine Manufacturer Kawasaki Type 17 hp* Power Lubrication Pressure with oil fi lter 1.7 qt (1.6 liters) Oil capacity excl fi lter 1.9 qt (1.8 liters) Oil capacity incl fi lter Engine oil, Synthetic SAE 30, 10w-30/10w-40 SAE 5W-20 (winter) SF, SG, SH, SJ Engine oil, Mineral Class 87 octane minimum, 10% max. - Page 54 TECHNICAL DATA Equipment 34" Cutting width Cutting height 1.5" - 4.5" Uncut circle Number of blades Blade length 17.38" Nose rollers Standard Michigan Seat Hinged armrests Standard Electric clutch Blade engagement 7 gauge w/7 gauge skirts Deck construction Productivity Productivity 2.75 acres/hr Overall dimensions Weight...

-

Page 55: Accessories

TECHNICAL DATA Accessories Collection system Torque Specifi cations Engine crankshaft bolt 50 ft/lb (67 Nm) Deck pulley bolts 45 ft/lb (61 Nm) Lug nuts 75 ft/lb (100 Nm) Blade bolt 45-55 ft/lb (60-75 Nm) Standard ¼" fasteners 9 ft/lb (12 Nm) Standard "... -

Page 56: Conformity Certificates

CONFORMITY CERTIFICATES Conformity Certifi cates USA requirements Labels are placed on the engine and/or in the engine compartment stating that the machine will fulfi ll the requirements. This is also applicable to special requirements for any of the states, (California emission rules etc.). Do not remove any of these labels. -

Page 57: Service Journal

SERVICE JOURNAL Action Date, mtr reading, stamp, sign Delivery Service 1. Charge the battery. 2. Adjust the tire pressure of all wheels to 15 PSI (1 bar). 3. Mount the steering controls in the normal position. 4. Connect the contact box to the cable for the seat’s safety switch. - Page 58 SERVICE JOURNAL Action Date, mtr reading, stamp, sign After the First 5-8 Hours 1. Change engine oil. English...

- Page 59 SERVICE JOURNAL Action Date, mtr reading, stamp, sign 25-Hour Service 1. Check the engine air fi lter. 2. Sharpen/Replace mower blades if required. 3. Check the tire pressures. 4. Check battery with cables. 5. Lubricate according to lubrication chart. 6. Check/clean the engine’s cooling air intake. 7.

- Page 60 SERVICE JOURNAL Action Date, mtr reading, stamp, sign 50-Hour Service 1. Perform the 25-hour service. 2. Clean/replace the air cleaner’s fi lter cartridge (paper fi lter) (shorter intervals for dusty operating conditions). 3. Change engine oil. 4. Lubricate according to lubrication chart. 5.

- Page 61 SERVICE JOURNAL Action Date, mtr reading, stamp, sign 100-Hour Service 1. Perform the 25-hour service. 2. Perform the 50-hour service. 3. Change the engine oil fi lter. 4. Clean/replace the spark plugs. 5. Replace the fuel fi lter. 6. Clean the cooling fi ns on the engine and transmission. 7.

- Page 62 SERVICE JOURNAL Action Date, mtr reading, stamp, sign 300-Hour Service 1. Perform the 25-hour service. 2. Perform the 50-hour service. 3. Perform the 100-hour service. 4. Check/adjust the mower deck. 5. Clean the combustion chamber and grind the valve seats. 6.

- Page 63 SERVICE JOURNAL Action Date, mtr reading, stamp, sign At Least Once Each Year 1. Clean the engine’s cooling air intake (25 hours). 2. Replace the air cleaner’s pre-fi lter (foam) (300 hours). 3. Replace the air fi lter’s paper cartridge. 4.

- Page 64 SERVICE JOURNAL Action Date, mtr reading, stamp, sign English...

- Page 65 SERVICE JOURNAL Action Date, mtr reading, stamp, sign English...

- Page 66 SERVICE JOURNAL Action Date, mtr reading, stamp, sign English...

- Page 68 Part No. 539 132449 R1 11/13/07...

Need help?

Do you have a question about the ZMMKW34170 and is the answer not in the manual?

Questions and answers