Subscribe to Our Youtube Channel

Summary of Contents for Yazoo/Kees ZVKH61272

-

Page 1: Operators Manual

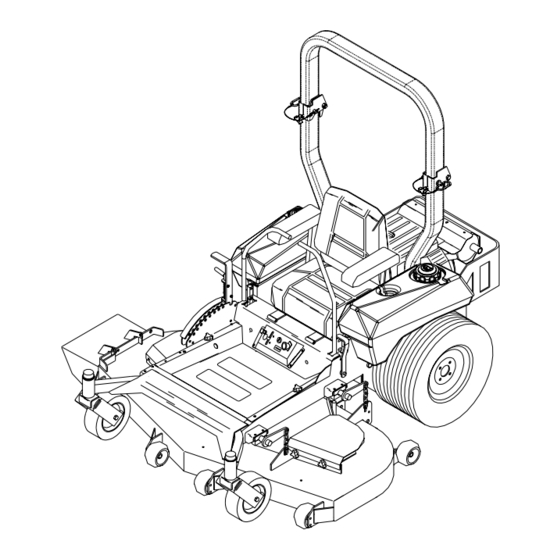

Models: Operators manual ZVKH61272 ZVKH72272 ZVKW52252 ZVKW61252 ZVHO61242 Please read these instructions carefully and make sure you understand them before using the machine. MANUAL NO. 110970 REV. IR (09/13/04) - Page 2 ©2004 Yazoo/Kees Power Equipment. All Rights Reserved. Beatrice, NE. Printed in U.S.A.

-

Page 3: Table Of Contents

CONTENTS INTRODUCTION ........4-5 OPERATING INSTRUCTIONS .... 19 SYMBOLS & DECALS ......6 Roll bar and seat belt ....19 SAFETY INSTRUCTIONS ....7 Starting and operation ....19 General use and safety rules ..7-8 Controls ........19-20 Driving on slopes ......9 MAINTENANCE ........ -

Page 4: Introduction

Introduction Congratulations Thank you for purchasing a Yazoo/Kees ride-on mower. This machine is built for the greatest efficiency and rapid mowing of large areas. Convenient controls and a hydrostatic transmission regulated by steering levers also contribute to the machine’s performance. -

Page 5: Introduction

INTRODUCTION Good Service Yazoo/Kees products are sold all over the world and only in specialized retail stores with complete service. This ensures that you as a customer receive only the best support and service. Before the product is delivered, the machine has, for example, been inspected and adjusted by your retailer, see the certificate in the Service Journal in this operator’s manual. -

Page 6: Symbols & Decals

SYMBOLS AND DECALS Symbols and Decals These symbols are found on the machine and in the operator’s manual. Study them carefully so that you know what they mean. WARNING! Xxxxxxxxxx xxx xxxxx xxxxxxxx. Xxxxxx xxxxx xxxxxxxxx xxxxx xxxxx xxx x xxxxx. Used in this publication to notify the reader of a risk of personal injury, particularly if the reader should neglect to follow instructions given in the manual. -

Page 7: Safety Instructions

SAFETY INSTRUCTIONS Safety Instructions These instructions are for your safety. Read them carefully. WARNING! This symbol means that important safety instructions need to be emphasized. It concerns your safety. General Use • Read all instructions in this operator’s manual and on the machine before starting it. Ensure that you understand them and then abide by them. - Page 8 SAFETY INSTRUCTIONS • Be careful when rounding fixed objects, so that the blades do not hit them. Never drive over WARNING! foreign objects. Engine exhaust and certain vehicle components contain or emit chemi- • Only use the machine in daylight or in other cals considered to cause cancer, well-lit conditions.

-

Page 9: Driving On Slopes

SAFETY INSTRUCTIONS Driving on Slopes Driving on slopes is one of the operations where the risk is greatest that the driver will lose control or the machine will tip over, which can result in serious injury or death. All slopes require extra caution. -

Page 10: Children Safety

SAFETY INSTRUCTIONS Children: • Serious accidents may occur if you fail to be on guard for children in the vicinity of the ma- chine. Children are often attracted to the ma- chine and mowing work. Never assume that children will stay put where you last saw them. •... - Page 11 SAFETY INSTRUCTIONS • Allow the engine to cool before refueling. Do not smoke. Do not fill fuel in the vicinity of WARNING! sparks or open flames. The engine, the exhaust system, • If leaks arise in the fuel system, the engine and the hydraulic system’s compo- must not be started until the problem has been nents become very warm during...

-

Page 12: Transportation

SAFETY INSTRUCTIONS • Never use the machine indoors or in spaces lacking proper ventilation. The exhaust fumes contain carbon monoxide, and odorless, poi- sonous, and lethal gas. • Stop and inspect the equipment if you run over or into anything. If necessary, make repairs before starting. -

Page 13: Rops Safety

SAFETY INSTRUCTIONS Roll Over Protection System WARNING! This structure’s capability may be imparired by structural damage if overturned, or al- teration occurs. If any of these conditions take place, the total structure MUST be re- placed. DO NOT use ROPS as a lifting, attaching or anchoring point. DO NOT exceed Max GVW: 2822;... -

Page 14: Presentation

PRESENTATION Presentation Thank you for buying a YAZOO/KEES! Before Lawnmowers and all power equipment, can be operating your new mower, read, understand potentially dangerous if used improperly. Safety and follow the safety instructions and other requires good judgement, careful use in accor- directions in this manual. -

Page 15: Setup And Adjustments

SETUP AND ADJUSTMENTS WARNING! No settings or adjustments are to be made unless: Engine is stopped, key has been removed, park brake is on and bat- 4. Torque all 1/2” hardware to 80 ft./lbs. (110 N•m). tery cable removed from battery. 5. -

Page 16: Control Arms

SETUP AND ADJUSTMENTS Control Arms Remove top bolt in control arm and loosen bot- tom bolt, rotate the control levers to the upright position. Align the levers so they are even in the neutral position. Reinstall hardware and tighten. FIG - 1 Control Motion Control... -

Page 17: Mower Deck Leveling

SETUP AND ADJUSTMENTS Loosen the nuts directly behind each ball joint on Mower Deck Leveling both rods that connect the pump arm to the mo- Position machine on a flat surface. Preferably level tion control assemblies. FIG - 5 concrete. Check the tire pressure in all four tires. -

Page 18: Park Brake Adjustment

SETUP AND ADJUSTMENTS Park Brake Adjustment When the park brake is on, the spring should If the 1/4” gap is not adjusted follow these step: measure 2 3/4” to2 7/8” and have a 1/4”-3/8” gap 1. Place the park brake in the off position. between the brake yoke and the washer on the 2. -

Page 19: Operating Instructions

OPERATING INSTRUCTIONS Operating instructions Roll Bar and Seat Belt By moving the levers an equal amount forward or Operate the unit with the roll bar in the raised and back the machine will move in a straight line in locked position and use seat belt. There is no rollover protection when the roll bar is down. - Page 20 OPERATING INSTRUCTIONS Key Switch Key switch is located on the console. Used to start the machine. NOTE: Do not run the starter for more than 5 seconds at a time. If the engine will Choke Throttle not start, wait about 10 seconds before trying again.

-

Page 21: Maintenance

Annual inspection and maintenance from an au- thorized Yazoo/Kees dealer is recommended to keep your machine in the best condition mechani- cally and ensures safe operation. Engine oil Should be checked daily before starting the ma- chine. -

Page 22: Hardware

MAINTENANCE Hardware Check daily. Inspect the entire machine for loose or missing hardware. ONLY USE Air filter See engine manufacturers specifications for cleaning and replacement intervals. Hydraulic system Tri-Synthetic Formula Check oil level in tank daily. Oil level should be 3/ 4”... -

Page 23: Pump Belt

MAINTENANCE Pump belt Check belt every 100 hours for excessive wear. the caster bolt off in 1/4 turn increments until wheel To replace belt. Relieve tension on the deck belt rotates freely. and remove deck belt from clutch. See deck belt NOTE: DO NOT add any type of tire liner or foam instructions on previous page. -

Page 24: Torque Specifications

MAINTENANCE Torque Specifications · Engine crankshaft bolt 67 Nm(50 ft/lb) · Deck pulley bolts 61 Nm (45 ft/lb) · Hydraulic tube nuts 41 Nm (30 ft/lb) · Wheel motor hub nut 122 Nm (90 ft/lb) · Lug nuts 100 Nm (75 ft/lb) ·... -

Page 25: Maintenance Schedule

MAINTENANCE Maintenance Schedule For ZTH Riders Maintenance Maintenance Interval (hours) Daily Engine (4) Check oil level Change oil and filter (1) Clean the air filter’s (3) Replace air filter’s (3) Check for fuel and oil leakage Clean cooling flanges (3) Check cooling air inlet Check fuel pump’s air filter Replace fuel filter... -

Page 26: Trouble Shooting

TROUBLE SHOOTING PROBLEM POSSIBLE CAUSES Blade switch on. Drive levers not in the neutral slots. Operator not in seat. ENGINE WILL NOT START. Park brake disengaged. Dead battery. Fuel valve closed or in the wrong position. No fuel. Spark plugs defective. Spark plug wires off. -

Page 28: Wiring Diagrams

WIRING DIAGRAMS... -

Page 29: Wiring Diagrams

WIRING DIAGRAMS...

Need help?

Do you have a question about the ZVKH61272 and is the answer not in the manual?

Questions and answers