Summary of Contents for Middleby Marshall PS520E

- Page 1 PS520-Series Electric Ovens:English installation & operation manual PS520-Series OVENS Model PS520E PS520 Single PS520 Triple PS520 Double Part No., 52358 ©2006 Middleby Marshall Inc. 090/6...

- Page 2 The warranty is NOT VALID unless the oven is installed, started, and demon- strated under the supervision of a factory-authorized installer Contact your authorized Service Agency to perform maintenance and repairs.

- Page 3 Middleby Marshall Inc. - 1400 Toastmaster Drive - Elgin, Illinois 60120-9272 - (847) 741-3300 - Fax: (847) 741-4406 MIDDLEBY MARSHALL INC. OVEN LIMITED WARRANTY (Non-U.S.A.) The Seller warrants equipment manufactured by it to be free from defects in material and workmanship for which it is responsible. The Seller’s ob- ligation under this warranty shall be limited to replacing or repairing, at Seller’s option, without charge, F.O.B.

-

Page 4: Table Of Contents

C. Conveyor Belt ... 17 D. Crumb Pan ... 17 II. MAINTENANCE - MONTHLY ... 18 A. Removing Conveyor From Oven For Cleaning ... 18 B. Air Fingers Disassembly For Cleaning ... 20 C. Reassembly of Air Fingers ... 21 D. -

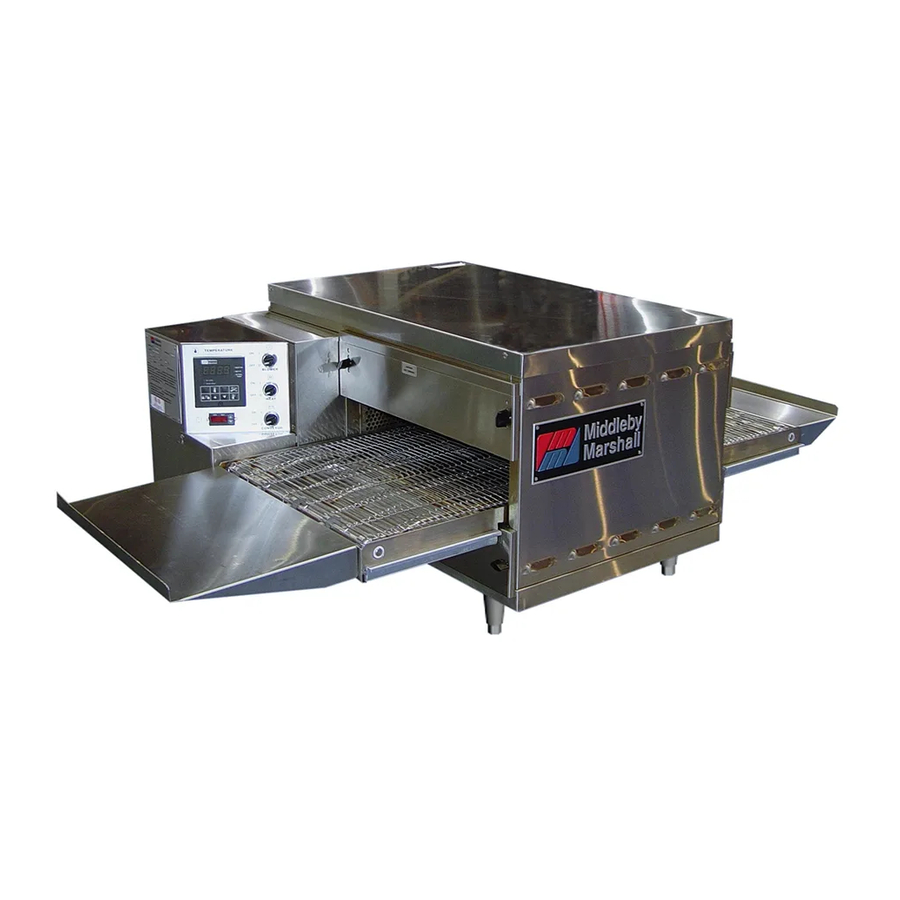

Page 5: Section 1 Description

DESCRIPTION I. MODEL IDENTIFICATION The Mideleby Marshall PS520-Series may be used either as a single oven or stacked for use as a double or triple ovens. A single PS520-Series Oven (Figure 1-1) is mounted on a base pad with legs. A double oven (Figure 1-2) consists of two, stacked, single ovens. -

Page 6: Series Ps520 Electrical Specifications

50/60 Hz Voltage 230-240V 1 Ph 50/60 Hz Voltage 3 Ph 50/60 Hz Voltage kW NOTE oven at the bottom of the control panel. 18.00” (457mm) 250 lbs (93.3kg) 8.3 kW/hr F (287 20 min. 1-10 minutes Amperage Poles Draw... -

Page 7: Component Function

B. Blower Fan The blower fans are located at the rear of the oven. These blowers force heated air through the air fingers. The BLOWER switch must be set to “ON” or “I” for oven warm- up and baking. -

Page 8: Section 2 Installation

0” to a left side wall, 18” to a right side wall and 6” from a back wall to air openings at the rear of the oven must be maintained. For servicing and cleaning, a minimum of 18”... -

Page 9: Parts List For Series Ps520 Electric Oven Installation Kit

PARTS LIST FOR SERIES PS520 ELECTRIC OVEN Item PART NO. 3101908 48392 48394 48396 51387 52358 59476 PARTS LIST FOR SERIES PS520 ELECTRIC OVEN Item PART NO. 48392 48394 48396 51387 M3828 52358 59476 INSTALLATION KIT Single and Double Stack Ovens... -

Page 10: Oven Dimensions - Single, Double, Triple

SECTION 2 INSTALLATION Figure 2-5. MODEL PS520 SINGLE OVEN DIMENSIONS Figure 2-6. MODEL PS520 DOUBLE OVEN DIMENSIONS Figure 2-7. MODEL PS520 TRIPLE OVEN DIMENSIONS The Opening Height is Adjustable from 2-1/4 inch minimum to 3-3/4 inch maximum in 1/2 inch... -

Page 11: Utility Rough In Dimensions And Positioning For Ps520 Series Ovens

240V control circuit and main blower motor, 2 pole, 3 wire system per oven (2 hot, 1 grd) •380V elements, 3 Ph, 21.8/21.8/1.2 Amp draw, 50/60 Hz, 5 pole, 4 wire system per oven (3 hot, 1 neut, 1 grd). •400V elements, 3 Ph, 23.0/23.0/1.2 Amp draw, 50/60... -

Page 12: Electrical Connection Information For Ps520-Series Ovens

‘C’ Channels. The “C” Channels are identical and once installed will allow ample amounts of air through the cooling fan mounted on the rear side of the oven by keeping the oven away from the rear wall. III. ELECTRICAL CONNECTION INFORMATION FOR PS520-SERIES OVENS. -

Page 13: Section 3 Operation

Never disassemble or clean the oven with the BLOWER switch or any other oven control turned “ON” or “I”. Turn “OFF” or “O” and lockout or tagout all electric power to the oven before attempting to clean or service the oven. -

Page 14: Component Functions

The blower switch has two positions. The switch must be “ON” or “I” for the main blowers to come on and permit the oven to run. The fan circulates the air throughout the oven and must stay on during baking and during the... -

Page 15: Conveyor

This should be the conveyor speed shown on the conveyor speed digital control. NOTE: In Figure 3-4 and 3-5, the oven shown is with the conveyor running left to right. WARNING A possibility of injury from rotating parts and electric shock exists in the oven. -

Page 16: Step-By-Step Operation

“ON” or “I”. The cooling fans cool the control components and blower motor. The cooling fans, located at the rear of the oven blows air into and through the cabinet. Air is exhausted through the front of the cabinet and also out the front of the oven. -

Page 17: Normal Operation - Step-By-Step

This allows you to monitor the oven tem- perature as it rises to the setpoint. Allow the oven to preheat for 10 minutes after it has reached the set point temperature. B. DAILY SHUTDOWN PROCEDURE Turn the “HEAT” and “BLOWER”... - Page 18 Lights when the set point is locked out from changes. This setting can only be changed by service personnel. OVERTEMP Light Lights when the oven temperature is greater than F (343 C). Refer to Quick Reference; Troubleshooting in this section.

-

Page 19: Quick Reference: Troubleshooting

IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN. PROBLEM • Follow the procedures under Daily Shutdown Procedures F (343 C), and in this section to shut down the oven. -

Page 20: Section 4 Maintenance

If the oven is to be removed from it’s installed location for servicing, perform the following procedure: 1. Switch off the oven and allow it to cool, DO NOT 2. Turn off main circuit breakers and disconnect 3. Move oven to desired location for servicing. -

Page 21: Maintenance - Daily

Crumb pan is extremely hot while oven is operating. Allow oven to cool before removing crumb pan. When oven is cool remove and clean the crumb pan at each end of the oven. Each crumb pan can be removed by sliding it out, as shown in Figure 4-2. Reinstall the crumb pans after cleaning. -

Page 22: Maintenance - Monthly

SECTION 4 MAINTENANCE II. MAINTENANCE - MONTHLY NOTE: The oven interior may require cleaning more than once a month depending on the volume of baking. To clean the interior , you have to disassemble some parts of the oven. When cleaning your PS520-Series Oven note the following: PRECAUTIONS- 1. - Page 23 Figure 4-4 Figure 4-5 5. Lift other side of conveyor and push toward other side. 6. Remove conveyor as shown. Figure 4-6 Figure 4-7 CAUTION Be careful no to bump the drive sprocket while handling the conveyor, to avoid damaging the drive shaft.

-

Page 24: Air Fingers Disassembly For Cleaning

Fingers are marked in the order shown; as viewed from the front of the oven. (The marks for an upper oven should be preceded with a “U”, example UB1, UT2, etc.) Standard Fingers 2. -

Page 25: Reassembly Of Air Fingers

6. To remove the inner plate, pull the plate out and then up. Figure 4-11 7. The outer finger plate is stainless steel and may be cleaned by either soaking in a hot, strong detergent solution or using a caustic cleaner. The conveyor belt can also be cleaned in the same way. - Page 26 SECTION 4 MAINTENANCE 4 . Replace the air fingers by pushing in at the back side. Remember to replace them according to the numbers marked on them when they were removed. They must go back in the same way they came out. IMPORTANT: When inserting fingers the tab on the outer plate must be in the groove as shown in Figure 4-18.

-

Page 27: Reinstall End Plugs

5. Install fingers and blank plates correctly with edges interlocked and no space between edges. Top Finger Tab on Outer Plate of Finger Located in Groove D. Reinstall End Plugs 1. Reinstall lower end plug. Be sure to tighten the wing screw on the end plug. 2. -

Page 28: Conveyor Reassembly Into Oven

1. Lift conveyor and position it in the oven as shown. NOTE: Conveyor may be inserted into either end of the oven. If it is ti be installed from the non-drive end of the oven the drive sprocket assembly must be removed as shown in conveyor disassembly section. -

Page 29: Conveyor Belt Link Removal

G. Conveyor Belt Link Removal 1. Using long nose pliers, an entire link can be removed with the conveyor assembly either in or out of the oven. Position master links at the end of the conveyor as shown in Figure 4-24. Master... -

Page 30: Attaching Drive Chain

Remember this hook travels backwards on the conveyor. Figure 4-30 7. Reconnect the outside master links. 8. Replace all parts removed from the oven. Figure 4-31 H. Attaching Drive Chain 1. If drive sprocket assembly was removed, reassemble it onto the conveyor drive shaft. Be sure flat on end of drive shaft aligns with set screw in conveyor shaft collar. -

Page 31: Maintenance - Every 3 Months

Figure 4- Figure 4-35 B. Ventilation Check that the air circulation throughout the oven is not blocked and is working properly. IV. MAINTENANCE - EVERY 6 MONTHS A. Check brushes on D.C. conveyor motor. When worn to less then 1/10”... -

Page 32: Key Spare Parts Kits

SECTION 4 MAINTENANCE PS520-SERIES ELECTRIC OVEN KEY SPARE PARTS KIT ITEM PART NO. 58504 51402 58390 58323 33812-5 50715 51017 51958 51961 57408 DESCRIPTION Kit, Temperature Control On/Off PID Relay, 100A Conveyor Drive Motor with 2 pole magnet Conveyor Speed control... -

Page 33: Section 5 Troubleshooting

TROUBLESHOOTING OVEN BLOWER AND CONVEYOR OPERATE, YET THE OVEN IS NOT HEATING Check for correct controller Start the oven again. If the oven still does not Turn temperature heat, call your Middleby Marshall Service Agency. control to correct setting. CONVEYOR WILL NOT HOLD PROPER... -

Page 34: Section 6 Electrical Schematics

SECTION 6 ELECTRICAL SCHEMATICS... -

Page 35: Wiring Diagram, E380-480V 50/60 Hz 1 Ph

SECTION 6 ELECTRICAL SCHEMATICS... -

Page 36: Wiring Diagram, E230-240V Ce, 1Ph

SECTION 6 ELECTRICAL SCHEMATICS... -

Page 37: Wiring Diagram, E380-400V Ce, 1Ph

SECTION 6 ELECTRICAL SCHEMATICS... -

Page 38: Wiring Diagram, E380-400V Ce, 3Ph

SECTION 6 ELECTRICAL SCHEMATICS... - Page 39 NOTES...

- Page 40 Equipment Service Association (CFESA). We recognize and applaud CFESA’s ongoing efforts to improve the quality of technical service in the industry. Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • USA • (847) 741-3300 • FAX (847) 741-4406 www.middleby.com...

Need help?

Do you have a question about the PS520E and is the answer not in the manual?

Questions and answers