Table of Contents

Advertisement

Operation

Pro Compact

- For portable spray applications of water-based architectural paints and coatings only -

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

Model 258861

Maximum Working Pressure 137 bar (13.7 MPa, 2000 psi)

Use only water-based materials. Do not use materials which state "FLAMMABLE" on the packaging. For

more information about your material, request MSDS from distributor or retailer.

Spraying certain materials may cause static build-up in the sprayer that can result in static shock to

the user. If this occurs, first ensure the material has a flash point greater than 100° F (38° C) and does not

state that it is FLAMMABLE anywhere on the package. If still feeling a static shock, the material likely con-

tains a non-mineral spirits fluid such as, but not limited to, xylene, toluene, or naphtha, which can build up

static. Switch to an alternative material.

™

A15 Cordless Paint Sprayer

- Not for use in explosive atmospheres -

WARNING

WARNING

WARNING

WARNING

3A0885E

EN

ti14773a

Advertisement

Table of Contents

Summary of Contents for Graco Magnum Pro Compact A15 258861

- Page 1 Operation ™ Pro Compact A15 Cordless Paint Sprayer 3A0885E - For portable spray applications of water-based architectural paints and coatings only - - Not for use in explosive atmospheres - IMPORTANT SAFETY INSTRUCTIONS Read all warnings and instructions in this manual.

-

Page 2: Table Of Contents

Install Tip/Guard Assembly Graco Standard Warranty ......28 (if not installed) ......12 Important User Information Read this before using your sprayer. -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual, refer back to these Warnings. - Page 4 Do not short-circuit the terminals of the battery. • Keep the battery away from fire. • Charge only with Graco approved charger as listed in this manual. • Do not expose to heat above 170° F (80° C). • Do not expose battery to water or rain.

-

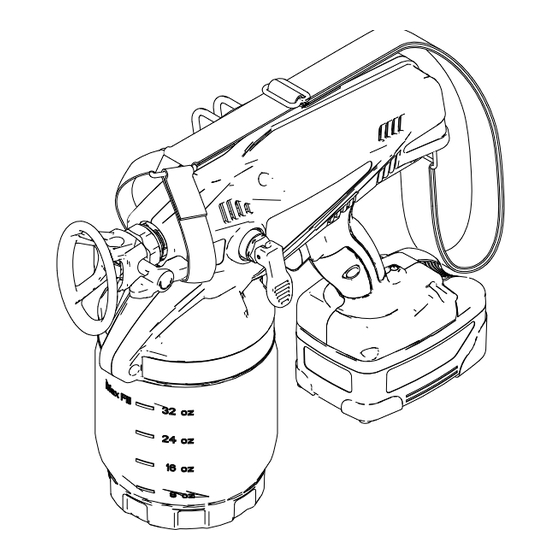

Page 5: Component Identification

Component Identification Component Identification ti15479a Lithium Ion Premium Power Battery Charger Pro Compact Cordless Paint Sprayer Material Cup Liners Sprayer Hook Shoulder Strap Spray Tip/Guard Assembly (311, 515 included) Lithium Ion Premium Power Battery (2 included) Tip Filter (*Reverse Threaded) Battery Release Button Standard Suction Tube Battery Status Indicator Light... -

Page 6: Common Procedures

Common Procedures Common Procedures Pressure Relief Procedure Spray Tip Position Do not operate or spray near children. Do not aim the Always perform Pressure Relief Procedure before sprayer at, or spray any person or animal. Keep hands adjusting spray tip position. and other body parts away from the front of the sprayer. -

Page 7: Charging The Battery

Batteries may leak, explode, cause burns or cause an explosion if mishandled. To reduce the risk of electric shock, only use Graco batteries with the Graco charger. Do not insert any Batteries are initially 50% charges to provide optimum foreign objects into the adapter cup. -

Page 8: Setup

Setup Setup Suction Tube Selection This sprayer comes with two different suction tubes. Standard Suction Tube (sprays ceilings and walls): When spraying walls, the inlet of the suction tube should be aimed at the front of the material cup. Use only water-based materials. Do not use materi- als which state “FLAMMABLE”... -

Page 9: Spraying Stains Or Clear Coats (Fine-Finish Optimizer)

Setup Spraying Stains or Clear Coats (Fine-Finish Optimizer) The Fine-Finish Optimizer should be installed and used 3. Push Fine-Finish Optimizer into pump inlet until when spraying thin material such as stain or clear coats. completely engaged and re-install suction tube. The Fine-Finish Optimizer restricts the material flow result- ing in a finer quality finish. -

Page 10: Sprayer Setup

Setup Sprayer Setup This sprayer arrives from the factory with a small 6. Unscrew and remove material cup. amount of test material in the system. It is important 7. Disengage trigger lock, put control valve DOWN, that you flush this material from the sprayer before hold sprayer slightly above material cup, and pull using it for the first time: trigger to discharge fluid from pump. - Page 11 Setup Materials 3. Install material cup liner, fill with material, and thread onto sprayer. ti15474a Use only water-based materials. Do not use materi- als which state “FLAMMABLE” on the packaging. For more information about your material, request MSDS from distributor or retailer. Spraying certain materials may cause static build-up in the sprayer that can result in static shock to the user.

-

Page 12: Install Tip/Guard Assembly

Install Tip/Guard Assembly (if not installed) Install Tip/Guard Assembly NOTICE The tip is a permanently attached to the guard. (if not installed) Removing the tip from the guard will result in damage to tip assembly. Reversible Tip Selection Chart Shoulder Strap Installation MATERIALS *Thin Medium... -

Page 13: Basic Spraying Techniques

Basic Spraying Techniques Triggering Sprayer Basic Spraying Techniques To achieve even spraying, pull trigger after starting the stroke. Release trigger before the end of the stroke. NOTE: Use a piece of scrap cardboard to practice these Sprayer must be moving when trigger is pulled and basic spraying techniques before you begin spraying the released. -

Page 14: Unclogging Spray Tip/Guard Assembly

Unclogging Spray Tip/Guard Assembly Unclogging Spray 4. Engage trigger lock. Put control valve UP to release pressure and rotate spray tip back to SPRAY posi- Tip/Guard Assembly tion. ti14994a ti14999a Do not operate or spray near children. Do not aim the sprayer at, or spray any person or animal. -

Page 15: Shutdown And Cleaning

Shutdown and Cleaning Shutdown and Cleaning 2. Remove material cup and properly dispose cup liner or excess material. NOTICE Failure to properly clean sprayer after each use will result in hardened materials, damage to the sprayer, and the warranty will no longer be valid. Flushing Sprayer 3. - Page 16 Shutdown and Cleaning 6. Disengage trigger lock and trigger sprayer for 10. Engage trigger lock and put control valve UP to approximately 15 seconds. Engage trigger lock. release pressure. ti14994a ti14999a ti14994 ti14994a 11. Remove material cup and discard used fluid. 7.

-

Page 17: Cleaning Sprayer Exterior

Storage Cleaning Sprayer Exterior 2. Thread cup into sprayer, put control valve to UP position and squeeze sprayer trigger for approxi- • Wipe paint off outside of sprayer using a soft cloth mately 10 seconds. moistened with water or flushing fluid. Do NOT submerge the sprayer. -

Page 18: Replacement Parts And Kits

Replacement Parts and Kits Replacement Parts and Kits ti15497a Ref. Part Description Ref. Part Description 16D799 Lithium Ion Battery Charger 262452 Sprayer, replacement (no tip, battery, suc- 16D560 Material Cup (1 L) cover and seal tion tube, or material cup) 16D561 Material Cup (1.5 L) cover and seal 16D562... -

Page 19: Troubleshooting

Troubleshooting Troubleshooting Check everything in this Troubleshooting Table before you bring the sprayer to an authorized service center. Problem Cause Solution Sprayer makes no sound when Trigger is locked. Disengage trigger lock. See page 6. trigger is pulled Status Indicator Light is solid RED when Replace with charged battery and place triggering, indicating that the battery old battery in charger or allow the battery... - Page 20 Troubleshooting Problem Cause Solution Sprays with poor results Tip is partially clogged See Unclogging Tip/Guard Assembly, page 14. Tip is not in correct position Rotate tip to SPRAY position. Incorrect tip for application of See Reversible Tip Selection Chart, material. page 12.

- Page 21 Troubleshooting Problem Cause Solution Spray pattern is too wide: Sprayer is too far away from target surface. Move sprayer closer to surface. Incorrect tip for application of material. See Reversible Tip Selection Chart, page 12. ti15527a Spray pattern “spits” at the end: Excess material has accumulated on Spray See Shutdown and Cleaning, page 15.

-

Page 22: Alternate Priming Method

Alternate Priming Method Alternate Priming Method 4. Hold sprayer above sink or waste area, disengage the trigger lock, and quickly trigger sprayer until material comes out of the drain tube. 1. Engage trigger lock and put prime/relief valve UP to release pressure. -

Page 23: Inlet Valve Cleaning

Inlet Valve Cleaning Inlet Valve Cleaning Removal 4. Clean as much excess material from pump cavity as possible. Make sure you also clean spring (a), o-ring 1. Engage trigger lock and pull relief valve UP to (c), and top of inlet fitting (d). release pressure. -

Page 24: Technical Data

Technical Data Technical Data Sprayer: Maximum working pressure 137.8 bar, 13.7 MPa (2000 psi) Weight 2.87 kg (6.32 lb) Dimensions: Length 33.6 cm (13.25 in.) Width 12.7 cm (5.0 in.) Height 26.4 cm (10.375 in.) Storage temperature range ◆❖ 0° to 50°C (32° to 122°F) Operating temperature range ✔... - Page 25 Notes Notes 3A0885E...

- Page 26 Notes Notes 3A0885E...

- Page 27 Notes Notes 3A0885E...

-

Page 28: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Magnum Pro Compact A15 258861 and is the answer not in the manual?

Questions and answers