Table of Contents

Advertisement

Checking Your Box

Receiving the box of your printer,

check first for the possible shipping damage. There are two ways you

can do it:

1. Inspect the outer appearances of both the box and the printer for

possible damage.

2. Raise the top cover of the printer to see if the media compartments

are in order.

If damages did occur, immediately file the claim to the shipping

company for settlement.

Having performed the primary inspections,

please check whether you have received the following accessories

together with the printer. If there is any item missing, contact your local

dealer to get it.

1

you are advised to

next step,

User's

Manual

CD ROM

Printer

Power Cord

Ribbon

2

Advertisement

Table of Contents

Summary of Contents for Argox X2000

-

Page 1: Checking Your Box

Checking Your Box Receiving the box of your printer, you are advised to check first for the possible shipping damage. There are two ways you can do it: 1. Inspect the outer appearances of both the box and the printer for possible damage. -

Page 2: Power Supply

Power Supply Setting up the Printer Power Switch Before setting up the printer you should first consider the following: AC Power Connector ♦ Find a solid flat surface with adequate room for the printer. Make sure there is enough room on the top side for the media and ribbon access. -

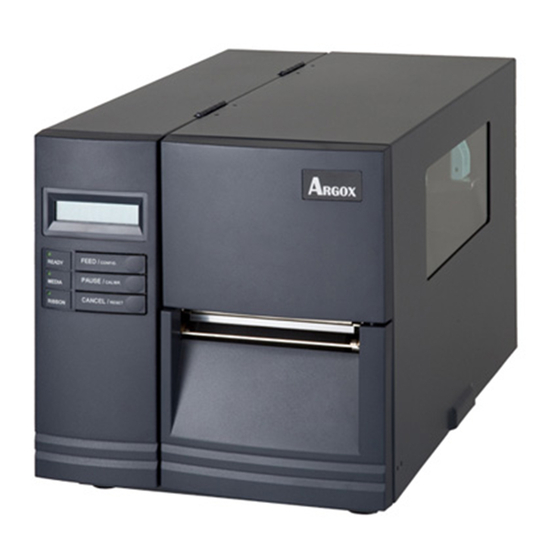

Page 3: Parts And Features

Parts and Features Ribbon Pick-up Spindle Ribbon Supply Spindle Top Access Door Media Supply Spindle LCD Display Feed Slot Thermal Print Head Bracket Front Access Door Thermal Print Head Head Latch Platen Roller Paper Sensor Guide... -

Page 4: Loading The Ribbon

Loading the Ribbon Reminder Notes: Peeler 1. This section is applicable to the transfer thermal printing. Sensor 2. Attached ribbon is coating inside. 1. Lift the top access door and the front access door to expose the compartment. ( Figure 1 ) 2. - Page 5 Print Head Module Bare Core Head Latch Bracket Ribbon Supply Spindle Ribbon Pick-up Spindle...

-

Page 6: Loading The Media

Loading the Media X 2000 Zip printers can be operated in three different options: standard, peel-off, or with a cutter. Media Guide Standard mode allows you to collect each label freely. In peel-off mode, the backing material is being peeled away from the label as it is printed. - Page 7 Print Head Module Paper Sensor Guide Head Latch Bracket Outside Media Guide...

-

Page 8: Peel Off Mode

Peel Off Mode Follow the common procedure of “ Loading the Media “ of Standard Mode from step 1 to 3. 4. Remove approximately 6” long labels from the label backing paper. ( Figure 11 ) 5. Lead the backing paper through the print head module. ( Figure 12 ) 6. - Page 9 Rewinder Kit Print Head Module Rewinder Kit Iron Stick...

-

Page 10: Cutter Mode

Cutter Mode Follow the common procedure of “ Loading the Media “ of Standard Head Mode from step 1 to 3. Latch 4. Insert the media into the print head module and under the paper sensor guide. ( Figure 17 ) 5. -

Page 11: Operator Controls

Operator Controls LED Indicators Front Panel There are three LED indicators on the front panel, “READY”, “MEDIA” and “RIBBON”. These indicators display the operation status of the printer. The front panel includes 3 LED indicators (READY, MEDIA and RIBBON) READY The READY indicator will remain lighted except if any of the 3 buttons (FEED, PAUSE and CANCEL) following conditions prevail. -

Page 12: Lcd Display

Buttons LCD Display There are three buttons, each having two basic functions. Basic Functions : to display the printer status Button Under normal condition Pressed the button and turn on the power to display the printer settings simultaneously to display the input data from a keyboard or barcode reader. - Page 13 Setting from Panel Selection Items You can change some settings from proper panel operation instead of Item Range Factory Default Remarks sending commands. CUT/PEEL POS -15 ~ 15 mm 0 mm Controls cut and peeling (mm) position. Buttons Function PRINT OFFSET -8 ~ 15 mm 0 mm Controls vertical print...

-

Page 14: Setting Display Language

BASE SPEED 0 ~ 4 IPS 0 IPS This is for the PPLB Before selecting the see-through sensor make sure the main board (IPS) emulation only. When version is 5.0 or later, otherwise it can not work. you choose TLP2642/ 3642 driver the speed is Setting Display Language limited under 2 ips. -

Page 15: Rear Panel

Rear Panel Performing Calibration The rear panel includes After the media and label are loaded, it is necessary to do the An 8-bit DIP switch calibration for the label sensor. A 36-pin parallel port A 9-pin RS-232 serial port Press and hold the PAUSE button. A PS/2 keyboard connector Turn on the power. -

Page 16: Printing Configuration Report

Printing Configuration Report Resetting the Printer to Factory Default Settings Performing the Self Test If you would like to reset the printer to its factory defaults after certain Turn off the printer. Press and hold the FEED button. commands have been sent or settings changed: Turn on the power. -

Page 17: Hooking Up The Printer & Computer

Hooking up the Printer & Computer Communicate with the Printer Connecting the Printer to Your Host Communicate with the Printer You can connect the printer with any standard Centronics cable to The bundled printer driver can be applied to all the applications under the parallel port of the host computer. -

Page 18: Installing Driver

Installing Driver Notes: If you are just updating your driver, make sure to delete the previous Note: Before installation, please make sure your “user’s right” is up tothe version first. level of ‘Administrator'. If you install a new bar code application software like ArgoBar, LabelLView or CodeSoft, the Label driver should be activated and Click the “Start”... - Page 19 Set the Parameters For Win 98 After installing the driver, you can follow the path below to set Ports parameters: Properties menu click “Details” Start Settings Printers Label Dr. Properties select the IO port The parameters include: click “OK” Ports Select the IO port to link with the printer.

- Page 20 Output bin Create User-Define (Accessory setting) Paper Properties menu Properties menu click "Paper" click "Paper" click "more option" select "Custom" select Enable/without User-Define size cutter, peeler set up a new size click "OK" click "OK" Print quality (Speed) Properties menu click "Device Options"...

- Page 21 Orientation For Win 2000 Printing Reference menu click "Layout" select "Portrait" or Ports "Landscape" Properties menu click "OK" click "Ports" select the IO port click "OK" Paper size Copies Media choice (Accessory setting) Paper/Output Paper source (Speed) (Media type) Print quality Back to Printers menu (Darkness) Label Dr.

- Page 22 For NT 4.0 Create a new size Printer menu right click to get pop-up Ports menu in blank space Properties menu select "Server Properties" click "Ports" enter a form name for select the IO port the new form in "Form click "OK"...

-

Page 23: Troubleshooting

Troubleshooting Paper/Output (Speed) Generally, when a malfunction or an abnormal condition occurs, the Print quality “READY” LED will keep blinking and printing and communication (Darkness) between the host and printer will stop. Default Document menu To understand what the problem, please check the click "Advanced"... -

Page 24: Problems On Ribbon

B. Problems on ribbon MEMORY FULL . Check the graphics and soft fonts fromhost. Blinking Indicators READY and RIBBON . Make sure to delete the graphics and soft fonts if they are no longer LCD display RIBBON OUT used bythe application software. (Refer to the Technical Rference Possible Problems Solutions... - Page 25 Addendum ♦ Vertical streaks in the printout usually indicate a dirty or faulty print head. Clean the print head first, if they still persist, replace the print head. If you use small labels ( label height is less than 30 mm ) and the area near top is unprintable you can adjust the top margin slightly by the following procedure.

-

Page 26: Caring For Your Printer

Caring for your Printer Reference Technical Information 1. General Specification Before maintenance be sure to turn off the printer power. 1. Cleaning the print head(TPH) Model Specification X-2000 Zip Turn off the printer, open the cover, print head module and remove Print method Direct thermal and thermal transfer the ribbon. -

Page 27: Fonts, Bar Codes And Graphics Specification

2. Fonts, Bar Codes and Graphics Specification Ribbon size OD 3 in. (76mm) ID 1 in. (25 mm) The specifications of fonts, bar codes and graphics depend on the Compact size W9.8” H10.2” L16.0” (W250 H260 L410 mm) ╳ ╳ ╳... -

Page 28: Connection With Host

3. Interface Specifications Connection with host: Introduction Host 25S Printer 9P Host 9S Printer 9P (PC or compatible) (PC or compatible) This appendix presents the interface specifications of IO ports for the printer. These specifications include pin assignments, protocols and DTR 20 ……….. -

Page 29: Parallel (Centronics)

Parallel (Centronics) The most simple way to connect to other hosts(not PC compatible) or terminals is: The parallel port is a standard 36-pin Centronics. Its pin assignments are listed as following. Printer Terminal/Host Pin 2- RxData ………… TxData Direction Definition Direction Definition Pin 3- TxData... -

Page 30: Ascii Table

Appendix A: Printer Status 4. ASCII TABLE 0 NUL LCD display Blinking LED Description 1 SOH PAUSE READY The printer is at pause state. Press PAUSE or CANCEL to return to normal 2 STX “ state. XOFF MEDIA OUT MEDIA The media is uninstalled or used up. - Page 31 Appendix B: Command Description Enable the store to flash STAND-ALONE OPERATION FOR FK"KBDFORM" Delete the previous one KEYBOARD AND BARCODE READER FS"KBDFORM" Start of form Apart from related hardware devices and PPLZ emulation, in order to V00,15,N,"Product Name ?" Variable and display message use keyboards and barcode readers (scanner) you should follow the C0,10,N,+1,"Product No.

-

Page 32: Barcode Reader

Key-in product name and Product Name ? number. Barcode Printer↵ Product No. ? 0123456789↵ Input the label count and LABEL SET NO. ? copy count. 2↵ COPIES PER LAB ? 3↵ Press <ENTER> to continue ENTER to go on, for next label and repeat Or ESC to return steps 5 ~ 7, or <ESC>... - Page 33 Example: 4. The form, READER will be Product No. ? 1. Make a command file for a form, READER.FRM. automatically executed. 11223344↵ Scan the product name and number from the printed bar Command Description Product Name ? codes by the barcode reader. Enable the store to flash APPLE↵...

- Page 34 Appendix C: 6. Loosen two screws (4) from bracket (5). INSTALLATION FOR CUTTER 1. Turn off the printer 2. Remove the top covers on both left and right sides. 3. Mount the cutter baby board to U22 on main board; Take care of the location and direction, the IC hole ix at lower Position.

- Page 35 Appendix D: 8. Thread the cutter cable through a hole (8) and route it to JP13 connector(CUTTER). INSTALLATION for DISPENSER and REWINDER 1. Turn off the printer. After the cutter is installed, install media and ribbon. 2. Remove the top covers on both left and right sides. 3.

- Page 36 Adjustment 5. Connect the dispenser sensor to JP12 (LABEL) of main board and secure the dispenser board in front of TPH module. The plastic core (13,14) of the rewinder kit must be parallel with the exit media or label. To adjust the position you may •...

- Page 37 Calibration for Dispenser Sensor If you find the sensor is not so sensitive or mis –detection you can send two commands to calibrate it. Command ASCII Binary Remark33 33 Set sensor without label <ESC>$R0 1BH 24H 52H 30H Command 0 Set sensor with label <ESC>$R1 1BH 24H 52H 31H...