Summary of Contents for Exmark Lazer Z LZE

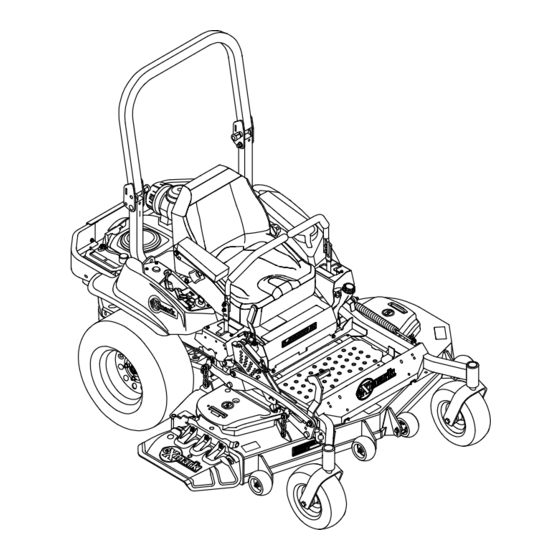

- Page 1 LAZER Z ® For Serial Nos. 411,294,212 & Higher Lazer Z (LZE, LZS, LZX) Models Part No. 4505-959 Rev. B...

- Page 2 To acquire a spark arrester for your unit, see your Engine Service Dealer. For all models that do not have Exmark engines, please refer to the engine manufacturer's information included with the machine. For models with Exmark engines, refer to this manual for information.

- Page 3 All Exmark parts are thoroughly tested and inspected before leaving the factory, however, attention is required on your part if you are to obtain the fullest measure of satisfaction and performance.

- Page 4 Contents Thread Locking Adhesives......68 Mobil HTS Grease (Or Food-Grade Anti-seize)X-Series Only ......68 Introduction ............3 Copper-Based Anti-seize .......68 Safety ..............5 Dielectric Grease..........68 Safety Alert Symbol ......... 5 Adjustments ............69 General Safety ..........5 Deck Leveling–Non-Wing Deck Safety and Instructional Decals ....... 6 Models ............69 Specifications ............18 Deck Leveling–Wing Deck Models ....71...

- Page 5 Safety Safety General Safety This machine is capable of amputating hands and This machine has been designed in conformance feet and of throwing objects. Always follow all safety with the American National Standards Institute instructions to avoid serious personal injury or death. B71.4 for Commercial Turf Care Equipment–Safety •...

- Page 6 Exmark equipment dealer or labels. distributor or from Exmark Mfg. Co. Inc. • Replace all worn, damaged, or missing safety • Safety signs may be affixed by peeling off the signs.

- Page 7 Safety decal109-6036 109-6036 1. Read the Operator’s manual 2. Remove the ignition key and read the instructions before servicing or performing maintenance. 3. Height of cut decal107-3069 decal112-9028 107-3069 112-9028 1. Warning-there is no rollover protection when the roll bar 1.

- Page 8 Safety decal114-4466 114-4466 Non-RED and Non-Smart Controller Equipped Models Only 1. Main, 25A 3. Charge, 25A decal116-8283 2. PTO, 10A 4. Auxiliary, 15A 116-8283 1. Warning—read the Operator's Manual for instructions on torquing the blade bolt/nut to 55-60 ft-lb (75-81 N-m). decal115-9625 115-9625 Suspension Models...

- Page 9 Safety decal116-8725 116-8725 LZE EFI Models Only 1. Throttle-fast 3. PTO 2. Throttle-slow 4. Check engine decal117-0346 117-0346 1. Fuel leak hazard—read the Operator's Manual; do not attempt to remove the roll bar; do not weld, drill or modify the roll bar in any way. decal116-8726 116-8726 1.

- Page 10 Safety decal126-2055 126-2055 All Models Except Wing Deck Models 1. Wheel lug nut—torque to 95 ft-lb (129 N-m). 2. Wheel hub nut—torque to 235 ft-lb ( 319 N-m). 3. Read and understand the Operator’s manual before performing maintenance; check torque after first 100 hours and every 500 hours thereafter.

- Page 11 Safety decal126-7875 126-7875 Kohler RED and Smart Controlled Equipped Models 1. Fuse location 4. Auxiliary, 15A 2. Relay location 5. Start relay 3. Main, 20A 6. Not used decal126-9275 126-9275 Wing Deck Models Only decal126-8597 126-8597 Wing Deck Models Only decal133-8062 133-8062 1.

- Page 12 Safety decal135-0670 135-0670 Wing Deck Models Only 1. Crushing hazard, hand - 2. Warning - Lock the read instructions before deck wings and read decal135-1432 servicing or performing the instructions before 135-1432 maintenance. servicing or performing Wing Deck Models Only maintenance.

- Page 13 Safety decal135-7226 135-7226 g224113 Message Display 1. Accessory—15 A 4. Engine power relay All LZE Models 2. Power—20 A 5. Fan relay All LZS/LZX Kawasaki Models except RED Equipped 3. Engine start relay 1. Fuel 6. Hour meter 2. Empty 7.

- Page 14 Safety g224114 Message Display LZS Kohler EFI Models 1. PTO 4. Operator presence switch 2. Parking brake 5. See user’s guide for operating condition code 3. Neutral decalptosymbols PTO Switch Symbols 1. PTO–disengage 2. PTO–engage...

- Page 15 Safety decal126-8823 126-8823 LZS Kohler EFI Models Only 1. PTO 4. Engine–start 2. Engine–off 5. Throttle-fast 3. Engine–on 6. Throttle-slow decal132-5080 132-5080 “C1” Model Only 1. Firmest position 2. Softest position...

- Page 16 Safety decal132-0871 132-0871 This machine complies with the industry standard stability test in the static lateral and longitudinal tests with the maximum recommended slope indicated on the decal. It is important that each operator review the slope operation instructions in the operator’s manual and review the conditions in which the machine is being operated to determine if the machine may be operated in the conditions that day and on that site.

- Page 17 Safety decal142-2935 142-2935 1. Read the instructions before servicing or performing 5. Check the tire pressure (2 locations). maintenance. 2. Time interval 6. Grease the idler pivots; refer to the Operator's Manual for further instructions (4 locations). 3. Check the engine-oil level. 7.

- Page 18 Electrical System • Engine Specifications: See your Engine Owner’s • Charging System: Flywheel Alternator Manual • Charging Capacity: • Engine Oil Type: Exmark 4–Cycle Premium Engine Oil Kohler and Kawasaki: 15 amps • RPM: Kohler EFI and Briggs EFI: 20 amps –...

- Page 19 Specifications • PTO must be disengaged, brake engaged, and System for reduced vibration, to enhance ride motion control levers out (neutral lock) to start of standard seat. engine. (It is not necessary for the operator to be – “C1” Models: in the seat to start the engine.) Standard seat with high back, extra wide foam •...

- Page 20 – 96 inch deck: ◊ 16cc Parker axial piston pump ◊ 310cc Parker geroler motor • Hydraulic Oil Type: Exmark Premium Hydro Oil. • Hydraulic Oil Capacity: 52 oz (1.5 L) per side • Hydraulic Filter: P/N 116-0164 • Speeds: –...

- Page 21 Specifications X-Series (“A5” Models): S-Series: Drive Drive Quantity Pneumatic (Air filled) Tread NPT Tractus ® 48 & 52 60 & 72 Deck Size 24 x 12.00-12 Size (60 & 72 Decks) Quantity Tread Turf Master Turf Master Important: Do Not use these tires with an Size 23 x 9.50-12 24 x 12.00-12...

- Page 22 Specifications – 48 and 52 inch, 60R, 72R Decks: “B” Section E-Series: (cont’d.) belt with self-tensioning idler. Front Caster – 60 and 72 inch Decks: 5V Section belt with Semi-Pneumatic Pneumatic self-tensioning idler. (Air filled) – 96 Inch Deck: One 5V belt on center deck. Deck Size “A1”...

- Page 23 Specifications Dimensions Overall Length: Side Discharge Models: Overall Width 48 and 52 60 inch 72 inch Side Discharge Models: inch Deck Deck Deck Roll Bar - 79.2 inches 83.1 inches 86.1 inches 48 inch Deck 52 inch Deck (201.2 cm) (211.1 cm) (218.7 cm) Without Deck...

- Page 24 Specifications Overall Height: Curb Weight: All Models Except “C1” Models with 48 Inch Side 1110–1160 lb Discharge Decks (503– 526 kg) Roll Bar - Up Roll Bar - Down Models with 52 Inch Side 1120–1250 lb 70.5 inches (179.1 cm) 46.8 inches (118.9 cm) Discharge Decks (508–567 kg)

- Page 25 Specifications Accessory Weight Table Worksheet: units should install a first under toe board kit for primary accessory weighting (scores 10-19); and a Use the table below to determine if extra weight second under toe board kit for secondary accessory is required for the unit. Identify the accessories weighting (scores 20 and higher).

- Page 26 Product Overview Product Overview Bolt Location Torque Suspension Platform Side 70-80 ft-lb (95-108 N-m) pivot 1/2 inch Mounting Rear Shock Lower 80-90 ft-lb (108-122 N-m) mounting 1/2 inch Mounting Nut Suspension Platform Rear 15-19 ft-lb (20-26 N-m) Cross Shaft 5/16 inch Retention Bolt Suspension Platform Rear 215-265 in-lb (24-30 N-m)

- Page 27 Operation Operation Note: Determine the left and right sides of the machine from the normal operating position. Controls Become familiar with all the controls before starting the engine and operating the machine. Motion Control Levers The motion control levers located on each side of the console control the forward and reverse motion of the machine.

- Page 28 Operation g223866 Figure 6 1. Fuses 4. PTO engagement switch 2. Message display 5. Throttle 3. Ignition switch 6. Choke g008593 Figure 5 Throttle Control 1. Neutral lock position 4. Forward (All Units Except RED Equipped (handles out) Units) 2. Neutral operate position 5.

- Page 29 Operation RED Equipped Logic Display Unit Refer to the RED Equipped User’s Guide (LDU) for detailed information explaining the Operator interface allowing users to access information, reset Located on the right console. counters, modify system settings, and troubleshoot the equipment. RED Equipped Information Screen Located at the top of the LDU, above the push buttons (see Figure 9).

- Page 30 Operation Note: Brake must be engaged, motion control When the alarm sounds, the error message will display and the LED will turn red. levers out (neutral lock position) and PTO switch disengaged to start engine. (It is not necessary for the •...

- Page 31 Operation the battery voltage will display in the area where the The fuel shut-off valve is used to shut off the fuel hours are normally displayed. when the machine will not be used for a few days, during transport to and from the jobsite, and when Note: The LCD indicators appear when each control parked inside a building.

- Page 32 Operation The LCD indicator will appear when the PTO WARNING switch is disengaged (see Figure 11 and Figure 12). The engine and hydraulic drive units can become Refer to the Hour Meter User’s Guide for more very hot. Touching a hot engine or hydraulic information.

- Page 33 Only use accessories and In the non-latching position, the deck will attachments approved by Exmark. automatically return to the cutting height when the • Inspect the area where the machine is to be used pedal is lowered (see item 3 in Figure 14).

- Page 34 Replace worn or • Do Not refill the fuel tank or drain the deteriorated parts with genuine Exmark parts machine indoors or inside an enclosed trailer. when necessary. • Never smoke when handling gasoline, and...

- Page 35 Operation the tank allows gasoline to expand. Overfilling WARNING may result in fuel leakage or damage to the engine Operating engine parts, especially the muffler, or emission system. become extremely hot. Severe burns can occur • Gasoline is harmful or fatal if swallowed. on contact and debris, such as leaves, grass, Long-term exposure to vapors may cause serious brush, etc.

- Page 36 Operation • Be alert, slow down and use caution when injury or death. The operator is responsible for making turns. Do not mow in reverse unless it safe slope operation. Operating the machine on is absolutely necessary. Always look down and any slope requires extra caution.

- Page 37 Loss of traction to the drive wheels may result in sliding and a loss of braking • Only Exmark approved accessories or attachments and steering. The machine can slide even if the may be added to the ROPS.

- Page 38 Operation Important: Always use the seat belt with the Pull the knob and rotate 90° to hold in the unlatched position to lower the roll bar. roll bar in the operate (raised) position. Ensure that the rear part of the seat is secured with the To return to the operate position, raise the roll seat latch.

- Page 39 Operation Remove the clevis pin and hairpin that secures DANGER each wing in the up position. Place them in the An uncovered discharge opening will allow storage position shown in Figure 18. objects to be thrown in an operator’s or bystander’s direction.

- Page 40 Operation Driving the Machine CAUTION Machine can spin very rapidly by positioning one lever too much ahead of the other. Operator may lose control of the machine, which may cause damage to the machine or injury. • Use caution when making turns. •...

- Page 41 Operation g016947 Figure 21 g008593 Figure 20 To turn left or right, pull the motion control lever back toward neutral in the desired turn direction. 1. Neutral lock position 4. Forward (handles out) The machine will move faster the farther the 2.

- Page 42 Operation To turn right, release pressure on the RH motion See the decal on the side of the deck lift plate for control lever and the rear of the machine will cut heights. move towards the rear and to the right. Push the deck lift pedal, release the transport lock To turn left, release pressure on the LH motion and allow the deck to lower to the cutting height.

- Page 43 Operation g295443 Figure 24 1. Unlock cam lock 3. Lynch pin g295444 Figure 25 2. Height of cut pin 1. Top hole (-1 on decal) 2. Middle hole (0 on decal) Remove the lynch pin from the height of cut 3.

- Page 44 Operation g035118 Figure 26 For cutting heights above 3.5 inches (90 mm) use the bottom hole. The rollers will still be effective against scalping. 1. Anti-scalp roller 2. Cutting height mounting bracket g023992 Figure 27 For Maximum Deck Flotation, place the rollers 1.

- Page 45 Operation g253920 Figure 30 1. Bolt 3. Nut 2. Bumper Move each bumper to the desired position and g295495 Figure 29 secure them with the bolts and nuts. Torque nut Underside of Wing Deck Model to 10-12 ft-lb (14-16 N-m). Note: Only use the top or center sets of holes to 1.

- Page 46 Operation g030096 g330350 Figure 31 1. Firmest position 3. Detents in the slots 2. Softest position To adjust the rear shock assemblies, unlock the lever, position to the desired comfort level, and lock the lever (Figure 32). Note: Make sure the left and right rear shock assemblies are always adjusted to the same positions.

- Page 47 Operation After Operation General Safety • Park machine on level ground, disengage drives, set parking brake, stop engine, and remove key. Wait for all moving parts to stop before leaving the operator’s position. Allow the machine to cool before servicing, adjusting, fueling, cleaning, or storing.

- Page 48 Operation ramp that is wider than the machine for this WARNING procedure. Back up ramps and drive forward down Loading a machine onto a trailer or truck ramps (Figure 35). increases the possibility of tip-over and could cause serious injury or death. •...

- Page 49 Operation • Never allow children or others in or on towed equipment. • On slopes, the weight of the towed equipment may cause loss of traction, increased risk of rollover, and loss of control. Reduce the towed weight and slow down. •...

- Page 50 The use of improper components to the original equipment or failure to use can result in system failure, gasoline leakage original Exmark parts could lead to serious and possible explosion. injury or death. Unauthorized changes to the Use only approved fuel lines and fuel filters machine, engine, fuel or venting system, may for high pressure systems.

- Page 51 Maintenance • Keep your hands and feet away from moving parts or hot surfaces. If possible, do not make adjustments with the engine running. • Keep all parts in good working condition and all hardware tightened, especially the blade-attachment hardware. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure...

- Page 52 • Change deck lift power unit fluid (Wing Deck Model Only). Yearly or before storage Periodic Maintenance mark on the dipstick. Exmark 4-Cycle Premium Engine Oil is recommended; refer to the Engine Owner's manual for an appropriate API rating Engine Maintenance and viscosity.

- Page 53 12 volt smart charger approved for use with AGM type batteries with an DANGER output of 3.5 amps or less. Exmark recommends Battery electrolyte contains sulfuric acid, which the use of battery charger P/N 135-7024. Make is poisonous and can cause severe burns.

- Page 54 Maintenance caps on both batteries. Be sure the vehicles do CAUTION not touch and that both electrical systems are Corrosion or loose connections can cause off and at the same rated system voltage. These unwanted electrical voltage spikes at anytime instructions are for negative ground systems only.

- Page 55 Always install the original Exmark blades, blade bushings, and blade bolts as shown. g006780 Figure 39 1.

- Page 56 Maintenance Check Safety Interlock System Service Interval: Before each use or daily Important: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use. Note: If machine does not pass any of these tests, Do Not operate. Contact an Authorized Service Dealer. Note: To prevent engine cut-outs on rough terrain, the seat has a 1/2 second time delay before the engine begins to shutdown.

- Page 57 Maintenance Check Engine Starting Circuit Chart Note: In the Check Engine Starting Circuit Chart, the state of system item that is bold is being checked in each scenario. System Parking Brake Motion Control Levers Operator Outcome (Blades) Operator Engaged Disengaged Both levers moved in, or either Starter must in seat...

- Page 58 Maintenance Check Shutdown Circuit Chart (continued) System Engine Parking Motion Control Operator Outcome Brake Levers (Blades) Running idle Disengaged Engaged Both levers moved in Raise off Engine must begin shutdown (1/3 throttle or of seat (but within 1 second efficient mode) don’t get off) Operator in Engine must...

- Page 59 Maintenance Check Shutdown Circuit Chart (continued) An additional check is required for Wing Deck Models: System Engine Parking Motion Control Operator Outcome Brake Levers (Blades) Running idle Disengaged Engaged Both levers moved Operator in seat PTO must begin (1/3 throttle or and Deck out (neutral lock) shutdown within...

- Page 60 Maintenance Check Rollover Protections Disengage the PTO and shut off the engine. Systems (Roll Bar) Knobs Remove and retain the clevis pins and hairpins from each wing deck storage location. Service Interval: Before each use or daily Be sure that all persons are clear of the deck wings. Check that both the mounting hardware and the Press and hold the top of the deck control switch;...

- Page 61 Maintenance g351363 Figure 45 1. Upper pivot point 3. Deck pin assembly bushing 2. Lower pivot point bolt 4. Bushing g350948 ® Apply a thin bead of Loctite 680 to the entire Figure 43 circumference of the rear edge of the new 1.

- Page 62 Maintenance Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Visually inspect machine for any loose hardware or any other possible problem. Tighten hardware or correct the problem before operating. Service Air Cleaner Service Interval: Every 100 hours—Clean or Replace (if necessary) the primary air cleaner element —...

- Page 63 Important: To prevent engine damage, always Before reinstalling new filter, apply a thin coating operate the engine with both air filters and cover of Exmark 4–Cycle Premium Engine oil on the installed. surface of the rubber seal. Turn filter clockwise...

- Page 64 Remove the oil gear pump in the tank (reference Figure 48). If ™ filter and dispose of it properly. needed, add Exmark Ruby Tran oil. Replace hydraulic reservoir cap and tighten until Clean around oil fill cover and install a new oil filter.

- Page 65 Maintenance Stop engine, wait for all moving parts to stop, and All Models Except Wing Deck Models (cont'd.) remove key. Engage parking brake. Check tire pressure in drive tires and pneumatic Lubrication Chart casters. Inflate pneumatic casters to 13 psi (90 kPa). Fitting Initial Number of...

- Page 66 Pack the bearings with a NLGI grade #1 multi-purpose grease. Insert one bearing, one new seal into the wheel. Note: Seals (Exmark P/N 103-0063) must be replaced. If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to one spacer nut and thread onto the axle with the wrench flats facing outward.

- Page 67 Before installing the new filters, apply a thin coat of Exmark Premium Hydro Oil on the surface Unlatch the hood and lift it up to access the oil of the two rubber seals.

- Page 68 Reinstall the power unit if it was removed to drain. Thread Locking Adhesives ™ Add enough Exmark Ruby Tran oil, approximately 24 oz (710 ml) and replace cap. Thread locking adhesives such as “Loctite 242” Important: Do Not overfill the power unit;...

- Page 69 Maintenance Adjustments Note: In most conditions, the back tips on the side blades should be adjusted: Note: Disengage PTO, shut off engine, wait for Side Discharge Units: 1/4 inch (6.4 mm) higher all moving parts to stop, engage parking brake, and than the front.

- Page 70 Maintenance • Side Discharge Units: The back tips of the side blades should measure 3 1/4 inches (8.3 cm). • Rear Discharge Units: The back tips of the side blades should measure 3 inches (7.6 cm). Re-measure until all four sides are the correct height.

- Page 71 Maintenance Raise the center deck and fold the wings by pressing down at the rear of the deck lift rocker switch. Hold the switch down until both wings are completely folded. Insert the center height adjustment pin into the 4 inches (102 mm) cutting height location.

- Page 72 Maintenance If the four deck adjusters do not have enough adjustment to achieve accurate cut height with the desired rake, the single point adjustment can be utilized to gain more adjustment To adjust the single point system, first loosen the front and rear height of cut plate mounting bolts.

- Page 73 Maintenance g232012 Figure 60 g295695 Figure 61 1. Single point height adjustment bolt 1. Rear hanger mounting nuts 2. Front height of cut plate mounting bolt 2. Rear height adjustment hardware location 3. Rear height of cut plate mounting bolt 3.

- Page 74 Maintenance Deck Belt Tension Push the caliper lever forward with finger pressure until the brake pad contacts the hub rotor. Self-tensioning - No adjustment necessary. Adjust the rear linkage until the spring clevis pin can be inserted in the hole in the caliper lever. Adjusting the Parking Brake Note: To lengthen the linkage, rotate the clevis one turn outward.

- Page 75 Maintenance Using a pneumatic line, blow out any debris from under the brake pole and around the brake spacers. Check the condition of the wire harness leads, connectors, and terminals. Clean or repair as G011733 necessary. Verify that 12V is present at the clutch connector when the PTO switch is engaged.

- Page 76 Maintenance Motion Control Linkage Adjustment Located on either side of the fuel tank, below the seat are the pump control linkages. Rotating the pump linkage with a 1/2 inch wrench allows fine tuning adjustments so that the machine does not move in neutral.

- Page 77 Maintenance Motion Control Handle Adjustment Adjusting the height: The motion control levers can be adjusted higher or lower for maximum operator comfort. Remove the two bolts holding the control lever to the control arm shaft (Figure 70). g008620 Figure 68 RH Motion Control Shown 1.

- Page 78 Maintenance Motion Control Full Forward Tracking Adjustment If the machine travels or pulls to one side when the motion control levers are in the full forward position, adjust the cover plates. Loosen the screws on a cover plate (see Figure 71). Slide the cover plate backward or forward to adjust the travel of the lever and tighten the screws.

- Page 79 Maintenance Cleaning CAUTION Excessive debris around engine cooling air intake and exhaust system area can cause engine, Cleaning and Storing Safety exhaust area, and hydraulic system to overheat • Park machine on level ground, disengage drives, which can create a fire hazard. set parking brake, stop engine, and remove key.

- Page 80 Maintenance Battery Disposal Clean Grass Build-Up Under Deck DANGER Service Interval: Before each use or daily Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns. Stop engine, wait for all moving parts to stop, and Swallowing electrolyte can be fatal or if it touches remove key.

- Page 81 Troubleshooting Troubleshooting Important: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. When a problem occurs, do not overlook the simple causes. For example: starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble.

- Page 82 Troubleshooting Problem Possible Cause Corrective Action Oil temperature light is on and engine RPM 1. Engine Control Unit has limited engine 1. Check oil level. If level is above “add”, is low RPMs, known as “limp” mode. contact an Authorized Service Dealer. Remove debris from hood and oil cooler.

- Page 83 Troubleshooting Problem Possible Cause Corrective Action Blades do not rotate. 1. Deck belt is worn, loose or broken. 1. Install new deck belt. 2. Deck belt is off pulley. 2. Install belt on clutch and deck pulleys, idlers, and tensioning idler per routing decal on deck.

- Page 84 Schematics Schematics Electrical Logic Schematic — Kawasaki (Non-CARB) Models g032372...

- Page 85 Schematics Electrical Logic Schematic — Kawasaki (CARB) Models g200804...

- Page 86 Schematics Electrical Logic Schematic — Kohler Carbureted Models g032373...

- Page 87 Schematics Electrical Logic Schematic — Kohler EFI for Lazer E-Series Models g200826...

- Page 88 Schematics Electrical Logic Schematic — 980 Kohler EFI RED Equipped Models–Non-Wing Decks g358895...

- Page 89 Schematics Electrical Logic Schematic — Kawasaki EFI RED Equipped Models g256757...

- Page 90 Schematics Electrical Logic Schematic — Kohler EFI Smart Controller Equipped Models g280659...

- Page 91 Schematics Electrical Logic Schematic — Kohler Models with Wing Decks g294455...

- Page 92 Schematics Electrical Logic Schematic — Briggs EFI Models g361552...

- Page 93 Schematics Hydraulic Diagram g008623...

- Page 94 Schematics Wing Deck Lift Hydraulic Diagram DECK LIFT FOLD CYLINDER CYLINDERS PORTS “A”, “B”, “C” 7/16-20 UNF (#4 SAE) .020 345 BAR ±7 5000 PSI ±100 .020 RATIO 221 BAR ±7 3200 PSI ±100 0.35 CC/REV 0.022 IN /REV g299104...

- Page 95 California Proposition 65 Warning Information What is this warning? You may see a product for sale that has a warning label like the following: WARNING: Cancer and Reproductive Harm—www.p65Warnings.ca.gov. What is Prop 65? Prop 65 applies to any company operating in California, selling products in California, or manufacturing products that may be sold in or brought into California. It mandates that the Governor of California maintain and publish a list of chemicals known to cause cancer, birth defects, and/or other reproductive harm.

- Page 96 Notes:...

- Page 97 Service Record Date: Description of Work Done: Service Done By:...

- Page 99 g011841 Figure 75 This page may be copied for personal use. 1. The maximum slope you can operate the machine on is 15 degrees. Use the slope indicator to determine the degree of slope of hills before operating. Do Not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope.

- Page 100 Pack) or Fill in Below Engine Model No. and Spec. No. Model No. Engine Serial No. (E/No) Serial No. ©2021 Exmark Mfg. Co., Inc. Part No. 4505-959 Rev. B 415 Industrial Row (402) 223-6375 Beatrice, NE 68310 Fax (402) 223-5489...