Exmark LAZER Z CT Operator's Manual

Hide thumbs

Also See for LAZER Z CT:

- Operator's manual (52 pages) ,

- Operator's manual (48 pages) ,

- Operator and parts manual (24 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Exmark LAZER Z CT

- Page 1 For Serial Nos. 720,000 & Higher LAZER Z ® Place Model No. and Serial No. Date Purchased Label Here (Included in the Literature Pack) or Fill in Below Engine Model No. and Spec. No. Model No. Engine Serial No. (E/No) Serial No.

- Page 2 Replacements may be ordered through the engine manufacturer. Exmark reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make such changes to products manufactured previously.

-

Page 4: Introduction

All Exmark parts are thoroughly tested and inspected before leaving the factory, however, attention is required on your part if you are to obtain the fullest measure of satisfaction and performance. -

Page 5: Table Of Contents

Contents Deck Leveling ..........33 Pump Drive Belt Tension....... 33 Deck Belt Tension ........34 Introduction ............4 Brake Adjustment.......... 34 Safety ..............6 Electric Clutch Adjustment......34 Safety Alert Symbol ......... 6 Reverse Indicator Adjustment......34 Safe Operating Practices ........6 Motion Control Linkage Adjustment ..... -

Page 6: Safety

• Evaluate the terrain to determine what accessories ALERT! YOUR SAFETY IS INVOLVED! and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by Exmark. • Wear appropriate clothing including safety glasses, Figure 2 substantial footwear, long trousers, and hearing 1. - Page 7 Safety DANGER DANGER In certain conditions gasoline is extremely In certain conditions during fueling, static flammable and vapors are explosive. electricity can be released causing a spark which can ignite gasoline vapors. A fire or A fire or explosion from gasoline can burn explosion from gasoline can burn you and you, others, and cause property damage.

- Page 8 Safety Operation damage and make repairs before restarting and operating the mower). WARNING – Before clearing blockages. – Whenever you leave the mower. Operating engine parts, especially the muffler, become extremely hot. Severe burns • Stop engine, wait for all moving parts to stop, and can occur on contact and debris, such as engage parking brake: leaves, grass, brush, etc.

- Page 9 Safety • Watch for ditches, holes, rocks, dips and rises that DANGER change the operating angle, as rough terrain could overturn the machine. Operating on wet grass or steep slopes can cause sliding and loss of control. Wheels • Avoid sudden starts when mowing uphill because dropping over edges, ditches, steep banks, or the mower may tip backwards.

-

Page 10: Maintenance And Storage

Safety Maintenance and Storage WARNING • Disengage drives, lower implement, set parking Hydraulic fluid escaping under pressure brake, stop engine and remove key or disconnect can penetrate skin and cause injury. Fluid spark plug wire. Wait for all movement to stop accidentally injected into the skin must be before adjusting, cleaning or repairing. -

Page 11: Safety And Instructional Decals

Exmark equipment dealer or labels. distributor or from Exmark Mfg. Co. Inc. • Replace all worn, damaged, or missing safety • Safety signs may be affixed by peeling off the signs. - Page 12 Safety 103–2644 1–633922 103–4892 1–653147 98-5954 103–4930...

- Page 13 Safety 103–9116 107-2102 103–9287 107-2112...

- Page 14 Safety 109-3148 109–1196 103–4891 108–5995 1. Fast 3. Neutral 4. Reverse 2. Slow...

-

Page 15: Specifications

Specifications Specifications Model Numbers Serial Nos: 720,000 and Higher LCT18BV483; LCT21BV523; LCT23BV603 Systems Operator Controls • Steering and Motion Control: Engine Note: Motion control levers are adjustable to • Engine Specifications: See your Engine Owner’s two heights. Manual – Separate levers, on each side of the console, •... -

Page 16: Hydrostatic Ground Drive System

Specifications – Optional suspension seat: molded adjustable • Discharge: Side flip-up armrests. • Blade Size: (3 ea.) • Seat Safety Switch: Incorporated into the – 48 inch Deck: 16.25 inches (41.3 cm) Safety Interlock System. Time delay seat switch – 52 inch Deck: 18.00 inches (45.7 cm) eliminates rough ground cut-outs. -

Page 17: Dimensions

Specifications Dimensions Torque Requirements Bolt Location Torque Overall Width: Cutter Housing Spindle 140-145 ft-lb (190–197 48 inch 52 inch 60 inch N-m) Deck Deck Deck Blade Mounting Bolt 55-60 ft-lb (75-81 N-m) Without 44.0 inches 44.0 inches 49.8 inches (lubricate with anti-seize) Deck (111.7 cm) (111.7 cm) -

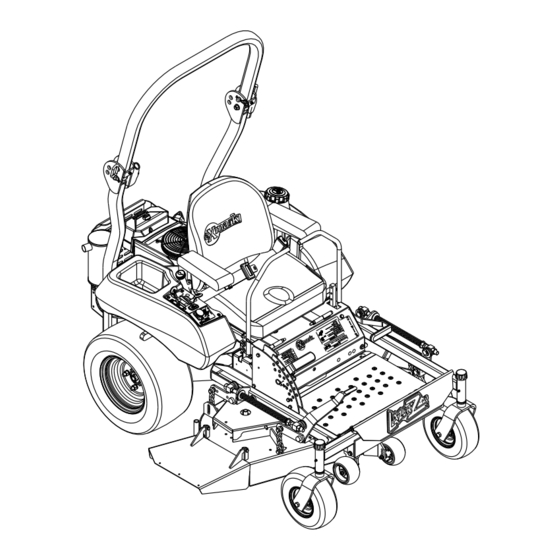

Page 18: Product Overview

Operation Product Overview Operation Note: Determine the left and right sides of the machine from the normal operating position. Controls Motion Control Levers The motion control levers located on each side of the console control the forward and reverse motion of the machine. -

Page 19: Pre-Start

Operation The unit must be tied down and brake engaged when Drive wheel release valves are used to release the transporting. hydrostatic drive system to allow the machine to be pushed without the engine running. Unhook seat Ignition Switch latch and tilt seat up to gain access to pumps. With a 5/8 inch wrench, turn both valves one turn Located on right fuel tank. -

Page 20: Operating Instructions

Operation Open the Fuel Shut-Off Valve (13 mm) below the bottom of the filler neck to allow for fuel expansion and prevent fuel spillage. The fuel shut off valve is located under the seat Make sure you understand the controls, their between the left fuel tank and the engine. -

Page 21: Stopping The Engine

Operation Driving the Machine DANGER CAUTION An uncovered discharge opening will allow objects to be thrown in an operator’s or Machine can spin very rapidly by positioning bystander’s direction. Also, contact with the one lever too much ahead of the other. blade could occur. -

Page 22: Adjusting The Cutting Height

Operation Adjusting the Cutting Height 3. To move forward in a straight line apply equal forward pressure to both levers. The cutting height of the mower deck is adjusted To turn left or right, pull the motion control lever from 1 1/2 to 4 1/2 inches (3.8 cm to 11.4 cm) in back toward neutral in the direction desired. -

Page 23: Transporting

Operation Adjusting the Anti-Scalp Rollers It is recommended to change the anti-scalp roller position, when the height of cut has changed. 1. Stop the machine and move the motion control levers outward to the neutral locked position. 2. Disengage the PTO. 3. - Page 24 Operation Important: Do Not attempt to turn the unit WARNING while on the ramp, you may lose control and drive off the side. Loading a unit on a trailer or truck increases the possibility of backward tip-over. Avoid sudden acceleration when driving up a ramp Backward tip-over could cause serious injury and sudden deceleration when backing down a ramp.

-

Page 25: Maintenance

Maintenance Maintenance Note: Determine the left and right sides of the machine from the normal operating position. WARNING WARNING While maintenance or adjustments are being The engine can become very hot. Touching made, someone could start the engine. a hot engine can cause severe burns. Accidental starting of the engine could Allow the engine to cool completely before seriously injure you or other bystanders. -

Page 26: Periodic Maintenance

Maintenance Maintenance Service Maintenance Procedure Interval • Check the battery charge. Monthly • Grease the front caster wheel hubs w/o zerk. • Grease front caster pivots. • Grease the deck drive belt idler arm. Yearly • Grease the pump drive belt idler arm. •... -

Page 27: Check Mower Blades

Always install the original Exmark blades, blade bushings, and blade bolts as shown. Check Safety Interlock System... -

Page 28: Check Rollover Protection System (Roll Bar) Pins

Note: If machine does not pass any of these tests, (whichever comes first) (May need more often do not operate. Contact your authorized EXMARK under severe conditions.) SERVICE DEALER. 1. Stop engine, wait for all moving parts to stop, and Important: It is essential that operator safety remove key. -

Page 29: Check Tire Pressures

Maintenance baffle inside the tank. If not, add oil. Use only 2. Lubricate fittings with one to two pumps of Mobil 1 15W-50 synthetic motor oil. Replace NGLI grade #2 multi-purpose gun grease. hydraulic reservoir cap and tighten until snug. Do Refer to the following chart for fitting locations Not overtighten. -

Page 30: Lubricate Caster Wheel Hubs

Bushings 7. Insert one bearing, one new seal into the wheel. Service Interval: Every 160 hours Note: Seals (Exmark P/N 103-0063) must be replaced. 1. Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. -

Page 31: Lubricate Motion Control Bronze Bushings

Note: Summer use above 32°F (0°C) use only remove nut and install washer (P/N 1-523157) Exmark Part No. 109–4180. between hub and nut. Winter use below 32°F (0°C) use only Exmark Part No. 1-523541. 4. Torque the slotted nut to 125 ft-lb (169 N-m). -

Page 32: Thread Locking Adhesives

Maintenance 5. Then tighten nut until the next set of slots line up On threads of Blade Bolts. See Check Mower with the cross hole in shaft. Blades section. 6. Replace cotter pin. Dielectric Grease Note: Do Not use anti-seize on wheel hub. Dielectric grease is used on all blade type electrical Fuel Tank —... -

Page 33: Adjustments

Maintenance Adjustments lift handle to the 1 1/2 inch (3.8 cm) position. Do Not push on deck lift handle. While continuing to Note: Disengage PTO, shut off engine, wait for press down, take the slack out of the rear chains all moving parts to stop, engage parking brake, and and tighten hardware at the bottom of the rear remove key before servicing, cleaning, or making any... -

Page 34: Deck Belt Tension

Maintenance Deck Belt Tension lever back until the clevis pin (on arm below pivot shaft) contacts the end of the slot (just beginning Self-tensioning - No adjustment necessary. to put pressure on spring). (Figure 16). 4. Check where lever is relative to notch in console Brake Adjustment (should be centered allowing lever to pivot outward to the neutral lock position). -

Page 35: Adjust Seat Switch

Maintenance 3. Temporarily install a jumper wire across the The left rod assembly controls the left wheel and terminals in the connector of the main wiring the right rod assembly controls the right wheel. harness. 10. Adjustment for the RH motion control lever: 4. -

Page 36: Caster Pivot Bearings Pre-Load Adjustment

Maintenance Cleaning brake disengaged or the PTO engaged, the engine should stop after 1/2 second has elapsed. 2. To adjust seat switch, loosen lock nut on bottom Clean Engine Cooling of the actuator rod (5/16 x 7 inch bolt) and adjust System the nuts to move the actuator plate up or down on the rod. -

Page 37: Waste Disposal

Maintenance 2. Raise deck to the transport (maximum cutting center. If no local recycling is available return the height) position. Lift the front of unit and support battery to any certified battery reseller. unit using jack stands or equivalent support. CAUTION Raising the mower deck for service or maintenance relying solely on mechanical... -

Page 38: Troubleshooting

Troubleshooting Troubleshooting Important: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. When a problem occurs, do not overlook the simple causes. For example: starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble. - Page 39 Troubleshooting Problem Possible Cause Corrective Action Engine overheats 1. Engine load is excessive 1. Reduce the ground speed. 2. Oil level in the crankcase is low. 2. Add oil to the crankcase. 3. Cooling fins and air passages for the 3.

-

Page 40: Schematics

Schematics Schematics Electrical Diagram GREEN GREEN STRIPE GREEN/WHT VIOLET WHITE BLACK BLACK BLACK BLACK BLACK GREEN BLACK GREEN BLACK STRIPE ORANGE/BLK GREY STRIPE GREEN/WHT YELLOW BROWN BLUE GREEN GREEN STRIPE PINK/BLK BROWN BLUE BLUE BLUE BLACK GREEN GREEN GREEN BLUE BLUE G006764... -

Page 41: Hydraulic Diagram

Schematics Hydraulic Diagram HIGH PRESSURE HIGH PRESSURE REVERSE FORWARD BYPASS VALVE FRONT OF UNIT FILTER HYDRAULIC TANK BYPASS VALVE HIGH PRESSURE FORWARD HIGH PRESSURE CHARGE PUMP INLET HIGH PRESSURE REVERSE CASE DRAIN G006765... - Page 42 No Claim of breach of warranty shall be cause for cancellation included with the product. or rescission of the contract of sale of any Exmark mower. All warranty work must be performed by an authorized Some states do not allow exclusions of incidental or...

- Page 44 © 2004–2007 Exmark Mfg. Co., Inc. Part No. 4500-130 Rev. A Industrial Park Box 808 (402) 223-6300 Beatrice, NE 68310 Fax (402) 223–5489 All Rights Reserved Printed in the USA.