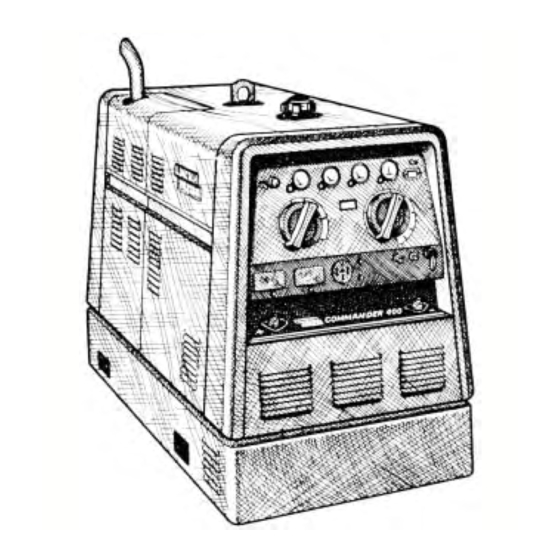

Lincoln Electric COMMANDER 400 SVM133-B Manuals

Manuals and User Guides for Lincoln Electric COMMANDER 400 SVM133-B. We have 1 Lincoln Electric COMMANDER 400 SVM133-B manual available for free PDF download: Service Manual

Lincoln Electric COMMANDER 400 SVM133-B Service Manual (197 pages)

Lincoln Electric Welder User Manual

Brand: Lincoln Electric

|

Category: Welding System

|

Size: 4 MB

Table of Contents

Advertisement

Advertisement

Related Products

- Lincoln Electric SPEEDTEC 400S

- Lincoln Electric Invertec 400SX

- Lincoln Electric MAGNUM 400FM

- Lincoln Electric VANTAGE 400

- Lincoln Electric Mobiflex 400-MS

- Lincoln Electric STATIFLEX 400-M

- Lincoln Electric VANTAGE 400 CE

- Lincoln Electric MAGNUM 400 K575

- Lincoln Electric MAGNUM 400 K1723

- Lincoln Electric SHIELD-ARC 400AS-50