Kval Commander III Manuals

Manuals and User Guides for Kval Commander III. We have 3 Kval Commander III manuals available for free PDF download: Operation Manual, Service Manual

Kval Commander III Operation Manual (168 pages)

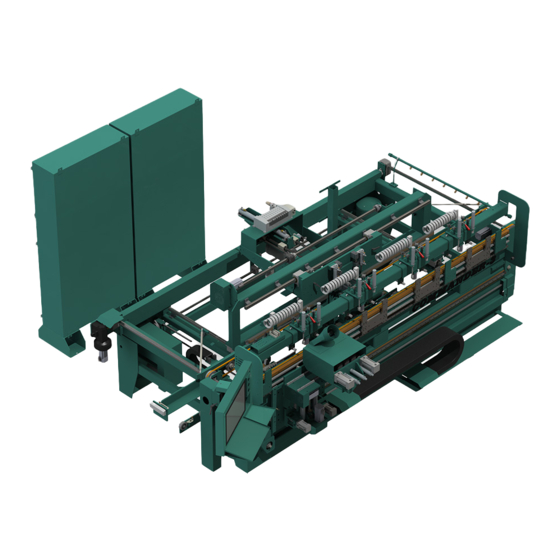

Door System With KvalCAM

Brand: Kval

|

Category: Industrial Equipment

|

Size: 5 MB

Table of Contents

Advertisement

Kval Commander III Operation Manual (124 pages)

Door System With KvalCAM

Brand: Kval

|

Category: Industrial Equipment

|

Size: 5 MB

Table of Contents

Kval Commander III Service Manual (104 pages)

Door System with KvalCam

Brand: Kval

|

Category: Industrial Equipment

|

Size: 12 MB

Table of Contents

Advertisement

Advertisement