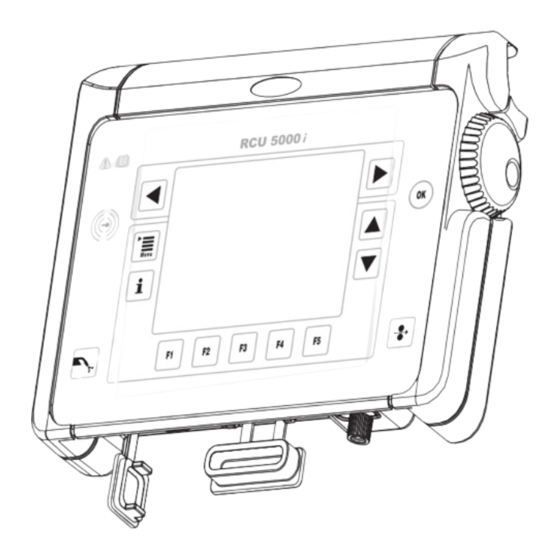

Fronius RCU 5000i Manuals

Manuals and User Guides for Fronius RCU 5000i. We have 1 Fronius RCU 5000i manual available for free PDF download: Operating Instructions & Spare Parts

Fronius RCU 5000i Operating Instructions & Spare Parts (248 pages)

Brand: Fronius

|

Category: Remote Control

|

Size: 8 MB

Table of Contents

-

Safety Rules11

-

General11

-

Proper Use12

-

EMC Measures13

-

EMF Measures13

-

Copyright15

-

General16

-

-

Main Menu22

-

Clothesline22

-

-

General24

-

Menu" Screen24

-

Data" Screen24

-

-

Start-Up28

-

-

Process36

-

CMT" Process39

-

-

General40

-

-

-

General49

-

-

-

General52

-

-

MMA Welding61

-

TIG Welding63

-

CC/CV Mode65

-

Job Welding67

-

Manage Jobs76

-

-

Ignition109

-

Arc (Static)109

-

Arc (Dynamic)110

-

End of Welding111

-

Guideline Values111

-

-

-

Ignition113

-

Arc (Static)115

-

Short Circuit117

-

End of Welding117

-

Guideline Values117

-

-

-

General118

-

Ignition118

-

CMT Parameters119

-

End of Welding120

-

Guideline Values120

-

-

-

General122

-

Ignition122

-

CMT Parameters123

-

Cmt/Pulsed124

-

End of Welding125

-

Guideline Values125

-

-

-

General126

-

Ignition126

-

Hotstart126

-

Weld Start127

-

En/Ep Cmt129

-

End of Welding129

-

Guideline Values129

-

-

-

General131

-

Ignition131

-

Hotstart131

-

CMT Parameters132

-

End of Welding135

-

Guideline Values135

-

-

Documentation139

-

-

General146

-

-

Welding Log150

-

Event Log152

-

General152

-

-

-

General153

-

-

Machine Pre-Sets155

-

Ethernet Setting158

-

General158

-

-

Profiles/Keys166

-

General166

-

Locked" Profile168

-

-

-

Requirement169

-

Procedure169

-

-

-

Requirement170

-

Editing Profile176

-

Deleting Profile180

-

-

Example Profiles181

-

General181

-

Locked181

-

Robot Programmer183

-

Welder/Worker184

-

-

-

General191

-

-

-

General197

-

-

-

General198

-

-

Creating Backup199

-

General199

-

-

Restoring Data201

-

General201

-

-

-

General208

-

L/R Alignment208

-

-

-

Explanation223

-

Parameters a - Z223

-

-

Appendix243

Advertisement

Advertisement