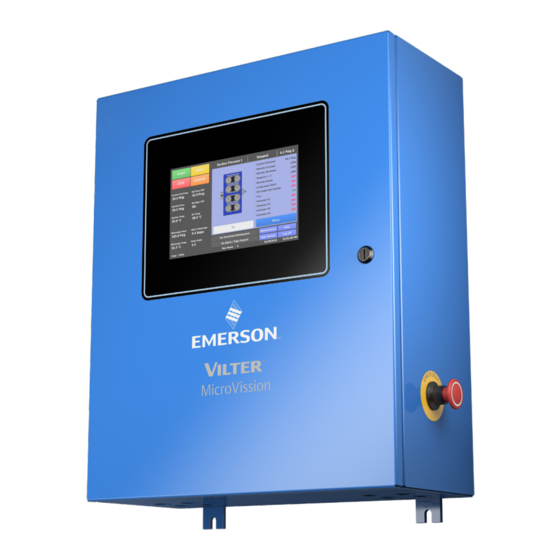

Emerson Vilter MicroVission Manuals

Manuals and User Guides for Emerson Vilter MicroVission. We have 2 Emerson Vilter MicroVission manuals available for free PDF download: Operation And Service Manual, Retrofit Manual

Emerson Vilter MicroVission Operation And Service Manual (262 pages)

Brand: Emerson

|

Category: Controller

|

Size: 32 MB

Table of Contents

Advertisement

Emerson Vilter MicroVission Retrofit Manual (20 pages)

Brand: Emerson

|

Category: Controller

|

Size: 1 MB