Summary of Contents for MTU 8 V 2000 M40A

-

Page 1: Operating Instructions

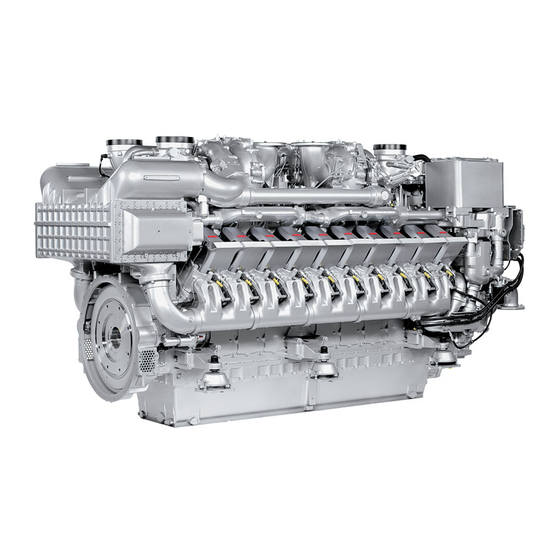

Operating Instructions Diesel engine 8 V 2000 M40A, 8 V 2000 M40B 12 V 2000 M40A, 12 V 2000 M40B 12 V 2000 M41A, 12 V 2000 M41B 16 V 2000 M40A, 16 V 2000 M40B 16 V 2000 M41A, 16 V 2000 M41B... - Page 2 This Publication is protected by copyright and may not be used in any way whether in whole or in part without the prior written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution, translation, micro‐ filming and storage or processing on electronic systems including data bases and online services.

- Page 3 Commissioning Note Important Please complete and return the “Commissioning Note” card below to MTU Friedrichshafen GmbH. The Commissioning Note information serves as a basis for the contractually agreed logistic support (war‐ ranty, spare parts, etc.).

-

Page 5: Table Of Contents

Table of Contents 1 Safety 2.6.12 16V 2000 M40A engine data: separate heat exchanger, reference conditions: 45 °C intake 1.1 General conditions air temperature 1.2 Personnel and organizational requirements 2.6.13 16V 2000 M40B engine data, engine-mounted 1.3 Transportation heat exchanger, reference condition: 45 °C intake air temperature 1.4 Safety precautions when working on the 2.6.14 16V 2000 M40B engine data, engine-mounted... - Page 6 7 Appendix A 6.13 Lube Oil System, Lube Oil Circuit 6.13.1 Engine oil level – Check 7.1 Abbreviations 6.13.2 Engine oil – Change 7.2 MTU contacts/service partners 6.14 Oil Filtration / Cooling 6 | Table of Contents | MS150031/03E 2011-10...

- Page 7 8 Appendix B 8.2 Consumables 8.3 Index 8.1 Special Tools MS150031/03E 2011-10 | Table of Contents | 7...

-

Page 8: Safety

Modifications or conversions Unauthorized modifications to the engine represent a safety risk. MTU will accept no liability or warranty claims for any damage caused by unauthorized modifications or conversions. Spare parts Only genuine MTU spare parts must be used to replace components or assemblies. MTU accepts no liability whatsoever for damage or injury resulting from the use of other spare parts and the warranty shall be voided in such case. -

Page 9: Personnel And Organizational Requirements

1.2 Personnel and organizational requirements Personnel requirements Work on the engine must only be carried out by appropriately qualified and instructed personnel. Observe the minimum legal age. Responsibilities of the operating, maintenance and repair personnel must be specified by the operating company. -

Page 10: Transportation

1.3 Transportation Transport without flange-mounted gearbox Illustration is essentially valid for 8V 2000 M engines Illustration is essentially valid for 12/16V 2000 M engines Transport with flange-mounted gearbox Illustration is essentially valid for 8V 2000 M engines 10 | Safety | MS150031/03E 2011-10... - Page 11 The eyebolts mounted at the driving end and on the gearbox must not be used for transporting plants with flange-mounted gearboxes. Only use transport and lifting devices approved by MTU. Take the engine's center of gravity into account. MS150031/03E 2011-10 | Safety | 11...

- Page 12 Only set down engine on a firm, level surface. Make sure that the consistency and load-bearing capacity of the ground or support surface is adequate. Never set an engine down on the oil pan unless expressively authorized to do so by MTU on a case-to- case basis.

-

Page 13: Safety Precautions When Working On The Engine

Do not use the assembly or plant as a ground terminal. Never place the welding cable across or near wiring harnesses of MTU plants. The welding current may otherwise induce an interference voltage in the wiring harnesses which could damage the electrical sys‐... - Page 14 If welding has to be carried out on components (e.g. exhaust manifold), these components must first be removed from the engine. Hydraulic installation and removal Check the tools and devices to be used for perfect operation and safe condition. Only use the specified devices for force-fitting/removing parts.

-

Page 15: Fluids And Lubricants, Fire Prevention And Environmental Protection

Only fuels of the specified quality required to achieve emission limits must be used. Dispose of used fluids, lubricants and filters in accordance with local regulations. Batteries can be returned within the EU to MTU FN / MTU Onsite Energy free of charge for correct recy‐ cling/disposal. - Page 16 Lead • When working with lead or lead-containing compounds, avoid direct contact to the skin and do not inhale lead vapors. • Prevent the buildup of white powder of lead. • Switch on fume extraction system. • After coming into contact with lead or lead-containing materials, wash your hands! Compressed air When working with compressed air, safety precautions must be constantly observed: •...

-

Page 17: Conventions For Safety Instructions In The Text

1.6 Conventions for safety instructions in the text DANGER In the event of immediate danger. Consequences: Death or serious injury • Remedial action WARNING In the event of potentially dangerous situations. Consequences: Death or serious injury • Remedial action CAUTION In the event of dangerous situations. -

Page 18: Product Summary

2 Product Summary 2.1 Product description Description of the engine Engine The engine is a liquid-cooled four-stroke diesel engine, rotating counterclockwise (seen from driving end), with direct injection, exhaust turbocharging and intercooling. The engine is monitored by an engine control and monitoring system. Monitoring in the engine room is carried out by the engine control and monitoring unit. - Page 19 • Interface to CAN field bus for connected, communicating monitoring system components. SOLAS – Fire protection specifications All fuel lines with fuel pressure >1.8 bar are fitted with SOLAS-compliant covers acc. to MTU standard MTN5233. All oil lines with oil pressure >1.8 bar are fitted with SOLAS-compliant covers acc. to MTU standard MTN5233.

- Page 20 Fuel system covers 20 | Product Summary | MS150031/03E 2011-10...

- Page 21 MS150031/03E 2011-10 | Product Summary | 21...

- Page 22 Lube oil system covers 22 | Product Summary | MS150031/03E 2011-10...

- Page 23 MS150031/03E 2011-10 | Product Summary | 23...

- Page 24 Special unions The following types of union are spray-proof in case of leakage even without covers and have been con‐ firmed as being SOLAS-compliant by GL and DNV. Plug-in pipe union Design precludes lateral spray as the parting line is shielded by the sleeve (4). Only seepage along the pipeline is possible whereby the pressure is greatly reduced by a faulty O-ring (3).

- Page 25 High-pressure unions 1 Jacketed pipe 8 Thrust ring 15 Union nut 2 HP line 9 Union nut 16 Thrust ring 3 O-ring 10 Union nut 17 External pipe of HP line 4 Union nut 11 Connecting piece 18 Internal pipe of HP line 5 Recess for O-ring 12 Snap ring 19 Spherical sealing area...

- Page 26 Shielding of fuel filters and lube-oil filters Shielding with plastic ring The plastic ring (1) precludes lateral spray. The fluid is diverted to the catch basin whereby the pressure is greatly reduced. Shielding by structural overhang The overhang (1) prevents lateral spray. The fluid is diverted to the catch basin whereby the pressure is greatly reduced.

-

Page 27: Series 2000 M40A/B - M41A/B

2.2 Series 2000 M40A/B - M41A/B Engine – Overview of functional groups 010 Crankcase and externally 080 Fuel system (low pres‐ 180 Lube oil system/lube oil mounted components sure) circuit 020 Gear train 100 Exhaust turbocharger 200 Coolant circuit 030 Crank drive 110 Intercooler 230 Mounting/support 040 Cylinder head... -

Page 28: Engine Side And Cylinder Designations

2.3 Engine side and cylinder designations Engine sides are always designated as viewed from the driving end (KS). The cylinders of the left engine side are designated "A" and those of the right side "B" (as per DIN ISO 1204). The cylinders of each bank are numbered consecutively, starting with No. 1 at the driving end of the engine. -

Page 29: Engine - Main Dimensions

2.4 Engine – Main dimensions Engine – Main dimensions Engine model Length (A) Width (B) Height (C) 8V 2000 M40A / M40B approx. 2005 mm approx. 1280 mm approx. 1315 mm 12V 2000 M40A / M40B / approx. 2106 mm approx. -

Page 30: Firing Order

2.5 Firing order Firing order A1-B4-A4-A2-B3-A3-B2-B1 12 V A1-B2-A5-B4-A3-B1-A6-B5-A2-B3-A4-B6 16 V A1-B5-A3-A5-B2-B8-A2-A8-B3-A7-B4-B6-A4-A6-B1-B7 30 | Product Summary | MS150031/03E 2011-10... -

Page 31: Technical Data

2.6 Technical Data 2.6.1 8V 2000 M40A engine data: engine-mounted heat exchanger, reference conditions: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. - Page 32 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 Raw water pump: Inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C...

- Page 33 CAPACITIES Number of cylinders Engine coolant, engine-side (with cooler) liter Engine oil at initial filling (standard oil system) (Option: max. operating incli‐ liter nations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 34: 2000 M40A Engine Data: Separate Heat Exchanger, Reference Conditions: 25 °C Intake Air Temperature

2.6.2 8V 2000 M40A engine data: separate heat exchanger, reference conditions: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 35 LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to Lube oil operating pressure (low idle) (meas. point: before engine) FUEL SYSTEM Number of cylinders Fuel pressure at engine supply connection, min.

- Page 36 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, DL, (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), DL, (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) 36 | Product Summary | MS150031/03E 2011-10...

-

Page 37: 2000 M40B Engine Data, Engine-Mounted Heat Exchanger, Reference Condition: 25 °C Intake Air Temperature

2.6.3 8V 2000 M40B engine data, engine-mounted heat exchanger, reference condition: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 38 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 Raw water pump: Inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C...

- Page 39 CAPACITIES Number of cylinders Engine coolant, engine-side (with cooler) liter Engine oil at initial filling (standard oil system) (Option: max. operating incli‐ liter nations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 40: 2000 M40B Engine Data, Separate Heat

2.6.4 8V 2000 M40B engine data, separate heat exchanger, reference condition: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 41 LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to Lube oil operating pressure (low idle) (meas. point: before engine) FUEL SYSTEM Number of cylinders Fuel pressure at engine supply connection, min.

- Page 42 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, DL , (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), DL, (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) 42 | Product Summary | MS150031/03E 2011-10...

-

Page 43: 2000 M40A Engine Data: Engine-Mounted Heat Exchanger, Reference Conditions: 45 °C Intake Air Temperature

2.6.5 12V 2000 M40A engine data: Engine-mounted heat exchanger, reference conditions: 45 °C intake air temperature Explanation: CP Ref. value: Continuous power (CP) FSP Ref. value: Fuel stop power (FSP) A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 44 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: inlet pressure, min. -0.2 Raw water pump: inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube oil temperature before engine, from °C Lube oil temperature before engine, to °C...

- Page 45 CAPACITIES Number of cylinders Engine coolant capacity (with cooling equipment) liter Engine oil capacity, initial filling (standard oil system) (Option: max. operat‐ liter ing inclinations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 46: 2000 M40A Engine Data: Engine-Mounted Heat Exchanger, Reference Conditions: 25 °C Intake Air Temperature

2.6.6 12V 2000 M40A engine data: Engine-mounted heat exchanger, reference conditions: 25 °C intake air temperature Explanation: CP Ref. value: Continuous power (CP) FSP Ref. value: Fuel stop power (FSP) A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 47 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: inlet pressure, min. -0.2 Raw water pump: inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube oil temperature before engine, from °C Lube oil temperature before engine, to °C...

- Page 48 CAPACITIES Number of cylinders Engine coolant capacity (with cooling equipment) liter Engine oil capacity, initial filling (standard oil system) (Option: max. operat‐ liter ing inclinations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 49: 2000 M40A Engine Data: Separate Heat Exchanger, Reference Conditions: 25 °C Intake Air Temperature

2.6.7 12V 2000 M40A engine data: Separate heat exchanger, reference conditions: 25 °C intake air temperature Explanation: CP Ref. value: Continuous power (CP) FSP Ref. value: Fuel stop power (FSP) A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 50 LUBE OIL SYSTEM Number of cylinders Lube oil temperature before engine, from °C Lube oil temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to Lube oil operating pressure, low idle (meas. point: before engine) FUEL SYSTEM Number of cylinders Fuel pressure at supply connection on engine, min.

- Page 51 WEIGHTS / MAIN DIMENSIONS Number of cylinders Engine dry weight (with attached standard accessories, without coupling) 2600 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, CP, (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), CP (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) MS150031/03E 2011-10 | Product Summary | 51...

-

Page 52: 2000 M40A Engine Data: Separate Heat Exchanger, Reference Conditions: 45 °C Intake Air Temperature

2.6.8 12V 2000 M40A engine data: Separate heat exchanger, reference conditions: 45 °C intake air temperature Explanation: CP Ref. value: Continuous power (CP) FSP Ref. value: Fuel stop power (FSP) A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 53 LUBE OIL SYSTEM Number of cylinders Lube oil temperature before engine, from °C Lube oil temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to Lube oil operating pressure, low idle (meas. point: before engine) FUEL SYSTEM Number of cylinders Fuel pressure at supply connection on engine, min.

- Page 54 WEIGHTS / MAIN DIMENSIONS Number of cylinders Engine dry weight (with attached standard accessories, without coupling) 2600 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, CP, (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), CP (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) 54 | Product Summary | MS150031/03E 2011-10...

-

Page 55: 2000 M40A Engine Data: Engine-Mounted Heat Exchanger, Reference Conditions: 25 °C Intake Air Temperature

2.6.9 16V 2000 M40A engine data: engine-mounted heat exchanger, reference conditions: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 56 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 Raw water pump: Inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C...

- Page 57 CAPACITIES Number of cylinders Engine coolant, engine-side (with cooler) liter Engine oil at initial filling (standard oil system) (Option: max. operating incli‐ liter nations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 58: 2000 M40A Engine Data: Engine-Mounted Heat Exchanger, Reference Conditions: 45 °C Intake Air Temperature

2.6.10 16V 2000 M40A engine data: engine-mounted heat exchanger, reference conditions: 45 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 59 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 Raw water pump: Inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C...

- Page 60 CAPACITIES Number of cylinders Engine coolant, engine-side (with cooler) liter Engine oil at initial filling (standard oil system) (Option: max. operating incli‐ liter nations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 61: 2000 M40A Engine Data: Separate Heat Exchanger, Reference Conditions: 25 °C Intake Air Temperature

2.6.11 16V 2000 M40A engine data: separate heat exchanger, reference conditions: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 62 LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to FUEL SYSTEM Number of cylinders Fuel pressure at engine supply connection, min.

- Page 63 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, DL , (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), DL, (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) MS150031/03E 2011-10 | Product Summary | 63...

-

Page 64: 2000 M40A Engine Data: Separate Heat Exchanger, Reference Conditions: 45 °C Intake Air Temperature

2.6.12 16V 2000 M40A engine data: separate heat exchanger, reference conditions: 45 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 65 LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to FUEL SYSTEM Number of cylinders Fuel pressure at engine supply connection, min.

- Page 66 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, DL , (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), DL, (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) 66 | Product Summary | MS150031/03E 2011-10...

-

Page 67: 2000 M40B Engine Data, Engine-Mounted Heat Exchanger, Reference Condition: 45 °C Intake Air Temperature

2.6.13 16V 2000 M40B engine data, engine-mounted heat exchanger, reference condition: 45 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 68 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 Raw water pump: Inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C...

- Page 69 CAPACITIES Number of cylinders Engine coolant, engine-side (with cooler) liter Engine oil at initial filling (standard oil system) (Option: max. operating incli‐ liter nations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 70: 2000 M40B Engine Data, Engine-Mounted Heat Exchanger, Reference Condition: 25 °C Intake Air Temperature

2.6.14 16V 2000 M40B engine data, engine-mounted heat exchanger, reference condition: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 71 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 Raw water pump: Inlet pressure, max. +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C...

- Page 72 CAPACITIES Number of cylinders Engine coolant, engine-side (with cooler) liter Engine oil at initial filling (standard oil system) (Option: max. operating incli‐ liter nations) Oil change quantity, max. (standard oil system) (Option: max. operating in‐ liter clinations) Oil pan capacity, dipstick mark min. (standard oil system) (Option: max. op‐ liter erating inclinations) Oil pan capacity, dipstick mark max.

-

Page 73: 2000 M40B Engine Data, Separate Heat Exchanger, Reference Condition: 45 °C Intake Air Temperature

2.6.15 16V 2000 M40B engine data, separate heat exchanger, reference condition: 45 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 74 LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to FUEL SYSTEM Number of cylinders Fuel pressure at engine supply connection, min.

- Page 75 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, DL , (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), DL, (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) MS150031/03E 2011-10 | Product Summary | 75...

-

Page 76: 2000 M40B Engine Data, Separate Heat Exchanger, Reference Condition: 25 °C Intake Air Temperature

2.6.16 16V 2000 M40B engine data, separate heat exchanger, reference condition: 25 °C intake air temperature Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without changes (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 77 LUBE OIL SYSTEM Number of cylinders Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil operating pressure before engine, from Lube oil operating pressure before engine, to FUEL SYSTEM Number of cylinders Fuel pressure at engine supply connection, min.

- Page 78 ACOUSTICS Number of cylinders Exhaust noise, unsilenced, DL , (free-field sound pressure level Lp, 1m dis‐ db(A) tance, ISO 6798) Engine surface noise with attenuated intake noise (filter), DL, (free-field db(A) sound pressure level Lp, 1m distance, ISO 6798) 78 | Product Summary | MS150031/03E 2011-10...

-

Page 79: Engine Data 12V 2000M41A/B

2.6.17 ENGINE DATA 12V 2000M41A/B Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without change (e.g. of power settings). N Not yet defined value - Not applicable X Applicable... - Page 80 Number of cylinders Number of inlet valves per cylinder Number of exhaust valves per cylinder RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 -0.2 Raw water pump: Inlet pressure, max. +0.5 +0.5 Pressure loss in off-engine raw water system, max.

- Page 81 STARTING SYSTEM (with compressed air/hydraulic starter motor) Number of cylinders Starting-air pressure before starter mo‐ tor, min. Starting-air pressure before starter, max. R FILLING CAPACITIES Number of cylinders Engine coolant, engine side (with cool‐ liters ing system) Engine oil, total, for initial filling (stand‐ liters ard oil system) (option: max.

-

Page 82: Engine Data 16V 2000M41A/B

2.6.18 ENGINE DATA 16V 2000M41A/B Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated without change (e.g. of power settings). N Not yet defined value - Not applicable X Applicable... - Page 83 Number of cylinders Number of inlet valves per cylinder Number of exhaust valves per cylinder RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump: Inlet pressure, min. -0.2 -0.2 Raw water pump: Inlet pressure, max. +0.5 +0.5 Pressure loss in off-engine raw water system, max.

- Page 84 STARTING SYSTEM (with compressed air/hydraulic starter motor) Number of cylinders Starting-air pressure before starter mo‐ tor, min. Starting-air pressure before starter, max. R FILLING CAPACITIES Number of cylinders Engine coolant, engine side (with cool‐ liters ing system) Engine oil, total, for initial filling (stand‐ liters ard oil system) (option: max.

-

Page 85: Operation

3 Operation 3.1 LOP – Controls LOP – Controls Item Color Lettering Meaning / Function White Function keys to control the human-machine interface. Functions vary and are displayed on the LCD screen. White White White White White ALARM AC‐ Pressing the key the first time stops alarm signalization. KNOWLEDGE Pressing the button a second time acknowledges an active alarm. - Page 86 Item Color Lettering Meaning / Function White DIMMER ↓ Holding down the key decreases LCD background illumina‐ tion. White LAMP TEST Pressing the button initiates lamp test. TEST OVER‐ Pressing the button initiates overspeed test. SPEED LED (spot) lights up as long as the overspeed test is run‐ ning.

-

Page 87: Putting The Engine Into Operation

3.2 Putting the engine into operation (out-of-service period > 3 months) Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specification (A001061/..) is available. Putting the engine into operation (out-of-service period > 3 months) Item Task Engine Depreserve (→... -

Page 88: Putting The Engine Into Operation After Scheduled Out-Of-Service Period

3.3 Putting the engine into operation after scheduled out-of- service period Preconditions ☑ Engine is stopped and starting disabled. Putting into operation Item Task Lube oil system Check oil level (→ Page 146). Cooling system Check coolant level (→ Page 159). Cooling system Preheat coolant with preheating unit. -

Page 89: Starting The Engine From Lop

3.4 Starting the engine from LOP Preconditions ☑ Gearbox is disengaged. ☑ External start interlock is not activated. ☑ Emergency air-shut-off flaps (if provided) are open. DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! •... -

Page 90: Operational Checks

3.5 Operational checks DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • Take special care when working on a running engine. WARNING Engine noise above 85 dB (A). Risk of damage to hearing! •... -

Page 91: Stopping The Engine At The Lop

3.6 Stopping the engine at the LOP Preconditions ☑ Engine is running in local mode. CAUTION Stopping the engine when it is running at full load causes extreme stress to the engine. Risk of overheating, damage to components! • Before stopping the engine, operate it at idle speed until operating temperatures decrease and stable values are indicated. -

Page 92: Emergency Stop From Lop

3.7 Emergency stop from LOP CAUTION An emergency stop causes extreme stress to the engine. Risk of overheating, damage to components! • Initiate emergency stop only in emergency situations. Emergency stop from LOP Item Task Open cap of EMERGENCY STOP button (→ Page 85). Press EMERGENCY STOP button. -

Page 93: After Stopping The Engine

3.8 After stopping the engine Preconditions ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. After stopping the engine Item Action Coolant circuit Drain coolant (→ Page 161) if: • freezing temperatures are expected and the engine is to remain out of service for an extended period, but engine coolant has no antifreeze additive;... -

Page 94: Plant - Cleaning

3.9 Plant – Cleaning Preconditions ☑ Engine is stopped and starting disabled. ☑ Operating voltage is not applied. Special tools, Material, Spare parts Designation / Use Part No. Qty. Steam jet cleaner Cleaner (Hakupur 312) 30390 WARNING Compressed air Risk of injury! •... -

Page 95: Maintenance

4 Maintenance 4.1 Maintenance task reference table [QL1] The maintenance tasks and intervals for this product are defined in the Maintenance Schedule. The Maintenance Schedule is a stand-alone publication. The task numbers in this table provide reference to the maintenance tasks specified in the maintenance schedule. -

Page 96: Troubleshooting

5 Troubleshooting 5.1 Troubleshooting Engine does not turn when starter is actuated Component Probable Cause Task Battery Low or defective Charge or replace (see manufacturer's documentation). Cable connections defective Check if cable connections are proper‐ ly secured (see manufacturer's docu‐ mentation). - Page 97 Defective Contact Service. Charge-air temperature too high Component Probable Cause Task Engine coolant Incorrect coolant concentration Check (MTU test kit). Intercooler Contaminated Contact Service. Engine room Air-intake temperature too high Check fans Check air supply / ventilation ducts. Charge-air pressure too low...

- Page 98 Exhaust gas black Component Probable Cause Task Air supply Air filter clogged Check signal ring position of service in‐ dicator (→ Page 144). Fuel injection equip‐ Injector defective Replace (→ Page 123). ment Injection pump defective Replace (→ Page 119). Engine Overloaded Contact Service.

-

Page 99: Lop Alarms

5.2 LOP alarms At the LOP, alarm texts and measuring-point messages are indicated on the DIS. Explanation of the dis‐ played texts can be gathered by pressing the help key on the touch screen. Alarms can also be caused by defective sensors / actuators. If troubleshooting in accordance with the following table is not success‐ ful, contact Service to have the sensors / actuators checked and, if required, replaced. - Page 100 Display text Meaning Task AL Power Amplifier 2 Power amplifier cylinder side B failure 1. Check LOP visually (→ Page 181). Fail 2. Perform LOP test procedures (→ Page 183). 3. Check ECU plug-in connections (→ Page 176). 4. Check engine wiring (→ Page 172). 5.

- Page 101 Display text Meaning Task DL 211+A003-ECU ECU 4 not detected on default bus 1. Check LOP visually (→ Page 181). 2. Perform LOP test procedures (→ Page 183). 3. Check ECU plug-in connections (→ Page 176). 4. Check engine wiring (→ Page 172). 5.

- Page 102 Display text Meaning Task RL 211+A004-EMU EMU 1 not detected on redundant bus 1. Check LOP visually (→ Page 181). 2. Perform LOP test procedures (→ Page 183). 3. Contact Service • Have EMU checked and re‐ placed, if required. SS Safety System Safety system has detected EMU fail‐...

- Page 103 Display text Meaning Task TD P-Lube Oil Different measurement values trans‐ 1. Check LOP visually (→ Page 181). mitted by the two sensors for lube-oil 2. Perform LOP test procedures pressure measurement (→ Page 183). 3. Check ECU plug-in connections (→...

-

Page 104: Task Description

6 Task Description 6.1 Engine 6.1.1 Engine – Barring manually Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Ratchet F30006212 Socket F30005655 DANGER Unguarded rotating and moving engine components. Risk of serious injury –... -

Page 105: Engine - Barring With Starting System

6.1.2 Engine – Barring with starting system Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • before barring or starting the engine, ensure that nobody is in the danger zone. •... -

Page 106: Cylinder Liner

6.2 Cylinder Liner 6.2.1 Cylinder liner – Endoscopic examination Preconditions ☑ Engine is stopped and starting disabled Special tools, Material, Spare parts Designation / Use Part No. Qty. Rigid endoscope Y20097353 Preparatory steps Remove cylinder head cover (→ Page 118). Remove injector (→... - Page 107 Final steps Install injector (→ Page 124). Install cylinder head cover (→ Page 118). MS150031/03E 2011-10 | Task Description | 107...

-

Page 108: Instructions And Comments On Endoscopic And Visual Examination Of Cylinder Liners

6.2.2 Instructions and comments on endoscopic and visual examination of cylinder liners Terms used for endoscopic examination Use the terms listed below to describe the condition of the cylinder-liner surface in the endoscopic exami‐ nation report. Finding Action Minor dirt scores Minor dirt scores can occur during the assembly of a new engine (honing prod‐... - Page 109 Finding Action Discolorations (Heat) These are caused by a disturbance in the liner / ring tribosystem. Usually they run over the whole ring-travel area (TDC/BDC), starting at the first TDC-ring and becoming more visible from the second TDC-ring onwards and less pro‐ nounced from TDC-ring 1.

-

Page 110: Crankcase Breather

6.3 Crankcase Breather 6.3.1 Crankcase breather – Oil separator element replacement, diaphragm check and replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ratchet adapter F30027340 Engine oil Filter element... - Page 111 Checking diaphragm Remove cover (4). Remove spring (5), gasket (2) and dia‐ phragm (3). Check diaphragm (3) for damage, fit new diaphragm if used one is damaged. Install diaphragm (3) on housing (1). Install new seal (2) and spring (5) together with cover (4).

-

Page 112: Crankcase Breather - Cleaning Oil Separator Element

6.3.2 Crankcase breather – Cleaning oil separator element Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Fuel Gasket (→ Spare Parts Catalog) WARNING Fuels are combustible. Risk of fire and explosion! •... -

Page 113: Crankcase Breather - Oil Separator Replacement, Diaphragm Check And Replacement

6.3.3 Crankcase breather – Oil separator replacement, diaphragm check and replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ratchet adapter F30027340 Filter element (→... - Page 114 Checking diaphragm Remove cover (4). Take off spring (5), seal (2) and diaphragm (3). Check diaphragm (3) for damage. Fit new diaphragm if used one is damaged. Mount diaphragm (3) on housing (1). Install new seal (2) and spring (5) together with cover (4).

-

Page 115: Valve Drive

6.4 Valve Drive 6.4.1 Valve clearance – Checking and adjusting Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine coolant temperature is max. 40 °C. ☑ Valves are closed. Special tools, Material, Spare parts Designation / Use Part No. Qty. - Page 116 Checking valve clearance at two crankshaft positions 1 Cylinder A1 is in firing TDC 2 Cylinder A1 is in overlap TDC I Inlet valve X Exhaust valve Check TDC position of piston in cylinder A1: • If the rocker arms are not under load on cylinder A1, the piston is in firing TDC. •...

- Page 117 Adjusting valve clearance Loosen locknut (1) and unscrew adjusting screw (2) slightly. Insert feeler gage between valve bridge and rocker arm. Readjust adjusting screw (2) so that the feeler gage just passes through the gap. Tighten locknut (1) applying the specified tightening torque, holding adjusting screw (2) firmly with screw‐ driver.

-

Page 118: Cylinder Head Cover - Removal And Installation

6.4.2 Cylinder head cover – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ratchet adapter F30027340 Gasket (→ Spare Parts Catalog) Preparatory steps Remove air filter (→... -

Page 119: Injection Pump / Hp Pump

6.5 Injection Pump / HP Pump 6.5.1 Injection pump – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Injection pump (→ Spare Parts Catalog) Remove injection pump and install new one . (→ Page 120) MS150031/03E 2011-10 | Task Description | 119... -

Page 120: Injection Pump - Removal And Installation

6.5.2 Injection pump – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 20-100 Nm F30026582 Ratchet adapter F30027340 Crow-foot box wrench F30027424 Crow-foot box wrench F30027425 Torque wrench, 0.5-5 Nm 0015384230... - Page 121 Removing injection pump Mark installation position of injection pump. Disconnect cabling (1) from injection pump. Remove fuel line (2). Unscrew securing screws of injection pump by approx. 6 mm. • The pretensioned compression spring presses the injection pump out of the crankcase, if not: a) turn crankshaft with engine barring de‐...

- Page 122 Install injection pump, observing marked in‐ stallation position. Install securing screws of injection pump and tighten with torque wrench to the specified torque. Name Size Type Lubricant Value/Standard Securing screw Tightening torque 60 Nm + 12 Nm Install fuel line (2). Tighten union nut on the injection pump to the specified tightening torque using a torque wrench.

-

Page 123: Injection Valve / Injector

6.6 Injection Valve / Injector 6.6.1 Injector – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Injector (→ Spare Parts Catalog) Remove injector and install new injector. (→ Page 124) MS150031/03E 2011-10 | Task Description | 123... -

Page 124: Injector - Removal And Installation

6.6.2 Injector – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Puller 3555890163/00 Fuel suction device F30378207 Torque wrench, 20-100 Nm F30026582 Open end socket wrench F30025897 Crow-foot box wrench F30027425... - Page 125 Removing injector Remove leak-off-fuel lines. Remove fuel line (3). Remove thrust screw (2). Pull off pressure pipe union (1). Extract fuel from the exposed bores using the suction device. Remove screw (2). Take off clamp (1). Screw puller into injector. Remove injector with puller.

-

Page 126: Installing Injector

Installing injector Remove all covers before installation. Clean sealing surface on cylinder head and protective sleeve. Coat sealing ring (1) with grease and fit on‐ to injector. Coat sealing ring (2) with grease and fit on‐ to injector. Press injector into cylinder head by hand. Result: •... - Page 127 Tighten union nut on the pressure-tube connection piece to the specified tightening torque using a torque wrench. Name Size Type Lubricant Value/Standard Union nut Tightening torque 20 Nm +5 Nm Install leak-off-fuel lines. Final steps Install cylinder head cover (→ Page 118). Vent fuel system (→...

-

Page 128: Fuel System

6.7 Fuel System 6.7.1 HP fuel line – Pressure pipe union replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 20-100 Nm F30026582 Open end socket wrench F30025897 Crow-foot box wrench F30027425... - Page 129 Replacing pressure pipe union Remove fuel line (3). Remove thrust screw (2). Pull off pressure pipe union (1). Coat sealing ring with grease (Kluthe Haku‐ form 30-10/Emulgier) and fit on to new pressure pipe union (1). Blow out fuel line (3) with compressed air. Coat sealing cone of pressure pipe union with engine oil.

-

Page 130: Fuel - Draining

6.7.2 Fuel – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Fuel – Draining Release threaded vent plugs on filter head. Open nipple on fuel line and drain fuel into appropriate container. -

Page 131: Fuel System Venting

6.7.3 Fuel system venting Preconditions ☑ Engine is stopped and starting disabled. WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Fuel system venting Unlock fuel priming pump, unscrew handle. Open vent plugs on filter head. - Page 132 Open nipple at fuel heat exchanger. Operate the pump with the handle until fuel without bubbles comes out of the nipple. Close nipple at fuel heat exchanger. Open nipple at fuel line. Operate the pump with the handle until fuel without bubbles comes out of the nipple.

-

Page 133: Fuel Filter

6.8 Fuel Filter 6.8.1 Fuel filter – Replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Oil filter wrench F30379104 Diesel fuel Easy-change filter (→ Spare Parts Catalog) Synthetic ring (→... - Page 134 Fuel filter replacement with the engine stopped Cut out the filter to be replaced. A Both filters cut in (operating position) B Left filter cut out C Right filter cut out Unscrew switched off easy-change filter with oil filter wrench. Clean sealing surface on filter head.

-

Page 135: Fuel Prefilter - Differential Pressure Check And Adjustment Of Gauge

6.8.2 Fuel prefilter – Differential pressure check and adjustment of gauge DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • Take special care when working on a running engine. WARNING Engine noise above 85 dB (A). Risk of damage to hearing! •... -

Page 136: Fuel Prefilter - Draining

6.8.3 Fuel prefilter – Draining Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel Seal (→ Spare Parts Catalog) WARNING Fuels are combustible. Risk of fire and explosion! •... -

Page 137: Fuel Prefilter - Flushing

6.8.4 Fuel prefilter – Flushing Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel Gasket (→ Spare Parts Catalog) DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • Take special care when working on a running engine. WARNING Fuels are combustible. - Page 138 Open threaded vent plug (5) of the filter to be flushed. Unlock drain valve (6) by pressing toggle, open it and drain fuel. Result: Fuel flows from filtered side back to the un‐ filtered side, flushing the filter deposits downwards out of the filter. Close threaded vent plug (5) and drain valve (6).

-

Page 139: Fuel Prefilter - Filter Element Replacement

6.8.5 Fuel prefilter – Filter element replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel Filter element (→ Spare Parts Catalog) Seal (→ Spare Parts Catalog) WARNING Fuels are combustible. - Page 140 Open threaded vent plug (5) of contaminat‐ ed filter. Unlock drain valve (6) by pressing toggle and open it. Drain water and contaminants from the fil‐ ter. Close drain valve (6). Remove screws securing the cover and take off cover (2). Remove spring housing (4) and filter ele‐...

-

Page 141: Charge-Air Cooling

6.9 Charge-Air Cooling 6.9.1 Intercooler – Checking condensate drain line for coolant discharge and obstruction DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • Take special care when working on a running engine. WARNING Engine noise above 85 dB (A). -

Page 142: Air Filter

6.10 Air Filter 6.10.1 Air filter – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Air filter (→ Spare Parts Catalog) Remove old air filter and install new air filter . (→ Page 143) Reset signal ring of service indicator . (→... -

Page 143: Air Filter - Removal And Installation

6.10.2 Air filter – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Air filter – Removal and installation Loosen clamp (2). Remove air filter (3) and clamp (2) from flange of intake housing (1). Verify that there are no objects in the flange of the intake housing (1) and clean it. -

Page 144: Air Intake

6.11 Air Intake 6.11.1 Service indicator - Signal ring position check Preconditions ☑ Engine is stopped and starting disabled. Checking signal ring position If the signal ring is completely visible in the control window (2), replace air filter (→ Page 142). After installation of new filter, press reset button (1). -

Page 145: Starting Equipment

6.12 Starting Equipment 6.12.1 Starter – Condition check Preconditions ☑ Engine is stopped and starting disabled. Checking starter condition Check securing screws of starter for secure seating and tighten if required. Check wiring (→ Page 172). MS150031/03E 2011-10 | Task Description | 145... -

Page 146: Lube Oil System, Lube Oil Circuit

6.13 Lube Oil System, Lube Oil Circuit 6.13.1 Engine oil level – Check Preconditions ☑ Engine is stopped and starting disabled. Checking oil level prior to engine start Withdraw oil dipstick from guide tube and wipe it. Insert oil dipstick into guide tube up to the stop, withdraw after approx. -

Page 147: Engine Oil - Change

6.13.2 Engine oil – Change Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine is at operating temperature. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Sealing ring (→... -

Page 148: Oil Filtration / Cooling

6.14 Oil Filtration / Cooling 6.14.1 Oil dipstick – Marking Preconditions ☑ Engine is stopped and starting disabled. WARNING Hot oil. Oil can contain combustion residues which are harmful to health. Risk of injury and poisoning! • Wear protective clothing, gloves, and goggles / safety mask. •... -

Page 149: Engine Oil Filter - Replacement

6.14.2 Engine oil filter – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Oil filter wrench F30379104 Engine oil Oil filter (→ Spare Parts Catalog) Plastic ring (→ Spare Parts Catalog) DANGER Unguarded rotating and moving engine components. Risk of serious injury –... - Page 150 Stop engine (→ Page 91) and disable engine start. Cut out the filter to be replaced. Remove cut-out oil filter using the oil filter wrench. Clean sealing surface on connecting piece. Check condition of new oil filter sealing ring and coat it with oil. Fit SOLAS shield (→...

-

Page 151: Centrifugal Oil Filter - Cleaning And Filter-Sleeve Replacement

6.14.3 Centrifugal oil filter – Cleaning and filter-sleeve replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Strap wrench F30379104 Cold cleaner (Hakutex 50) 50622 Filter sleeve (→ Spare Parts Catalog) O-ring (→... - Page 152 Centrifugal oil filter – Cleaning and filter-sleeve replacement Remove nut, holding the rotor with a strap wrench. Remove nut (1), washer (2), rotor cap (3) and sealing ring (4). Remove sleeve (1). Measure the layer thickness of the oil resi‐ due.

- Page 153 Fit new sealing ring (4). Set on rotor cap (3), observe marks. Fit washer (2). Hold rotor (new design) with strap wrench and tighten nut (1) with torque wrench to the specified torque. Name Size Type Lubricant Value/Standard M18 x 1.5 Tightening torque 10 Nm Hold rotor (old design) with strap wrench and tighten nut (1) with torque wrench to the specified torque.

-

Page 154: Coolant Circuit, General, High-Temperature Circuit

6.15 Coolant Circuit, General, High-Temperature Circuit 6.15.1 Drain and venting points Top view 1 Engine coolant vent 4 Engine coolant expansion 6 Engine oil filter 2 Intercooler tank 3 Overflow line 5 Fuel filter 154 | Task Description | MS150031/03E 2011-10... - Page 155 Left side 1 Engine coolant drain plug 3 Raw water pump drain 2 Engine coolant drain plug plug MS150031/03E 2011-10 | Task Description | 155...

- Page 156 Free end (KGS) 1 Three-way cock 6 Connection for oil extrac‐ 8 Oil filler neck (connection 2 Fuel filter tion left or right engine side 3 Fuel vent valve 7 Oil dipstick (connection optional) 4 Raw water pump filling left or right engine side 9 Fuel priming pump plug optional)

- Page 157 Right side 1 Engine coolant drain plug 6 Oil filler neck (connection 4 Leak-off-fuel tank 2 Engine coolant drain plug left or right engine side 3 Engine oil filter optional) 4 Fuel priming pump 7 Oil dipstick (connection 5 Raw water pump filling left or right engine side plug optional)

- Page 158 Driving end (KS) 1 Engine coolant drain plug 4 Oil dipstick (connection 7 Fuel vent 2 Oil filler neck (connection left or right engine side left or right engine side optional) optional) 5 Oil filler neck (connection 3 Oil dipstick (connection left or right engine side left or right engine side optional)

-

Page 159: Engine Coolant - Level Check

6.15.2 Engine coolant – Level check Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specification (A001061/..) is available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. -

Page 160: Engine Coolant - Change

6.15.3 Engine coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine coolant Drain engine coolant. (→ Page 161) Fill with engine coolant. (→ Page 162) 160 | Task Description | MS150031/03E 2011-10... -

Page 161: Engine Coolant - Draining

6.15.4 Engine coolant – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. • Wear protective clothing, gloves, and goggles / safety mask. Preparatory steps Provide a suitable receptacle to catch the coolant. -

Page 162: Engine Coolant Filling

6.15.5 Engine coolant filling Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specification (A001061/..) is available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant WARNING Coolant is hot and under pressure. -

Page 163: Ht Coolant Pump - Relief Bore Check

6.15.6 HT coolant pump – Relief bore check DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • Take special care when working on a running engine. WARNING Engine noise above 85 dB (A). Risk of damage to hearing! •... -

Page 164: Engine Coolant - Sample Extraction And Analysis

6.15.7 Engine coolant – Sample extraction and analysis Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specification (A001061/..) is available. Special tools, Material, Spare parts Designation / Use Part No. Qty. MTU test kit 5605892099/00 WARNING Coolant is hot and under pressure. -

Page 165: Raw Water Pump With Connections

6.16 Raw Water Pump with Connections 6.16.1 Raw water pump – Relief bore check Preconditions ☑ Engine is stopped and starting disabled. DANGER Unguarded rotating and moving engine components. Risk of serious injury – danger to life! • Take special care when working on a running engine. WARNING Engine noise above 85 dB (A). -

Page 166: Belt Drive

6.17 Belt Drive 6.17.1 Drive belt – Condition check Preconditions ☑ Engine is stopped and starting disabled. ☑ Guard is removed. Drive belt – Condition check Item Findings Action Drive belt A Singular cracks None Drive belt Belt is oily, shows signs of over‐ Replace(→... -

Page 167: Battery-Charging Generator

6.18 Battery-Charging Generator 6.18.1 Battery-charging generator drive – Drive belt check and adjustment Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Assembly device F6559691 Preparatory steps Remove limit switch (4). Remove indicator (1). - Page 168 Adjusting belt tension Hold adjustment lever (2) at square (5). Rotate adjusting lever until drive belt (4) is released. Loosen screws (1) and (3). Use assembly device to adjust distance (A) by turning adjustment lever (2). Tighten screws (1) and (3). Measure distance (A) with assembly device.

-

Page 169: Battery-Charging Generator Drive - Drive Belt Replacement

6.18.2 Battery-charging generator drive – Drive belt replacement Preconditions ☑ Engine is stopped and starting disabled. Preparatory steps Remove limit switch (4). Remove indicator (1). Remove screws (3) of protective cover (2). Take off protective cover. Replacing drive belt Counterhold adjustment lever (2) at square (5) using a square socket wrench. - Page 170 Final steps Install guard. Install securing screws (3) of protective cov‐ er (2). Install indicator (1). Install limit switch (4) (→ Page 175). 170 | Task Description | MS150031/03E 2011-10...

-

Page 171: Engine Mounting / Support

6.19 Engine Mounting / Support 6.19.1 Engine mounting – Checking condition of resilient mounts Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine is filled with engine coolant and engine oil. ☑ Engine is under static load. Special tools, Material, Spare parts Designation / Use Part No. -

Page 172: Wiring (General) For Engine/Gearbox/Unit

6.20 Wiring (General) for Engine/Gearbox/Unit 6.20.1 Engine wiring – Check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Isopropyl alcohol X00058037 Engine wiring – Check Check securing screws of cable clamps on engine and tighten loose threaded connections. Ensure that cables are fixed in their clamps and cannot swing freely. -

Page 173: Accessories For (Electronic) Engine Governor / Control System

6.21 Accessories for (Electronic) Engine Governor / Control System 6.21.1 Engine control unit and connectors – Cleaning Preconditions ☑ Engine shut down and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 Isopropyl alcohol 46181 Cleaning engine control unit and connectors... -

Page 174: Engine Monitoring Unit And Connectors

6.21.2 Engine monitoring unit and connectors – Cleaning Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 Isopropyl alcohol 46181 Cleaning engine monitoring unit and connectors Remove coarse dirt from housing surface with isopropyl alcohol. -

Page 175: Start Interlock Limit Switch - Check

6.21.3 Start interlock limit switch – Check Preconditions ☑ Engine is stopped and starting disabled. Note: Being in OFF-position, the limit switch initiates start interlock, i.e. the engine cannot be started. Start interlock limit switch – Check Check if switch housing (1) and cover plate (3) are mounted and the switch (2) is in ON- position. -

Page 176: Ecu - Checking Plug Connections

6.21.4 ECU – Checking plug connections Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 Checking plug connections on ECU Use connector pliers (3) to make certain that all plug connections of ECU are se‐... -

Page 177: Engine Monitoring Unit, Plug Connections - Check

6.21.5 Engine monitoring unit, plug connections – Check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 Checking engine monitoring unit plug connections Use connector pliers (3) to make certain that all engine monitoring unit plug connec‐... -

Page 178: Engine Control Unit - Removal And Installation

6.21.6 Engine control unit – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 Covering caps for Cannon sockets Removing control unit from engine Note or mark assignment of cables to con‐... - Page 179 Disconnect ground strap from engine con‐ trol unit grounding stud (7). If the screws (4) are easily accessible: 1. Remove screws (4). 2. Remove engine control unit housing (3) from mounting plates (2). 3. Unscrew mounting plates (2), cable shock absorbers (5) and further secur‐ ing parts (6) as one unit from engine.

-

Page 180: Emergency Instrumentation (Local Operating Panel)

6.22 Emergency Instrumentation (Local Operating Panel) 6.22.1 LOP and connectors – Cleaning Preconditions ☑ Engine shut down and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Isopropyl alcohol 46181 Cleaning LOP Wipe LCD display with dry cloth, without applying excessive pressure. Remove dirt from keys using isopropyl alcohol. -

Page 181: Lop - Visual Inspection

6.22.2 LOP – Visual inspection Preconditions ☑ Engine is stopped and starting disabled. Preparatory steps If READY FOR OPERATION pushbutton is illuminated brightly, press switch briefly. Result: READY FOR OPERATION pushbutton returns to basic brightness. Switch master power switch to OFF. Disconnect battery in accordance with battery manufacturer's instructions. - Page 182 Checking unassigned connector sockets Ensure that non-assigned connector sock‐ ets are protected with covering caps. Make certain that the two securing ele‐ ments (1) are engaged in the lugs (2) so that the covering cap (3) is held firmly in place in the socket.

-

Page 183: Lop - Test Procedures

6.22.3 LOP – Test procedures Preconditions ☑ Engine is stopped and starting disabled. Preparatory steps Connect battery in accordance with battery manufacturer's instructions. Switch master power switch to ON. Switch on engine management system ECS-5. Result: • LOCAL OPERATION pushbutton (1) is il‐ luminated brightly (local control mode is active);. - Page 184 Overspeed test with the engine at standstill Note: Overspeed test with the engine at standstill can only be carried out if the engine is equipped with Engine Monitoring Unit. Press OVERSPEED TEST illuminated pushbutton (3). Observe speed limit and speed simulated by Engine Monitoring Unit on display.

-

Page 185: Abbreviations

Alarm: Default CAN bus failure Engine Control System Engine Control Unit Engine Data Module Engine Monitoring Unit Fluids and Lubricants Specification MTU Publication No. A01061/.. High Alarm: Measured value exceeds 1st maximum limit HIHI High High Alarm: Measured value exceeds 2nd maximum lim‐... - Page 186 Abbrevia‐ Meaning Explanation tion Local Operating Panel Local Operating Station Monitoring and Control System Message Microprocessor Unit, Microprocessing Unit Oberer Totpunkt Top dead center (TDC) P-xyz Pressure-xyz Pressure measuring point xyz Panel Peripheral Interface Module Remote Control System Redundancy Lost Alarm: Redundant CAN bus failure Society of Automotive Engineers U.S.

-

Page 187: Mtu Contacts/Service Partners

Local support Experienced and qualified specialists place their knowledge and expertise at your disposal. For locally available support, go to the MTU internet site: http://www.mtu-online.com 24h hotline With our 24h hotline and the outstanding flexibility of our service staff, we are always ready to assist you - either during operation, for preventive maintenance, corrective work in case of malfunction or changed operating conditions, or for spare parts supply. -

Page 188: Special Tools

8 Appendix B 8.1 Special Tools Assembly device Part No.: F6559691 Qty.: Used in: 6.18.1 Battery-charging generator drive – Drive belt check and adjustment (→ Page 167) Connector pliers Part No.: 0135315483 Qty.: Used in: 6.1.2 Engine – Barring with starting system (→ Page 105) Qty.: Used in: 6.21.1 Engine control unit and connectors –... - Page 189 Fuel suction device Part No.: F30378207 Qty.: Used in: 6.6.2 Injector – Removal and installation (→ Page 124) MTU test kit Part No.: 5605892099/00 Qty.: Used in: 6.15.7 Engine coolant – Sample extraction and analysis (→ Page 164) Oil filter wrench Part No.:...

- Page 190 Ratchet adapter Part No.: F30027340 Qty.: Used in: 6.3.1 Crankcase breather – Oil separator element replacement, diaphragm check and replacement (→ Page 110) Qty.: Used in: 6.3.3 Crankcase breather – Oil separator replacement, diaphragm check and replace‐ ment (→ Page 113) Qty.: Used in: 6.4.2 Cylinder head cover –...

- Page 191 Torque wrench, 20-100 Nm Part No.: F30026582 Qty.: Used in: 6.4.1 Valve clearance – Checking and adjusting (→ Page 115) Qty.: Used in: 6.6.2 Injector – Removal and installation (→ Page 124) Qty.: Used in: 6.7.1 HP fuel line – Pressure pipe union replacement (→ Page 128) Torque wrench, 20-100 Nm Part No.: F30026582...

- Page 192 8.2 Consumables Cleaner (Hakupur 312) Part No.: 30390 Qty.: Used in: 3.9 Plant – Cleaning (→ Page 94) Cold cleaner (Hakutex 50) Part No.: 50622 Qty.: Used in: 6.14.3 Centrifugal oil filter – Cleaning and filter-sleeve replacement (→ Page 151) Coolant Part No.: Qty.:...

- Page 193 Engine oil Part No.: Qty.: Used in: 6.3.1 Crankcase breather – Oil separator element replacement, diaphragm check and replacement (→ Page 110) Qty.: Used in: 6.7.1 HP fuel line – Pressure pipe union replacement (→ Page 128) Qty.: Used in: 6.13.2 Engine oil –...

- Page 194 8.3 Index 12V 2000 M40A engine data: Engine-mounted heat ex‐ changer, reference conditions: 25 °C intake air tem‐ Centrifugal oil filter – Cleaning and filter-sleeve replace‐ perature 46 ment 151 12V 2000 M40A engine data: Engine-mounted heat ex‐ Connectors changer, reference conditions: 45 °C intake air tem‐ –...

- Page 195 LOP and connectors – Cleaning 180 LOP – Controls 85 LOP – Visual inspection 181 Maintenance and repair work – Safety requirements 13 Maintenance task reference table [QL1] 95 MTU contact persons 187 Oil dipstick – Marking 148 Operational checks 90 MS150031/03E 2011-10 | Appendix B | 195...

Need help?

Do you have a question about the 8 V 2000 M40A and is the answer not in the manual?

Questions and answers