Table of Contents

Advertisement

ORIGINAL INSTRUCTIONS

SPX Hydraulic Technologies

5885 11th Street

Rockford, IL 61109-3699

USA

62072 (See P159)

62087 (See P55)

64122 (See P55)

64215 (See P59)

64372 (See P55)

66463 (See P59)

64662 (See P157)

64663 (See P157)

© SPX Hydraulic Technologies

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

Internet Address: http://www.powerteam.com

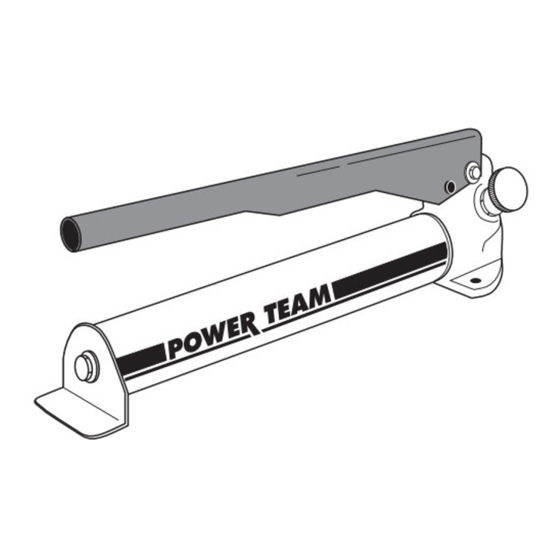

SINGLE-STAGE AND TWO-STAGE

HYDRAULIC HAND PUMP

Max. Pressure: See Pump Data Plate

Operating Instructions for:

201338-TID (See P12)

P12 SERIES

P19 SERIES

P23 SERIES

P30F SERIES

P55 SERIES

P59 SERIES

P59F SERIES

Form No.102842

5

P157 SERIES

P175D SERIES

P159 SERIES

P159D SERIES

P300 SERIES

P300D SERIES

P460 SERIES

YM-01

Page No. 1 of 14

Issue Date: Rev 14

1 Sep. 2012

Advertisement

Table of Contents

Summary of Contents for Power Team 62072

- Page 1 Order Entry: (800) 541-1418 Fax: (800) 288-7031 Internet Address: http://www.powerteam.com SINGLE-STAGE AND TWO-STAGE HYDRAULIC HAND PUMP Max. Pressure: See Pump Data Plate Operating Instructions for: 62072 (See P159) 201338-TID (See P12) P157 SERIES 62087 (See P55) P12 SERIES P175D SERIES 64122 (See P55)

-

Page 2: Table Of Contents

Draining And Flushing The Reservoir For models with Reservoir Type B & C: For models with Reservoir Type D: TROUBLESHOOTING GUIDE ................... 11 POWER TEAM FACILITIES ....................13 DECLARATION OF INCORPORATION ................14 Page No. 2 Issue Date: Rev 14 28 May 2012... -

Page 3: Safety Explanations

Only the user can decide the suitability of this machinery in these conditions or extreme environments. Power Team will supply information necessary to help make these decisions. -

Page 4: Safety Precautions

Operating Instructions Form No. 102842 SAFETY PRECAUTIONS WARNING To help prevent personal injury, • Before operating the pump, all hose connections must be tightened with the proper tools. Do not overtighten. Connections need only be tightened securely and leak-free. Over- tightening may cause premature thread failure or high pressure fittings to split at pres- sures lower than their rated capacities. -

Page 5: P59Fp

Operating Instructions Form No. 102842 SINGLE-STAGE AND TWO-STAGE HYDRAULIC HAND PUMP Max. Pressure: See Pump Data Plate Definition: A hydraulic hand pump delivers hydraulic fluid under pressure by directly applied anual effort. Note: Illustrations depict general pump configurations. P59F P59FP P30F P30FP P460... - Page 6 Operating Instructions Form No. 102842 Volume & Pressure Reservoir Volume per Maximum Handle or Foot Usable Oil Product For Use Order stroke Pressure Lever Effort Oil Capacity Capacity Weight With Stage lbs. Type lbs. 0.069 10000 34.0 0.305 24.4 0.091 10000 98.5 44.7...

-

Page 7: Set-Up

Operating Instructions Form No. 102842 SET-UP 1. Hydraulic Connections IMPORTANT Seal all hydraulic connections with a high grade, nonhardening thread sealant. PTFE tape may also be used to seal hydraulic connections if only one layer of tape is used. Apply the tape carefully, two threads back, to prevent it from being pinched by the coupler and broken off inside the pipe end. -

Page 8: Two-Way Valve

Operating Instructions Form No. 102842 1. Two-way Valve Pumps with a two-way valve are for use with singleacting cylinders. 1. To extend the cylinder, turn the valve knob counterclockwise to a closed (seated) posi- tion. Note: Hand tight only! Work the pump handle up and down to build pressure. 2. -

Page 9: Hydraulic Fluid Level

4. Draining And Flushing The Reservoir Drain, clean and replenish the reservoir with high-grade, approved Power Team hydraulic fluid yearly or more often if necessary. The frequency of fluid change will depend upon the general Page No. 9... -

Page 10: For Models With Reservoir Type B & C

Removing the filter from the pump assembly could result in its breakage. Attempt to clean it as well as possible with it installed. 3. Reassemble and fill the reservoir with Power Team hydraulic fluid. Replace the filler cap. 6. For models with Reservoir Type D: Remove the ten screws fastening the reservoir cover to the reservoir, and lift the pump and valve assemblies off. -

Page 11: Troubleshooting Guide

Operating Instructions Form No. 102842 TROUBLESHOOTING GUIDE WARNING To help prevent personal injury, always release pump pressure and disconnect hose(s) from pump before making repairs. Refer to the appropriate pump parts list during troubleshooting. Repairs must be performed in a dirt- free environment by qualified personnel familiar with this equipment.. - Page 12 1. This is normal operation on significantly after some pres- most two-stage hand sure has been obtained. pumps. *Power Team recommends these hand pump repairs be performed by an Authorized Hydraulic Service Center. Page No. 12 Issue Date: Rev 14 28 May 2012...

-

Page 13: Power Team Facilities

Operating Instructions Form No. 102842 POWER TEAM FACILITIES Page No. 13 Issue Date: Rev 14 28 May 2012... -

Page 14: Declaration Of Incorporation

Operating Instructions Form No. 102842 DECLARATION OF INCORPORATION Page No. 14 Issue Date: Rev 14 28 May 2012...

Need help?

Do you have a question about the 62072 and is the answer not in the manual?

Questions and answers