Roland VersaUV LEC-300A User Manual

Hide thumbs

Also See for VersaUV LEC-300A:

- User manual (180 pages) ,

- Setup manual (68 pages) ,

- Supplemental manual (34 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Setup Manual

USER'S MANUAL

Thank you very much for purchasing this product.

To ensure correct and safe usage with a full understanding of this product's performance, please be sure to read

through this manual completely and store it in a safe location.

Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

The contents of this operation manual and the specifications of this product are subject to change without notice.

The operation manual and the product have been prepared and tested as much as possible. If you find any

misprint or error, please inform us.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur through

use of this product, regardless of any failure to perform on the part of this product.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur with respect

to any article made using this product.

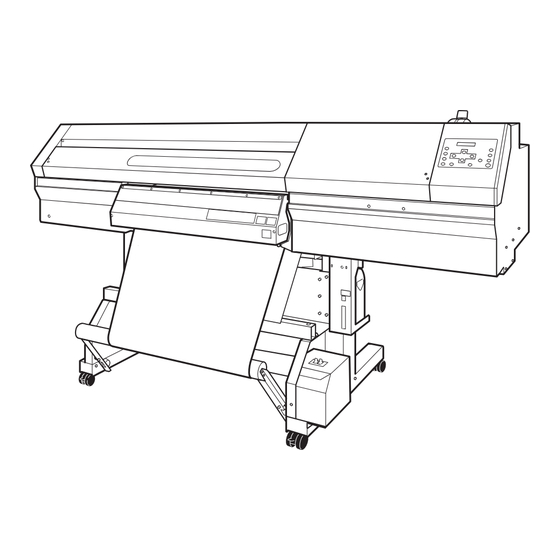

Most of the figures in this document depict the LEC-330.

Advertisement

Table of Contents

Summary of Contents for Roland VersaUV LEC-300A

- Page 1 Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur with respect to any article made using this product.

-

Page 2: For Canada

Manufacturer: ROLAND DG CORPORATION 1-6-4 Shinmiyakoda, Kita-ku, Hamamatsu-shi, Shizuoka-ken, 431-2103 JAPAN The authorized representative in the EU: Roland DG EMEA, S.L. Parc Tecnologic del Valles C/ Ceramistes, 6 08290 Cerdanyola del Valles / Barcelona Spain... -

Page 3: Table Of Contents

Contents Contents ......................1 To Ensure Safe Use .................5 Pour utiliser en toute sécurité ..............12 Important Notes on Handling and Use.............20 Printer Unit ....................20 Ink Cartridges ....................21 Chapter 1 Introduction ..................23 1-1 Introduction ...................24 Features of the Machine ......................24 About This Manual .........................24 Other User's Manuals ........................24 1-2 Part Names and Functions ..............25 Printer Unit ............................25... - Page 4 Contents Chapter 4 Maintenance and Adjustment ............61 4-1 Daily Care and Maintenance ..............62 Disposing of Discharged Ink ......................62 Cleaning .............................64 Care and Maintenance of the Print Heads ................64 4-2 When Head Cleaning Is Not Effective ...........65 Performing More Powerful Cleaning..................65 When Powerful Cleaning Is Not Effective ................67 4-3 Cleaning Using the Cleaning Kit ............68 When the Cleaning Kit Becomes Necessary .................68...

- Page 5 Contents 5-5 Optimizing Printing to Match Media Thickness ..........105 Adjusting Head Height to Match Media Thickness ............105 Correcting for Misalignment in Bidirectional Printing ........... 106 Correcting for Misalignment in Bidirectional Printing More Precisely ..... 107 Performing Feed Correction to Alleviate Horizontal Bands and the Like ....110 Performing Distance Correction During Cutting .............

- Page 6 7-3 About the Blade ...................171 7-4 Locations of the Power Rating and Serial Number Labels ....172 7-5 Specifications ..................173 Company names and product names are trademarks or registered trademarks of their respective holders. http://www.rolanddg.com/ Copyright © 2009-2013 Roland DG Corporation...

-

Page 7: To Ensure Safe Use

To Ensure Safe Use Improper handling or operation of this machine may result in injury or damage to prop- erty. Points which must be observed to prevent such injury or damage are described as follows. About WARNING and CAUTION Notices Used for instructions intended to alert the user to the risk of death or WARNING severe injury should the unit be used improperly. - Page 8 To Ensure Safe Use Incorrect operation may cause injury WARNING WARNING Be sure to follow the operation pro- Never attempt to disassemble, repair, cedures described in this documenta- or modify the machine. tion. Never allow anyone unfamiliar Doing so may result in fire, electrical with the usage or handling of the shock, or injury.

- Page 9 Continuing to use the machine may Never place any flammable object result in fire, electrical shock, or injury. nearby. Never use a combustible Contact your authorized Roland DG aerosol spray nearby. Never use in Corp. dealer. any location where gases can ac- cumulate.

- Page 10 To Ensure Safe Use Important notes about the power cord, plug, and electrical outlet Never place any object on top or subject to Never allow to get wet. damage. Never bend or twist with undue force. Never make hot. Never pull with undue force. Dust may cause fire.

- Page 11 To Ensure Safe Use Ink, cleaning liquid, and discharged fluid are flammable and toxic WARNING WARNING Never drink or sniff ink, cleaning Keep open flame away from the work liquid, or discharged fluid, or allow area. them to come in contact with the eyes Ink and discharged fluid are flammable.

- Page 12 To Ensure Safe Use This machine weighs 210 kg (463 lb.). Media weighs 20 kg (44 lb.). WARNING WARNING Install the machine in a location that When storing roll media, implement adequate safety measures to ensure is level, stable, and able to bear the that the stored media will not roll, fall, weight of the machine.

-

Page 13: Warning Labels

To Ensure Safe Use Warning Labels Warning labels are affixed to make areas of danger immediately clear. The meanings of these labels are as follows. Be sure to heed their warnings. Also, never remove the labels or allow them to become obscured. Flammable Ink and discharged fluid are flammable. -

Page 14: Pour Utiliser En Toute Sécurité

Pour utiliser en toute sécurité La manipulation ou l'utilisation inadéquates de cet appareil peuvent causer des blessures ou des dommages matériels. Les précautions à prendre pour prévenir les blessures ou les dommages sont décrites ci-dessous Avis sur les avertissements Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure ATTENTION grave en cas de mauvaise utilisation de l'appareil. - Page 15 Pour utiliser en toute sécurité L'utilisation incorrecte peut causer des blessures ATTENTION ATTENTION S'assurer de suivre les procédures Débrancher le câble d'alimentation d'utilisation décrites dans la docu- avant de procéder au nettoyage ou à mentation. Ne jamais permettre à l'entretien de l'appareil, et avant d'y quiconque ne connaît pas le fonc- fixer ou d'en retirer des accessoires tionnement ou la manutention de...

- Page 16 Pour utiliser en toute sécurité PRUDENCE PRUDENCE Utiliser l'appareil dans un endroit Ne jamais grimper ni s'appuyer sur propre et bien éclairé. la machine. Travailler dans un endroit sombre ou La machine n'est pas conçue pour sup- encombré peut causer un accident; porter le poids d'une personne.

- Page 17 électrique soit facile d'alimentation et communiquer avec le d'accès. représentant Roland DG Corp. autorisé. S'il se produit des étincelles, de la Ne jamais placer d'objet inflammable fumée, une odeur de brûlé, un bruit à...

- Page 18 Pour utiliser en toute sécurité Remarques importantes à propos du câble d'alimentation, de la fiche et de la prise électrique Ne jamais déposer aucun objet sur le Ne jamais laisser l'eau toucher le câble, la câble, sur la fiche ou sur la prise car fiche ou la prise.

- Page 19 Pour utiliser en toute sécurité L'encre, les liquides nettoyants et les liquides usées sont inflammables et toxiques ATTENTION ATTENTION Ne pas approcher une flamme nue de Ne jamais boire l'encre, le liquide de l'espace de travail. nettoyage ni les liquides usés, ne L'encre et les liquides usés sont inflam- pas en respirer les vapeurs et ne pas mables.

- Page 20 Pour utiliser en toute sécurité Le poids de cet appareil est de 210 kg (463 lb.) Le poids du support est de 20 kg (44 lb.) ATTENTION ATTENTION Installer l'appareil à un endroit stable S'assurer de verrouiller les roulettes et plat et capable de supporter son de la base.

- Page 21 Pour utiliser en toute sécurité Vignettes d'avertissement Des vignettes d'avertissement sont apposées pour qu'il soit facile de repérer les zones dangereuses. La signification des vignettes est donnée ci-dessous. Respecter les aver- tissements. Ne jamais retirer les vignettes et ne pas les laisser s'encrasser. Inflammable L'encre et les liquides usés sont inflamma- bles.

-

Page 22: Important Notes On Handling And Use

Important Notes on Handling and Use This machine is a precision device. To ensure the full performance of this machine, be sure to observe the following important points. Failure to observe them may not only result in loss of performance, but may also cause malfunction or breakdown. -

Page 23: Ink Cartridges

Use a type that is compatible with the printer. Also, be sure to use only genuine items from Roland DG Corp. Never subject to impact or attempt to disassemble. Never drop or shake forcefully. The impact may rupture the internal pouch and cause ... -

Page 25: Chapter 1 Introduction

Chapter 1 Introduction... -

Page 26: Introduction

Be sure to read this first. This describes setup, important conditions about the installation location, and other information for enabling use of this machine. "Roland VersaWorks Quick Start Guide" This describes the installation, setup, and basic operation for Roland VersaWorks, the included software raster image processor (RIP). "White and Gloss Ink Guide"... -

Page 27: Part Names And Functions

1-2 Part Names and Functions Printer Unit Front cover Side cover Loading lever Be sure to close this when You remove this when you You operate this when you you perform printing. perform maintenance. load media. Operation panel You use this to perform various operations. - Page 28 1-2 Part Names and Functions *The figures in this document depict the LEC-330. Cutting carriage Print-head carriage The blade and the separating knife The print heads are inside this. are inside here. UV emitter This is the ultraviolet (UV) LED. It emits light only during printing.

-

Page 29: Operation Panel

1-2 Part Names and Functions Operation Panel Display screen BUSY light BASE POINT key This displays various This lights up during You use this when you setting menus and printing and other such want to set the print- other information. operations. -

Page 30: Media Take-Up System

1-2 Part Names and Functions Media Take-up System AUTO switch MANUAL switch This makes the direction of rota- You use this when you tion for take-up during printing want to operate the media change automatically. take-up system manually. Take-up cable This is connected to the printer. -

Page 31: Chapter 2 Basic Operation

Chapter 2 Basic Operation... -

Page 32: Before Starting Operations

2-1 Before Starting Operations Before Starting the Day's Work The ingredients in white ink tend to settle. Each day, before starting the day's operations, be sure to carry out the following steps. Allowing the ink to stand without carrying out these steps can cause the settled material to harden, resulting in malfunction or other problems. -

Page 33: Switching The Power On And Off

2-2 Switching the Power On and Off Switching the Power On and Off This machine has a main power switch and a sub power switch. Switch on both to use the machine. Whenever printing is finished, switch off the sub power. You also flip down the loading lever to the rear of the machine. -

Page 34: The Power-Saving Feature (Sleep Mode)

2-2 Switching the Power On and Off The Power-saving Feature (Sleep Mode) This machine is provided with a power-saving feature that switches to a low-power "sleep mode" when a fixed interval passes with no operation. The factory default for the time after which the machine switches to the sleep mode is 30 minutes. -

Page 35: Loading And Cutting Off Media

2-3 Loading and Cutting Off Media Loading Media Media may be of one of two types: media wound onto a paper tube (called “roll media”) and media not rolled in this way (called “sheet media”). This section explains how to load media, using roll media as an example. - Page 36 2-3 Loading and Cutting Off Media Attach the media flanges to the roll media. If the inner diameter of the roll-media core measures 3 inches, fit the media flanges onto the core, then turn each knob clockwise all the way to keep the media flanges from falling out. 3 inches 2 inches Press in to fit on...

- Page 37 2-3 Loading and Cutting Off Media Secure the stoppers in place in alignment with the width of the media. Make sure the media flanges are straight. Correct media feed is impossible if either of the media flanges is at an angle. Screws Stoppers Not OK...

- Page 38 2-3 Loading and Cutting Off Media Make sure both edges of the media are above the grit rollers, then place pinch rollers over all grit rollers covered by the media. Placing the pinch rollers inside each of the grit patterns ensures that they are positioned above the grit rollers.

- Page 39 2-3 Loading and Cutting Off Media Secure the media in place so that it is without slack. Hold the media at the center and pull it out, being sure to keep it straight. Make sure all areas of the media are taut. ...

- Page 40 2-3 Loading and Cutting Off Media Clamp the edges of the media with the media clamp. Move the media clamps as shown in the figure below. Left media clamps Right media clamps Line up the edge of the media Line up the edge of the media with the centers of the holes.

- Page 41 2-3 Loading and Cutting Off Media Important Note When Using the Media Clamps Insert the media clamps firmly all the way until they engage with an audible click, and make sure they will not come loose. Incorrect mounting may cause the media to catch or snag and make cor- rect printing impossible, or may lead to malfunction or poor printing quality.

-

Page 42: Cutting Off The Media

2-3 Loading and Cutting Off Media Cutting Off the Media Some media may be thick or may be composed of plastic or other hard material. For such media, never perform cutoff using . Doing so may cause mal- function or other problems. Procedure ... - Page 43 2-3 Loading and Cutting Off Media Give Attention to Media Composition For some types of media, cutoff is not possible. Some types of media may remain on the platen after cutoff. If the media remains on the platen, remove it by hand. When you cut off media while using the short media clamps, then depending on the ...

-

Page 44: Starting Printing

2-4 Starting Printing Getting Ready to Receive Data from a Computer When you have finished loading media, then follow the steps below. This procedure enables the machine to receive data from the computer and perform output. When printing data that includes cutting paths is received, you can also carry out cutting immediately after performing printing. -

Page 45: Printing Tests And Normal Cleaning

2-4 Starting Printing Printing Tests and Normal Cleaning We recommend performing a printing test to check for problems such as dot drop-out before you carry out actual printing. If problems such as dot drop-out are found, clean the print heads. How to Perform a Printing Test Procedure ... - Page 46 2-4 Starting Printing LEC-300A Press NORMAL CL. LEC-330 Press NORMAL CL. A B C LEC-300A to choose the group of heads NORMAL CL. that is not to be cleaned. to get rid of the group display. LEC-330 Repeat this procedure to display the groups of only the heads that require cleaning.

- Page 47 2-4 Starting Printing Perform a printing test again to make sure the dot drop-out has been cor- rected. If the problem persists, try performing cleaning a second time. If the problem doesn't go away even after performing cleaning two or three times, then try cleaning using a different method.

-

Page 48: If Ink Runs Out

2-5 If Ink Runs Out Checking for Remaining Ink Procedure Press MENU INK REMAINING Press several times. Press Press W 736mm Press to go back to the original screen. SETUP SHEET ROLL Amount of ink remaining Much The number of cartridge slots Little The display shows an approximate guide to the amount of remaining ink, which may differ somewhat... -

Page 49: If Ink Runs Out

2-5 If Ink Runs Out If Ink Runs Out When ink runs out, a warning beep sounds and printing pauses (unless the default settings have been changed). Pull out the empty ink cartridge and insert a new one. Printing resumes. Procedure ... - Page 50 2-5 If Ink Runs Out Close the ink cartridge cover. Important Notes on Replacing Cartridges Make sure that the ink cartridge cover is always closed except when absolutely nec- essary, such as when you are replacing ink cartridges. The ink inside the cartridges will become hardened, and it may cause the printer to malfunction.

-

Page 51: Performing Cutting

2-6 Performing Cutting To Perform Cutting To perform cutting, carry out the procedure described below. Move the media clamps to locations where they don’t clamp the media. Alter- natively, remove the media clamps. Media clamps When You're Performing Cutting Only When you're performing cutting, then if you're cutting roll media, allow the ... - Page 52 2-6 Performing Cutting Important Notes on Cutting Never use the media clamps. You can also detach them when not in use. When you’re performing printing followed immediately by cutting, then before you start cutting, allow the ink to dry sufficiently. Use your software RIP to make the setting for the drying time.

-

Page 53: Performing A Cutting Test

2-6 Performing Cutting Performing a Cutting Test For high-quality cutting, then before you perform actual cutting, we recommend carrying out a cutting test to check the cutting quality for the media. Before carrying out a cutting test, detach the media clamps. -

Page 54: Making The Setting For Blade Force

2-6 Performing Cutting Making the Setting for Blade Force Procedure Press FORCE 50gf 60gf to enter the value. Press to finish making the setting, and go W 736mm back to the original screen. SETUP SHEET ROLL Pressing enters the cutting configuration menu. You can also make the settings for other cut- ting conditions in addition to the blade force. -

Page 55: Chapter 3 Operation Of The Media Take-Up System

Chapter 3 Operation of the Me- dia Take-up System... -

Page 56: The Media Take-Up System

3-1 The Media Take-up System Features of the Media Take-up System Using the media take-up system lets you perform printing while the media is taken up automatically. This makes possible unattended operation at night and efficient printing of lengthy media. Operating Conditions for the Media Take-up System Never Use When Performing Cutting Never use the media take-up system when you're performing cutting operations. -

Page 57: About The Paper Tube

To purchase a replacement, contact your authorized Roland DG Corp. dealer or Roland DG Corp. Chapter 3 Operation of the Media Take-up System... -

Page 58: Using The Media Take-Up System

3-2 Using the Media Take-up System Loading Roll Media Pass the media through the printer. Move the dancer roller toward the rear. Dancer roller Load the roll media. P. 33, "Loading Media" Pull back the loading lever. The media is secured in place. - Page 59 3-2 Using the Media Take-up System Press to adjust the length of the media to be pulled out. You can adjust the length of the media in 10-millimeter steps by pressing To pull out media continuously, hold down Fasten the media in place with tape at three locations (the center and both edges) so that the media is not at an angle.

- Page 60 3-2 Using the Media Take-up System Make the setting for the direction of automatic take-up and perform take-up of the media onto the paper tube. Press The media is pulled out and the screen shown in the figure appears. ...

- Page 61 3-2 Using the Media Take-up System ■ Take-up with inward curl Ensure there is no slack. Press W 736mm Making the setting is complete when the screen shown in the figure (the top menu) appears. When you begin take-up, take care to ensure that the end of the media does not become rolled or creased.

-

Page 62: Removing Taken-Up Media

3-2 Using the Media Take-up System Removing Taken-up Media CAUTION Removal of taken-up roll media from the unit is a task which must be carried out by two or more persons. If dropped, such items may cause injury. Cut off the media. ... -

Page 63: Chapter 4 Maintenance And Adjustment

Chapter 4 Maintenance and Adjustment... -

Page 64: Daily Care And Maintenance

4-1 Daily Care and Maintenance Disposing of Discharged Ink The drain bottle collects discharged fluid. Dispose of collected material before the bottle becomes full. The message shown in the figure appears when a certain amount of discharged fluid has collected in the bottle. - Page 65 4-1 Dairy Care and Maintenance Attach the emptied bottle and reset the discharged-fluid count. Attach the emptied bottle. Press RESET DRAIN COUNTER Press a second time. MAINTENANCE DRAIN BOTTLE Press W 736mm Press to go back to the original screen. SETUP SHEET ROLL WARNING...

-

Page 66: Cleaning

P. 68, "4-3 Cleaning Using the Cleaning Kit" Note: The print heads are components that wear out. Periodic replacement is required, with the frequency of replacement depending on use. Purchase them from your autho- rized Roland DG Corp. dealer. Chapter 4 Maintenance and Adjustment... -

Page 67: When Head Cleaning Is Not Effective

4-2 When Head Cleaning Is Not Effective Performing More Powerful Cleaning When the problems such as dot drop-out are not cleared up by the "normal cleaning," try the more forceful "medium cleaning" or the even more forceful "powerful cleaning." Note, however, that this consumes more ink than "normal cleaning,"... - Page 68 4-2 When Head Cleaning Is Not Effective If the Printing-test Results Are Difficult to Interpret Examine the results from different angles in a well-lighted location. Take advantage of reflected light to enable visual checking. We recommend performing the printing test on transparent or silver-colored media.

-

Page 69: When Powerful Cleaning Is Not Effective

4-2 When Head Cleaning Is Not Effective Press W 736mm Press to go back to the original screen. SETUP SHEET ROLL When Powerful Cleaning Is Not Effective If problems such as dot drop-out persist even after you have performed powerful cleaning several times, then use the cleaning kit to clean the heads. -

Page 70: Cleaning Using The Cleaning Kit

When Hardening of the Ink on Printed Material Is Insufficient Clean the UV emitter using the cleaning kit. If you use up the cleaning kit, purchase a new one from your authorized Roland DG Corp. dealer. -

Page 71: How To Perform Cleaning

4-3 Cleaning Using the Cleaning Kit How to Perform Cleaning Important Notes on This Procedure Cleaning requires the included cleaning liquid and commercially available glass cleaner. Have these on hand before you start. Before attempting this operation, remove any media. ... - Page 72 4-3 Cleaning Using the Cleaning Kit Press OPEN MAINTE- NANCE COVER Open the front cover and remove the maintenance cover. Screws Screws Maintenance cover Close the front cover and press The print-head carriage moves to the left side of the machine, and then the screen shown in the figure appears.

- Page 73 4-3 Cleaning Using the Cleaning Kit Clean using the cleaning stick. Be especially careful to clean away any fibrous dust (lint). Moisten the cleaning stick with the cleaning liquid. Perform cleaning in the sequence shown in the figure below. Never rub the nozzle surface of the head.

- Page 74 4-3 Cleaning Using the Cleaning Kit Apply commercially available glass cleaner to the cleaning stick. Use a new cleaning stick. Clean the locations shown in the figure. Area to clean Area to clean *The figures in this document depict the LEC-330. Quit the manual cleaning mode.

- Page 75 4-3 Cleaning Using the Cleaning Kit Press CLOSE FRONT COVER Close the front cover. The print-head carriage moves to the right side of the machine, and then the screen shown in the figure appears. Open the front cover and attach the maintenance cover.

-

Page 76: The Concentration And Dot Drop-Out Of The White Ink

4-4 The Concentration and Dot Drop-Out of the White Ink Restoring White Ink Concentration Prolonged use of this machine may cause the concentration of the white ink to decrease. This is because white ingredients in white ink easily precipitate. The "CIRCULATING INK" feature circulates the ink to eliminate white ink precipitation. -

Page 77: When The Dot Drop-Out Cannot Be Cleared

4-4 The Concentration and Dot Drop-Out of the White Ink When the Dot Drop-Out Cannot be Cleared When white ink is used, dot drop-out or other problems that impede normal ink discharge may occur even when powerful cleaning or manual cleaning of the print heads has been performed. This can occur because the ingredients in white ink tend to settle, and may harden if allowed to stand for a lengthy time. - Page 78 4-4 The Concentration and Dot Drop-Out of the White Ink Remove the SOL INK cleaning cartridges from slots REMOVE CL‑LIQUID 1 2 3 4 5 6 5 and 6. Carry out steps as many times as indicated by the Number 5 and 6 flashes.

-

Page 79: Replacing Consumable Parts

4-5 Replacing Consumable Parts Replacing the Wipers The wipers are components that you use when cleaning the TIME FOR print heads. When the screen displays a message like the one WIPER REPLACE shown, it means the item needs to be replaced. Replace with new items. - Page 80 4-5 Replacing Consumable Parts Touch the location shown in the figure to discharge any static electricity. Preparations are complete when this screen appears. FINISHED? Replace the wipers. Use the included tweezers. Detach the old wipers. Detach the hook and pull up and out. ...

- Page 81 4-5 Replacing Consumable Parts Attach the hook. Hook Quit the [REPLACE WIPER] menu. Press CLOSE SIDE COVER Screws Attach the side cover. Side cover Screws Hook Press CLEANING... >> After the process to quit the wiper replacement mode, the screen shown in the figure appears.

-

Page 82: Replacing The Blade

4-5 Replacing Consumable Parts Replacing the Blade If the blade becomes dull, replace it with the included replacement blade. CAUTION Be sure to perform operations as specified by these instructions, and never touch any area not specified in the instructions. Sudden movement of the machine may cause injury. - Page 83 4-5 Replacing Consumable Parts Remove the old blade. Press this pin Blade holder Old blade Install a new blade. Blade holder New blade Reinstall the blade holder. If installed without supporting the screw in this Insert until way, cutting quality may become poor.

-

Page 84: Replacing The Separating Knife

4-5 Replacing Consumable Parts Quit the blade replacement mode. Close the front cover. MAINTENANCE REPLACE KNIFE Press Press W 736mm Press to go back to the original screen. SETUP SHEET ROLL Replacing the Separating Knife If the separating knife becomes dull, replace it with the included replacement knife. CAUTION Be sure to perform operations as specified by these instructions, and never touch any area not specified in the instructions. - Page 85 4-5 Replacing Consumable Parts Replace the separating knife. Remove the separating knife. Loosen the screw until it slips out. Grasp the screw portion, and slowly pull it out in the direction of the arrow. When doing this, do not pull it back toward you. ...

- Page 86 4-5 Replacing Consumable Parts Quit the blade replacement mode. Close the front cover. MAINTENANCE REPLACE KNIFE Press Press W 736mm Press to go back to the original screen. SETUP SHEET ROLL Chapter 4 Maintenance and Adjustment...

-

Page 87: When Not In Use For A Prolonged Period

4-6 When Not in Use for a Prolonged Period Keep Performing Maintenance Switch on the power once every two weeks. Switch on the sub power once every two weeks. When you turn on the power, the machine automati- cally performs some operations such as those to keep the print heads from drying out. Allowing the machine to stand completely unused for a prolonged period may damage the print heads, so be sure to switch on the power to perform these automatic operations. -

Page 88: When Moving The Unit

Insert each color ink cartridge into the slot labeled with the matching color. If you insert wrong cartridges when filling ink, the condition cannot be restored easily. Contact your authorized Roland DG Corp. dealer or us, if you filled ink with wrong cartridges inserted. Drain the ink and wash the interior. - Page 89 4-7 When Moving the Unit Press CHECK DRAIN BOTTLE Discard the discharged ink in the drain bottle. Be sure to discard the discharged ink. Press Thereafter, follow the on-screen instructions to carry out the operations. After cleaning has finished, the sub power is automatically switched off. ...

-

Page 91: Chapter 5 Feature Reference

Chapter 5 Feature Reference... -

Page 92: Pausing Or Canceling Output

5-1 Pausing or Canceling Output Canceling Output Before It Finishes Procedure Press Hold down for one second or longer. Stop sending output data from the computer. Description pauses output. Pressing a second time here resumes printing, but a horizontal stripe is produced at the location where printing was stopped. -

Page 93: Setting The Print-Start Position

5-2 Setting the Print-start Position Setting the Print-start Position Procedure to move the cutting carriage. Align the center of the blade with the new print-start position. Printing area Print-start position Scan-direction start position Feed-direction start position Press W 600mm This indicates that the printing-start position has been set. - Page 94 5-2 Setting the Print-start Position Description You can set the print-start position at any location you want. Note, however, that this setting returns to its default value after printing, and so it needs to be set separately for each page. When the start location has been set, lights up and screen displays the character “B”...

-

Page 95: Accommodating Various Kinds Of Media

5-3 Accommodating Various Kinds of Media Using Transparent Media Procedure Press MENU MENU SUB MENU SUB MENU Press several times. Press twice. EDGE DETECTION ENABLE DISABLE to select "DISABLE." Press to enable the setting. The settings are changed and the screen shown in the figure appears. -

Page 96: Speeding Up Printing For Narrow Media

5-3 Accommodating Various Kinds of Media Description The platen uses suction to grip the media and keep it stable. When media comes loose from the platen because it is warped or wrinkled, increasing the suction force may help correct the problem. Conversely, when the media is flimsy and cannot move smoothly, reducing the suction force may help. -

Page 97: Preventing Soiling Of The Media And Dot Drop-Out During Printing

5-3 Accommodating Various Kinds of Media ■Range of print-head movement when set to "OFF" Next print-start position Print-end position Feed direction Print-start position Scan direction Printing area Print-head movement range Default Setting [FULL WIDTH S]: FULL Preventing Soiling of the Media and Dot Drop-out During Printing Procedure ... -

Page 98: Printing Media That Warps Easily

5-3 Accommodating Various Kinds of Media Description Ink tends to collect on the surface of the heads when you use media prone to buildup of static charge, when the ambient temperature is low, or when the head height is set to “HIGH. ” Under some conditions, this ink may be transferred to the media or cause dot drop-out. -

Page 99: Default Setting

5-3 Accommodating Various Kinds of Media Replace the short media clamps with the long ones. Remove the short media clamps. Pull back while hold- Push here. ing down the area. Attach the long media clamps. Insert until it clicks into place. -

Page 100: How To Load Sheet Media

5-3 Accommodating Various Kinds of Media How to Load Sheet Media To load and use sheet media, follow the steps below. Load the sheet media. Measure the thickness of the sheet media. If the measured value is 0.5 millimeters or more, increase the height of the print heads. ... - Page 101 5-3 Accommodating Various Kinds of Media Open the front cover. Align the end of the sheet media with the location shown in the figure. Sheet media Align here Pull back the loading lever. The sheet media is secured in place. Loading lever ...

- Page 102 5-3 Accommodating Various Kinds of Media Make sure that media feed is stable. If any of the situations described below takes place, problems such as the print heads striking the sheet media may occur, resulting in malfunction or the like. Reload the sheet media. If the problem persists, the sheet media cannot be used.

- Page 103 5-3 Accommodating Various Kinds of Media Press and hold Hold down until the print-end position reaches the platen. ① ② For media that passes through the media discharge port of , be sure to comply with the following. Otherwise problems such as the print heads striking the sheet media may occur, resulting in malfunction or the like.

-

Page 104: Changing How The Printer Operates

5-4 Changing How the Printer Operates Executing Environment Matching Automatically Procedure Press MENU CUTTING MENU Press several times. Press CUTTING MENU AUTO ENV. MATCH Press Press AUTO ENV. MATCH DISABLE ENABLE to select "ENABLE." Press to enable the setting. ... -

Page 105: Setting The Interval Until Activation Of The Sleep Mode

5-4 Changing How the Printer Operates Press W 736mm Press to go back to the original screen. SETUP SHEET ROLL Description This lets you change, according to your purpose, the operation that takes place when an ink cartridge is empty. "STOP"... -

Page 106: Changing The Menu Language And The Units Of Measurement

5-4 Changing How the Printer Operates Changing the Menu Language and the Units of Measurement Procedure Hold down and switch on the sub power. to select the display (menu) language. Press to select the measurement unit LENGTH UNIT INCH for length. -

Page 107: Optimizing Printing To Match Media Thickness

5-5 Optimizing Printing to Match Media Thickness Adjusting Head Height to Match Media Thickness Procedure Press MENU HEAD HEIGHT Press several times. Press HEAD HEIGHT Open the front cover. Move the lever to adjust the height of the head. Moving the lever to "HIGH"... -

Page 108: Correcting For Misalignment In Bidirectional Printing

5-5 Optimizing Printing to Match Media Thickness Correcting for Misalignment in Bidirectional Printing Print a test pattern. Press MENU ADJUST BI-DIR Press Press ADJUST BI-DIR TEST PRINT Press to start printing. Read the correction values from the test pattern. Choose the value that produc- es the least misalignment. -

Page 109: Correcting For Misalignment In Bidirectional Printing More Precisely

5-5 Optimizing Printing to Match Media Thickness Description The bidirectional-printing mode (in which the heads perform printing during both their outbound pass and return pass) offers the advantage of being able to shorten printing times, but subtle misalignment occurs during the outbound and return passes. The procedure to correct this and eliminate misalignment is bidirectional correction. - Page 110 5-5 Optimizing Printing to Match Media Thickness Read the correction values from the test pattern. Test pattern LEC-330 NO.4 LEC-300A NO.3 NO.4 NO.3 NO.2 NO.2 NO.1 NO.1 Choose the value that produces the least misalignment. NO.1 Correction-value Current correction value scale If the Printing-test Results Are Difficult to Interpret Examine the results from different angles in a well-lighted location.

- Page 111 5-5 Optimizing Printing to Match Media Thickness Press DETAIL SETTING SETTING NO.2 Press to select. Use set the correction value. Only LEC-330 Press to finish making the settings for [SET- TING NO.2]. Press DETAIL SETTING SETTING NO.3 ...

-

Page 112: Performing Feed Correction To Alleviate Horizontal Bands And The Like

5-5 Optimizing Printing to Match Media Thickness Performing Feed Correction to Alleviate Horizontal Bands and the Like Print a test pattern. Press MENU CALIBRATION Press several times. Press CALIBRATION TEST PRINT Press to start printing. Read the correction values from the test pattern. In the printing example shown below, "-0.40"... - Page 113 5-5 Optimizing Printing to Match Media Thickness Description The movement distance of media experiences subtle changes due to the thickness of the media . When the movement distance becomes discrepant, horizontal stripes are more likely to occur during print- ing. We recommend performing correction to match the media you're using. Also, perform the actual printing in an operating environment identical to that used for the test pattern.

-

Page 114: Performing Distance Correction During Cutting

5-5 Optimizing Printing to Match Media Thickness Performing Distance Correction During Cutting Procedure Press MENU CUTTING MENU Press several times. Press CUTTING MENU CALIBRATION Press twice. Press twice. FEED SETTING 0.00% 0.00% to make the setting for the cor- rection value. -

Page 115: Making Various Adjustments For Cutting

5-6 Making Various Adjustments for Cutting Making the Cutting Conditions Set on the Machine Take Precedence Procedure Press MENU CUTTING MENU Press several times. Press CUTTING MENU CUTTING PRIOR Press several times. Press CUTTING PRIOR COMMAND MENU to select "MENU."... - Page 116 5-6 Making Various Adjustments for Cutting Description This enables you to check and verify the settings for the cutting conditions using cutting-test results. P. 51, "Performing a Cutting Test" [FORCE]: This sets the force (pressure) of the blade. [SPEED]: This sets the speed of cutting. [OFFSET]: This makes the blade-offset setting for the blade.

-

Page 117: Adjusting The Cutting-In Amount

5-6 Making Various Adjustments for Cutting Adjusting the Cutting-in Amount When you want to perform accurate and fine adjustment of the cutting-in amount, such as when cutting media with thin carrier paper, you can obtain good results by adjusting the tip of the blade. Turn the cap portion of the blade holder to adjust the amount of blade extension. -

Page 118: Adjusting For When Cutting The Printed Surface

5-6 Making Various Adjustments for Cutting Adjusting for When Cutting the Printed Surface Decide on the starting position for cutting-test printing. Load the media. P. 33, "Loading Media" P. 98, "How to Load Sheet Media" to move the cutting carriage. You can perform cutting-test printing at any location you want. - Page 119 5-6 Making Various Adjustments for Cutting Perform a cutting test overtop the cutting-test print pattern. Check the results of the cutting test and make adjustments. Open the front cover. Check the results of the cutting test and make adjustments. ...

-

Page 120: Preventing Pulling Of The Media With Undue Force When Performing Cutting Only

5-6 Making Various Adjustments for Cutting Open the front cover. Check the results of the cutting test. Adjustment is complete when optimal results are obtained. If further adjustment is needed, go back to step and fine-tune the adjustment. Description Hardened ink is thick. -

Page 121: Correcting Misalignment Of The Printing And Cutting Positions

5-6 Making Various Adjustments for Cutting Correcting Misalignment of the Printing and Cutting Positions Check the setting for the [AUTO ENV. MATCH] menu item. Make sure the [AUTO ENV. MATCH] menu item is set to "ENABLE." P. 102, "Executing Environment Matching Automatically" Execute the [ADJUST BI-DIR] menu item. - Page 122 5-6 Making Various Adjustments for Cutting Print and cut a test pattern for setting the correction values. Press PRINT - CUT ADJ. TEST PRINT 2 Press to execute. From the test pattern, read the value at the location. Test pattern Cutting line Check the value on the [SCAN] side.

- Page 123 5-6 Making Various Adjustments for Cutting Check the results of adjustment. Press PRINT - CUT ADJ. TEST PRINT Press to execute. If the printing and cutting lines are aligned, adjustment is complete. If further adjustment is needed, go back to step and fine- tune the adjustment.

-

Page 124: Performing Printing And Cutting Separately

5-7 Performing Printing and Cutting Separately To Perform Printing and Cutting Separately When you remove printed media and then reload it and perform cutting, you carry out alignment to prevent misalignment of the printing results and the cut lines. You do this at times such as when, for example, you perform lamination or other processing after printing, then reload the media and perform cutting. -

Page 125: Aligning Automatically And Cutting

5-7 Performing Printing and Cutting Separately Aligning Automatically and Cutting When you make the setting for reading crop marks when sending cutting data from the computer, alignment is performed with the presence or absence of crop marks determined automatically. For information on how to make the setting, refer to the documentation for the software RIP you're using. -

Page 126: Aligning Manually And Cutting

5-7 Performing Printing and Cutting Separately To Quit Detection and Start Cutting Press CANCEL CROPMARK DETECTION? Crop-mark detection stops. Depending on the content of the data, some time may pass before detection actually stops. Press This stops detection and starts cutting. ... - Page 127 5-7 Performing Printing and Cutting Separately Hold down for one second or longer. SETTING ALIGN POINT 1 The number of the align point you set is automatically deter- mined. Press This indicates that the base point and align point 1 have been set. ...

-

Page 128: Correcting Misalignment For Printing And Cutting When Using Crop Marks

5-7 Performing Printing and Cutting Separately Correcting Misalignment for Printing and Cutting When Using Crop Marks Check the setting for the [AUTO ENV. MATCH] menu item. Make sure the [AUTO ENV. MATCH] menu item is set to "ENABLE." P. 102, "Executing Environment Matching Automatically" Execute the [ADJUST BI-DIR] menu item. - Page 129 5-7 Performing Printing and Cutting Separately Print and cut a test pattern for adjustment. Press PRINT - CUT ADJ. TEST PRINT 2 Press to execute. From the test pattern, read the correction value at the location. Test pattern Cutting line Check the value on the [SCAN] side.

- Page 130 5-7 Performing Printing and Cutting Separately Check the results of adjustment. Press CROP - CUT ADJ. SETTING Press to execute. If the printing and cutting lines are aligned, adjustment is complete. If further adjustment is needed, go back to step and fine- tune the adjustment.

-

Page 131: Gloss Ink Features And Printing Methods

5-8 Gloss Ink Features and Printing Methods Features of Gloss Ink The Gloss ink that this unit uses can impart a glossy feel to the printed item, as well as enhancing weatherability and robustness*. Also, depending on the printing settings, you can even deliberately eliminate glossiness and produce a matte finish, or perform fill overprinting using gloss ink to raise the printed surface and create an embossed finish. -

Page 132: White Ink Features And Printing Methods

5-9 White Ink Features and Printing Methods Features of White Ink The white ink that this unit uses achieves high density and concealment, and is capable of providing attractive results when white and CMYK inks are overprinted. This ink is suited to printing on transpar- ent media, and lets you create results intended to be viewed from the back (the side opposite the printed surface) by reversing the image and changing the sequence in which the white ink and CMYK inks are printed. -

Page 133: Saving The Printer Settings To Match The Media

5-10 Saving the Printer Settings to Match the Media Saving Optimized Media Settings As Preset Values Procedure Press MENU PRESET Press Press Press to select any one from "NAME1" to "NAME8." Press to save. The present menu settings are saved in the preset you chose ... -

Page 134: Loading A Saved Preset

5-10 Saving the Printer Settings to Match the Media [PRINT-CUT ADJ.] P. 119, "Correcting Misalignment of the Printing and Cutting Positions" [CROP-CUT ADJ.] P. 126, "Correcting Misalignment for Printing and Cutting When Using Crop Marks" Up to eight types of presets can be saved. You can assign a name to each one. Using media names for these may aid recognition and clarity. - Page 135 5-10 Saving the Printer Settings to Match the Media Press NAME to enter a character. Press NAME SAMPLE_ to enter the next character. Enter the following characters in the same way. When you're finished entering text, press Press W 736mm Press...

-

Page 136: Making The Network Settings

5-11 Making the Network Settings Setting the IP Address, Subnet Mask, Etc. Procedure Press MENU SYSTEM INFO. Press several times. Press SYSTEM INFO. NETWORK Press Press NETWORK IP ADDRESS to choose the item whose setting you want to make. ... -

Page 137: Viewing Information About The Media And The System

5-12 Viewing Information about the Media and the System Displaying the Amount of Media Remaining Procedure Press MENU SHEET REMAIN Press several times. Press SHEET REMAIN SET LENGTH Press Press SET LENGTH 0.0 m 25.0 m to set the amount of media re- maining. -

Page 138: Verifying The Setting For The Amount Remaining Every Time The Media Is Changed

5-12 Viewing Information about the Media and the System Verifying the Setting for the Amount Remaining Every Time the Media Is Changed Procedure Press MENU SHEET REMAIN Press several times. Press SHHET REMAIN AUTO DISPLAY Press twice. Press AUTO DISPLAY DISABLE... -

Page 139: Printing The Amount Of Remaining Media

5-12 Viewing Information about the Media and the System Printing the Amount of Remaining Media Procedure Press MENU SHEET REMAIN Press several times. Press SHHET REMAIN PRINT MEMO Press to perform printing. Press W 736 mm L 25.0 m Press to go back to the original screen. -

Page 140: Viewing The Serial Number, Firmware Version, And Other Information

5-12 Viewing Information about the Media and the System Viewing the Serial Number, Firmware Version, and Other Information Procedure Press MENU SYSTEM INFO. Press several times. Press SYSTEM INFO. SERIAL NO. to choose the information you want to view. ... -

Page 141: Viewing The Network Settings

5-12 Viewing Information about the Media and the System Viewing the Network Settings Procedure Press MENU SYSTEM INFO. Press several times. Press SYSTEM INFO. NETWORK Press Press NETWORK IP ADDRESS to choose the information you want to view. ... -

Page 142: Performing Maintenance

5-13 Performing Maintenance Draining Ink and Performing Internal Washing Procedure Press MENU SUB MENU Press several times. Press SUB MENU INK CONTROL Press twice. Press INK CONTROL HEAD WASH Press twice. Press to execute. Description This drains the ink inside the printer and washes the interior using cleaning SOL INK cartridges as a preliminary procedure for moving the printer or conducting maintenance. -

Page 143: Switching The Ink Type

5-14 Switching the Ink Type Restrictions on Switching Ink Type On this machine, you can switch the ink type using the [HEAD WASH] INK CONTROL HEAD WASH menu after filling with ink. However, there are the restrictions given below: The ink types that can be used on this machine are the ECO-UV ink and ECO-UVS ink. ... -

Page 144: Method For Switching The Ink Type

5-14 Switching the Ink Type Method for Switching the Ink Type This operation requires four unused SOL INK cleaning cartridges. Have these on hand before you start. Affixing the Cartridge-slot Labels. Open the ink cartridge cover. Knob Hold the knob. ... - Page 145 Insert each color ink cartridge into the slot labeled with the matching color. If you insert wrong cartridges when filling ink, the condition cannot be restored easily. Contact your authorized Roland DG Corp. dealer or us, if you filled ink with wrong cartridges inserted. ...

- Page 146 Be sure to perform the following operation after filling with ink. Otherwise, you cannot use VersaWorks. Procedure From the [Start] menu, click [All programs (or Programs) ] - [Roland VersaWorks] - [Roland VersaWorks] - [Initialize Application]. Click [ Yes ] when a confirmation message for initialization of the application appears.

-

Page 147: Menu List

5-15 Menu List Main Menu Press To the [CUT TEST PRINT] menu To the [NAME8] menu To the [NAME] menu MENU PRESET LOAD PRESET LOAD NAME1 LOAD NAME2 LOAD NAME3 LOAD NAME4 LOAD NAME5 LOAD NAME6 LOAD NAME7 LOAD NAME8 To the [NAME1] menu To the [NAME8] menu PRESET... - Page 148 5-15 Menu List Continued Continued Continued To the [NAME8] menu PRESET NAME NAME NAME NAME1 To the [LOAD] menu NAME NAME NAME2 NAME NAME NAME3 NAME NAME NAME4 NAME NAME NAME5 NAME NAME NAME6 NAME NAME NAME7 NAME NAME NAME8 To the [NAME1] menu To the [DETAIL SETTING] menu MENU...

- Page 149 5-15 Menu List Continued MENU HEAD HEIGHT HEAD HEIGHT To the [MAINTENANCE] menu MENU SUB MENU EDGE DETECTION SUB MENU EDGE DETECTION ENABLE ENABLE SUB MENU VACUUM POWER. VACUUM POWER AUTO AUTO SUB MENU FULL WIDTH S FULL WIDTH S FULL FULL SUB MENU...

- Page 150 5-15 Menu List Continued To the [NETWORK] menu MODEL MODEL MENU SYSTEM INFO . LEC-330 LEC-300A SYSTEM INFO . MODEL SYSTEM INFO . SERIAL NO . SERIAL NO . ZS00001 SYSTEM INFO . ECO-UV C M Y K Gl W SYSTEM INFO .

- Page 151 5-15 Menu List Continued To the [TEST PRINT 2] menu To the [AUTO ENV. MATCH] menu MENU CUTTING MENU PRINT-CUT ADJ. CUTTING MENU PRINT-CUT ADJ. TEST PRINT (*1) PRINT-CUT ADJ. SETTING PRINT-CUT ADJ. TEST PRINT 2 To the [TEST PRINT] menu To the [TEST PRINT 2] menu CUTTING MENU CROP-CUT ADJ.

-

Page 152: Language And Unit Menu

5-15 Menu List Language and Unit Menu Hold down and switch on the sub power. MENU LANGUAGE ENGLISH LENGTH UNIT TEMP UNIT Cleaning Menu Press To the [POWERFUL CL.] menu NORMAL CL. NORMAL CL. CLEANING NORMAL CL. MEDIUM CL. MEDIUM CL. CLEANING MEDIUM CL. -

Page 153: Cutting Configuration Menu

5-15 Menu List Cutting Configuration Menu Press FORCE SPEED OFFSET UP SPEED 50 gf 50 gf 30 cm/s 30 cm/s 0.250 mm 0.250 mm 30 cm/s 30cm/s Chapter 5 Feature Reference... -

Page 155: Chapter 6 What To Do If

Chapter 6 What to Do If... -

Page 156: The Machine Doesn't Run

6-1 The Machine Doesn't Run network has not been made. Make sure the network The Printer Unit Doesn't Run routing is suitable. Try connecting the computer and Is the power switched on? the machine to the same hub, or connecting them Switch on the printer's main power, then press the directly using a crossover cable. -

Page 157: Attractive Printing Is Impossible

6-2 Attractive Printing Is Impossible Printed Results Are Coarse or Contain Horizontal Stripes Have you carried out bidirectional correc- tion? Do the print heads show dot drop-out? When you are performing bidirectional printing, Carry out a printing test and make sure no dot drop- use the [ADJUST BI-DIR] menu item to carry out out occurs. -

Page 158: Colors Are Unstable Or Uneven

6-2 Attractive Printing Is Impossible Are the operating parameters set to appro- Are the settings for the [PRESET] menu item priate values? appropriate? Depending on the settings for such menu items as If the settings selected with the [PRESET] menu item [FULL WIDTH S] and [PERIODIC CL.], uneven colors are not suitable for the type of media, printing may may occur. -

Page 159: Cutting Is Misaligned Or Skewed

6-2 Attractive Printing Is Impossible Are you using media that exhibits large Are the print heads dirty? expansion and contraction? The following may cause ink to drip on the media When you're performing printing followed immedi- during printing. ately by cutting, misalignment occurs if the media • Buildup of fibrous dust (lint) around the expands or contracts. -

Page 160: The Media Jams

6-3 The Media Jams The Media Jams If an error message is displayed because the media has jammed, immediately correct the problem. Failure to do so may damage the print heads. P. 165, "[MOTOR ERROR TURN POWER OFF]" Is the media warped or wrinkled? Many factors can cause warping or wrinkling. -

Page 161: The Media Cannot Be Taken Up Smoothly

6-4 The Media Cannot Be Taken Up Smoothly The Media Cannot Be Taken Up Smoothly Is media feed unstable? Various factors can make media feed unstable. Refer to the following and correct the problem. P. 160, "6-5 Media Wrinkles or Shrinks, or Feed Is Unstable" ... -

Page 162: Media Wrinkles Or Shrinks, Or Feed Is Unstable

6-5 Media Wrinkles or Shrinks, or Feed Is Unstable A variety of problems can occur if the media feed is not smooth. This can cause such problems as poor printing quality, contact with the media by the print heads, misaligned positioning, or media jams. -

Page 163: The Print Heads Stopped Moving

If the Heads Still Do Not Move If the heads still do not move, carry out the following emergency response measure, then contact your authorized Roland DG Corp. dealer. 1. Switch off the main power. 2. Open the front cover. -

Page 164: If A Message Appears

6-7 If a Message Appears [INSTALL DRAIN BOTTLE] These are the main messages that appear on the machine's display to prompt correct op- Check whether the drain bottle is installed. Install the eration. They do not indicate any error. Follow drain bottle, then press the prompts and take action accordingly. -

Page 165: If An Error Message Appears

Note the number displayed, then switch off the sub power. After you switch off the power, inform your authorized Roland DG Corp. dealer of the number that appeared on the display. Chapter 6 What to Do If... - Page 166 6-8 If an Error Message Appears power. The displayed temperature is the current [SHEET TOO SMALL CONTINUE?] ambient temperature of the installation location. The size of the data is larger than the print- Bring the installed location to a temperature at ing or cutting area of the loaded media.

-

Page 167: Powerful Cleaning

Switch off the sub power. After you switch off the Excessive tension was applied to the media, and power, inform your authorized Roland DG Corp. additional action is necessary to recover from this dealer. state. First, move the loading lever to the rear and adjust the media to create a small amount of slack, then switch on the sub power. -

Page 169: Chapter 7 Specifications

Chapter 7 Specifications... -

Page 170: Usable Media

7-1 Usable Media Conditions for Usable Media Media width 182 to 762 mm (7.2 to 30 inches) A) Cuttable media thickness 0.08 to 0.22 mm (3.2 to 8.6 mil) (depending on media composition) B) Maximum media thickness (including backing paper) Printing only: 1.0 mm (39 mil) When performing cutting: 0.4 mm (15 mil) C) Roll outer diameter... -

Page 171: Printing Or Cutting Area

7-2 Printing or Cutting Area Maximum Area The printing or cutting area along the horizontal plane (the direction in which the carriage moves) is determined by the position of the pinch rollers. 210 mm Max. 736 mm (29 in.) (8.3 in.) Media Max. -

Page 172: Media-Cutoff Location During Continuous Printing

7-2 Printing or Cutting Area Media-cutoff Location During Continuous Printing When a media-cutoff command is sent from the computer, the cutoff location on the media is as shown in the figure below. Second page 75 mm (3 in.) Location where separated Margin (setting on the computer) -

Page 173: About The Blade

7-3 About the Blade The cutting conditions and the service life of the blade change according to the media and the operat- ing environment, even when using identical blades. The service life also differs according to the type of blade. A rough guide is shown below. Amount of Blade life* Blade... -

Page 174: Locations Of The Power Rating And Serial Number Labels

7-4 Locations of the Power Rating and Serial Number Labels Serial Number This is required when you seek maintenance, servicing, or support. Never peel off the label or let it get dirty. Power Rating Use an electrical outlet that meets the requirements for voltage, fre- quency, and amperage given here. -

Page 175: Specifications

Ink-curing unit Dual UV LED Lamp Printing resolution (dots per inch) Maximum 1440 dpi Acceptable tool Roland CAMM-1 series compatible Cutting speed 10 to 600 mm/s (10 to 300 mm/s in media-feed direction) Blade force 30 to 300 gf Blade offset compensation 0.000 to 1.500 mm (0 to 0.0591 in.) - Page 176 Exclusive stands, power cord, blade, blade holder (XD-CH2), media clamps, replacement blade for separating knife, clean- ing kit, software RIP (Roland VersaWorks) , User's Manual, etc. The length of printing or cutting is subject to the limitations of the program.

- Page 177 For China 产品中有毒有害物质或元素的名称及含量 有毒有害物质或元素 部件名称 六价铬 多溴联苯 多溴二苯醚 铅(Pb) 汞(Hg) 镉(Cd) (Cr(Ⅵ)) (PBB) (PBDE) 印刷电路板 × ○ × ○ ○ ○ 头部 × ○ ○ ○ ○ ○ 壳体、底架 × ○ ○ ○ ○ ○ 电源 × ○ × ○ ○...

- Page 180 (LGPL) soft-ware. You have the right to acquire, modify, and distribute the source code for this GPL/LGPL software. You can obtain the GPL/LGPL source code used in this product by downloading it from the following website. URL: http://www.rolanddg.com/gpl/ Roland DG Corp. has licensed the MMP technology from the TPL Group. R4-130327...

Need help?

Do you have a question about the VersaUV LEC-300A and is the answer not in the manual?

Questions and answers