Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ESAB LPH 120

- Page 1 LPH 120 Bruksanvisning Gebruiksaanwijzing Brugsanvisning Instrucciones de uso Bruksanvisning Instruzioni per l’uso Käyttöohjeet Manual de instruções Instruction Manual Οδηγίες χρήσεως Betriebsanweisung Instrukcja obsługi Manuel d’instructions 0349 301 036 011212 Valid for serial no. 152-xxx-xxxx...

-

Page 2: Table Of Contents

SAFETY ..............................44 INTRODUCTION ............................46 3.1 GENERAL .............................. 46 3.2 SCOPE OF MANUAL..........................46 3.3 TECHNICAL DATA ..........................46 3.4 LPH 120 CUTTING SET PACKAGE...................... 46 INSTALLATION ............................47 4.1 GENERAL .............................. 47 4.2 EQUIPMENT REQUIRED........................47 4.3 LOCATION............................. 47 4.4 INSPECTION ............................ -

Page 3: Directive

Esab Welding Equipment AB, S-695 81 Laxå, Sweden, gives its unreserved guarantee that Plasma Arc Cutting Set LPH 120 from serial number 907 complies with standard EN 60974-1, in accordance with the requirements of directive (73/23/EEC) and addendum (93/68/EEC) and with standard EN 50192, EN 50199, in accordance with the requirements of directive (89/336/EEC) and addendum (93/68/EEC). - Page 4 ! WARNING ! ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING OR CUTTING. ASK YOUR EMPLOYER FOR SAFETY PRACTICES THAT SHOULD BE BASED ON MANUFACTURER’S HAZARD DATA. ELECTRIC SHOCK - Can kill - Install and earth welding equipment in accordance with obligatory standards. - Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothes.

-

Page 5: Introduction

LPH 120 is compact, self-contained plasma cutting system. As shipped, it’s fully assembled and ready to operate after being installed. The set consists of LPH 120 power source and heavy duty PT 25 torch, and is capable of severing materials up to 45 mm thick. -

Page 6: Installation

Adequate ventilation is necessary to provide proper cooling of power source. Amount of dirt, dust and excessive heat, that unit is exposed to, should be minimised. Between LPH 120 and wall (or any obstruction) should remain distance of at least 300 mm, to secure proper air movement through it. -

Page 7: Secondary Connections

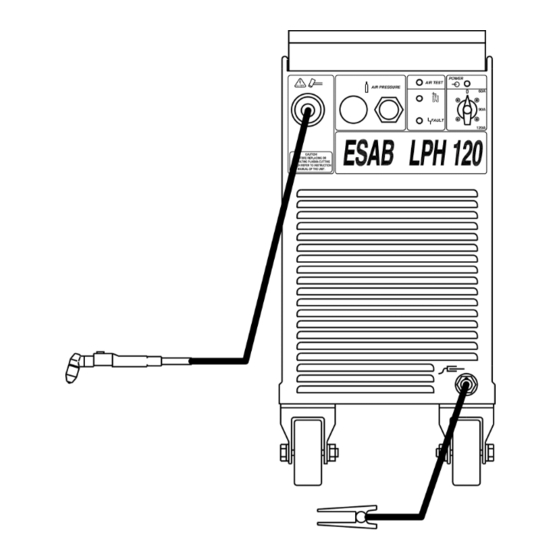

1. Connect air supply line to inlet of regulator. 2. Clamp work cable to workpiece. Make sure the workpiece is connected to ground with properly sized cable. Fig. 4-1. LPH 120 connection diagram. - 48 -... - Page 8 Fig. 4-2. Ground and current cable connections. - 49 -...

-

Page 9: Operation

It is automatic feature that guarantees safe operation of machine (obligatory for units with S symbol). Description power switch knob “power on” LED air test button “arc on” LED “fault” LED air pressure knob pressure gauge line outlet (rubber) current cable socket wheel air filter-preregulator Fig. 5-1. LPH 120 Controls. - 50 -... -

Page 10: Maintenance

MAINTENANCE NOTE: All warranty undertakings given by supplier cease to apply if customer attempts to rectify any faults on machine during warranty period. 6.1 CLEANING A. Power source should be regularly blown with dry compressed air at reduced pressure, more frequently in dirty environment. -

Page 11: Piercing Technique

Below are listed common cutting problems, followed by possible cause of each. If problems are caused by power source, refer to maintenance section of this manual. If it’s still impossible to correct the problem, contact your ESAB distributor. A. Insufficient penetration.

Need help?

Do you have a question about the LPH 120 and is the answer not in the manual?

Questions and answers