Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for MTU 12 V 1600 R50

-

Page 1: Operating Instructions

Operating Instructions Diesel engine 12 V 1600 R50 MS15033/01E... - Page 2 This Publication is protected by copyright and may not be used in any way whether in whole or in part without the prior written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution, translation, mi- crofilming and storage or processing on electronic systems including data bases and online services.

-

Page 3: Table Of Contents

Table of Contents 1 Safety 7.1.2 Cylinder head cover – Removal and installation 1.1 Important provisions for all products 7.2 Fuel System 1.2 Personnel and organizational requirements 7.2.1 Fuel system ‒ Venting 1.3 Transportation 7.3 Fuel Filter 1.4 Safety regulations for startup and operation 1.5 Safety regulations for maintenance and 7.3.1 Fuel filter –... - Page 4 8.2 MTU contact persons/service partners 7.14.4 NOx sensor – Replacement 7.14.5 Lambda sensor – Replacement 9 Appendix B 8 Appendix A 9.1 Special Tools 9.2 Index 8.1 Abbreviations 4 | Table of Contents | MS15033/01E 2014-02...

-

Page 5: Safety

• With fluids and lubricants approved by the manufacturer in accordance with the (→ Fluids and Lubri- cants Specifications of the manufacturer) • With spare parts approved by the manufacturer in accordance with the (→ Spare Parts Catalog/MTU contact/Service partner) •... -

Page 6: Personnel And Organizational Requirements

1.2 Personnel and organizational requirements Organizational measures of the operator This manual must be issued to all personnel involved in operation, maintenance, repair or transporta- tion. Keep this manual handy in the vicinity of the product such that it is accessible to operating, mainte- nance, repair and transport personnel at all times. -

Page 7: Transportation

Only set down engine on a firm, level surface. Make sure that the consistency and load-bearing capacity of the ground or support surface is adequate. Never set an engine down on the oil pan unless expressively authorized to do so by MTU on a case-to- case basis . -

Page 8: Safety Regulations For Startup And Operation

1.4 Safety regulations for startup and operation Safety regulations for startup Install the product correctly and carry out acceptance in accordance the manufacturer's specifications before putting the product into service. Before the product is put into operation for the first time, all official authorizations must be available and commissioning preconditions met. -

Page 9: Safety Regulations For Maintenance And Repair Work

1.5 Safety regulations for maintenance and repair work Safety regulations prior to maintenance and repair work Have maintenance or repair work carried out by qualified and authorized personnel only. Allow the product to cool down to less than 50°C before starting maintenance work (risk of explosion of oil vapors, fluids and lubricants, risk of burning). - Page 10 Ensure particular cleanness during maintenance and repair work on the product. After completion of maintenance and repair work, make sure that no unattached parts are in/on the product (e.g. cloths and cable ties). Safety regulations after completion of maintenance and repair work Before barring, make sure that nobody is standing in the danger zone of the product.

- Page 11 Working on electrical and electronic assemblies Always obtain the permission of the person in charge before commencing maintenance and repair work or switching off any part of the electronic system required to do so. De-energize the appropriate areas prior to working on assemblies. Do not damage cabling during removal work.

-

Page 12: Fire Prevention And Environmental Protection, Fluids And Lubricants, Auxiliary Materials

The latest version can be found on the website on the "Technical Info" or "Spare Parts and Service" tabs at http://www.mtu-online.com. Consumable fluids and materials may also be hazardous or toxic. When using fluids, lubricants, consum- ables and other chemical substances, follow the safety regulations that apply to the product. -

Page 13: Compressed Air

Lead • Adopt suitable measures to avoid the formation of lead dust. • Switch on extraction system. • When working with lead or pastes that contain lead, avoid direct contact with the skin. Do not inhale lead vapors. • Wash hands after contact with lead or lead-containing substances. Compressed air Observe special safety precautions when working with compressed air: •... -

Page 14: Standards For Safety Notices In The Text

1.7 Standards for safety notices in the text DANGER In the event of immediate danger. Consequences: Death, serious or permanent injury! • Remedial action. WARNING In the event of a situation involving potential danger. Consequences: Death, serious or permanent injury! •... -

Page 15: General Information

2 General Information 2.1 Engine side and cylinder designations Engine sides are always designated as viewed from the driving end (KS) (4). For designation of the cylinders (to DIN ISO 1204) the letter "A" (1) is used to refer to the cylinders on the left-hand side of the engine and the letter "B"... -

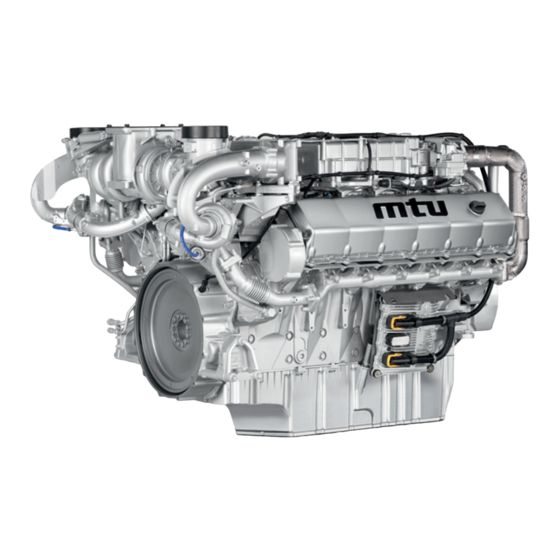

Page 16: Engine Layout

2.2 Engine layout 1 Exhaust outlet 9 Fuel filter 17 Engine governor 2 Air intake 10 Thermostat housing 18 Oil pan 3 Intermediate intercooler 11 Oil filter 19 Exhaust elbow 4 Lifting eye, driving end 12 EGR flap before EGR cool- 20 Flywheel housing 5 Intermediate intercooler 21 Coupling... -

Page 17: Sensors And Actuators

2.3 Sensors and actuators Description Monitoring of B5.1 Lube oil pressure after filter Charge-air pressure B9.1 Charge-air temperature before EGR B5.3 Lube oil pressure before filter Residual oxygen content in exhaust gas (Lambda sensor) Nitrogen oxide levels in exhaust gas (NOx sensor) MS15033/01E 2014-02 | General Information | 17... - Page 18 Description Monitoring of B44.3 Turbocharger C speed B44.4 Turbocharger D speed B44.2 Turbocharger B speed Camshaft speed Crankshaft speed B44.1 Turbocharger A speed 18 | General Information | MS15033/01E 2014-02...

- Page 19 Description Monitoring of Charge-air coolant temperature Lube oil level B4.22 Exhaust temperature, B-side MS15033/01E 2014-02 | General Information | 19...

-

Page 20: Technical Data

3 Technical Data 3.1 Firing order 12 V A1–B2–A5–B4–A3–B1–A6–B5–A2–B3–A4–B6 Direction of rotation Direction of rotation (as viewed on driving c.c.w., not reversible end) 20 | Technical Data | MS15033/01E 2014-02... -

Page 21: Engine - Main Dimensions

3.2 Engine – Main dimensions Item Dimensions Length (A) approx. 1871 mm Width (B) approx. 1228 mm Height (C) approx. 1327 mm MS15033/01E 2014-02 | Technical Data | 21... -

Page 22: 1600 R50 Engine Data

3.3 12V 1600 R50 engine data Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 23 Number of cylinders Compression ratio 17.7 Number of inlet valves per cylinder Number of exhaust valves per cylinder Combustion air / exhaust gas Number of cylinders Exhaust temperature after turbocharger °C Coolant system (high-temperature circuit) Number of cylinders Coolant temperature (at engine connection: outlet to cooling equipment) °C Coolant temperature after engine, shutdown °C...

- Page 24 Weights / main dimensions Number of cylinders Dry engine weight (basic-configuration engine) 2309 Acoustics Number of cylinders Exhaust noise, unsilenced - BL (free-field sound-pressure level Lp, 1m dis- dB(A) tance, ISO 6798, +3dB(A) tolerance) Engine surface noise with attenuated intake noise (filter) - BL (free-field sound- dB(A) pressure level Lp, 1 m distance, ISO 6798, +2dB(A) tolerance) 24 | Technical Data | MS15033/01E 2014-02...

-

Page 25: Operation

4 Operation 4.1 Preparation for startup after a scheduled break in operation Preconditions ☑Engine is stopped and starting disabled. Starting up Item Action Lube oil system Check engine oil level (→ Page 87). Coolant circuit Check engine coolant level (→ Page 90); Check charge-air coolant level (→... -

Page 26: Preparation For Startup After Extended Out-Of-Service Periods (>3 Months)

4.2 Preparation for startup after extended out-of-service periods (>3 months) Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001063/..) are available. Startup after long out-of-service periods (>3 months) Item Action Engine Depreserve (→ MTU Fluids and Lubricants Specifications A001063/..). -

Page 27: Starting The Engine

4.3 Starting the engine Preconditions ☑Engine is not connected to load. ☑External start interlock is not active. DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Before cranking the engine with starter system, make sure that there are no persons in the en- gine's danger zone. -

Page 28: Operational Checks

4.4 Operational checks DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. Risk of damage to hearing! •... -

Page 29: Engine - Stop

4.5 Engine – Stop Preconditions ☑Engine is not connected to load NOTICE Stopping the engine when it is running at full load subjects it to extreme thermal and mechanical stresses. Overheating of and, therefore, damage to components is possible! • Before shutting down the engine, allow it to idle until the engine temperatures decrease and constant levels are indicated. -

Page 30: After Engine Shutdown

If the engine is to remain out of service for more than 1 week, seal the en- tems gine's air and exhaust sides. If the engine is to remain out of service for more than 1 month, carry out preservation (→ MTU Fluids and Lubricants Specifica- tions A001063/..). 30 | Operation | MS15033/01E 2014-02... -

Page 31: Plant - Cleaning

4.7 Plant – Cleaning Preconditions ☑Engine is stopped and starting disabled. ☑Operating voltage is not applied. Special tools, Material, Spare parts Designation / Use Part No. Qty. Steam jet cleaner Cleaner (Hakupur 312) 30390 WARNING Compressed air gun ejects a jet of pressurized air. Risk of injury to eyes and damage to hearing, risk of rupturing internal organs! •... -

Page 32: Engine - Barring Manually

4.8 Engine – Barring manually Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Barring gear F6790714 Adapter F30011619 Ratchet adapter F30027340 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... -

Page 33: Maintenance

5 Maintenance 5.1 Maintenance task reference table [QL1] The maintenance tasks and intervals for this product are defined in the Maintenance Schedule. The Maintenance Schedule is a stand-alone publication. The task numbers in this table provide reference to the maintenance tasks specified in the Maintenance Schedule. -

Page 34: Troubleshooting

6 Troubleshooting 6.1 Troubleshooting Engine does not turn when starter is actuated Component Cause Action Battery Low or faulty Charge or replace (see manufacturer's documentation). Cable connections faulty Check if cable connections are properly secured (see manufacturer's documen- tation). Starter Engine cabling or starter faulty Check cable connections for secure seating;... - Page 35 Contact Service. Table 6: Engine speed not steady Charge-air temperature too high Component Cause Action Engine coolant Engine coolant treatment incorrect Check (MTU test kit). Intercooler Contaminated Contact Service. Engine room Air-intake temperature too high Check fan; check air inlet/outlet ducts.

- Page 36 Black exhaust gas Component Cause Action Air supply Air filter clogged Replace air filter (→ Page 85). Fuel injection equip- Injector faulty Contact Service. ment Engine Overloaded Contact Service. Table 10: Black exhaust gas Blue exhaust gas Component Cause Action Engine oil Too much oil in engine Drain engine oil (→...

-

Page 37: Fault Messages Of Engine Governor Ecu

6.2 Fault messages of engine governor ECU 9 for Series 1600, rail applications 3 – HI T-Fuel ZKP-Number: 2.0122.931 Yellow alarm; warning Cause Corrective action Fuel temperature too high. u Reduce power. 4 – SS T-Fuel (Limit 2) ZKP-Number: 2.0122.932 Red alarm;... - Page 38 10 – SS T-Coolant Intercooler (Limit 2) ZKP-Number: 2.0124.932 Yellow alarm; power limitation < 20%; Cause Corrective action Coolant temperature in 1. Reduce power. intercooler too high. 2. Check engine lines for leaks. Check coolant cooler for leaks, contamination and operation. 3.

- Page 39 21 – HI T-Exhaust B ZKP-Number: 2.0127.931 Yellow alarm; warning Cause Corrective action Exhaust gas temperature (B- 1. Reduce power. side) too high. 2. Check air filter. 3. Request towing locomotive if required. 22 – SS T-Exhaust B ZKP-Number: 2.0127.932 Red alarm;...

- Page 40 31 – HI ETC1 Overspeed (Limit 1) ZKP-Number: 2.3011.931 Yellow alarm; power limitation > 20% Cause Corrective action ETC 1 (A-side) speed too high. 1. Reduce power. 2. Check air filter. 3. Check exhaust pipe visually for leaks. 4. Request towing locomotive if required. 32 –...

- Page 41 37 – SS ETC2 Overspeed (Limit 2) ZKP-Number: 2.3013.912 Red alarm; power reduction ≥ 20% Cause Corrective action ETC 2 (B-side) speed too high. 1. Reduce power. 2. Check air filter. 3. Check exhaust pipe visually for leaks. 4. Request towing locomotive if required. 51 –...

- Page 42 60 – SS T-Coolant (Limit 4) ZKP-Number: 2.0120.934 Red alarm; engine stop Cause Corrective action Coolant temperature too high. 1. Allow engine to cool down. 2. Check engine coolant cooler, clean if dirty. 3. Acknowledge alarm. 4. Restart engine (→ Page 27). 5.

- Page 43 67 – HI T-Coolant (Limit 1) ZKP-Number: 2.0120.931 Yellow alarm; warning Cause Corrective action Coolant temperature too high. 1. Reduce power. 2. Check engine coolant cooler, clean if dirty. 68 – SS T-Coolant (Limit 2) ZKP-Number: 2.0120.932 Yellow alarm; power limitation < 20%; Cause Corrective action Coolant temperature too high.

- Page 44 90 – SS Idle Speed Not Reached ZKP-Number: 2.1090.925 Yellow alarm; warning Cause Corrective action Idle speed not reached. 1. Check battery. 2. Check wiring and voltage supply. 3. Initiate new starting attempt. 4. Request towing locomotive if required. 91 – SS Release (Run up)Speed Not Reached (< ~300 RPM) ZKP-Number: 2.1090.924 Yellow alarm;...

- Page 45 94 – LO T-Preheat ZKP-Number: 2.1090.921 Yellow alarm; warning Cause Corrective action Preheating temperature too low; 1. Extend preheating period. coolant temperature too low for 2. Check preheating unit. engine start. Excessive engine wear. Engine start might be inhibited by the locomotive control system.

- Page 46 120 – HI ECU Power Supply Voltage ZKP-Number: 2.0140.931 Yellow alarm; warning Cause Corrective action u Check engine governor supply voltage. Supply voltage too high. 121 – HIHI ECU Power Supply Voltage (Limit 2) ZKP-Number: 2.0140.932 Red alarm; engine stop Cause Corrective action Supply voltage too high.

- Page 47 182 – AL CAN Wrong Parameters ZKP-Number: 2.0500.682 Yellow alarm; warning Cause Corrective action u Contact Service. Incorrect parameter values entered in data record. 183 – AL CAN No PU-Data ZKP-Number: 2.0500.683 Yellow alarm; warning Cause Corrective action The selected CAN mode 1.

- Page 48 188 – AL CAN2 Bus Off ZKP-Number: 2.0500.688 Yellow alarm; warning Cause Corrective action CAN controller 2 is in "Bus-Off" 1. Check CAN bus for short circuit, rectify short circuit as status. Automatic changeover to necessary. CAN 1; short circuit; massive 2.

- Page 49 205 – SD T-Coolant Intercooler ZKP-Number: 1.8004.574 Yellow alarm; warning Cause Corrective action u Check sensor B26 and wiring, replace as necessary Intercooler coolant temperature sensor faulty; short circuit or (→ Page 109). wire break. 206 – SD T-Exhaust A ZKP-Number: 1.8004.576 Yellow alarm;...

- Page 50 214 – SD P-CrankCase ZKP-Number: 1.8004.568 Yellow alarm; warning Cause Corrective action u Check sensor B50 and wiring, replace as necessary Crankcase pressure sensor faulty; short circuit or wire (→ Page 109). break. 215 – SD P-HD High Pressure Fuel ZKP-Number: 1.8004.567 Yellow alarm;...

- Page 51 227 – SD P-Lube Oil before Filter ZKP-Number: 1.8004.620 Yellow alarm; warning Cause Corrective action u Check sensor B5.3 and wiring, replace as necessary Sensor for lube oil pressure before filter faulty; short circuit (→ Page 109). or wire break. 228 –...

- Page 52 232 – SD Charger 1 Speed ZKP-Number: 1.3011.128 Yellow alarm; warning Cause Corrective action u Check sensor B44.1 and wiring, replace as necessary Speed sensor of primary turbocharger faulty; short circuit (→ Page 109). or wire break. 233 – SD Charger 2 Speed ZKP-Number: 1.3011.129 Yellow alarm;...

- Page 53 266 – SD Speed Demand ZKP-Number: 2.8006.586 Red alarm; forced idle Cause Corrective action Analog nominal speed setting 1. Check wiring (→ Page 109). faulty; short circuit or wire 2. Check speed setting. break. 3. Contact Service. 270 – SD Frequency Input ZKP-Number: 2.8006.590 Red alarm;...

- Page 54 324 – AL Wiring Cylinder A4 ZKP-Number: 1.8004.523 Yellow alarm; warning Cause Corrective action u Check solenoid valve. Short circuit in cylinder injector wiring. Result: Misfiring. 325 – AL Wiring Cylinder A5 ZKP-Number: 1.8004.524 Yellow alarm; warning Cause Corrective action u Check solenoid valve.

- Page 55 334 – AL Wiring Cylinder B4 ZKP-Number: 1.8004.533 Yellow alarm; warning Cause Corrective action u Check solenoid valve. Short circuit in cylinder injector wiring. Result: Misfiring. 335 – AL Wiring Cylinder B5 ZKP-Number: 1.8004.534 Yellow alarm; warning Cause Corrective action u Check solenoid valve.

- Page 56 344 – AL Open Load Cylinder A4 ZKP-Number: 1.8004.543 Yellow alarm; warning Cause Corrective action u Check solenoid valve. Open circuit in cylinder injector wiring. Result: Misfiring. 345 – AL Open Load Cylinder A5 ZKP-Number: 1.8004.544 Yellow alarm; warning Cause Corrective action u Check solenoid valve.

- Page 57 354 – AL Open Load Cylinder B4 ZKP-Number: 1.8004.553 Yellow alarm; warning Cause Corrective action u Check solenoid valve. Open circuit in cylinder injector wiring. Result: Misfiring. 355 – AL Open Load Cylinder B5 ZKP-Number: 1.8004.554 Yellow alarm; warning Cause Corrective action u Check solenoid valve.

- Page 58 363 – AL Stop Power Stage ZKP-Number: 1.8004.560 Red alarm; engine stop Cause Corrective action Internal electronic fault, 1. Check wiring (→ Page 109). electronics possibly faulty. 2. Acknowledge alarm. 3. Restart engine. 4. Request towing locomotive if required. 365 – AL Stop MV-Wiring Ground (Injector Amplifier Ground) ZKP-Number: 1.8004.561 Red alarm;...

- Page 59 384 – AL Wiring TOP 4 ZKP-Number: 2.8006.641 Yellow alarm; warning Cause Corrective action u Check wiring to plant (→ Page 109). Short circuit or wire break on transistor output 4 plant-side (TOP 4). 408 – AL Open Load Emerg. Stop Input ESI ZKP-Number: 2.8006.633 Yellow alarm;...

- Page 60 413 – HIHI U-PDU (Injector Voltage) (Limit 2 ZKP-Number: 2.0141.932 Red alarm; engine stop Cause Corrective action Injector voltage too high. 1. Check wiring (→ Page 109). 2. Check supply. 3. Acknowledge alarm. 4. Restart engine. 5. Request towing locomotive if required. 414 –...

- Page 61 439 – HI P-Fuel 2 (Common Rail) ZKP-Number: 2.0116.931 Red alarm; power reduction ≥ 20% Cause Corrective action u Contact Service. Rail pressure above specified value; DBR reduction. HP fuel control block faulty, short circuit or wire break. 441 – AL Rail 2 Leakage ZKP-Number: 1.8004.047 Yellow alarm;...

- Page 62 454 – SS Power Reduction Active ZKP-Number: 2.7000.011 CAN message Cause Corrective action Alarm is only available as a 1. Observe any other messages. separate CAN message, power 2. Determine and rectify cause of power reduction. reduction is active. 467 – AL L2 T-Aux 1 ZKP-Number: 2.0130.922 Red alarm;...

- Page 63 476 – AL Crash Rec. Init. Error (Occurs when ADEC has power) ZKP-Number: 1.8010.007 Yellow alarm; warning Cause Corrective action u Check setting with DiaSys. Initialization error of crash recorder. 478 – AL Comb. Alarm Yel (Plant) ZKP-Number: 2.8006.001 Yellow alarm; warning Cause Corrective action u Observe any other messages.

- Page 64 502 – AL Open Load POM Alternator ZKP-Number: 1.4500.902 Yellow alarm; warning Cause Corrective action u Check connection between POM and battery-charging A line interruption was detected at the battery-charging generator. generator connection for the POM. 503 – AL Battery Not Charging ZKP-Number: 1.4500.903 Yellow alarm;...

- Page 65 510 – AL Override applied ZKP-Number: 2.7002.010 No alarm, fault is entered Cause Corrective action u Deactivate Override. Override Acknowledged 515 – Al Starter Not Engaged ZKP-Number: 2.1090.926 Yellow alarm; warning Cause Corrective action Starter on POM could not be 1.

- Page 66 551 – SS Engine Overspeed Camshaft ZKP-Number: 2.2510.933 Red alarm; engine stop Cause Corrective action Engine overspeed of camshaft 1. Acknowledge alarm. 2. Restart engine (→ Page 27). 3. Request towing locomotive if required. 558 – AL Wiring PWM_CM2 ZKP-Number: 1.1041.922 Yellow alarm;...

- Page 67 596 – AL Develop PR Set ZKP-Number: 1.8004.645 Yellow alarm; warning Cause Corrective action u Contact Service. Standard production data record available. The data record stored is for testing. 598 – AL L1 UDV Defekt Rail 2 ZKP-Number: 1.1302.900 Yellow alarm; warning Cause Corrective action Pressure relief valve of second...

- Page 68 606 – AL Double Nodes Lost CAN 1+2 ZKP-Number: 2.0500.691 Red alarm; forced idle Cause Corrective action No communication between 1. Check wiring and power supply of plant. ADEC and PAU. 2. Acknowledge alarm. 3. Restart engine (→ Page 27). 4.

- Page 69 628 – AL Wiring PWM_CM10 ZKP-Number: 1.1041.930 Yellow alarm; warning Cause Corrective action u Check wiring to connected device or check connected device Wire break or short circuit on channel PWM_CM10. (actuator/sensor), replace if necessary. 629 – AL AGR Throttle A Defect ZKP-Number: 1.0700.011 Yellow alarm;...

- Page 70 634 – SD T0-Ambient Air (HDT2800) ZKP-Number: 1.0700.089 Yellow alarm; warning Cause Corrective action u Check sensor B90 and wiring, replace as necessary. T0 ambient air HDT2800 CAN temperature sensor faulty; short circuit or wire break. 635 – SD Air Humidity (HDT2800) ZKP-Number: 1.0700.091 Yellow alarm;...

- Page 71 647 – SD P-Exhaust Lambda ZKP-Number: 1.0163.900 Yellow alarm; warning Cause Corrective action Exhaust pressure sensor near 1. Check sensor B91.3 and wiring, replace as necessary. lambda sensor faulty; short 2. Restart engine (→ Page 27). circuit or wire break. 648 –...

- Page 72 728 – AL L2 Delta T-NT Intercooler ZKP-Number: 2.1075.903 No alarm, fault is entered Cause Corrective action T-Max. Coolant Intercooler 1. Reduce power. Exceeded L2. 2. Check intercooler and coolant cooler. 3. Check charge-air coolant circuit. 745 – AL Emission Fault ZKP-Number: 2.1600.004 Red alarm;...

- Page 73 797 – AL HIHI T-Charge Air B ZKP-Number: 2.0146.932 Yellow alarm; power limitation < 20%; Cause Corrective action Charge-air temperature too high. 1. Reduce power. 2. If fault code number 9 is signaled at the same time, then it has priority.

- Page 74 834 – AL Gas Path Warning ZKP-Number: 2.1600.010 Yellow alarm; warning Cause Corrective action Gas path warning alarm. 1. Check flap control. 2. Check sensors. 835 – AL Gas Path Fault ZKP-Number: 2.1600.012 Red alarm; power reduction ≥ 20% Cause Corrective action Gas path fault alarm.

- Page 75 855 – AL Bypass Throttle 2 Defect ZKP-Number: 1.0700.841 Yellow alarm; warning Cause Corrective action u Replace actuator or flap. Actuator at bypass flap or flap mechanism faulty. 872 – AL EGR A Fast learn failed ZKP-Number: 1.0700.021 Yellow alarm; warning Cause Corrective action u xxx...

-

Page 76: Task Description

7 Task Description 7.1 Valve Drive 7.1.1 Valve clearance – Check and adjustment Preconditions ☑Engine is stopped and starting disabled. ☑Engine coolant temperature is max. 40 °C. ☑Valves are closed. Special tools, Material, Spare parts Designation / Use Part No. Qty. -

Page 77: Adjusting Valve Clearance

Checking valve clearance at two crankshaft positions Check TDC position of piston in cylinder A1: • If the rocker arms are unloaded on cylinder A1, the piston is in firing TDC. • If the rocker arms are under load on cylinder A1, the piston is in overlap TDC. Check valve clearance with cold engine: •... -

Page 78: Cylinder Head Cover - Removal And Installation

7.1.2 Cylinder head cover – Removal and installation Preconditions ☑Engine is stopped and starting disabled. Removing and installing cylin- der head cover Note: Cover the engine beneath the cylinder head with rags to soak up escaping residual oil. Remove screws (2). Remove cylinder head cover (1). -

Page 79: Fuel System

7.2 Fuel System 7.2.1 Fuel system ‒ Venting Preconditions ☑Engine is stopped and starting disabled. ☑Engine cooled down to ambient temperature. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 4-20 Nm F30044239 Ratchet F30027340 WARNING Fuels are combustible. - Page 80 Venting fuel filter Unlock fuel priming pump, unscrew han- dle (arrow). Provide a suitable container in which to col- lect the fuel. Note: Do not remove threaded vent plug. Open threaded vent plug (arrow). Screw in threaded vent plug (arrowed) and tighten to specified torque using a torque wrench. Name Size Type...

-

Page 81: Fuel Filter

7.3 Fuel Filter 7.3.1 Fuel filter – Replacement Preconditions ☑Engine is stopped and starting disabled. ☑Engine cooled down to ambient temperature. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 4-20 Nm F30044239 Torque wrench, 10-60 Nm F30510423 Ratchet F30027340... - Page 82 Vent fuel system (→ Page 79). 82 | Task Description | MS15033/01E 2014-02...

-

Page 83: Fuel Prefilter - Drain Condensate

7.3.2 Fuel prefilter – Drain condensate Preconditions ☑Engine is stopped and starting disabled. WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Draining condensate from fuel prefilter Provide a suitable container to collect the water. -

Page 84: Fuel Prefilter - Filter Element Replacement

7.3.3 Fuel prefilter – Filter element replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ratchet F30027340 Diesel fuel Filter element (→ Spare Parts Catalog) Sealing ring (→... -

Page 85: Air Filter

7.4 Air Filter 7.4.1 Air filter – Replacement Preconditions ☑Engine is stopped and starting disabled. For air filter replacement, carry out operations as specified by the manufactur- er – filter is plant/vehicle manufacturer's supply. MS15033/01E 2014-02 | Task Description | 85... -

Page 86: Air Intake

7.5 Air Intake 7.5.1 Service indicator – Signal ring position check Preconditions ☑Engine is stopped and starting disabled. Checking signal ring position Replace air filter, if the signal ring (2) is completely visible in the red area of the service indicator control window (3) (→... -

Page 87: Lube Oil System, Lube Oil Circuit

7.6 Lube Oil System, Lube Oil Circuit 7.6.1 Engine oil level – Check Preconditions ☑Engine is stopped and starting disabled. Checking oil level prior to en- gine start Withdraw oil dipstick (arrow) from guide tube and wipe it. Insert oil dipstick (arrow) into guide tube up to the stop, withdraw after approx. -

Page 88: Engine Oil - Change

7.6.2 Engine oil – Change Preconditions ☑Engine is stopped and starting disabled. ☑Engine is at operating temperature. ☑MTU Fluids and Lubricants Specifications (A001063/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil WARNING Hot oil. -

Page 89: Oil Filtration / Cooling

7.7 Oil Filtration / Cooling 7.7.1 Engine oil filter ‒ Replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 10-60 Nm F30510423 Ratchet F30027340 Socket, 32 mm F30006120 Engine oil Oil filter element (→... -

Page 90: Coolant Circuit, General, High-Temperature Circuit

7.8 Coolant Circuit, General, High-Temperature Circuit 7.8.1 Engine coolant – Level check Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001063/..) are available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. -

Page 91: Engine Coolant - Change

7.8.2 Engine coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Engine coolant change Drain engine coolant (→ Page 92). Fill with engine coolant (→ Page 94). MS15033/01E 2014-02 | Task Description | 91... -

Page 92: Engine Coolant - Draining

7.8.3 Engine coolant – Draining Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine coolant Sealing ring (→ Spare Parts Catalog) WARNING Coolant is hot and under pressure. Risk of injury and scalding! •... - Page 93 Open drain screws and drain coolant at crankcase, right side (1,2). Open drain screws and drain coolant at crankcase, left side (1,2). Install drain screw with new sealing ring. Place breather valve on filler neck and close. MS15033/01E 2014-02 | Task Description | 93...

-

Page 94: Engine Coolant - Filling

7.8.4 Engine coolant – Filling Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001063/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant WARNING Coolant is hot and under pressure. Risk of injury and scalding! •... - Page 95 Final steps Start the engine and operate it at idle speed for some minutes. Check coolant level (→ Page 90), top up with coolant if required. MS15033/01E 2014-02 | Task Description | 95...

-

Page 96: Engine Coolant Pump - Relief Bore Check

7.8.5 Engine coolant pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 97: Low-Temperature Circuit

7.9 Low-Temperature Circuit 7.9.1 Charge-air coolant level – Check Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001063/..) are available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. -

Page 98: Charge-Air Coolant - Change

7.9.2 Charge-air coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Charge-air coolant – Change Drain charge-air coolant (→ Page 99). Fill with charge-air coolant (→ Page 100). 98 | Task Description | MS15033/01E 2014-02... -

Page 99: Charge-Air Coolant - Draining

7.9.3 Charge-air coolant – Draining Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Sealing ring (→ Spare Parts Catalog) Sealing ring (→ Spare Parts Catalog) WARNING Coolant is hot and under pressure. Risk of injury and scalding! •... -

Page 100: Charge-Air Coolant - Filling

7.9.4 Charge-air coolant – Filling Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001063/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Charge-air coolant Sealing ring (→ Spare Parts Catalog) WARNING Coolant is hot and under pressure. - Page 101 Final steps Start the engine and operate it at idle speed for some minutes. Check coolant level (→ Page 97). MS15033/01E 2014-02 | Task Description | 101...

-

Page 102: Charge-Air Coolant Pump - Relief Bore Check

7.9.5 Charge-air coolant pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 103: Belt Drive

7.10 Belt Drive 7.10.1 Coolant pump – Drive belt replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Assembly jig F6794712 Poly-vee belt (→ Spare Parts Catalog) DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... - Page 104 Replacing charge-air coolant pump drive belt (LT circuit) Fit new poly-vee belt (2) on front three grooves of belt pulley (1) to crankshaft. Fit poly-vee belt (2) on front three grooves of belt pulley (3) to crankshaft and preload with assembly jig (4). Bar engine with barring gear until poly-vee belt (2) lies completely on belt pulley (3).

-

Page 105: Battery-Charging Generator

7.11 Battery-Charging Generator 7.11.1 Battery-charging generator – Belt tensioner and diverter pulley replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 20-100 Nm F30026582 Ratchet adapter F30027340 Engine oil Belt tensioner (→... - Page 106 Replacing diverter pulley Remove cap on diverter pulley (3). Remove screw (2). Remove diverter pulley (3). Coat thread of screw (2) with engine oil. Install new diverter pulley (3) with screw (2). Tighten screw (2) to specified torque using a torque wrench. Name Size Type...

-

Page 107: Battery-Charging Generator - Drive Belt Removal And Installation

7.11.2 Battery-charging generator – Drive belt removal and installation Preconditions ☑Engine is stopped and starting disabled. WARNING Spring/circlip/tensioning roller preload. Risk of injury! • Only use specified tool and equipment. Removing battery-charging gen- erator drive belt Place toggle on belt tensioner (3). Tighten belt tensioner (3) with toggle. -

Page 108: Drive Systems, Driving End And Free End (Coupling)

7.12 Drive Systems, Driving End and Free End (Coupling) 7.12.1 Coupling – Checking (radial/axial) play Preconditions ☑Engine is stopped and starting disabled. ☑Guard is removed. Checking radial play “A” Mount dial gage on engine-side coupling flange. Set dial-gage anvil onto outer coupling part. -

Page 109: Wiring (General) For Engine/Gearbox/Unit

7.13 Wiring (General) for Engine/Gearbox/Unit 7.13.1 Engine wiring – Check Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Isopropyl alcohol X00058037 Engine wiring – Check Check securing screws of cable clamps on engine and tighten loose threaded connections. Ensure that cables are fixed in their clamps and cannot swing freely. -

Page 110: Accessories For (Electronic) Engine Governor / Control System

7.14 Accessories for (Electronic) Engine Governor / Control System 7.14.1 Injector functions Preconditions ☑Engine is stopped and starting disabled. Note: Failure to reset drift compensation parameters (CDC) will void the emissions certification for the en- gine. Resetting drift correction parameters (CDC) with DiaSys® (→... -

Page 111: Engine Governor And Connectors - Cleaning

7.14.2 Engine governor and connectors – Cleaning Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Isopropyl alcohol X00058037 Note: Always use test connectors to enter the connectors. Never use test leads for this purpose. Otherwise the contacts could be bent. -

Page 112: Engine Control Unit - Plug Connection Check

7.14.3 Engine Control Unit – Plug connection check Preconditions ☑Engine is stopped and starting disabled. Checking Engine Control Unit plug connections Check firm seating of all connectors on the Engine Control Unit. Make sure that the clips (2) are engaged. Check firm seating of all screws (1) on En- gine Control Unit cable clamps. -

Page 113: Nox Sensor – Replacement

7.14.4 NOx sensor – Replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 10-60 Nm F30510423 Ratchet F30027340 Assembly compound (Molykote P 37) 50564 NOx sensor (→ Spare Parts Catalog) WARNING Component is hot. - Page 114 Note: Always replace NOx sensor together with control unit. Installing NOx sensor Note: Install control unit. Note: When the sensor was subjected to shock or impact load, it is deemed to be defective and may not be used. Remove protective cap on thread only just before installation.

-

Page 115: Lambda Sensor – Replacement

7.14.5 Lambda sensor – Replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 10-60 Nm F30510423 Ratchet F30027340 Assembly compound (Molykote P 37) 50564 Lambda sensor (→ Spare Parts Catalog) WARNING Component is hot. - Page 116 Installing Lambda sensor Note: When the sensor was subjected to shock or impact load, it is deemed to be defective and may not be used. Remove protective cap on thread only just before installation. Note: Do not wipe off the thread lubricant applied by the manufacturer.

-

Page 117: Appendix A 8.1 Abbreviations

Abgasturbolader Exhaust turbocharger Air Temperature Sensor Baureihe Series Betriebsstoffvorschrift Fluids and Lubricants Specifications, MTU Pub- lication No. A01063/.. Controller Area Network Data bus system, bus standard Calibration Drift Compensation Setting of drift compensation in engine gover- nor with DiaSys... - Page 118 Abbreviation Meaning Explanation Ersatzteilkatalog Spare Parts Catalog Electronic Unit Injector Fuel Pressure Sensor Monitors fuel pressure Fuel - Differential Pressure Sensor Fuel Temperature Sensor Monitors fuel temperature FWCP Fire Water Control Panel Control cabinet Ground Hochdruck High pressure High Alarm: Measured value exceeds 1st maximum limit HIHI High High...

- Page 119 Abbreviation Meaning Explanation Check Engine Light 1st function: Warning lamp (stop engine and rectify fault) 2nd function: Read out fault codes System Identifier Synchronous Reference Sensor TDC cylinder 1 Safety System Safety system alarm Turbocharger Boost Sensor Monitors charge-air pressure Turbo Compressor Inlet Turbo Compressor Outlet Transmitter Deviation...

-

Page 120: Mtu Contact Persons/Service Partners

Local support Experienced and qualified specialists place their knowledge and expertise at your disposal. For locally available support, go to the MTU Internet site: http://www.mtu-online.com 24h hotline With our 24h hotline and the outstanding flexibility of our service staff, we are always ready to assist you –... -

Page 121: Special Tools

9 Appendix B 9.1 Special Tools Adapter Part No.: F30011619 Qty.: Used in: 4.8 Engine – Barring manually (→ Page 32) Allen key, 5 mm Part No.: F30002815 Qty.: Used in: 7.1.1 Valve clearance – Check and adjustment (→ Page 76) Assembly jig Part No.: F6794712... - Page 122 Barring gear Part No.: F6790714 Qty.: Used in: 4.8 Engine – Barring manually (→ Page 32) Qty.: Used in: 7.1.1 Valve clearance – Check and adjustment (→ Page 76) Box wrench, 14 mm Part No.: F30028346 Qty.: Used in: 7.1.1 Valve clearance – Check and adjustment (→...

- Page 123 Ratchet adapter Part No.: F30027340 Qty.: Used in: 4.8 Engine – Barring manually (→ Page 32) Qty.: Used in: 7.11.1 Battery-charging generator – Belt tensioner and diverter pulley replacement (→ Page 105) Socket, 32 mm Part No.: F30006120 Qty.: Used in: 7.3.1 Fuel filter –...

- Page 124 Torque wrench, 4-20 Nm Part No.: F30044239 Qty.: Used in: 7.2.1 Fuel system ‒ Venting (→ Page 79) Torque wrench, 6-50 Nm Part No.: F30027336 Qty.: Used in: 7.3.3 Fuel prefilter – Filter element replacement (→ Page 84) Torque wrench, 10-60 Nm Part No.: F30510423 Qty.:...

-

Page 125: Index

9.2 Index Abbreviations 117 ECU 9 Actuators – Fault messages 37 – Overview 17 Engine After engine shutdown 30 – Barring manually 32 Air filter – Overview 16 – Replacement 85 – Start 27 – Stop 29 – Wiring check 109 Battery-charging generator Engine Control Unit ... - Page 126 Lambda sensor – Adjustment 76 – Replacement 115 – Check 76 Main engine dimensions 21 Maintenance schedule – Maintenance task reference table [QL1] 33 MTU contact persons 120 NOx sensor – Replacement 113 Operational checks 28 Overview – Actuators 17 – Sensors 17 Plant ...

Need help?

Do you have a question about the 12 V 1600 R50 and is the answer not in the manual?

Questions and answers