Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Orien FS-260IM

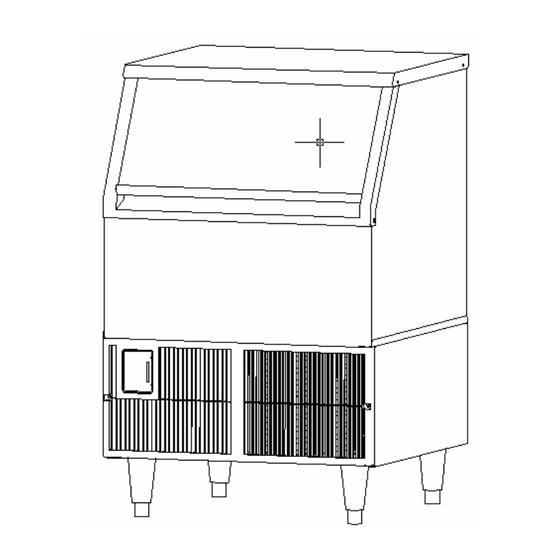

- Page 1 Ice Maker vice Manual DEL FS-260IM A...

-

Page 2: Table Of Contents

Table of contents How the Icemaker works --------------------------------------------- 2-10 ooling System -----------------------------------------------------------------2 ater System ---------------------------------------------------------------- 3-4 iring Connections and Controller------------------------------ ---------4-7 xploding Drawing ----------------------------------------------------------7-8 TroubleShooting ------------------------------------------ ----------- -- 9-17 efore Maintenance------------------------------------------------------------9 asic Checking -----------------------------------------------------------------9 roubleshootingGuide----------------------------------------------------- 9-14 Adjustment and Replacement 15-17 ---------------------------------------------------- eplace the controller---------------------------------------------------- -----15 djust the size of ice cube----------------------------------------------------15... -

Page 3: How The Icemaker Works

How the Icemaker Works Please refer to the section “Operation of user manual” from page 12 to 14 . It describes clear how the icemaker makes ice and uses the water. There are 3 systems including Cooling System, Water System and Wiring Connection and Controller. -

Page 4: Water System

ITEM NO CODE DESCRIPTION 1858420900 Compressor 1861512102 Discharge tube 1861530100 Cu three ways 1880013102 Condenser 1880007900 Drier and filter 1805000600 Capillary tube 1861502502 Connection tube 1854701800 Hot gas valve 1861501701 Hot gas tube 1880024700 Evaporator (Ice Mold) 1860700100 Fan blade(φ 200X28°) suction pipe 1880020202 1858200601... - Page 5 ITEM NO CODE DESCRIPTION 1811306014 Water supply tube 1864526301 Water inlet connector 1864529100 Nut of water inlet tube 1864515100 Supporting tube 1811206006 Water pump inlet tube 1880001701 Floater valve 1864802001 Water trough 1858904000 Water pump 1811330102 Water pump outlet tube 1861701802 Ice slideway 1864550601...

- Page 6 Wiring Connection : Circuit Description 1. Electrify Status For The First Time switch on the water tap, let the water trough full As the icemaker is properly installed. (reach on the level), then on the panel. The turn the Power switch to the ON position icemaker will start working automatically In this status, the time is fixed about 3 minutes.

- Page 7 The fan motor is also controlled by a condenser sensor. When the ambient temperature is too lower, the motor fan stop working for good condensation to refrigerant. The Yellow LED indicates the ice harvest status. 5. Cleaning Status Turn the machine CLEAN SWITCH at the CLEAN in 3 minutes after the POWER SWITCH is turned on, the machine turn to Cleaning Status.

-

Page 8: Exploding Drawing

5. The thickness of ice cubes is adjustable. 6. A sensitive probe and accurate timer enhance the performance of the ice maker. Built-in compressor protection system. Exploding Drawing Spare parts list of FS-260IM A... - Page 9 ITEM CODE DESCRIPTION 1864701601 ice storage bin 1864800100 Ice scoop 1860106303 top panel 1860110802 down right panel 1860410601 right slide way 1864514100 Drain nut 1864536200 Drain connector 1860004904 right cover wind panel 1858420900 condenser 1854701210 Hot gas valve body (EVU3) 1854701800 Hot gas valve coil(042N4212)...

- Page 10 1860111700 stability support 1803200100 locked screw 1880014901 foot compressor base 1860604600 1880007900 Drier 1861530100 T shape three ways control panel of FS-260IM control 1860617100 box) 15A fuse of control box 1854800300 Control box 1854204602 1880013101 Condenser 1854700800 Drain valve 1861530802...

-

Page 11: Troubleshooting

Troubleshooting ELECTRICAL SHOCK HAZARD Disconnect Electrical Power Before Beginning Removal of Parts Before Maintenance 1. Check out the user if the user uses a 115 VAC, 60Hz. only 15ampere electrical supply, and have properly grounded, ensure the maintainer against electrical shock. 2. - Page 12 Problem Check part Possible Cause Probable Correction kinds or point Plug The icemaker is unplugged. Plug the icemaker in. Socket Socket is damaged Check and replace Power switch The icemaker power Turn the icemaker power switch to switch turns to OFF. ICE.

- Page 13 doesn't start coil / The motor of the compressor Replace the compressor. running coil or start is short circuit. frequency Condenser The condenser may be dirty. Clean the condenser. The fan may be dirty or Clean or Replace the fan . damaged The control box is damaged Replace the Electronic control box.

- Page 14 The water distribution Water Clean the water distribution tube tube blocks distribution tube Using a filter apparatus installed in The water quality is too Water Water line front of the water inlet valve. poor. water line System blocks silica tubes Make the silica gel tubes resile Silica gel tubes distort, lead to block.

- Page 15 4.Other problems Problem Check part Possible Cause Probable Correction kinds or point Earth line The earth line isn't in the Please use the socket meeting the The body socket. standard. is electrified Lines The lines are creepage. Adjust, reconnect /replace lines Electric The electric component is Replace this electric component.

-

Page 16: Adjustment And Replacement

The ambient The ambient and water Adjust the temperature. and water temperature is too low temperature Ice cubes size The size is too big. See “the adjust of ice cube size”. The lines of the hot gas Plug into again valve loose. - Page 17 2.Remove the front panel, l ocate the Electronic control box, 3.Locate the cube size adjustment screw, and to make fuller c ubes, turn the screw clockwise about Control box 1/36 turn (10°-15°). This will make the freezing cycle longer. 4. To shorten the freezing cycle and make cubes that are not as full, turn the adjustment screw 1/36 turn (10°-15°) counter clockwise.

-

Page 18: Replace The Water Pump

Before replace the water system components, it will be necessary to drain the system of water. Replace the water pump Disconnect electrical powe Remove the front cover. Unplug the lines connector with the water pump, the water outlet tube of pump. Loosen the screws, replace a new one. - Page 19 Locate the drier and hot gas valve, weld open , ,replace the drier and hot gas valve, weld ,recover refrigerant , evacuate and weigh in the nameplate charge. Reverse the above step to reassemble. If need replace the evaporator. Remove the front and top pane l, locate the evaporator, open the process/suction , weld open the two welds, replace a new one.

Need help?

Do you have a question about the FS-260IM and is the answer not in the manual?

Questions and answers