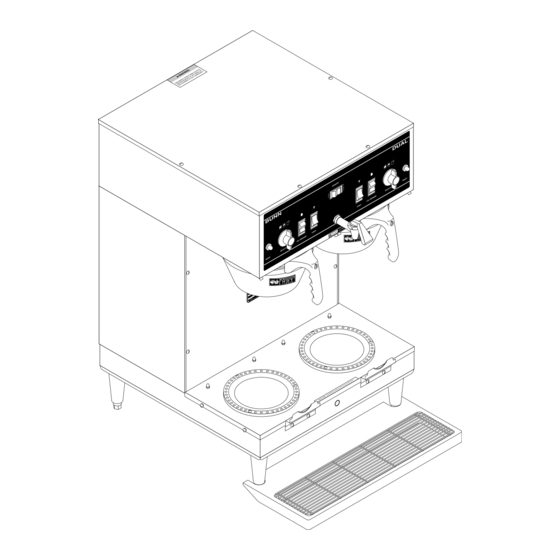

Bunn Dual Service Manual

Hide thumbs

Also See for Dual:

- Operating & service manual (53 pages) ,

- Illustrated parts catalog (51 pages) ,

- Installation & operating manual (8 pages)

Table of Contents

Advertisement

N

ER

U T

IO

CA

NT

D DE

C A

AR

DI SC

!

IF:

D

AC

KE

HE

D

PT

Y

. CR

RA

TC

DR

EN

Y

EM

AM

IC

E

. SC

ILE

D

WH

H

FL

TR

. BO

AT

ED

HIG

D

EL

EC

. HE

ED

ON

SE

. US

EX

PO

TS

. OR

EN

RY

TS

EL

EM

S IN

JU

N

EN

RI SK

POR

ATIO

CO

NT

COR

EL

T

MP

LY

-MA

TIC

NN

E HO

CO

5 BUN

N-O

FU

AR

TO

198

RE

ILU

FA

PN:

658

SERVICE & REPAIR MANUAL

41976.0000 09/11 ©2009 Bunn-O-Matic Corporation

R

TE

T WA

HO

N

UT

IO

CA

!

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

SINGLE

AT

ER

T W

HO

N

IO

CA

UT

!

N

ER

U T

IO

NT

D DE

CA

C A

SC

AR

!

DI

IF:

D

AC

KE

HE

D

PT

Y

. CR

RA

TC

DR

Y

EN

EM

AM

IC

E

. SC

ILE

D

WH

H

FL

TR

. BO

AT

ED

HIG

D EL

EC

. HE

ON

SE

. US

ED

EX

PO

TS

. OR

EN

JU

RY

TS

EL

EM

S IN

ON

EN

RI SK

POR

ATI

NT

COR

EL

CO

T

MP

LY

-MA

TIC

NN

E HO

CO

N-O

FU

AR

TO

198

5 BUN

RE

ILU

FA

PN:

658

!

R

TE

T WA

HO

N

UT

IO

CA

!

N

NT

ER

U T

IO

CA

DE

C A

AR

D

SC

!

DI

IF:

KE

D

D

Y

AC

TC

HE

Y

EM

PT

E

. CR

RA

D

DR

EN

FL

AM

IC

. SC

ILE

WH

H

EC

TR

. BO

AT

ON

ED

HIG

EL

D

. HE

ED

PO

SE

. US

EX

TS

RY

. OR

EM

EN

JU

N

TS

EL

S IN

ATIO

NT

EN

RI

SK

POR

CO

LY

TIC

COR

EL

E HO

T

MP

N-O

-MA

NN

CO

5 BUN

FU

AR

TO

198

ILU

RE

FA

658

PN:

DUAL

®

DUAL

®

(Serial # DUAL010000 - Up)

SINGLE

®

(Serial # SNG0005000 - Up)

GR

L

E

F

T

gal

1

1⁄2

1 gal

gal

1⁄2

AR

T

ST

UT

!

CA

M ER

AR

/ W

O N

O R

CT

SE

LE

Y

AD

RE

N

NT

ER

U T

IO

CA

C A

D DE

AR

DI SC

!

IF:

KE

D

D

Y

AC

HE

Y

PT

E

. CR

RA

D

TC

DR

EN

EM

AM

IC

. SC

ILE

WH

H

FL

EC

TR

. BO

AT

ED

ON

HIG

D

EL

. HE

ED

PO

SE

. US

EX

TS

. OR

EM

EN

JU

RY

TS

EL

S IN

ATIO

N

NT

EN

SK

POR

CO

LY

RI

TIC

COR

EL

E HO

T

MP

-MA

NN

CO

5 BUN

N-O

FU

AR

TO

198

RE

FA

ILU

658

PN:

&

SH

&

®

SH

gal

1

1⁄2

1 gal

gal

1⁄2

Y

AD

RE

R

DE

IN

R

I

O R

G

CT

H

LE

T

SE

M ER

AR

/ W

O N

T

AR

ST

TE

R

T WA

HO

IO

N

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Bunn Dual

- Page 1 . SC . BO . HE . US . OR S IN ATIO E HO 5 BUN SERVICE & REPAIR MANUAL BUNN-O-MATIC CORPORATION POST OFFICE BOX 3227 SPRINGFIELD, ILLINOIS 62708-3227 PHONE: (217) 529-6601 FAX: (217) 529-6644 41976.0000 09/11 ©2009 Bunn-O-Matic Corporation...

- Page 2 SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND. In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

- Page 3 TROUBLESHOOTING A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department. • Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

- Page 4 TROUBLESHOOTING (cont.) Problem Probable Cause Remedy Brew cycle will not start (cont.) 3. ON/OFF switch Refer to Service - ON/OFF switch for testing procedures. 4. Start switch Refer to Service - Start switch for testing procedures. 5. Timer Refer to Service - Timer for testing procedures.

- Page 5 TROUBLESHOOTING (cont.) Probable Cause Problem Remedy Beverage level will not adjust 1. Brew Selector switch Refer to Service - Selector switch (Selector switch in any position) for testing procedures. Water flows into tank continuously 1. Solenoid valve Refer to Service - Solenoid valve for (On/Off Switch "OFF").

- Page 6 TROUBLESHOOTING (cont.) Problem Remedy Probable Cause Water from tank is not hot (cont.). Refer to Service - Relay for testing 6. Relay (Brewers with Recovery procedures. Booster) Server warmer is not hot. Refer to Service - ON/OFF switch for 1. ON/OFF switch testing procedures.

- Page 7 Guide, Initial Set-Up. Refer to Installation & Operating 2. Needle Valve Guide, Initial Set-Up 3. Type of paper filters BUNN paper filters should be used for proper extraction. 4. No sprayhead Check sprayhead The brew cycle should be started Beverage overflows server.

- Page 8 A clean sprayhead should be used Weak beverage (cont.) 3. Sprayhead to properly wet the bed of ground coffee in the funnel. The BUNN paper filter should be 4. Funnel loading centered in the funnel and the bed of ground coffee leveled by gentle shaking.

- Page 9 TROUBLESHOOTING (cont.) Remedy Probable Cause Problem 1. Circuit breaker A) Check and reset if necessary Server will not heat B) Refer to Service - Circuit breaker for test procedures. Clean or replace. 2. Receptacle Contacts Refer to Service - Relay (Soft Heat) 3.

-

Page 10: Table Of Contents

SINGLE SH front access panel (8) #6-32 DUAL front access panel (5) #6-32 DUAL SH front access panel (11) #6-32 SINGLE & DUAL warmer base (4) #6-32 SINGLE SH & DUAL SH server platform (4) #6-32 41976 031709 Page 10... -

Page 11: Bypass Valve

SERVICE (cont.) 6. Connect the voltmeter lead ends to the bypass valve BYPASS VALVE coil terminals. Connect the brewer to the power source. With the selector switch in the 1 or 1-1/2 gallon position, place "ON/OFF" Switch in the "ON" position. -

Page 12: Brewer Selector Switch

SERVICE (cont.) 12. Reconnect the pink wire to the grind switch. BREW SELECTOR SWITCH 13. Disconnect the tan wire from the left or right selec- tor switch and tan wire from interface socket. 14. Check for continuity across the tan wires. 15. - Page 13 SERVICE (cont.) 5. Check for continuity across terminals (e) and (5). (cont.) BREW SELECTOR SWITCH When the selector switch is in the small batch position, continuity should not be present. When To Timer WHI/VIO to By-Pass Valve the selector switch is in the medium or large batch positions, continuity should be present.

-

Page 14: Circuit Breakers

SERVICE (cont.) Removal and Replacement: CIRCUIT BREAKERS 1. Remove the wires from the circuit breaker. 2. Compress the clips on the back side of the server platform and gently push the circuit breaker through the opening in the server platform. 3. -

Page 15: Contactor Assembly

The indication just to the rear of the dispense valve (Right side for must be: DUAL and DUAL SH models). a.) 120 volts ac for two wire 120 volt models, 208 volts ac for three wire 120/208 volt models and Test Procedures: 240 volts ac for three wire 120/240 volt models. - Page 16 SINGLE and SINGLE SH models and three wire 120/240 volt models. b.) 200 to 240 volts ac for two wire 200 or 240 DUAL and DUAL SH models volt models. 4. Disconnect the brewer from the power source. BLK T2 to Left Tank Heater...

-

Page 17: Control Thermostat

SERVICE (cont.) CONTROL THERMOSTAT Location: 5. Locate the black wires from the control thermo- The control thermostat is located inside the lower stat. left front of the brewer on the component bracket. 6. Gently remove the capillary bulb and grommet from the tank. -

Page 18: Dispense Valve

SERVICE (cont.) DISPENSE VALVE CONTROL THERMOSTAT (cont.) NOTE - The capillary tube must be clear of any electri- cal termination and not kinked. 7. Using a #8-32 slotted head screw fasten the control thermostat to the component bracket. 8. Refer to Fig. 10 when reconnecting the wires. 1⁄2 1 ga 1⁄2... - Page 19 WHI/GRN to Right Timer TL4 Diagrams and check brewer wiring harness. WHI/GRN to Right By-Pass Valve 6. Check for continuity across the dispense valve coil SINGLE Brewers & RIGHT on DUAL Brewers terminals. WHI/RED to Left Timer TL1 WHI/RED to Left Brew Selector Switch...

-

Page 20: Grinder Selector Switch

P787 FIG. 14 GRINDER SELECTION P786 SWITCH TERMINALS FIG. 13 GRINDER SELECTOR SWITCH (DUAL and DUAL SH BREWERS only) Location: The grinder selector switch is located in the upper center on the front of the hood. Test Procedure: 1. Disconnect the brewer from the power source. -

Page 21: Level Control Board And Level Probe

SERVICE (cont.) LEVEL CONTROL BOARD AND LEVEL PROBE (Electro/ mechanical only) If voltage is not present as described, refer to the Wiring Diagrams and check brewer wiring harness. 5. Reconnect the violet wire to terminal 1. 6. Carefully connect a piece of insulated jumper wire to terminal 4. - Page 22 SERVICE (cont.) LEVEL CONTROL BOARD AND LEVEL PROBE (cont.) T4 PNK to Probe b.) 200 to 240 volts ac for two wire 200 or 240 volt T3 WHI to Terminal Block (White models after a delay of approximately 1 second. Insert on 120V Two Wire, 120/208V 15.

-

Page 23: Limit Thermostat

SERVICE (cont.) LIMIT THERMOSTAT If voltage is present as described, reconnect the black wire to the limit thermostat from the terminal block, the limit thermostat is operating properly. If voltage is not present as described, refer to the Wiring Diagrams and check brewer wiring harness. Removal and Replacement: 1. -

Page 24: On/Off Switch (Warmer)

SINGLE & SINGLE SH BREWERS wire. Connect the brewer to the power source. DUAL & DUAL SH BREWERS The indication must be: a.) 120 volts ac for two wire 120 volt models, three... -

Page 25: Overflow Protection Switch

SERVICE (cont.) OVERFLOW PROTECTION SWITCH overflow protection switch. Removal and Replacement: 1. Disconnect the red leads from the overflow protec- tion switch from the blue wire from the thermostat and the black wire from the terminal block or black and red wires from electronic control assembly. 1⁄2 1 ga 1⁄2... -

Page 26: Receptacle

SERVICE (cont.) BLK to (-) Terminal on Right Rectifier RECEPTACLE ASSEMBLIES (SH Brewers only) RED to (+) Terminal on Right Rectifier RIGHT BLK to (-) Terminal on Left Rectifier RED to (+) Terminal on Left Rectifier TI O C AU D EC D IS IF :... -

Page 27: Relay

RELAY (Brewers W/Recovery Booster) SERVICE (cont.) RECTIFIERS (cont.) Test Procedures: 1. Disconnect the brewer from the power source; 2. Remove the red wire and the black wire from the rectifier to be tested. 3. With a voltmeter check the voltage across the (+) and (-) terminals on the rectifier. - Page 28 If continuity is present as described, reconnect blue SERVICE (cont.) wires to terminal 5 on the right relay, the black wires to Relay (Brewers W/Recovery Booster) (cont.) terminal 5 on the left relay and the red wire to left and right terminal 7, the relays are operating properly.

- Page 29 The relay(s) are located inside the hood, in front for Single brewers or right relay for Dual brewers. of the tank. 7. On Single brewers or left or right relay on Dual NOTE: On brewers with recovery boost, the server brewers, disconnect the black wires from terminals power relays are located just in front of the recovery 1 and 7 of the relay.

- Page 30 - GRN to Left Start Switch A - GRN to Start Switch (Right on Dual Brewers) 7 - BLK 7 - BLK LEFT ON DUAL BREWERS SINGLE BREWERS and RIGHT ON DUAL BREWERS P1379 FIG. 33 SERVER POWER RELAYS Page 30 41976 031709...

- Page 31 SERVICE (cont.) a.) 120 volts ac for three wire 120/208 volt models RELAY (Brewers W/Recovery Booster) and three wire 120/240 volt models. b.) 200 to 240 volts ac for two wire 200 or 240 NOTE - Electro/mechanically controlled brewers have volt models.

- Page 32 SERVICE (cont.) Relay (Brewers W/Recovery Booster) (cont.) and 7 by manually closing relay contact. Continuity wire with left and right "ON/OFF" switch in the must not be present when contact is released. "ON" position. Connect the brewer to the power source and press the left and right start switch.

-

Page 33: Solenoid

The solenoid valve is located inside the lower right or the solenoid valve may require inspection for wear, front of Dual brewers and inside the hood on the upper and removal of waterborne particles. component bracket on Single brewers. - Page 34 7. Securely install the new solenoid valve to its mounting bracket. 8. DUAL BREWERS: Attach the solenoid valve and mounting bracket to the brewer trunk. 9. Securely fasten the water lines to and from the solenoid valve.

-

Page 35: Start Switches (Brew)

Location: The momentary start switches are located on the P801 front of the hood next to the on/off switches. DUAL BREWERS Test Procedure: 1. Disconnect the brewer from the power source WITH RELAY (Prior to S/N SNG0014000) and remove the wires from both terminals of the switch. -

Page 36: Tank Heaters

200 to 240 volts ac for two wire 200 or 240 volt models. 3. Disconnect the brewer from the power supply. LEFT & RIGHT for DUAL Brewers ELECTRO/MECHANICAL If voltage is present as described, proceed to #4. If voltage is not present as described, refer to the Wir- BLK to Limit ing Diagrams and check the wiring harness. -

Page 37: Timers (Early Models)

NOTE: ECA MODELS ONLY - Brewer must be at op- erating temperature to perform step 5 or brew-lock must be bypassed. To bypass brew-lock on DUAL models, disconnect white/orange wire and brown/ black wire for right timer or orange wire and red/black wire for left timer from brew-lock of ECA and connect the harness leads together. - Page 38 Interlock Assy (electronic models) WHI/BRN TL4 to Left Dispense Valve WHI/GRN TL4 to Right Dispense Valve YEL TL5 to Left Start Switch WHI/YEL TL5 to Right Start Switch LEFT RIGHT DUAL BREWERS P805 FIG. 43 TIMER TERMINALS 41976 031709 Page 38...

- Page 39 SERVICE (cont.) Timers (Early Models)(cont.) 1 .5 6 - 0 P / N WHI/VIO TL1 to ON/OFF Switch WHI/VIO TL1 to ON/OFF Switch WHI/VIO TL1 to Warmer Element WHI/VIO TL1 to Warmer Element WHI TL2 To Terminal Block and Warmer Element WHI TL2 To Terminal Block and Warmer Element (120V Two Pole, 120/208V or 120/240V Three Pole (120V Two Pole, 120/208V or 120/240V Three Pole...

-

Page 40: Digital Timer (Late Models)

SERVICE (cont.) 6. With a voltmeter, check the voltage across terminals TIMERS (Late Models) TL1 and TL4 when the "ON/OFF" switch is in the "ON" position. Connect the brewer to the power source. The indication must be 0 volts. If voltage is as described, proceed to #7. If voltage is not as described, disconnect the brewer from the power source and replace the timer. - Page 41 Each time the switch is pressed, two seconds are added to the brew LEFT TIMER (Dual Brewers) time period. Allow the brew cycle to finish in order to verify that the desired volume has been achieved.

-

Page 42: Transformers

SERVICE (cont.) TRANSFORMERS (SH models only) 5. Disconnect the blue/black wires from terminals #7 and #12 on the transformer. 6. With a voltmeter check the voltage across the 1⁄2 blue/black wires. Connect the brewer to the power 1 ga 1⁄2 source. - Page 43 #1 BLK from Transformer Start Switch Terminal #5 Terminal #5 LEFT RIGHT P1383 DUAL SH BREWERS WITH RELAY (Prior to S.N. SNG0014000) WITHOUT RELAY (After S.N. SNG0014000) #6 WHI or RED from #6 WHI or RED from #12 BLU/BLK to #12 BLU/BLK to...

-

Page 44: Warmer Elements

1. Disconnect the brewer from the power source. 2. Using the white wire in the terminal block and the white/red wire to left warmer (Dual Brewers) or the white/violet wire to warmer (Single Brewers) or right warmer (Dual Brewers) check the voltage. -

Page 45: Main Power Switch

SERVICE (cont.) MAIN ON/OFF SWITCH If continuity is not present as described, replace the switch. Removal and Installation: 1. Disconnect the wires from the switch terminals. 2. Remove the two screws securing the switch to the base plate from the bottom side of the brewer. 3. -

Page 46: Wiring Diagrams

120 VOLTS AC 2 WIRE + GRD 200WATT MAXIMUM 120/208 VOLTS AC OR 120/240 VOLTS AC 3 WIRE + GRD SINGLE PHASE 26885.0001D 01/07 © 1996 BUNN-O-MATIC CORPORATION White Strip-Tac Plus Black Ink Finished Size: 5.0" x 5.75" ?65% Reduction... - Page 47 (NO CONNECTION) 3/4 BATCH WHI/YEL START BATCH COMMON SWITCH DISPENSE WATER BYPASS WHI/VIO WHI/GRN WHI/RED ON/OFF SWITCH GRINDER INTERFACE CONNECTOR WHI/VIO 200 OR 240 VOLTS AC 2 WIRE + GRD 26885.0003C 11/06 © 1996 BUNN-O-MATIC CORPORATION 41976 031709 Page 47...

- Page 48 OVERFLOW PROTECTION SWITCH CONNECTOR SWITCH N.C. TEMP SENSOR DRY PLUG DETECTION LIQUID LEVEL SENSOR 120/208 OR 120/240 VOLTS AC 3 WIRE CONTROL & DISPLAY SINGLE PHASE CONNECTOR J3-40 INTERFACE 10851.0000E 9/00 © 1994 BUNN-O-MATIC CORPORATION 41976 031709 Page 48 White Strip-Tac Plus...

- Page 49 120 VOLTS AC 2 WIRE 120/208 VOLTS AC OR BLU/BLK – 120/240 VOLTS AC 3 WIRE 24VDC TRANSFORMER SINGLE PHASE – 28170.0000C 9/98 © 1997 BUNN-O-MATIC CORPORATION Front view of Brewer Server Connector White Strip-Tac Plus Page 49 41976 031709 Black Ink...

- Page 50 BREAKER RESETTABLE FUSE BLU/BLK – 24VDC 230 VOLTS AC TRANSFORMER – 2 WIRE + GRD SINGLE PHASE Front view of Brewer Server Connector 28170.0001E 11/06 © 2002 BUNN-O-MATIC CORPORATION NOT A PURCHASED SCHEMATIC Page 50 41976 031709 FOR REFERENCE ONLY...

- Page 51 120 VOLTS AC 2 WIRE + GRD BLU/BLK 120/208 VOLTS AC OR – 120/240 VOLTS AC 3 WIRE + GRD 24VDC TRANSFORMER – SINGLE PHASE Front view of Brewer 28170.0003C 01/07 © 1999 BUNN-O-MATIC CORPORATION Server Connector Page 51 White Strip-Tac Plus 41976 031709 Black Ink...

- Page 52 SERVER DETECT BOARD BLU/BLK BLU/BLK – CIRCUIT FAUCET TUBE HEATER RECTIFIER BREAKER BLU/BLK – 208/240 VOLTS 24VDC TRANSFORMER AC 2 WIRE + GND – SINGLE PHASE Front view of Brewer Server Connector 28170.0004D 01/07 © 1999 BUNN-O-MATIC CORPORATION Page 52 41976 031709...

- Page 53 BLU/BLK BLU/BLK CIRCUIT RECTIFIER BREAKER 120 VOLTS AC 2 WIRE 120/208 VOLTS AC OR BLU/BLK 120/240 VOLTS AC 3 WIRE 24VDC TRANSFORMER SINGLE PHASE Front view of Brewer 33824.0000A 2/01 © 2001 BUNN-O-MATIC CORPORATION Server Connector Page 53 41976 031709...

- Page 54 SCHEMATIC WIRING DIAGRAM DUAL BREWER (W/TWO-GRINDER INTERFACE) LIMIT THERMOSTAT BLK-12 BLK-12 BLK-12 RED-12 TANK HEATERS (TWO) RED-12 BLK-12 RED-12 N.O. READY INDICATORS N.O. OVERFLOW SW. & THERMOSTAT PROTECTION SW OPTIONAL RECOVERY BOOSTER LIQUID LEVEL K2 N.O. K3 N.O. BOARD PIN-20...

- Page 55 SCHEMATIC WIRING DIAGRAM DUAL-A & -B BREWER (W/TWO-GRINDER INTERFACE) GRN/YEL LIMIT THERMOSTAT BLK-12 BLK-12 BLK-12 RED-12 TANK HEATERS (TWO) BLK-12 RED-12 RED-12 N.O. READY INDICATORS N.O. OVERFLOW SW. & THERMOSTAT PROTECTION SW OPTIONAL RECOVERY BOOSTER LIQUID LEVEL K2 N.O. K3 N.O.

- Page 56 SCHEMATIC WIRING DIAGRAM DUAL BREWER (W/ONE-GRINDER INTERFACE) MODELS WITH MAIN ON/OFF SWITCH ONLY BLK-12 BLK-14 BLK-14 RED-12 RED-14 RED-14 LIMIT THERMOSTAT BLK-12 BLK-12 BLK-12 RED-12 TANK HEATERS (TWO) READY INDICATORS BLK-12 RED-12 N.O. N.O. OVERFLOW SW. & THERMOSTAT PROTECTION SW...

- Page 57 SCHEMATIC WIRING DIAGRAM DUAL-A & -B BREWER (W/ONE-GRINDER INTERFACE) GRN/YEL LIMIT THERMOSTAT BLK-12 BLK-12 BLK-12 RED-12 TANK HEATERS (TWO) BLK-12 RED-12 RED-12 N.O. READY INDICATORS N.O. OVERFLOW SW. & THERMOSTAT PROTECTION SW OPTIONAL RECOVERY BOOSTER LIQUID LEVEL K2 N.O. K3 N.O.

- Page 58 SCHEMATIC WIRING DIAGRAM DUAL BREWER W/DIGITAL BREWER CONTROL WHI/VIO 120V.A.C. 208 0R 240V.A.C. 120V.A.C. WHI/RED J1-1 WHI/RED RT ON/OFF SW RT WARMER WHI/RED WHI/RED OPTIONAL RT BREW RT BYPASS RT LIMIT T'STAT RT TANK HEATER TRIAC WHI/VIO WHI/GRN WHI/GRN LT ON/OFF SW...

- Page 59 SCHEMATIC WIRING DIAGRAM DUAL, CE 3 PHASE W/NEUTRAL TERMINAL (W/ONE GRINDER INTERFACE) BLOCK LIMIT • FOR 3 PHASE OPERATION, WIRE AS SHOWN. • FOR SINGLE PHASE OPERATION, MOVE RED HEATER WIRE INTO TERMINAL BLOCK WITH BLK WIRE (OPTIONAL FIELD WIRING)

- Page 60 (Prior to S.N. DUAL026000) Page 60 41976 031709...

- Page 61 SCHEMATIC WIRING DIAGRAM DUAL BREWER SH (W/ONE-GRINDER INTERFACE) (After S.N. DUAL026000) MODELS WITH MAIN ON/OFF SWITCH ONLY BLK-12 BLK-14 BLK-14 RED-12 RED-14 RED-14 LIMIT THERMOSTAT RED-12 BLK-12 BLK-12 BLK-12 TANK HEATERS (TWO) RED-12 BLK-12 RED-12 N.O. READY INDICATORS N.O. TANK HEATER OVERFLOW SW.

- Page 62 SCHEMATIC WIRING DIAGRAM DUAL SH, 230V CE GRN/YEL THERMAL THERMAL SAFETY FUSE SAFETY FUSE LIMIT THERMOSTAT RED-12 BLK-12 BLK-12 BLK-12 TANK HEATERS (TWO) RED-12 BLK-12 RED-12 N.O. READY INDICATORS N.O. TANK HEATER OVERFLOW CONTACTOR SW. & THERMOSTAT PROTECTION SW N.C.

- Page 63 DUAL SH BREWER W/DIGITAL BREWER CONTROL WHI/VIO SCHEMATIC WIRING DIAGRAM 120V.A.C. 208 0R 240V.A.C. 120V.A.C. WHI/RED J1-1 WHI/RED RT ON/OFF SW J1-5 OPTIONAL RT BREW RT BYPASS RT LIMIT T'STAT BLK RT TANK HEATER J1-10 TRIAC WHI/VIO WHI/GRN WHI/GRN J1-15...

- Page 64 SCHEMATIC WIRING DIAGRAM DUAL SH, CE 3 PHASE W/NEUTRAL TERMINAL BLOCK LIMIT • FOR 3 PHASE OPERATION, WIRE AS SHOWN. • FOR SINGLE PHASE OPERATION, MOVE RED HEATER WIRE INTO TERMINAL BLOCK WITH BLK WIRE (OPTIONAL FIELD WIRING) LIMIT HEATER...

- Page 65 SCHEMATIC WIRING DIAGRAM DUAL BREWER SH (W/ONE-GRINDER INTERFACE) MODELS WITH MAIN ON/OFF SWITCH ONLY BLK-12 BLK-14 BLK-14 RED-12 RED-14 RED-14 LIMIT THERMOSTAT RED-12 BLK-12 BLK-12 BLK-12 TANK HEATERS (TWO) RED-12 BLK-12 RED-12 N.O. READY INDICATORS N.O. TANK HEATER OVERFLOW SW. & THERMOSTAT...

Need help?

Do you have a question about the Dual and is the answer not in the manual?

Questions and answers