Oki ML420 Maintenance Manual

Oki impact printer maintenance manual

Hide thumbs

Also See for ML420:

- Maintenance manual (117 pages) ,

- Guía del usuario (97 pages) ,

- User manual (97 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Oki ML420

-

Page 1: Maintenance Manual

PRINTING SOLUTIONS ML420/ML421 Maintenance Manual 080603F Oki Data CONFIDENTIAL... - Page 2 Copyright Information Copyright © 2007 by Oki Data. All Rights Reserved Disclaimer Every effort has been made to ensure that the information in this document is complete, accurate, and up-to-date. The manufacturer assumes no responsibility for the results of errors beyond its control. The manufacturer also cannot guarantee that changes in software and equipment made by other manufacturers and referred to in this guide will not affect the applicability of the information in it.

- Page 3 Oki Data CONFIDENTIAL PREFACE This maintenance manual describes how to maintain the printer in the field. This manual is for customer engineers. For further information, refer to the Users Manual for handling or operating the equipment. The relation between the destination point and the model name of this printer is as follows.

-

Page 4: Table Of Contents

Oki Data CONFIDENTIAL Contents 1. CONFIGURATION ....................6 Standard Printer Configuration .................... 6 Options ..........................7 2. THEORY OF OPERATION ..................9 Electrical Operation ......................9 2.1.1 Summary ......................... 9 2.1.2 Microprocessor and the Peripheral Circuit .............. 9 2.1.3 Initialization ......................16 2.1.4... - Page 5 Oki Data CONFIDENTIAL 3.3.20 Rear Tractor Assy ....................76 3.3.21 Rear Pressure Assy ....................77 3.3.22 Switch Lever ......................78 4. ADJUSTMENT ....................79 5. CLEANING AND LUBRICATION ...............87 Cleaning ..........................87 Lubrication ......................... 88 6. TROUBLESHOOTING AND REPAIR ..............95 Items to Check Before Repair .................... 95 Troubleshooting Table .......................

-

Page 6: Configuration

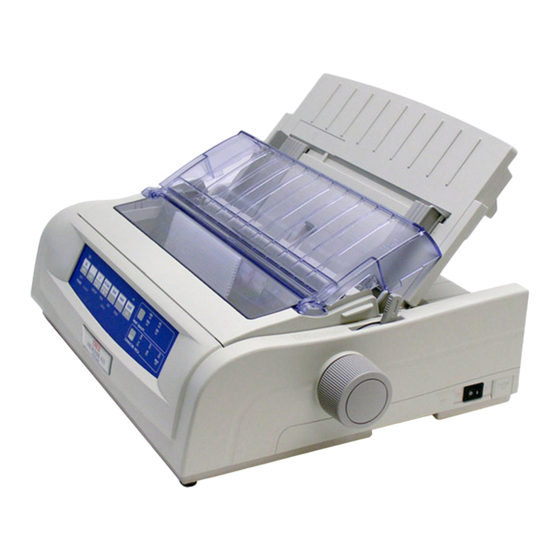

Oki Data CONFIDENTIAL CONFIGURATION Standard Printer Configuration This printer consists of the following assemblies: Platen knob Sheet guide assy Access cover assy Upper cover Transformer assy Pull-up roller assy Power supply board Operation panel assy Control board Main chassis assy Figure 1-1 Configuration 42113901TH01 Rev.3... -

Page 7: Options

Oki Data CONFIDENTIAL Options Cut sheet feeder unit (CSF) (Narrow and wide versions available) Dual-bin CSF Single-bin CSF Attachment assy Attachment assy Pull-tractor assy 42113901TH01 Rev.3... - Page 8 Oki Data CONFIDENTIAL Bottom push tractor unit Roll paper stand (Narrow only) RS232C Serial interface board 42113901TH01 Rev.3...

-

Page 9: Theory Of Operation

Microprocessor This processor is a CMOS single-chip computer with integrated peripheral device functions and a 16 bit MPU core, all OKI original architecture. The processor has a 20 bit address bus and a 16 bit data bus. It is capable of accessing up to 1M word program memory and 1M bytes of data memory. - Page 10 Oki Data CONFIDENTIAL 10 / 42113901TH01 Rev.3...

- Page 11 Oki Data CONFIDENTIAL Program ROM This is a 256 × 16 bits (4M bit) EPROM or MASK ROMwith the control program for the printer stored. The MPU executes instructions under this program. The program ROM is assigned to the program memory area of the MPU and is fetched by the PSEN-N signal of the MPU.

- Page 12 Oki Data CONFIDENTIAL The RAM is CMOS dynamic RAM with 256K × 16-bit (4Mbit), and used as buffers (such as receiving buffer, printing buffer, DLL buffer and working buffer). The following shows the examples of the memory access operation. A0~A8...

- Page 13 Oki Data CONFIDENTIAL USB Controller The USB Controller detects and controls the USB interfacee. The following shows the USB Controller access operation. USB Controller A0~A7 D0~D7 USBCS-N RD-N WRL-N PSEN Clockout * A0~A7 USBCS-N RD-N D0~D7 (Read) WRL-N D0~D7 (Write) * Clockout is provided when the original excitation is selected.

- Page 14 Oki Data CONFIDENTIAL EEPROM The EEPROM is a CMOS serial I/O type memory which is capable of electrically erasing and writing 1,024 bits. The EEPROM contains menu data. The following shows the memory access operation. EEPROM EEDIN-P EECS-P EEDOUT-P EECLK-P...

- Page 15 Oki Data CONFIDENTIAL This LSI detects and controls the SP motor speeds by monitoring the two phase sensor signals obtained from the DC motors and modifying the excitation phases as appropriate. This LSI is connected in multiplex to the MPU.

-

Page 16: Initialization

Oki Data CONFIDENTIAL 2.1.3 Initialization This printer is initialized when the power is turned on or when the I-PRIME-N signal is input from the host side via the parallel interface. For the initialize operation, the RST-N signal is first output from the reset circuit to reset the MPUs and LSIs. -

Page 17: Interface Control

Oki Data CONFIDENTIAL 2.1.4 Interface Control Parallel Interface The parallel data input from the host to the interfaced LSI is latched to its internal register at the falling edge of the STROBE-N signal. At the same time, the LSI sets the BUSY signal to the high level to inform the host that the data is being processed, and outputs the RXD signal to inform the MPU of data reception. - Page 18 Oki Data CONFIDENTIAL Universal Serial Bus (USB) Universal Serial Bus Specification Revision 1.0 compliance. Connector • Printer Side : “B” Receptacle (Upstream Input to the USB Device) • Cable Side : Series “B” Plug Cable • Cable Length : Approx 1.8m (A cable must be met USB Spec Rev 1.1 for normal operation) Note: Cable is not supplied.

- Page 19 Oki Data CONFIDENTIAL Signal Level • Input / Output Level Parameter Symbol Min. Max. Units Input Levels : High (driven) High (floating) Output Levels : High (driven) Output Signal Crossover Voltage 19 / 42113901TH01 Rev.3...

-

Page 20: Print Control

Oki Data CONFIDENTIAL 2.1.5 Print Control Print data is transmitted as parallel data (HEAD1~HEAD9) from LSI to print head. LSI generates print timing and drive time. Control Board A/D bus DRIVER Print Head Print Data Print Data HEAD1-N~ HEAD1~ HEAD9-N... - Page 21 Oki Data CONFIDENTIAL Print Compensation Control The print compensation can be made as shown below: (a) Voltage compensation (See 2.1.8 “Alarm Circuit.”) (b) Temperature compensation (See 2.1.8 “Alarm Circuit.”) Pin stroke compensation Platen Print Head Pin 1,2 As shown in the drawing left, the stroke length up to the platen is different for each pin.

-

Page 22: Sp/Lf Motor Control

Oki Data CONFIDENTIAL 2.1.6 SP/LF Motor Control The MPU transmits serially the SP motor data and the LF motor control data too the SP/LF motor driver, according to the commands sent from the MPU. MHM2025 SP Motor SPM U SPM V... - Page 23 Oki Data CONFIDENTIAL Space motor control The SP motor driver (MHM2025) drives the three-phase brushless motor based on the phase signal (SPU, SPV and SPW) from the LSI and the speed instruction data from the MPU. The MPU can identify the current speed of the space motor by measuring through the LSI the pulse length of the output (øA, øB) of the slit encoder included in the space...

- Page 24 Oki Data CONFIDENTIAL Encoder disk In the operation of the spacing motor, the PHASE-A and PHASE-B signals are generated when the encoder disk interrupts the photo sensor. The LSI divides these edge pulse signals in accordance with the print pitch, and sends the IPT signal to provide dot-on timing and carriage position detection timing.

-

Page 25: Operation Panel

Oki Data CONFIDENTIAL 2.1.7 Operation Panel The clock synchronization OPCLK of LSI is used to input the switch data and output the LED data through the operation panel control IC. Operation panel control IC OPTXD OPTD OPCLK OPCK Command LED driver... - Page 26 5 or 8 bit0 bit7 OPTXD Command (second) Command (first) Power ON OPCLK bit0 bit7 OPRXD Write instruction for IC Command response (second) Command response (first) reset Note OPCLR-N IC write for LED data, etc. Reset within IC Read instruction for data read Response check for OK or NG...

-

Page 27: Alarm Circuit

Oki Data CONFIDENTIAL 2.1.8 Alarm Circuit AC fuse open alarm (a) Head drive time alarm circuit This circuit monitors the drive time using the HDALM signal interlocked with the overdrive signal of each drive circuit. If the drive time of any drive circuit exceeds the specified time, the drive fault alarm circuit sends an ALM-N signal to turn on the Thyristor. - Page 28 Oki Data CONFIDENTIAL Overheat alarm (a) Head overheat alarm The voltage of the output HTEMP signal of the thermistors, one of which is contained in the print head and the other in the SP/LF driver, is monitored by the A/D port of the MPU to control the voltage.

- Page 29 Oki Data CONFIDENTIAL (b) SP motor overheat alarm The voltage of the output SPTEMP signal of the thermistors, one of which is contained in the SP Motor, is monitored by the A/D port of the MPU to control the voltage.

-

Page 30: Power Supply Circuit

Oki Data CONFIDENTIAL 2.1.9 Power Supply Circuit This power supply circuit supplies the +3.3VDC, +5VDC, +12VDC, +42VDC, +50VDC, -8VDC. Power supply board Noise Rectifier +50V filter AC Fuse circuit Trans- Rectifier former +12V Converter Regulation Circuit Converter +3.3V +50V Converter... -

Page 31: Mechanical Operation

Oki Data CONFIDENTIAL Mechanical Operation 2.2.1 Printhead Mechanism and Operation (See Figure 2-2.) The printhead is a spring charged 9-pin driving head using a permanent magnet. It is attached to the carriage, which moves in parallel with the platen. Electrically, this unit is connected to the control circuits through the control board. - Page 32 Oki Data CONFIDENTIAL Operation of printhead (See Figure 2-3.) (a) When the printhead is idle, the armature is attracted by a permanent magnet and the spring fixing the armature is compressed. The print wires fixed to each armature are thus concealed under the wire guide.

- Page 33 Oki Data CONFIDENTIAL Paper Printhead Print wire Platen When printing Paper Armature assembly Thermistor Print wire Wire guide Yoke Magnet assembly Spacer When not printing Paper Figure 2-3 33 / 42113901TH01 Rev.3...

-

Page 34: Spacing Operation

Oki Data CONFIDENTIAL 2.2.2 Spacing Operation (See Figure 2-4.) The spacing mechanism consists of a carriage shaft mounted in parallel with the platen, and a carriage frame that moves along the shaft. It is driven by a DC motor mounted on the bottom of the carriage frame. -

Page 35: Head Gap Adjusting

Oki Data CONFIDENTIAL 2.2.3 Head Gap Adjusting (See Figure 2-5.) The head gap adjusting lever moves back and forth to tilt the carriage frame, altering the gap between the printhead and the platen. The adjusting screw, which is connected to the adjusting gear rotates when the adjusting lever is moved creating a fine gap adjustment. - Page 36 Oki Data CONFIDENTIAL Platen Range Carriage shaft Printhead Adjusting screw Adjusting lever Adjusting gear Idler gear Narrows Range from Printhead Adjusting screw Adjusting cam C.C.W. Platen Guide rail Widens Range from C.W. Figure 2-5 36 / 42113901TH01 Rev.3...

-

Page 37: Ribbon Drive

Oki Data CONFIDENTIAL 2.2.4 Ribbon Drive (See Figure 2-6.) The ribbon driver mechanism moves the ribbon in synchronization with the space motor operation. The ribbon drive mechanism consist of the following items: (a) Ribbon drive gear assembly (b) Ribbon gear (space motor) -

Page 38: Paper Feed Operation

Oki Data CONFIDENTIAL 2.2.5 Paper Feed Operation Feeding of the paper is performed by turning the platen and the pin tractor, which is driven by the LF pulse motor. Item of the paper feed mechanism are as follows: Pulse motor with gears... - Page 39 Oki Data CONFIDENTIAL Cut sheet and continuous sheet switching mechanism (See Figure 2-7.) Three different paper paths can be selected and set by the change lever. TOP (for cut sheet) When the cut sheet is used in the manual mode or fed by the CSF (option), set the change lever at the position marked TOP.

- Page 40 Oki Data CONFIDENTIAL Control Power supply Assy Switch lever Bottom switch Change gear shaft Rear switch Change lever Release shaft Change arm Platen BOTTOM Change lever REAR Tractor gear Change gear Platen gear (R) Reset spring Idle gear (Bottom tractor unit)

- Page 41 Oki Data CONFIDENTIAL Cut-sheet feeder operation (See Figure 2-8.) The pulse motor used for the paper feed mechanism is mounted on the left of the frame, and the rotation of the motor is transmitted through decelerating gears (LF idle gear, platen gear) to the platen.

- Page 42 Oki Data CONFIDENTIAL Continuous paper feed operation (Rear) (See Figure 2-9.) The force transmitted to the platen, rotates the tractor gear through platen gear, the idler gear and the change gear. The rotation of the tractor gear makes the pin tractor belt rotate through a sheet feeder shaft, feeding the continuous paper.

- Page 43 Oki Data CONFIDENTIAL Push and pull tractor mechanism (Option) (See Figure 2-10). This mechanism consist of an optional pull tractor and a standard push tractor mechanism. This mechanism can perform forward and reverse feed by setting continuous sheets to the push tractor and pull tractor.

- Page 44 Oki Data CONFIDENTIAL Pull tractor mechanism (option) (See Figure 2-11.) Bottom feed of continuous sheets is possible only when an optional pull tractor unit is installed. The rotation of the platen is transmitted to the idle gear of the pull tractor unit through the platen gear at the left end of the platen.

- Page 45 Oki Data CONFIDENTIAL Bottom push feed operation (Option) (See Figure 2-12.) The bottom push feed of the continuous sheet is possible only when the bottom tractor feed unit is installed. When the platen rotates, the rotational force of the platen is transmitted through the tractor idle gear and the tractor change gear to the tractor drive gear of the bottom push tractor, and the sheet of paper is fed in to the print start position.

- Page 46 Oki Data CONFIDENTIAL Paper clamp mechanism (See Figure 2-13.) When setting the change lever to the BOTTOM , TOP or REAR position, the operation of the front release gear arm changes according to the position of the release cam. And at the same time, the position of the cam installed to the front release gear shaft changes, and the open and close of the pressure roller.

- Page 47 Oki Data CONFIDENTIAL Change lever Release cam Platen Front release gear arm BOTTOM REAR Figure 2-13 47 / 42113901TH01 Rev.3...

-

Page 48: Paper Detection Mechanism

Oki Data CONFIDENTIAL 2.2.6 Paper Detection Mechanism (See Figure 2-14.) Cut sheet detection When the cut sheet is inserted, the point A is pushed backward and the paper near end lever B rotates counter clockwise (CCW). At this time, the rear sensor lever rotates counterclockwise (CCW), the rear sensor lever and pulls out of the rear and top paper end sensor to detect that the sheet is provided. - Page 49 Oki Data CONFIDENTIAL Top line print mechanism (See Figure 2-15.) The front edge of the sheet is protected by the ribbon protector so that it can stop at a position just near to the print head (0 tear off position) to start printing at the front end of the sheet, without causing the sheet to crumple or curl up.

-

Page 50: Automatic Sheet Feed

Oki Data CONFIDENTIAL 2.2.7 Automatic Sheet Feed This function is used to feed in the sheet automatically up to the print start position when the cut sheet or the continuous sheet is used. [Operational procedure] When using the cut sheet Set the change lever to the TOP position. - Page 51 Oki Data CONFIDENTIAL When using the continouos paper Set the change lever either to the rear side or the bottom side position. (See Figure 2-16.) Set a sheet of paper either to the push tractor or the bottom tractor. Press the “FF/LOAD” switch.

-

Page 52: Paper Park Function

Oki Data CONFIDENTIAL 2.2.8 Paper Park Function (Continuous paper) Continuous sheets which have been inserted can be reversed automatically by using the “PARK” button on the operation panel. Press the “PARK” button on the operation panel. Reverse LF is started and paper is fed in reverse until paper end occurs or 19 inches maximum have been fed. -

Page 53: Assembly/Disassembly

Oki Data CONFIDENTIAL ASSEMBLY/DISASSEMBLY This section explains the procedures for removing and installing various assemblies and units in the field. Description is mainly limited to the removal procedure; installation should basically be performed in the reverse sequence of the removal procedure. -

Page 54: Service Tools

Oki Data CONFIDENTIAL Service Tools Table 3.1 lists the tools necessary for replacing printed circuit boards and parts of units in the field. Table 3.1 Service tools Service Tool Q’ty Remarks No. 1-100 Phillips Screws screwdriver 2.6 mm No. 2-200 Phillips... -

Page 55: Disassembly/Reassembly Procedure

Oki Data CONFIDENTIAL Disassembly/Reassembly Procedure This section explains the assembly replacement procedures according to the following disas- sembly system. [Parts Layout] Upper cover assy Transformer assy Printhead Power supply board Control board Operation panel board Printer unit Figure 3-1 Printer unit 55 / 42113901TH01 Rev.3... - Page 56 Oki Data CONFIDENTIAL [How to Change Parts] This section explains how to change parts and assemblies appearing in the disassembly diagram below. Printer unit 3.3.1 Printhead 3.3.2 Ribbon protector 3.3.3 Pull-up roller assy 3.3.4 Upper cover, access cover and sheet guide 3.3.5...

-

Page 57: Printhead

Oki Data CONFIDENTIAL 3.3.1 Printhead Open the access over. Pull up and rotate the head clamp 1 to unclamp the printhead 2 as shown fig. 3.3.1. Disconnect the printhead 2 from PC connector 3. To install, follow the removal steps in the reverse order. -

Page 58: Ribbon Protector

Oki Data CONFIDENTIAL 3.3.2 Ribbon Protector Remove the printhead (see 3.3.1). Open the pull-up roller cover 1. Raise and remove the ribbon protector 2. To install, follow the removal steps in the reverse order. 58 / 42113901TH01 Rev.3... -

Page 59: Pull-Up Roller Assy

Oki Data CONFIDENTIAL 3.3.3 Pull-up Roller Assy Open the access cover 1. Lift up the sheet guide Assy 4 to remove. Tilting the pull-up roller Assy 2 toward the front, remove from the shaft of platen Assy To install, follow the removal steps in the reverse order. -

Page 60: Upper Cover Assy, Access Cover Assy And Sheet Guide Assy

Oki Data CONFIDENTIAL 3.3.4 Upper Cover Assy, Access Cover Assy and Sheet Guide Assy Pull off the platen knob 1. Turn the change lever 2 toward the bottom position. Insert a flat-blade screwdriver into grooves (5 places) (4 places for narrow type) of frame and twist to disengage claws of upper cover 3. -

Page 61: Gear Case Assy

Oki Data CONFIDENTIAL 3.3.5 Gear Case Assy Remove the printhead (see 3.31). Remove the upper cover (see 3.3.4 (1) – (5)). Move the carriage Assy to right hand side, remove two screws 1, then the space motor 2. Disconnect a carriage cable. -

Page 62: Pc Connector

Oki Data CONFIDENTIAL 3.3.6 PC Connector Remove the printhead (see 3.3.1). Remove the upper cover (see 3.3.4 (1) – (5)). Remove the gear case Assy (see 3.3.5). Remove the PC connector 1 from the space motor Assy 2. To install, follow the removal steps in the reverse order. -

Page 63: Space Motor, Guide Roller Assy

Oki Data CONFIDENTIAL 3.3.7 Space Motor, Guide Roller Assy Remove the printhead (see 3.3.1). Remove the upper cover (see 3.3.4 (1) – (5)). Remove the gear case Assy (see 3.3.5). Remove the PC connector (see 3.3.6). Remove screw 2, then the guide roller Assy 3 from the space motor 1. -

Page 64: Space Rack

Oki Data CONFIDENTIAL 3.3.8 Space Rack Remove the printhead (see 3.3.1). Remove the upper cover (see 3.3.4 (1) – (5)). Remove the gear case Assy (see 3.3.5). Remove the space motor (see 3.3.7). Remove the spring 1. Disengage the claw on left side of space rack 2 from the frame, and remove the space rack 2 in upper direction. -

Page 65: Carriage Cable

Oki Data CONFIDENTIAL 3.3.9 Carriage Cable Remove the printhead (see 3.3.1). Remove the upper cover (see 3.3.4 (1) – (5)). Remove the gear case Assy (see 3.3.5). Remove the space motor (see 3.3.7). Remove the space rack (3.3.8). Remove two screws 1, release the Control Board 2 and PCB sheet 9 by lifting clamp 8, and disconnect cable from connector 3, 4, 5, 6. -

Page 66: Backup Roller Holder Assy

Oki Data CONFIDENTIAL 3.3.10 Backup Roller Holder Assy Remove the printhead (see 3.3.1), Remove the upper cover (see 3.3.4 (1) – (5)). Remove the gear case Assy (see 3.3.5). Remove the space motor (see 3.3.7). Remove the backup roller spring 2. -

Page 67: Platen Assy

Oki Data CONFIDENTIAL 3.3.11 Platen Assy Remove the printhead (see 3.3.1). Remove the ribbon protector (see 3.3.2). Remove the pull-up roller Assy (see 3.3.3). Remove the upper cover (see 3.3.1 (1) – (5)). Turn the change lever 1 to the bottom position. -

Page 68: Control Board (Nns)

Oki Data CONFIDENTIAL 3.3.12 Control Board (NNS) Remove the upper cover (see 3.3.4 (1) – (5)). Remove two screws 1, and release the Control Board 2 and PCB sheet 5 by lifting clamp 4. Disconnect all cables from Control Board 2. -

Page 69: Lf Motor

Oki Data CONFIDENTIAL 3.3.13 LF Motor Remove the printhead (see 3.3.1). Remove the ribbon protector (see 3.3.2). Remove the pull-up roller Assy (see 3.3.3). Remove the upper cover (see 3.3.4 (1) – (5)). Remove the platen Assy (see 3.3.11). Remove the driver board (see 3.3.12). -

Page 70: Operation Panel Board (Leop)

Oki Data CONFIDENTIAL 3.3.14 Operation Panel Board (LEOP) Remove the upper cover (see 3.3.4 (1) – (5)). Disconnect the cable 1 from connector 3 of Control Board 2. Disengage claws on both sides from the frame, and remove the operation panel 4. -

Page 71: Power Supply Board (Tpw)

Oki Data CONFIDENTIAL 3.3.15 Power Supply Board (TPW) Remove the upper cover (see 3.3.4 (1) – (5)). Disconnect two flexible cable 3 from the connector 2 the Power Supply Board 1. Remove the cable 5 from the connector 4 on the Power Supply Board 1. -

Page 72: Transformer Assy

Oki Data CONFIDENTIAL 3.3.16 Transformer Assy Remove the upper cover (see 3.3.4 (1) – (5)). Remove AC inlet 1 and AC switch 2 from the frame guide. Disconnect the cable 3 from the connector 4 on the Power Supply Board 5. -

Page 73: Change Lever And Gears

Oki Data CONFIDENTIAL 3.3.17 Change Lever and Gears Remove the upper cover (see 3.3.4 (1) – (5)). Remove the reset spring 1, then remove the idle gear 2, the tractor gear 4 and the change gear 5. Push back the protrusion of the Change Gear Shaft 6 with a flatblade screw driver to remove the change lever 3. -

Page 74: Carriage Shaft

Oki Data CONFIDENTIAL 3.3.18 Carriage Shaft Remove the printhead (see 3.3.1). Remove the upper cover (see 3.3.4 (1) – (5)). Remove the driver board (see 3.3.12). Remove the FG plate (L) 2. Slide the carriage shaft 1 to the left side (in the direction of the arrow) to remove. -

Page 75: Paper Pan

Oki Data CONFIDENTIAL 3.3.19 Paper Pan Remove the printhead (see 3.3.1). Remove the ribbon protector (see 3.3.2). Remove the pull-up roller assy (see 3.3.2). Remove the upper cover assy (see 3.3.4 (1) – (5)). Remove the platen assy (see 3.3.11). -

Page 76: Rear Tractor Assy

Oki Data CONFIDENTIAL 3.3.20 Rear Tractor Assy Remove the printhead (see 3.3.1). Remove the ribbon protector (see 3.3.2). Remove the pull-up roller assy (see 3.3.3) Remove the upper cover (see 3.3.4 (1) – (5)). Remove the reset spring (see 3.3.17 (3)) Remove the tractor gear 1. -

Page 77: Rear Pressure Assy

Oki Data CONFIDENTIAL 3.3.21 Rear Pressure Assy Remove the upper cover (see 3.3.4 (1) – (5)). Remove the change lever and gears (see 3.3.17). Remove the paper pan (see 3.3.19). Remove the rear pressure roller 1. Rotate the release shaft 2 and move it to the left to detach the release shaft 2. -

Page 78: Switch Lever

Oki Data CONFIDENTIAL 3.3.22 Switch Lever Remove the upper cover (see 3.3.4 (1) – (5)). Remove the change lever and gears (see 3.3.17). Remove the paper pan (see 3.3.19). Remove the rear pressure assy (see 3.3.21). Pull the Switch Lever toward you and remove it upward. -

Page 79: Adjustment

Oki Data CONFIDENTIAL ADJUSTMENT Be sure to carry out this adjustment with the printer mechanism mounted on the lower cover. Be sure to carry out this adjustment operation on a level and highly rigid work table (flatness: less than 0.039 inch or 1 mm) so as to minimize adjustment error. - Page 80 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method 4–1–1 Gap between the plat- It shall be measured en and the print head at 3 points: the left end, the center and 1) Parallelism the right end of the justment Variation of platen.

- Page 81 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method Note 1) Adjust lever The head gap shall be measured with the change lever set to rear position. Adjust gear Note 2) The head gap shall be measured positioning Adjust spring the platen gear (R) Adjust craw on the top.

- Page 82 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method Adjust lever Gap between the con- 0.3mm or more Confirm followings. tact and the monitor Make sure that the gap between the con- tact and the motor PCB is 0.3 mm or more.

- Page 83 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method 4–2 between 1±0.5 Confirm followings. platen and the paper (1) When the change lever is set at Change lever Friction position, the gap between Bottom Rear the platen and the paper pan at the rear side shall be 1±0.5mm.

- Page 84 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method 4–4–1 Rotation of the push To confirm: tractor The tractor gear shall rotate smoothly when the change lever is set at Friction posi- tion. Change lever (Center friction) Push tractor Tractor gear Slight backlash Approx.

- Page 85 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method 4–5–1 Ribbon feed To confirm: Ribbon shall be fed smoothly when the carriage is moved from side to side. Ribbon feeding Ribbon 4–5–2 Running load to spac- 250g or less To confirm:...

- Page 86 Oki Data CONFIDENTIAL Item Specification Drawing Adjustment method 4–6 Engagement of the To confirm: double gear and the LF The idle gear of the motor idle gear of the LF motor and the Platen Assy. platen gear (L) and the bias gear of the...

-

Page 87: Cleaning And Lubrication

Oki Data CONFIDENTIAL CLEANING AND LUBRICATION Cleaning [Cautions] Be sure to turn OFF the AC POWER switch before cleaning. Remove the AC power cord from the printer. Avoid dust inside the printer mechanism when cleaning. If a lubricated part has been cleaned, be sure to apply lubricating oil to that portion after cleaning. -

Page 88: Lubrication

Oki Data CONFIDENTIAL Lubrication This printer is designed to be maintenance free and requires no lubrication during normal operation. However it is necessary to apply lubricant in case the printer is disassembled, reassembled, cleaned or parts have been changed. Cleaning time Remarks: 1) Turn off the power before cleaning. - Page 89 Oki Data CONFIDENTIAL Lubrication point Ribbon feed gear Assy. Planetary gear shaft Drive gear shaft (upper and lower) (upper and lower) PM-B (0.006–0.002g) EM-30L-A Idle gear shaft (upper and lower) PM-B (0.006±0.002g) Space rack Space rack Rack upper side Approx. 35 (greasing range) EM-30L-A Approx.

- Page 90 Oki Data CONFIDENTIAL Platen Assy. Grease the contact face of platen gear (L) and bias gear Bias gear PM-B Platen gear (L) 90 / 42113901TH01 Rev.3...

- Page 91 Oki Data CONFIDENTIAL Tractor driving mechanism Change lever Tractor gear bearing portion EM-30L-A Change arm Idle gear teeth EM-30L-A Reset spring Sliding surface of Sliding surface of change lever and gear Gear bearing portion reset spring and gear EM-30L-A EM-30L-A...

- Page 92 Oki Data CONFIDENTIAL Pressure roller Change arm Release shaft Support spring Contact portion of support spring and shaft EM-30L-A Contact portion of rear Front pressure roller holder and shaft EM-30L-A Controller holder Sliding portion of release shaft Sliding portion of rear roller holder...

- Page 93 Oki Data CONFIDENTIAL Pull up roller Assy. Pull-up roller frame Pull-up roller shaft All bearing portions of pull-up roller shaft and pull-up roller frame EM-30L-B Gear and post EM-30L-A 93 / 42113901TH01 Rev.3...

- Page 94 Oki Data CONFIDENTIAL Main chassis Assy. Grease portion (N: 3 portions) rear side EM-30L-A Grease portion at rib (N: 9 portions) EM-30L-A Grease portion Carriage Assy. NK2-10-SUS Bearing portion of guide roller EM-30L-B 94 / 42113901TH01 Rev.3...

-

Page 95: Troubleshooting And Repair

Oki Data CONFIDENTIAL TROUBLESHOOTING AND REPAIR Items to Check Before Repair Check the inspection items specified in the instruction manual. Find out as many details of the trouble as possible from the customer. Inspect in the conditions as close as possible to those at the time the trouble occurred. -

Page 96: Lamp Display

Oki Data CONFIDENTIAL Lamp Display Printer mode display Table 6.2 LED CONDITION TROUBLE ALARM ALARM CONTENTS CATEGORY SHOOTING ALARM MENU 10CPI 15CPI From, cut sheet or bottom Set New paper. Paper end alarm — — — paper end Change lever is set to TOP •... - Page 97 Oki Data CONFIDENTIAL 97 / 42113901TH01 Rev.3...

- Page 98 Oki Data CONFIDENTIAL 98 / 42113901TH01 Rev.3...

- Page 99 Oki Data CONFIDENTIAL Operation Panel Board Centro-connector Control Board AC connector Switch Transformer Print head LF motor Power Supply Board Space motor FAN motor 99 / 42113901TH01 Rev.3...

-

Page 100: Connection Circuit Check For Printhead And Sp/Lf Motor

Oki Data CONFIDENTIAL Connection Circuit Check for Printhead and SP/LF Motor Printhead Signal Connector pin number HEAD1 HEAD2 HEAD4 HEAD6 HEAD8 Thermistor HTEMP (5KΩ at 25°C) +50V +50V +50V HEAD9 HEAD7 HEAD5 HEAD3 100 / 42113901TH01 Rev.3... - Page 101 Oki Data CONFIDENTIAL Line Feed Motor Resistance of each coil should be about 10.4Ω. Signal Connector pin number motor Space Motor Resistance of each coil should be about 22.4Ω. Signal Connector pin number SP-U SP-V Motor SP-W Photo φA sensor φB...

-

Page 102: Troubleshooting Flow Chart

Oki Data CONFIDENTIAL Troubleshooting flow chart Power is not supplied. Is the AC cable connected correctly? Connect the AC cable correctly. Is fuse F1 on the transformer assy/or F1 on the Power Supply Board blown? Replace fuse (with same type and rating). - Page 103 Oki Data CONFIDENTIAL No Yes Replace Control Board. Control Board Replace Transformer assy. Remedied? No Yes Replace Power Supply Board. Pin No. 19 18 17 16 15 14 13 12 11 10 8 7 4 Signal +12V -8V 103 /...

- Page 104 Oki Data CONFIDENTIAL No spacing operation (The alarm LED Blinks) Is carriage assembly binding or jammed? Check around space motor to repair the mechanism of space rack, back up roller, ribbon feed mechanism, and carriage frame etc. Replace Space motor assy.

- Page 105 Oki Data CONFIDENTIAL Homing does not end normally Check around space motor to repair the mechanism. (Space rack, ribbon feed assembly back up roller, carriage frame, support protector and ribbon protector.) Remedied? Replace Space motor assy. Replace Space motor assy.

- Page 106 Oki Data CONFIDENTIAL Paper jam while paper insertion Jam 1 Check the ribbon protector. Check the pull up roller cover is closed properly. Pull up roller cover Platen Ribon Protector Paper Jam 2 (wrinkled paper) Check around pressure roller mechanism.

- Page 107 Oki Data CONFIDENTIAL Smearing/missing dots Does ALARM LED blink and display alarm? See Tables 6.2 and 6.3 for troubleshooting information. Replace Printhead. Remedied? Replace Control Board. Remedied? Replace Carriage cable or Space motor assy. 107 / 42113901TH01 Rev.3...

- Page 108 Oki Data CONFIDENTIAL Faint or dark print Is the print head gap set properly? Adjust the printhead gap (see section 5). Remedied? Replace Printhead. Remedied? Replace Control Board. Remedied? Replace Ribbon feed mechanism. 108 / 42113901TH01 Rev.3...

- Page 109 Oki Data CONFIDENTIAL Ribbon feed trouble Remove the ribbon cartridge. Move carriage to left and right. Does the ribbon drive shaft rotate? Change Ribbon cartridge. Remove Ribbon feed mechanism. Move carriage to left and right. Does the ribbon drive shaft rotate? Replace Ribbon feed mechanism.

- Page 110 Oki Data CONFIDENTIAL Line feed trouble Turn the power off, and rotate the platen manually. Does the platen rotate smoothly? Is the platen gear (L) broken? Replace Platen assembly. Is the LF motor idle gear broken? Replace the LF motor assembly or LF idle gear.

- Page 111 Oki Data CONFIDENTIAL Malfunction of switch on operation panel Is the CN1 of Operation panel connected to the CN3 on the Control Board? Connect the cable properly. Replace Operation panel board. Remedied? Replace Control Board. 111 / 42113901TH01 Rev.3...

- Page 112 Oki Data CONFIDENTIAL Data receiving failure Is the SEL LED blinking? Printer went into the print suppress mode. Wait until printer to receives DC1 code, or change the menu item “Print sup- press-Ineffective” when the function is not required. Is the I/F RS232C?

- Page 113 Oki Data CONFIDENTIAL 10-2 (RS232C I/F) Printer I/F pin assignment. Is the correct cable used? 2 pin, 3 pin, 11 pin, 20 pin, Change I/F cable. 6 pin. Is ALARM LED blinking? See tables 6.2 and 6.3 for the troubleshooting.

-

Page 114: Appendix Apcb Layout

Oki Data CONFIDENTIAL Appendix A PCB LAYOUT PCB list Circuit board TPW (Power Supply Board) Circuit board NNS (Control Board) Circuit board LEOP (Operation Panel Board) 114 / 42113901TH01 Rev.3... -

Page 115: Appendix Bspare Parts List

Oki Data CONFIDENTIAL Appendix B SPARE PARTS LIST Quantity per year: Indicates the recommended number of each part that should be ordered for routine maintenance for one year for 500 units of printers and assuming that the printers are operated for 2 hours/day of 600 hours/year. The following codes are used to indicate the number of printers for which maintenance parts are ordered. - Page 116 Table B-1 Upper Cover Assy Part No. Description Remarks Required 42040801 Upper Cover (N) ML420 (Beige) 42040802 Upper Cover (N) ML420 (Black) 42040901 Upper Cover (W) ML421 (Beige) 42040902 Upper Cover (W) ML421 (Black) 51009409 Sheet Gude Assy (N) ML420 (Beige)

- Page 117 Oki Data CONFIDENTIAL Figure B-2 Printer General Assy 117 / 42113901TH01 Rev.3...

- Page 118 Table B-2 Printer General Assy Part No. Description Remarks Required 51902220 Platen Knob Beige 40211004 Platen Knob Black 42024002 Power Supply Board (TPW) 42021802 Control Board (NNS) 55081107 Op Panel Board (LEOP) 42116101 Operation Panel Beige 42116405 Operation Panel Black 56609701 AC Cord 120V...

- Page 119 Oki Data CONFIDENTIAL Figure B-3 Printer Unit 119 / 42113901TH01 Rev.3...

- Page 120 Table B-3 Printer Unit (1/2) Part No. Description Remarks Required 42114901 Main Chassis Assy (N) ML420 (Beige) 42114902 Main Chassis Assy (N) ML420 (Black) 42115001 Main Chassis Assy (W) ML421 (Beige) 42115003 Main Chassis Assy (W) ML421 (Black) 50809201 Bottom paper end Sensor...

- Page 121 51114201 Carriage Shaft ML420 51114202 Carriage Shaft ML421 42284401 FG (Weld) 42044701 Pull-Up Roller Assy (N) ML420 (Beige) 42044703 Pull-Up Roller Assy (N) ML420 (Black) 42045701 Pull-Up Roller Assy (W) ML421 (Beige) 42045704 Pull-Up Roller Assy (W) ML421 (Black) 40355101...

- Page 122 Oki Data CONFIDENTIAL Figure B-4 Carriage Assy 122 / 42113901TH01 Rev.3...

- Page 123 53349801 Carriage Frame Set 53343201 Back Up Roller Holder Assy 40493301 Guide Roller Assy 42103601 Space Motor Assy 42252703 Head Cable (23) ML420 42252701 Head Cable (23) ML421 56731301 15 Pin Connector 42348103 Gear Case Assy 50702901 Head Clamp 51022501...

- Page 124 Oki Data CONFIDENTIAL [Pull-Tractor] [Bottom-Tractor] [I/F Board] Figure B-5 Option Spare Parts 124 / 42113901TH01 Rev.3...

- Page 125 Part No. Description Remarks Required 50098001 Pull & Bottom Tractor L 50097901 Pull & Bottom Tractor R 53077201 Tractor Cover Assy (N) ML420 53077301 Tractor Cover Assy (W) ML421 51902301 Bottom Push Stand L Beige 42451601 Bottom Push Stand L Black...

-

Page 126: Appendix Crs-232C Serial Interface Board (Option)

Oki Data CONFIDENTIAL Appendix C RS-232C SERIAL INTERFACE BOARD (OPTION) GENERAL This section describes the operation of the RS-232C Serial Interface board installed in the Printer as an option using a start-stop synchronization and serial communications circuit. This serial interface board is capable of transmitting and receiving simultaneously at speeds up to 19,200 bits per second. -

Page 127: Circuit Description

Oki Data CONFIDENTIAL Circuit Description A block diagram is shown in Figure C-1. 80C51 75188 75189 ADR latch IF WR DB0 to DB9 LS245 64Kbit 64Kbit Serial data +5 VD +9 V control line +12VDC ±9 V power –9 V... -

Page 128: Communication Procedure Flowchart

Oki Data CONFIDENTIAL Communication Procedure Flowchart 2.3.1 Mode a Ready/Busy Received one character? Is DSR valid? DSR High? Buffer overflow? Parity error Error? No error Store the received Store 40 H in buffer. character in buffer. Is the printer in DESELECT... -

Page 129: Mode B

Oki Data CONFIDENTIAL 2.3.2 Mode b X-ON, X-OFF Received one character? Is DSR valid? DSR High? Buffer overflow? Parity error Error? No error Store the received Store 40 H in buffer. character in buffer. Is the printer in DESELECT state or is the paper... -

Page 130: Troubleshooting Flowchart

Oki Data CONFIDENTIAL TROUBLESHOOTING FLOWCHART Before Repairing a Fault Before servicing the printer, ask the customer in what situation the trouble occurred and record the response. Before starting troubleshooting, operate the printer in the same situation as that at the time of trouble occurrence to see if the same trouble occurs again. - Page 131 Oki Data CONFIDENTIAL Yes Are ALE, PSEN, RD, WR, signals as specified in Figure C-6? 542ns 180ns PSEN 271ns 542ns RD/WR Figure C-6 Replace the Q3. Yes Are (T1) SELECT and (INTO) BUSY signals low level? Check Q3 on the Control Board.

- Page 132 Oki Data CONFIDENTIAL In receiving by serial interface, printing data is omitted or printing operation is not performed. Are RxD and SSD of Q3 as specified in Figure C-7? Replace the Q2. Yes Are, WR, and BUS signals of Q3 pin 3 as specified in Figure C-8?

-

Page 133: Local Test

Oki Data CONFIDENTIAL Local Test 3.3.1 Circuit test mode 3.3.1.1 Setting Diagnostic test (set by menu) Test connector Connect the test connector shown in Figure C-9 to the interface connector Equivalent to Cannon DB-25P Figure C-9 Test Connector Connection Diagram 3.3.1.2 Function...

Need help?

Do you have a question about the ML420 and is the answer not in the manual?

Questions and answers